Field Testing of an Inclined-Box Solar Thermal Cooker

Ibrahim Ladan Mohammed*, Musa Bala Ibrahim, Hussaini A. Abdulkareem

Department of Mechanical Engineering, College of Engineering, Kaduna Polytechnic, Kaduna, Nigeria

Abstract

In this paper the thermal performance of an inclined-box solar cooker is analysed using a method adopted by ASABE: cooking power and standardised cooking power. During thermal load test 1.6 kg of water was heated from ambient temperature of 29°C to the boiling point in 3 hours 45 minutes. The coefficient of determination, r2, for standardized cooking power is 0.5064 and the standardized cooking power for temperature difference of 50°C is 23.00W. This figure is shown to be far less than the figures obtained by other researchers in the field; hence, the thermal and optical properties of the cooker must be greatly improved before it can be considered as a very good cooker. Cooking tests of various food items were carried out to complement the water boiling test. The overall cooking performance of the solar cooker is satisfactory, as it is found to be capable of making 2 cycles of cooking in a day, for 3-4 persons per meal, in a total period of just about 6 hours.

Keywords

Field, Testing, Inclined-Box, Solar, Thermal, Cooker

Received: July 2, 2016

Accepted: July 29, 2016

Published online: August 16, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Cooking is a method of processing food using thermal energy to make it more suitable for human consumption. Cooking of food is of much importance to humans that it is considered as an obligatory act; because people who choose a raw-food life-style have been found to experience low energy and impaired reproductive function [1].

In developing countries, most of the energy required for cooking comes from biomass such as agricultural wastes, fuelwood, animal dung, and charcoal. These traditional fuels account for more than 90% of household energy consumption [2]. About a decade ago it was estimated that about 2.5 billion people depended on the aforementioned biomass fuels to meet their energy demands for cooking. The number of people was projected to increase to over 2.6 billion by 2015 and to 2.7 billion by 2030 because of population growth [2]. In other words, about one-third of the world’s population will still be depending on these fuels for their cooking and other household

energy needs even in the next one and a half decades.

Household cooking of food using biomass-based solid fuels (wood, agricultural wastes, etc.) creates both indoor and outdoor air pollutions which results in serious public health danger in terms of premature deaths, and healthy life lost in many parts of the world [3]. Long-term exposure to wood smoke in poor countries of the world has resulted in respiratory infections in children, reduced lung function, and lung cancer in women [4], [5]. Other ailments include stillbirths and low birth weight of newborn babies.

The use of biomass fuels and fossil fuels of coal, oil, and natural gas for household cooking produces, among other combustion products, carbon dioxide and carbon monoxide. CO2 is a greenhouse gas which is responsible for global warming. CO is a poisonous gas with no any detectable colour or odour. Inhaling high level of it could cause unconsciousness or even death.

The combined problems of indoor/outdoor air pollution and global warming require that mitigating strategies be employed to ameliorate the resulting public health burden and environmental degradation. This could be achieved using three principal ways. The first is to decrease the amount of harmful gases/particles released to the environment during cooking, by promoting the use of energy-efficient, well-improved cookstoves. The second is to promote the use of non-combusting cooking devices such as solar thermal cookers. This second option forms the basis of the present technical study. The third option is to use a hybrid method; that is, to use a combination of the first and second options. This may prove to be most viable and economical. In this regard, solar thermal cooking devices are used to cook food during sunny, clear-sky days while energy-efficient stoves are used in the night and during overcast days. Trial programme studies in some countries have suggested savings of 25-40% in charcoal expenditure and firewood collection time, on the basis of solar cookers used in Bolivia, Ethiopia, and Kenya [6]. Some studies have also shown strong cookstove use over time with about 92.7% of solar cookers in Bolivia still being in use 3-5 years after trial programme ended [7].

