Study of Some Electrolysis Parameters for Chlorine and Hydrogen Production Using a New Membrane Electrolyzer

Domga1, Richard Domga1, Guy Bertrand Noumi2, *, Jean Bosco Tchatchueng1

1Department of Applied Chemistry, National School of Agro-industrial Sciences, University of Ngaoundere, Ngaoundere, Cameroon

2Department of Chemistry, Faculty of Science, University of Ngaoundere, Ngaoundere, Cameroon

Abstract

This work reports the most important parameters during brine electrolysis. Herein, cells design was built and optimized for chlorine and hydrogen production using graphite electrodes. These electrodes were from recycling batteries. Also, a series of experiments were conducted in order to test the effect of the space between the electrodes on minimal cell voltage. The results clearly show that when the space between the electrodes decreases, the cell voltage decreases too. Thus, the optimum value was 0.75 cm and the minimum cell voltage with this gaps was 2.83V. Likewise, the effects of some operating parameters like electrolytes concentration and temperature on conductivity were studied. The optimum conditions for brine electrolysis were 320 g.L-1 NaCl (pH=2), 24% NaOH, T = 80°C. To express the efficiency of electrochemical reactions, two types of current efficiency were calculated based on Faraday’s law of electrolysis. The current efficiencies were 81% and 83% respectively for chlorine and hydrogen production.

Keywords

Electrolysis, Current Efficiency, Conductivity, Chlorine, Hydrogen, Electrodes

Received: July 19, 2016

Accepted: August 4, 2016

Published online: November 21, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

The chlor-alkali industry (industry that produces chlorine and alkali, sodium hydroxide or potassium hydroxide, by electrolysis of a salt solution), occupies an important position in the global chemical trade. Chlorine and sodium hydroxide (caustic soda) are among the top 10 chemicals produced in the world, and involved in the manufacturing of a myriad of products that are used in day-to-day life [1]. Chlorine is used in production of most (more than 85%) pharmaceuticals, and is involved in the production of a large part of all other modern chemicals and materials. In addition, for every ton of chlorine made, 1.1 tons of caustic soda (100%) and 0.03 ton of hydrogen are produced [2]. Caustic soda is used in chemical industries and for manufacture of products such as soap, detergents, textiles, paints, glass and ceramics [3]. Hydrogen can be used as a chemical reagent in integrated production sites, for energy generation in fuel cells or in electrolyzer with depolarized cathodes. Chlorine and caustic soda are the base elements of 60% of Europe’s chemical industry production [4]. The chlorine production of a country is an indicator of the state of development of its chemical industry [5, 6].

Chlor-alkali process is performed in an electrolytic cell called electrolyzer. It is a reactor vessel, filled with an electrolytic bath or electrolyte, in which the electrodes are immersed and electrically connected via busbars to power supply [7]. During the electrolysis of brine, chlorine is generated at the anode while sodium hydroxide and hydrogen are produced at the cathode. Total cell reaction proceeds through the following reactions:

At the anode: Cl- → Cl2 + 2e- (1)

At the cathode: 2H2O + 2e- → 2OH- + H2 (2)

Overall reaction: 2H2O + 2NaCl → Cl2 + 2NaOH + H2 (3)

A challenge in the process is parasitic oxygen evolution [7-8]. The possible pathways for this oxygen evolution, reaction (4) include direct anodic oxidation, competing with reaction 1, direct anodic chlorate formation, reaction (5) as well as decomposition of hypochlorite, reaction (6).

2H2O + 2e- → O2 + 4H+ + 4e- (4)

6ClO- + 3H2O → ClO3- + 4Cl- + 6H+ + 1.5O2 + 6e- (5)

2HOCl → 2HCl + O2 (6)

The reduction in current efficiency due to these parasitic reactions ranges from 1-5%. Whiles measures such as usage of selective electrodes and anolyte acidification can reduce the oxygen side reaction to enable a current efficiency of close to 99% [9].

All modern cells (since the 1970's) use these so-called "Dimensionally Stable Anodes" (DSA) [5]. The DSA as an industrial electrode made of RuO2 as active component, inert oxide such as TiO2 as stabilizer and coated onto titanium substrate [8, 10, 11]. The cathode is typically steel in diaphragm cells, nickel in membrane cells, and mercury in mercury cells [4].

The main technologies applied for chlor-alkali production are diaphragm, mercury and membrane cell electrolysis. The difference in these technologies lies in the manner by which the chlorine gas and the sodium hydroxide are prevented from mixing with each other to ensure generation of pure products. Currently, the membrane cell is the best available technique for the chlor-alkali production, which represents about 61% of the chlorine production capacity in Europe [12]. Two types of electrolyzers were developed, they are monopolar and bipolar. In the monopolar type, all of anode and the cathode elements are arranged electrically in parallel. In the bipolar type, the cathode of a cell is connected to the anode of an adjoining cell, so that the cells are in series. Each type of electrolyzer had advantages and disadvantages [13-14].

The main problem of all these chlor-alkali processes is the high electric energy consumption which usually represents a substantial part of the production cost [6, 15]. The knowledge of the influencing parameters of electrolysis reactions is a need for the improvement of an electrolyzer performance. Despite being a mature technology, the knowledge about the chlor-alkali membrane process is dominated by membrane suppliers [16]. There are only five major suppliers of cell technology and they are: Asahi Kasei Corporation, Chlorine Engineers, Eltech Systems Corporation, INEOS Chlor, and Uhde [1]. In addition, there are few studies reported in the scientific journals [14]. In the present work the electrochemical reactor (electrolyzer) was conceived and used to identify the most important parameters of the chlor-alkali membrane process and to investigate their effect on the cell performance.

2. Material and Methods

2.1. Membrane Cell Setup

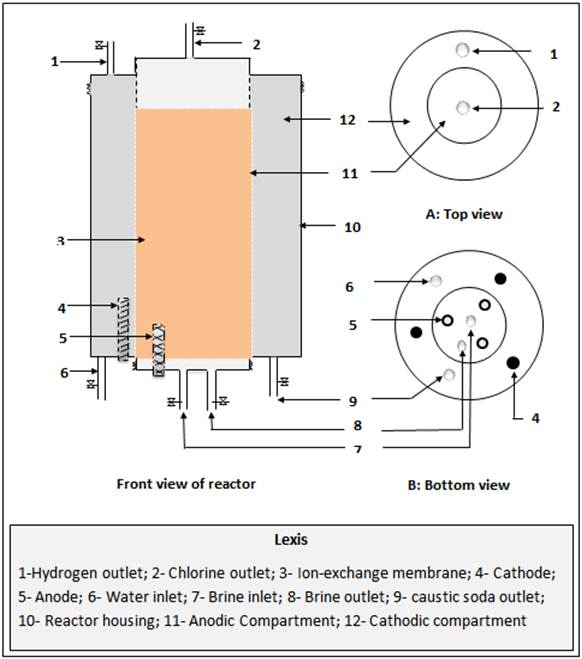

In this study, many monopolar cells design were used to study and optimize various operating parameters (temperature, electrolyte concentration, current density) and engineering parameters (electrode surface area, gap between the electrodes). The setup used was made in PVC to avoid corrosion from chlorine, brine and sodium hydroxide. It has the cylindrical structure (10 cm of diameter) and comprises two cylindrical compartments (one is inside the other). The inside cylindrical with 0.65 L forms the anode side and was fed with sodium chloride. The other cylindrical with 0.75 L forms the cathode compartment and water was introduced in this side. The compartments were separated by an ion exchange membrane (DuPont N324). Electrodes (anode and cathodes) used in this study were composed of graphite tube with an effective surface area of 12,058 cm2. These electrodes are recycled from the used batteries. A more detailed description of the electrolyser and a design of this electrochemical reactor are illustrated in figure 1.

Figure 1. Components of the electrochemical cell.

2.2. Experimental Protocol of Electrolysis

A high purity sodium chloride solution (26% NaCl, 80°C) was fed to the anode compartment, to produce chlorine gas; whereas, hot water (80°C) was fed to the cathode side to produce hydrogen and sodium hydroxide. Electrolysis occurs when direct current electricity flows between anodes and cathodes, through the electrolytes (brine and water). Chlorine then generated at the anode, bubbling up through the brine, and is carried away by the collecting system. Simultaneously, the other gas generated hydrogen and is similarly collected. The hydrogen gas like chlorine, at approximately 80°C, is water-saturated when the cell exits. It was cooled at around 15°C and dehydrated using a wash bottle (500 mL) filled with the concentrated sulfuric acid (96-98%). Similarly, the chlorine gas was cooled and dehydrated. The gas production was measured by water replacement.