Solar cookers have a long history dating back to 18th century when the first solar concentrator furnace was fabricated by naturalist Georges Louis Buffon [8]. Horrace de Saussure, a Swiss scientist, was the first to use solar box cooker in 1767 to cook food (fruits), attaining a maximum temperature of 88°C in the process [9]. Since then the solar box cooker has been the subject of extensive research and development, mainly centred on size, shape, glazings, sidings, insulators, reflectors, and nature and composition of absorber surfaces. Today there are hundreds of variations and more than 60 major designs [10], [11].

This technical paper presents the thermal performance evaluation of an inclined-box solar thermal cooker (IBSTC) using test methods described in ASABE Standard (ASAE S 580.1NOV2013) [12]. Cooking test results have been included to complement the evaluation of the cooker using this Standard.

2. Cooking Power and Standardized Cooking Power

The cooking power, Pc, is defined as the rate of useful energy available during cooking period [13]. It is derived by multiplying the mass of the water inside the cooking container by its specific heat capacity and by change in water temperature for each time interval. The result is divided by the time interval to give the cooking power in watts.

![]() (1)

(1)

where Mw is the mass of the water, Cw is the specific heat of water, θw1 is the initial temperature of water, θw2 is the final temperature of water, t is the measured time difference in which the water temperature rises from θw1 to θw2.

The cooking power is then corrected to a standard solar insolation of 700 w/m2 to give a standardized cooking power, Ps This is achieved by multiplying the interval cooking power by 700 w/m2 and dividing the result by the interval average solar insolation, H, recorded during the corresponding time interval.

![]() (2)

(2)

A temperature difference, θd, is derived by subtracting the ambient temperature from the water temperature for each time interval. Mathematically:

![]() (3)

(3)

where θw is the water temperature (°C) and θa is the ambient temperature (°C).

The standardized cooking power and the temperature difference are correlated by a line of best-fit of the form Ps = a + bθd (where a is intercept and b is slope). The proportion of variation in cooking power that is attributable to the relationship found by the equation, i.e. r2, should be greater than 0.75 or as specially observed [9]. A single measure of performance is gotten by calculating the value of standardized cooking power (Ps) corresponding to a temperature difference (θd) of 50°C.

3. Materials

The IBSTC is illustrated pictorially in Fig. 1. The most important physical and optical properties of the cooker are:

Figure 1. Photograph of the IBSTC.

1 –a built-in, mild-steel absorber plate of thickness 0.5 mm which absorbs solar energy and impart it to water or food items; 2 - a transparent glazing material (glass) of thickness 2 mm which traps solar energy and keeps it within the cooking chamber; 3 – an insulation material (cotton) which prevents heat losses to the environment; 4 – door reflectors which intensify solar energy collection by reflecting solar rays to heat the absorber surfaces; 5 – a mild-steel casing of thickness 2 mm which houses the cooking chamber section.

A rectangular, aluminium container of dimensions 12 cm (l) x 10 cm (b) x 17 cm (h) and 0.5 mm wall thickness was provided for the water boiling and cooking tests. K-type digital thermometers of accuracy ±1°C were provided for all temperature measurements. A solar power meter was used for measuring solar insolation.

4. Method and Analysis

4.1. Water Boiling

The water boiling test was performed on 6th November, 2015, within the premises of the main campus of Kaduna Polytechnic, Kaduna (latitude 10.5°). It commenced at 10:50 a.m. and was finished after 3 hours 45 minutes. Water of mass 1.6 kg was put in the rectangular, black-painted, aluminium pot. The container was placed in the cooking chamber of the cooker and the two glass mirror reflectors were exposed to solar radiation. Using the four wheels, the position of the cooker facing the sun was changed slightly until maximum solar radiation was impinging on the aperture.

The water and ambient temperatures were measured using two k-type digital thermometers, while solar insolation was measured using the solar power meter. All measurements were taken at intervals of 5 minutes throughout the test. The position of the cooker was slightly changed after every 30 minutes, to keep track of the sun. The data recording continued until the mean water temperature attained 100°C and pool boiling began. The result of the test is given in Table 1.