2.3. Theoretical Cell Voltages

Electrolysis of brine is decomposed into chlorine (at the anode) and hydrogen (at the cathode) gases due to the passage of an electric current. With established reversibility and absence of cell current between the two different electrode reactions, the equilibrium cell voltage is defined as the equilibrium potential difference between the respective anode and cathode. It is described by equation (7).

![]() (7)

(7)

Equation (8) reveals the change in the Gibbs free energy ΔG of the electrochemical reaction to the equilibrium cell voltage as follows:

![]() (8)

(8)

Where n is the number of moles of electrons transferred in the reaction, and F the Faraday constant.

In electrochemical systems there are three fundamental variables: current, potential and time [16]. The relationship between current and potential curves, gives information about the overall performance of the system. The output cell potential is the sum of all these contributions (thermodynamics, reaction kinetics, charge and mass transport) and is given by the following equation:

![]() (9)

(9)

Where Eanode and Ecathode are the thermodynamic potential of anode and cathode reactions,![]() and

and ![]() are the anodic and cathodic activation overpotentials, and

are the anodic and cathodic activation overpotentials, and ![]() is the ohmic resistance to the charge transport through the electrolytes and the membrane.

is the ohmic resistance to the charge transport through the electrolytes and the membrane.

2.4. Electrodes from Used Batteries Recycling

In this investigation, the graphite electrodes were used. These electrodes are from recycling used batteries. Indeed, alkaline batteries contain manganese dioxide, graphite, steel and zinc. Thus, the used batteries Tiger Head brand (type R20 UM-1) were collected and shredded to recover the electrodes (graphite). The electrodes was cleaned in acid bath contain hydrochloric acid 0.1N. Afterwards, they were treated with an abrasive paper at their surface, in order to remove impurities. The last step was to clean the electrodes with 0.1N hydrochloric acid solution.

2.5. Calculation and Measurement

The efficiency of electrochemical reactions is often expressed in terms of current efficiency. Two types of current efficiency were calculated based on Faraday’s law of electrolysis: chlorine production at the anode compartment and hydrogen production at the cathode compartment. The current efficiency (CE) was calculated as follows [1].

Current efficiency for Cl2 production at the anode compartment:

![]() (10)

(10)

Current efficiency based on H2 production (![]() ) at the cathode compartment:

) at the cathode compartment:

![]() (11)

(11)

Where Vproduced is gas volume produced from the cathode compartment (L/hr), Vm= 22.414 (L/mol) is the molar volume of a gas at standard temperature and pressure, T0 = 273 (K) is standard temperature, T is room temperature (K), NA = 6.022×1023 (mol-1) is the Avogadro constant, C is Coulomb, which is equal to the charge of approximately proton number of electrons (6.241 × 1018 /C), and I is the actual current applied at the electrolytic cell (ampere, C/sec). Laboratory pressure was assumed to be standard pressure (1 atm.).

The voltage and current was monitored and registered by a digital multimeter (Jeulin Evolution®, R30, France). The pH was measured using a bench-top pH meter (Oakton Instruments Co., Ltd., USA) and the electrical conductivity was measured by a bench-top conductivity meter (Mectler-Toledo Co., Ltd., USA). The gas production was measured by water replacement.

3. Results and Discussion

3.1. Effect of Electrolytes Concentration on Conductivity

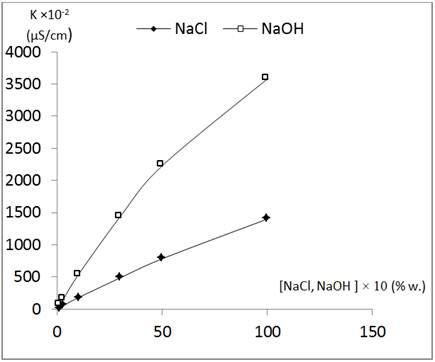

To study the effect of concentration of electrolytes on conductivity, different solutions of NaCl and NaOH at different concentration were used. The experimental results are shown in figure 2.

Figure 2. Evolution conductivity at 25°C according to NaCl and NaOH concentration.

In figure 2, the conductivity of brine and sodium hydroxide is shown to increase with concentration. Indeed, the conductivity of 0.1% NaCl is 5825 mS/cm and by increasing the concentration to 1% NaCl, the conductivity also increased to 17600 mS/cm. Similarly to the brine, the conductivity of sodium hydroxide increases with the concentration. These results are in agreement with the literature. The chlorine reaction is concentration dependent. Increasing the chloride concentration is one of the main ways through which the selectivity for the desired products can be maximized. Authors [17] reported that, in the case of current efficiency, the highest contribution percentage is due to brine concentration with 33%. Decreasing the brine concentration in systems results in slow, reaction and decrease in system voltage and electrolysis pause. However, too high caustic or brine concentration can lead to the formation of blisters on membrane accelerating the degradation of the whole membrane [16]. The presence of blisters on the membrane structure causes the ohmic resistance to increase. A lower sodium hydroxide (26% NaOH) concentration has a positive effect on the cell voltage.

In others hands, Oxygen evolution by water oxidation, reaction (4), is an important anodic side reaction. Anolyte acidification (pH = 2 - 2.5) can reduce the oxygen side reaction to enable a current efficiency of close to 99% in the chlor-alkali process [18]. Others authors also reported the same effect [19]. In this study, to optimize the chlorine, hydrogen production and reduce oxygen side reaction, we recommend these values: 320 g.L-1 NaCl (pH = 2) and 24% NaOH.

3.2. Influence of Temperature on the Conductivity

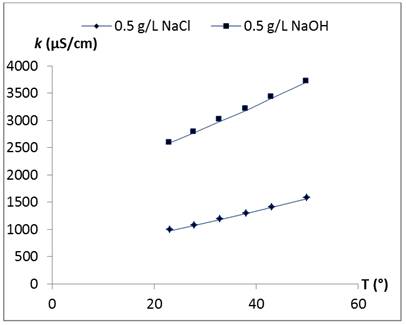

To demonstrate the effect of temperature on conductivity, different solutions were used: 0.5 g/L NaCl and 0.5 g/L NaOH. Conductivity measurements were taken for each solution set at 23, 28, 33, 38, 43 and 50°C. The experimental conductivity values for each solution are shown in figure 3.

Figure 3. Effect of temperature on the conductivity of 0.5 g/L NaCl and 0.5 g/L NaOH.

The temperature profile has a great impact on the electrolyte conductivity. For example, the brine conductivity at 23°C is 973.8 mS/cm and by increasing the temperature at 28°C, its conductivity increases to 1077.54 mS/cm. This could be related to the mobility of ions. As the matter of fact, by increasing the temperature of solution, the mobility of ions (Na+, Cl- for NaCl and Na+, NaOH- for NaOH) in solution also increases, and consequently this will lead to an increase in its conductivity. Additionally, different ionic species show different effects with temperature which is due to the size of the ion and its charge density. This study shows the conductivity response to temperature of 0.5 g/L NaCl compared to 0.5 g/L NaOH. The ion OH-, being smaller than Cl-, has a higher charge density and hence the conductivity of a solution of the same concentration is greater.

From figure 3 it can be concluded that the optimum electrolyte conductivity value was observed for higher temperatures. The cell performance improved with electrolyte temperature [16]. This positive contribution could be related to the internal kinetic processes, which are normally exponentially temperature dependent, and to the NaCl and NaOH conductivity increase. Authors [17] reported that cell temperature was one of the most striking parameters on the cell voltage with contribution percentage of 23%. However, the increase in the temperature is limited by the behavior of electrolyzer materials and at temperatures higher than 90°C the amount of water vapor increases tremendously, while the membrane stability decreases [20]. In addition, the membrane stability may decrease due to decarboxylation for temperatures higher than 90°C [21]. At industrial scale, physical damage to the membrane (blistering) becomes more likely to occur at temperatures lower than 75°C. It is usually recommended to operate in the range 80 - 90°C [16].

In these experiments, the value of 80°C was retained for chlor-alkali production. The anolyte and catholyte temperatures must be similar (80°C) in both compartments. This value is in agreement which the value previously reported [16, 21].

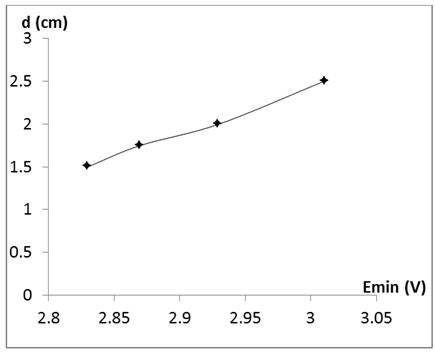

3.3. Effect of Gaps Between the Electrodes

Electrolysis of brine is decomposed into chlorine and hydrogen gases due to the passage of an electric current. Theoretical voltage to start brine electrolysis in membrane cell is 2.19 V. The gap between electrodes is the distance that the ions have to travel in the electrolyte [22]. A series of experiments have been conducted in order to test the effect of the space between the electrodes on minimal cell voltage. For this investigation, different gap electrodes were used. The experimental cell voltage values for each distance between anode and cathode are shown in figure 4. Electrolysis took place under the conditions of: 320 g.L-1 NaCl (pH=2), 24% NaOH, T= 80°C.