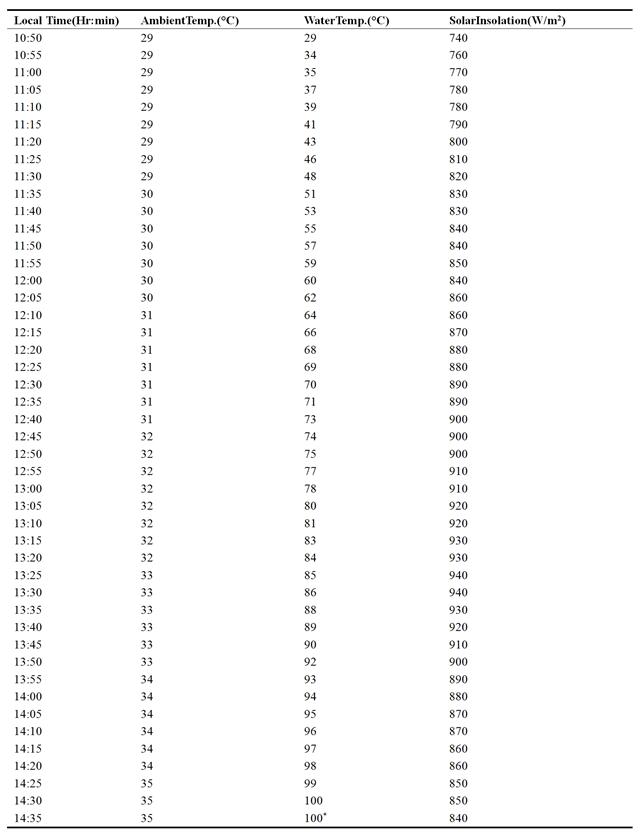

Table 1. Water Boiling Test Result.

*Water boiled at 100°C.

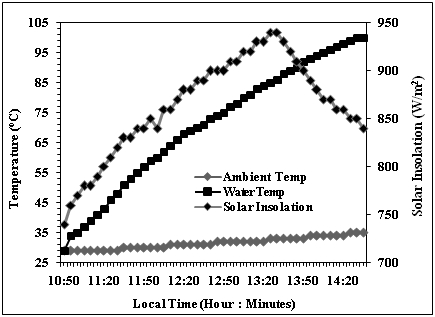

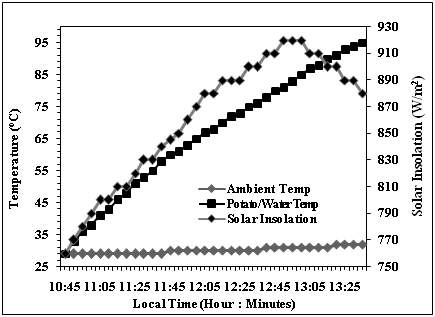

The water and ambient temperatures as well as solar insolation during the test are shown in Fig. 2.

Figure 2. Temperature profile of water boiling test result.

It takes 70 minutes of experimental time before the water temperature reaches 60°C (temperature at which real cooking starts), and it takes another 105 minutes before the water temperature rises to 90°C. It takes a total of 220 minutes for the water temperature to reach 100°C starting from ambient temperature of 29°C.

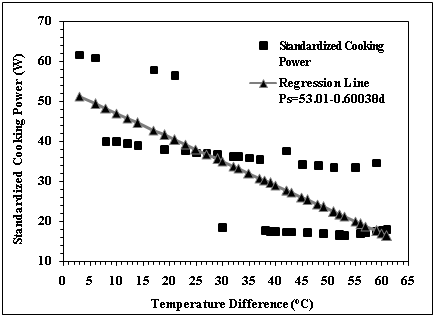

4.2. Standardized Cooking Power Against Temperature Difference

Figure 3 shows standardized cooking power plotted against temperature difference for the water boiling test. Temperature range considered is 32 – 95 °C. Correlation analysis shows that the coefficient of determination, r2, is 0.5064. This means only about 50.64% of the variation of standardized cooking power is attributable to temperature difference. The straight line is the regression line that describes the average relationship between the standardized cooking power and temperature difference. The regression equation is:

![]() (4)

(4)

At θd=50°C, Ps is 23.00 W. This value of standardized cooking power for the cooker is far less than the values obtained by other researchers such as Purohit et al [14], Aremu et al [15], and Mohammed [16] who recorded highest figures of 64.9, 67.06 and 73.9 W respectively.