Figure 4. Effect of gap between the electrodes on cell voltage.

The results indicate that when the space between the electrodes of cell increases, the cell voltage also increases. Indeed, the minimum cell voltage for a distance between the electrodes of 1.5 cm is 2.83 V. It increases at 2.93 V when the distance between anode and cathode increased at 2 cm. The reason is expressed to be the distance traveled by the electrons during the formation of products. Indeed, inside the electrolysis cell, electrons start their journey from the surface of an electrode, move through the electrolyte and end their journey at the surface of the other electrode. By increasing the inter-electrode distance, the ohmic resistance of electrolyte also increases and consequently this will lead to an increase the cell voltage. In others words, these experiments show that to minimize the cell voltage, the gaps between the electrodes are minimized in membrane cells. Author [16] was obtained a significative reduction of cell ohmic resistance and higher current densities with a lower gap between electrodes. Others authors [5, 23] also reported the same effect. However, if the gap is very small, a rise in voltage is observed due to the entrapment of gas bubbles between the electrodes and the membrane [24]. On the other hand, a close distance means a higher frequency of short-circuiting, electric sparks [5, 21]. In this study the optimum space between the electrodes and membrane in our electrochemical reactor was 0.75 cm. This value is higher than the value (6.0 mm for the solid electrodes and 2.75 mm for the mesh electrodes) previously reported [16].

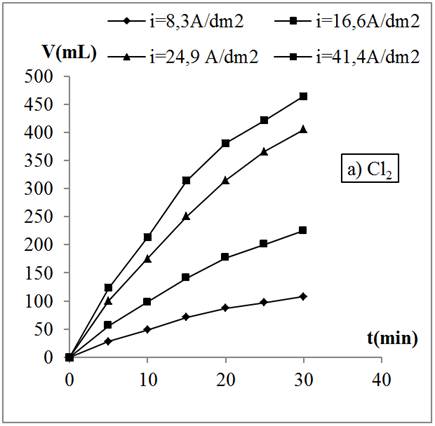

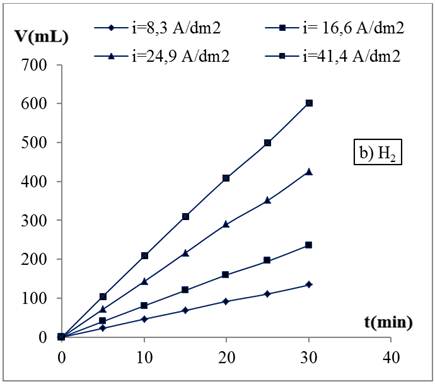

3.4. Effect of Current Density

The rate of an electrochemical reaction is measured as current density. Current density is a current which passes on one square meter of electrode. It’s a critical parameter in electrolysis, because, it’s the only parameter which can be controlled directly [25]. To study the effect of current density on chlorine and hydrogen production, several experiments were performed at different current densities from 8.294 A/dm2 to 41.468 A/dm2. Electrolysis took place under the conditions of: 320 g.L-1 NaCl (pH=2), 24% NaOH, T= 80°C. The effect of applied current density on chlorine and hydrogen production during the electrolysis is shown in figure 5.

Figure 5. Effect of current density on the electrolysis kinetic.

The chlorine production rate increases with increased current density (figure 5a). As a matter of fact, after 10 minutes of electrolysis, the production of chlorine was 213.5 mL with a current density of i = 41.4 A/dm2, whereas to produce same volume with a current density i = 16.6 A/dm2, it was necessary to wait more than 25 minutes. A similar effect was noticed from catholyte compartment, in which hydrogen production rate almost increased with increased current density (figure 5b). This indicates that, the chlorine and hydrogen production rate are the most dependent upon the applied current density. That confirmed to the previous report; a high current density should result in a high selectivity for hydrogen and chlorine evolution [26]. Others authors [17] reported that current density was the most striking parameters on the cell voltage with contribution percentage of 70%. The maximum current density (i = 41.4 A/dm2) in this study was smaller than the standard because small electrode was used. Its standard normal rate was 1-7 kA.m-2 [1, 18, 27].

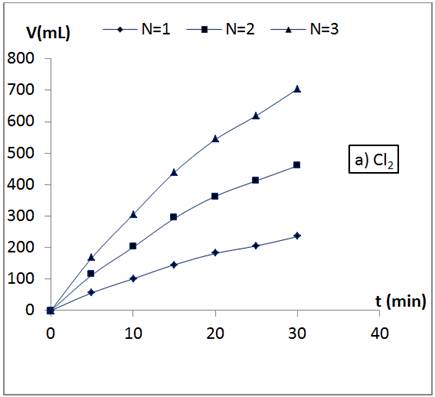

3.5. Effect of Electrode Surface Area

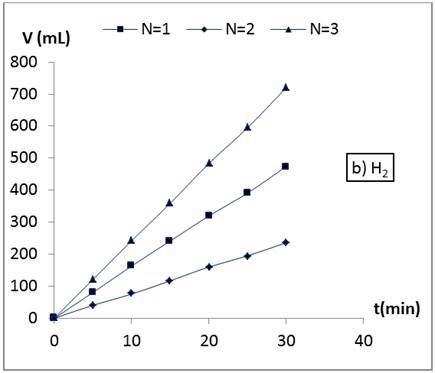

The electrode surface can directly affect the kinetics of electrolysis. Thus, the cell performance of different number of electrodes was evaluated. Three experimental setups (monopolar) was developed; N=1 for 1 anode and 1 cathode, N=2 with 2 anodes and 2 cathodes, N=3 with 3 anodes and 3 cathodes. The operating conditions were: 320 g.L-1 NaCl (pH=2), 24% NaOH, T= 80°C. The experimental results are shown in figure 6.

Figure 6. Effect of surface area of electrode on the electrolysis kinetic.

The volume of chlorine increased with the number of anode (figure 6a). Indeed, to produce 300 mL of chlorine, we need only 10 minutes with 3 anodes, whereas with an anode, it’s necessary to wait for more than 30 minutes to obtain 300 mL under the same operating conditions. Similarly, the production of hydrogen increased with the number of cathode, figure 6b. Results indicate that a larger electrode surface area per unit volume was better for the production of chlorine and hydrogen with the same current density. According to this investigation, the use of several electrodes assembled in series makes it possible to optimize the production of gases, despite for the fact that the current crosses each electrode. In addition, current efficiency drops off due to high current consumption [26]. However, increase the cell with electrodes (reduction of inter-electrodes distance), the density of current becomes too high and could cause short circuits [28]. The choice of the electrode number (3 anodes and 3 cathodes) in this study was for practical reasons. Indeed, the electrodes number lower than three would not be interesting, because gases production would slow and the electrodes number higher than 3 will be difficult to realize taking into account the dimensions of cell.

3.6. Current Efficiency

3.6.1. Current Efficiency for Anodic Reaction

The current efficiency for Cl2 production was calculated from the ratio of the obtained values by the thermodynamic values from the Faraday’s law of electrolysis, equation (10). The current efficiency is 81%. Thus the current was not exclusively used for the oxidation of chlorides ions to chlorine gas. This may be accounted for by one or more of a number of factors. The generation of secondary compounds may cause reduction of faradaic efficiency. Chloride ions in the brine are converted into various chlorine compounds during electrolysis and hydrolysis. In addition, according to previous study, the production of oxygen during the NaCl electrolysis, although slow, is inevitable [29]. Thus reactive oxygen species from oxygen evolution also reacts with chloride in water to produce reactive chlorine species such as free chlorine: HOCl, ClO– [27]. According to [26] the presence of chlorate in the effluent is expected due to high cell temperature. The reduction in current efficiency due to these parasitic reactions ranges from 1-5% [9]. In this study, the material anode was graphite and the overpotential for chlorine evolution was as high as 500 mV which increased energy consumption and consequently the current efficiency is affected. There was some attempt to replace these by a dispersed form of a precious metal such as Pt, Pt/Ir, and Ru on a titanium base, and indeed these did reduce the overpotential to about 100 mV. These anodes were, however, expensive and not entirely stable, platinum in the concentrated chloride medium being lost at the rate of 0.2-0.4 g per ton of chlorine [30]. Additionally, the electrochemical cell has a large gap between the electrodes (1.5 cm). This gap resulted in a significant ionic resistance and then should deeply affect the current efficient.