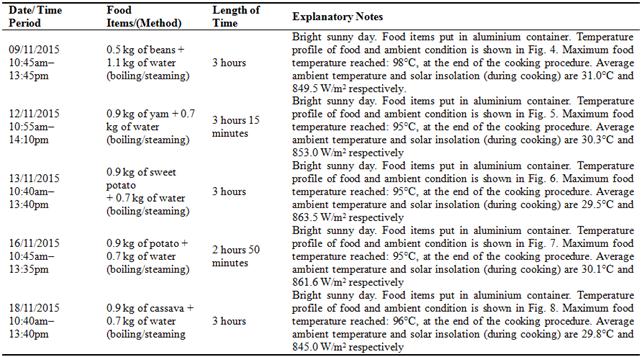

4.3. Cooking Tests

Cooking tests of the IBSTC were performed for several days. Food items cooked were beans, yam, potato, sweet potato, and cassava. Total mass of each food item plus water was 1.6 kg. The method of cooking in all cases was boiling/steaming. The procedure was similar to the procedure described for water boiling test, except that the final temperature of the container content was specific to each particular food item, specially observed when the food was judged to be well cooked.

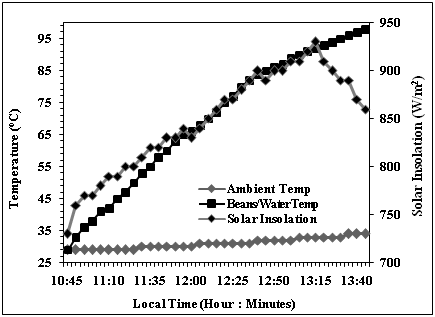

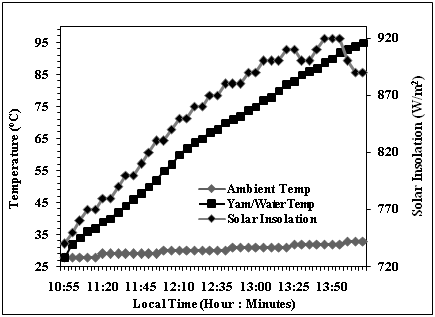

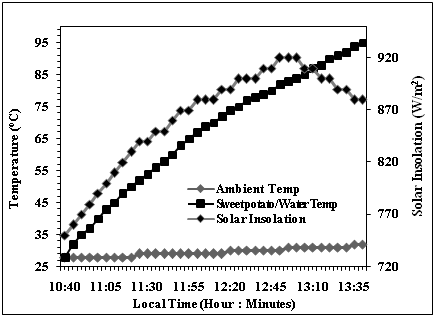

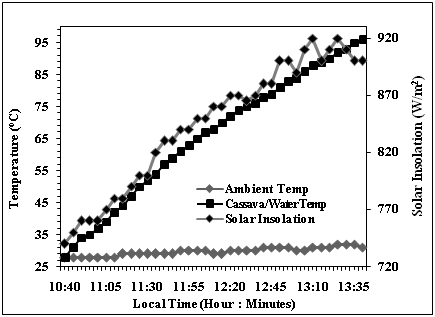

Results of the cooking tests are summarised in Table 2 and graphically elaborated in Figures 4-8. Factors affecting cooking times include the quantity and type of food, ambient condition, and solar insolation.

5. Conclusion

The results of water boiling, and cooking tests of an inclined-box solar thermal cooker has been presented. The value of 23.00 W of standardized cooking power obtained for the cooker is far less than values obtained by other researchers in the field, as observed in available literature. The thermal and optical properties of the cooker must be greatly improved before it can be considered as a very good cooker. Despite these shortcomings, the overall cooking-test performance of the cooker is satisfactory as it is capable of cooking 2 meals in a day, for 3-4 people per meal, in a total length of time of 6 hours.