3.6.2. Current Efficiency for Cathodic Reaction

Similarly to chlorine, the hydrogen current efficiency is determined from the ratio of the obtained values by the thermodynamic values calculated from Faraday’s law of electrolysis, equation (11). The obtained current efficiency was around 83%. This current efficiency depended from the current densities. The differences between the obtained hydrogen flow rate and the thermodynamic values should be related to hydrogen crossover through membrane to find side of the anodic compartment, combine with oxygen (from parasite reaction) and can form water [31]. The material of the electrode was also important and can contribute to reduce or increase the current efficiency. At the cathode where hydrogen is evolved, the design must permit rapid bubble release, otherwise the bubbles will contribute to additional IR (ohmic resistant) loss. In addition to the overpotential for the cathode reaction in chlor-alkali cell, is critical to the energy consumption. Similarly to the anode material, the use of the graphite cathode where the hydrogen overpotential was about 400 mV, potentially decreases the current efficiency was observed. Thus, catalytic coating such as nickel alloys or platinum will decrease this overpotential it further to 20 - 50 mV [9, 29]. For example, [32] obtained a hydrogen efficiency of 99% on platinum electrode for 120 mA cm-2 current density. These platinum cathodes were, however, expensive. Similarly, to the anolyte compartment, the electrochemical cell had a large gap between the electrodes and the membrane (0.75 cm). This gap originates a significant ionic resistance and then should deeply affect the current efficient.

4. Conclusion

Membrane electrolyzer was performed to study the parameters of electrolysis for chlorine and hydrogen production. The electrodes used in this study were composed of graphite tube with an effective surface of 12.058 cm2. These electrodes were recycled from used batteries. To reduce the energy consumption, the optimum gap between electrode and membrane was 0.75 cm. Also, the cell performance of different number of electrode was evaluated. Results indicate that a larger electrode surface area was better for chlorine and hydrogen production. The operating parameters of electrolysis were optimized and they were: 320 g.L-1 NaCl (pH=2), 24% NaOH, T= 80°C, i= 41.4 A/dm2. Under these conditions, the current efficiency was 81% for chlorine and 83% for hydrogen production. The research described in this paper has enabled a better understanding of chlorine-hydrogen membrane process. Further study will focus on the optimization of the electrode parameters for maximization of chlorine and hydrogen current efficiency.

References

- O’Brien, Th. F.; Bommaraju, T. V.; Hine F., (2005). Handbook of Chlor-Alkali Technology. Springer US, LXXXVI, Hardcover ISBN: 978-0-306-48623-4.

- Euro Chlor, (2011). Le chlore en perspective. Euro Chlor©: Avenue E Van Nieuwenhuyse 4, box 2 B-1160 Brussels-Belgium.

- Saksono, N., Abqari, F., Bismo, S., Kartohardjono, S., (2013). Effect of Process Condition in Plasma Electrolysis of Chlor-alkali Production. International Journal of Chemical Engineering and Applications, vol. 4, No. 5, 266-270.

- Siracusano, S., (2010). Development and characterization of catalysts for electrolytic hydrogen production and chlor-alkali electrolysis cells. Thesis, University of Rome.

- European Commission, (2001). Integrated Pollution Prevention and Control, Reference Document on Best Available Techniques in the Chlor-Alkali Manufacturing industry.

- Chen, R., (2010). Electrochemical Chlorine Evolution at Sol-Gel Derived Mixed Oxide Electrocatalyst Coatings. Dissertation, Saarlandes University.

- Cardarelli, F., (2008). Materials Handbook: A concise Desktop Reference, 2nd Edition. Springer, London, New York, 540-590.

- Hansen, H. A., Man, I. C., Studt, F., Abild-Pedersen, F., Bligaard, T., Rossmeisl J., (2010). Electrochemical chlorine evolution at rutile oxide (110) surface. Physical Chemistry Chemical physics, 12, 283-290.

- Karlsson R. K. B., (2015). Theoretical and experimental studies of electrode and electrolyte processes in industrial electrosynthesis. Doctoral Thesis, KTH Royal Institute of Technology, Sweden.

- Chandler, G. K., Genders, J. D., Pletcher, D., (1997). Electodes Based on Noble Metals. Platinum Metals Rev., 41, 2, 54-63.

- Malpass, G. R. P., Neves, R. S., Motheo, A. J., (2006). A comparative study of commercial and laboratory-made Ti/Ru0.3Ti0.7O2 DSA@ electrodes: ‘‘In-situ’’ and ‘‘ex-situ’’ surface characterization and organic oxidation activity. Electrochim. Acta, 52, 936.

- Euro Chlor, (2015). Chlorine Industry Review 2014-2015. Euro Chlor©: Avenue E Van Nieuwenhuyse 4, box 2 B-1160 Brussels-Belgium.

- Ullberg, Ø., (2003). Modeling of advanced alkaline electrolyzers: a system simulation approach. International journal of hydrogen energy, 28, 21-33.

- Zeng, K., and Zhang, D., (2010). Recent progress in alkaline water electrolysis for hydrogen production and applications. Progress in energy and combustion science. 36, 307-326.

- Stantorelli, R., Schervan, A., (2009). Energy Production from Hydrogen Co-Gnerated in Chlor-Alkali by the Means of Pem Fuel Cells System. Nuevera Fuel Cells Europe, Via XXV.

- Ana, C. B., (2005). Chlor-Alkali Membrane Cell Process: study and characterization. Dissertation: Chemical and Biological Engineering; University of Porto.

- Jalali, A. A., Mohammadi, F., Ashrafizadeh, S. N., (2009). Effects of process conditions on cell voltage, current efficiency and voltage balance of chlor-alkali membrane cell. Desalination, 237, 126-139.

- Zahedipoor, A. R., Eslami, S. H., Deylami, M., Mohaghegh, S. S., Montazeri, GH., (2013). Investigation of producing chlorine with electrodialysis method and the effect of operating parameters. American Journal of oil and chemical technologies ISSN (online): 2326-6589; ISSN (print): 2326-6570 Vol. 1, Issue 6 17-26.

- Farzami, F., Joudaki, E., Hashemi, S. J., (2011). Comparative study on application of bimetallic Pt-based alloy electrocatalysts in advanced chlor-alkali electrolysis. Engineering, 3, 836-841.

- Mounir, S., (2010). Etude de la production d’hydrogène par électrolyse et pile à combustible. Mémoire: énergies renouvelables, Université Mentouri de Constantine.

- Strathmann, H., (2004). Ion- exchange membrane separation processes, Membrane Science and Technology series, vol. 9, Elsevier, Amsterdam.

- Nunes, S. P., Peinemann, K. V., (2007). Membranes technology. 2nd ed. Weinheim: Wiley-VCH Verlag GmbH & KGaA.

- Leroy, R. L., Janjua, M. B. I., Renaud, R., and Leuenberger, U., (1979). Analysis of time-variation effects in water electrolyzers. J. Electrochem. Soc., Vol. 126 (10), 1674-1682.

- Nagai, N., Takeuchi, M., Kimura, T. and Oka, T., (2003). Existence of optimum space between electrodes on hydrogen production by water electrolysis. Int. J. Hydrogen Energy, 28, 35-41.

- Holt, P. K., Barton, G. W., Mitchell, C. A., (2005). The future for electrocoagulation as a localized water treatment technology. Chemosphere 59 (3). 355-367.

- Shim Jae-Ho, Jeong, J. Y., Park, J. Y., (2015). Effects of operating conditions on improving alkali and electrical efficiency in chlor-alkali diaphragm cell. Int. J. Electrochem. Sci., 10 6338-6347.

- Schmittinger, P., Florkiewicz, T., Curlin, L. C., Lüke, B., Scannell, R., Navin, T., Zelfel, E., Bartsch, R., (2012). Chlorine, in Ullmann’s Encyclopedia of Industrial Chemistry, chap. Chlorine. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim.

- Daneshvar N., Khataee A. R., Amani Ghadim A. R., Rasoulifard M. H., (2007). Decoolorization of C. I. Acid yellow 23 solution by electrocoagulation process: Investigation of operational parameters and evaluation of specific electrical energy consumption (SEEC). J. Hazard Mater., 148 (3): 566-572.

- Devilliers, D., Mahé, E., (2003). Cellules électrochimiques: aspects thermodynamiques et cinétiques. Applications aux générateurs et aux électrolyseurs industriels. L’actualité chimique, 31-40.

- Pletcher, D., (2013). Industrial electrochemistry. Springer Science and Business Media, Vol. 204, ISBN 9401718725, 9789401718721, 90-92.

- Yeo, R. and McBreen, J. (1979). Transport properties of Nafion membranes in electrochemically regenerative hydrogen/halogen cells. Journal of the Electrochemical Society, vol. 126, no. 10, 1682–1687.

- Abdel-Aal H. K., Zohdy K. M. and Abdel Kareem, (2010). Hydrogen production using sea water electrolysis. The Open Fuel Cells Journal, 3, 1-7.