Table 2. Cooking test results.

Figure 3. Standardized cooking power against temperature difference.

Figure 4. Temperature profile of beans cooking result.

Figure 5. Temperature profile of yam cooking result.

Figure 6. Temperature profile of sweet potato cooking result.

Figure 7. Temperature profile of potato cooking result.

Figure 8. Temperature profile of cassava cooking result.

References

- Wrangham R., Conklin Brittain N.L. (2003). Cooking as a biological trait. Comparative Biochemistry and Physiology Part A 136, 35-46. Elsevier Science Inc.

- Chapter 15 - Energy for Cooking in Developing Countries. World Energy Outlook 2006 - Focus on Key Topics. OECD/IEA 2006. Available: www.iea.org. Retrieved on 04/01/2016.

- ECE/UN (2014). Residential heating with wood and coal: health impacts and policy options in Europe and North America. Economic Commission for Europe/ United Nations (2014). Available:https. Retrieved on 04/01/2016.

- Smith K.R., McCracken J.P., Weber M.W., Hubbard A., Jenny A., Thompson L.M., Balmes J., Diaz A., Arana B., Bruce N. (2011). Effect of reduction in household air pollution on childhood pneumonia in Guatemala (RESPIRE): a randomised controlled trial. The Lancet Vol. 378, No. 9804, p1717–1726. DOI: http://dx.doi.org/10.1016/S0140-6736(11)60921-5

- WHO (2015). Residential heating with wood and coal – health impacts and policy option in Europe and North America. World Health Organisation 2015. Retrieved from: ehsdiv.sph.berkeley.edu/krsmith/.../2015/ResidentialHeatWoodCoal...on 01/10/2015.

- ESMAP Technical Report 007/15 (2015). The State of the Global Clean and Improved Cooking Sector. Global Alliance for Clean Cookstoves. The International Bank for Reconstruction and Development / The World Bank Group

- Szulczewski M. (2016). Lasting Impacts of a Solar Cooker Project in Bolivia. Center for Development with Solar Energy (CEDESOL). Available:stoves.bioenergylists.org/taxonomy/term/866

- Nahar N.M., Sharma P., Chaudhary G.R (2009). Processing of agricultural products in solar cooker for income generation. International Solar Food Processing Conference 2009. Available:http://solarfood-org.webhostingeinfach.desolarfood2009/3_Full_papers/Technologies/32_nmna...Retrieved on 22/05/2014.

- Sharma S.K. (2004). Solar cookers. Encyclopedia of Energy, Vol. 5. Elsevier Inc.

- Kundapur A. (1998). Review of Solar Cooker Designs. TIDE, 8 (1), pp 1-37.

- Kundapur A. and Sudhir C.V. (2009). Proposal for New World Standard for Testing Solar Cookers. Journal of Engineering Science and Technology, Vol. 4, No. 3, pp 272-281.

- ASABE (ASAE S580.1NOV2013). Testing and reporting Solar Cooker Performance – American Society of Agricultural and Biological Engineers.

- Purohit I., Purohit P. (2009). Instrumentation error analysis of a paraboloid concentrator type solar cooker. Energy for Sustainable Development13 (2009), 255–264. Elsevier Inc.

- Purohit I., Purohit P., Negi B.S. Design and testing of a box type solar cooker employing non-tracking reflectors. Available:http://img1.wikianocookie.net/__cb20080428190409/solarcooking/images/7/7a/Granada06_ishan_puroh...Retrieved on 23/05/2014.

- Aremu A.K., Akinoso R. (2013). Potential use of box-type solar cooker in developing countries. The Journal of the Association of Professional Engineers of Trinidad and Tobago,41(1),11–17.

- Mohammed I.L. (2015). Field testing and evaluation of a truncated pyramid solar thermal cooker. International Journal of Renewable Energy and Environmental Engineering, Vol. 03, No. 02.