Utilization of Plastic Bottle Waste in Concrete

Salahaldein Alsadey*

Department of Civil Engineering, Faculty of Engineering, Bani Waleed University, Beni Walid City, Libya

Abstract

Now a day are facing environment protection problems. Many things which are invented for our luxurious life are responsible for polluting environment due to improper waste management technique. One of them is a plastic which has to be disposed or recycled properly to maintain the beauty of our nature. On the other hand, urbanization growth will increase rubbish especially non-renewable ones. Eco friendly architectural principles are being incorporated into more buildings every day in the world but they are still out of reach of many people due to lack of knowledge and awareness. In this study is to explore the possibility of recycling a plastic bottles waste material. To address this issue the fibers from used plastics were added in various percentages in the M25 grade concrete. An experimental work has been carried out on the specimen’s cubes which were casted in the laboratory and their behavior under the test was observed. The plastic fibers were added from 0.0% to 3.0%. The compressive strengths of concrete were determined after 28 days of curing period and compared with control concrete. Experiments done shows increase in compressive strength by 12%. Plastic bottle fibre additive can be adopted. The plastic bottle fibre reduces the quantity of industry fibers used in concrete and also plastic bottle fibre is proved to be more economical.

Keywords

Compressive Strength, Plastic Bottles, Flakes, Environmental, Recycling

Received: June 10, 2016

Accepted: July 4, 2016

Published online: July 27, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Concrete structure is the most common type of structure, and it keeps developing and improving day after day to meet up with the global and environmental requirements, this structure is basically a mixture of cement, water, sand, and coarse aggregate. However, cement considered as the most expensive and significant ingredient in concrete production. Concrete is the major structural material widely consumed in the world, after water. Most of the infrastructure and building construction in Libya are using concrete as construction material. Concrete is major construction material. However, concrete is a brittle material which is strong in compression and weak in tension. Findings on the reinforcement of these brittle matrixes in search of improving their mechanical properties are a continuous process since ancient periods, where straws used to reinforced clay bricks. From 1960’s the modern development of fiber reinforced concrete has experienced rapid growth.

Plain concrete has two major deficiencies, the low tensile strength and a low strain at fracture. The tensile strength of concrete is very low because plain concrete normally contains numerous micro cracks. It is the rapid propagation of these micro cracks under applied stress that is responsible for the low tensile strength of the material, eventually leading to brittle fracture of concrete. In past attempts have been made to impart improvements in tensile properties of concrete members by way of using conventional reinforced steel bars and also by applying restraining techniques. Although both methods provide tensile strength to concrete members, they how ever do not increase inherent tensile strength to concrete it. It has been found that the addition of small closely spaced and uniformly dispersed fibers to concrete would act as crack arresters and would substantially improve its static and dynamic properties. This type of concrete is known as "Fiber Reinforced Concrete".

Fiber Reinforced Concrete can be defined as "A composite material consisting of a mixture of cement, mortar or concrete and discontinuous, discrete uniformly dispersed suitable fibers ". The new generation technology utilizes discrete fiber from 19mm to 64mm in length. The fibers are randomly throughout the concrete matrix providing for better distribution of both internal and external stresses by using a three dimensional network. The Primary role of fibers in hardened concrete is to modify the cracking mechanism. The cracks are smaller in width thus reducing the permeability of concrete and the ultimate cracking strain of concrete is enhanced. Un-reinforced concrete will separate at a crack, reducing the load carrying ability to zero across the crack. The fibers are capable of Carrying a load across the crack.

Utilization of waste materials and by products is a partial solution to environmental and ecological problems. Use of these materials not only helps in getting them utilized in concrete and other construction materials, it helps in reducing the cost of concrete manufacturing, but also has numerous indirect benefits such as reduction in landfill cost, saving in energy, and protecting the environment from possible pollution effects. Plastic waste generated from the cold drinks or water bottle etc. is a major problem for disposal. Efforts have been made in the concrete industry to use non-biodegradable components of plastic waste.

The amount of plastics of all types consumed annually all over the world has increased significantly. The manufacturing processes, municipal solid wastes and service industries generate a large amount of waste plastic materials. Recycling is one of the ways to reduce the environmental impact of the waste plastic bottles. But the biggest problem with plastic recycling is that it is difficult to automate the sorting of plastic waste and so is labor intensive. Materials recycled in concrete such as plastic bottles, can be utilized in concrete as Fiber–reinforced. With the development of concrete technology, high strength concrete has been commonly employed in many concrete structures around the world. It is clear that the plastics are not harming our natural environment and health all by themselves; it is our use of them that has catastrophic consequences. Plastic pollution is alarmingly increasing and the major reasons for that are improper disposal, irresponsible design and unsustainable throwaway habits. Hence, the need arises to route the waste plastic bottles to their optimum usage.

High strength concrete has some disadvantages such as brittleness and poor resistance to fire. In order to minimize this problem, polypropylene fibers can be used due to the favorable properties of these fibers and such as economical benefits. Use a certain amount of fibers in the concrete mix does not have adverse effect on its mechanical properties. The effect of polypropylene fibers on the compressive strength and heat resistance of concrete with high strength has been investigated. The results indicated that the strength and heat resistance of the concrete have increased with the use of polypropylene fibers [1].

Fiber–reinforced concrete is becoming an increasingly popular construction material due to its improved mechanical properties over unreinforced concrete and its ability to enhance the mechanical performance of conventionally reinforced concrete. Fiber reinforcement is one of the most important modification methods to alter the brittle nature of plain concrete. Fibers are generally used as resistance of cracking and strengthening of concrete. In this paper an experimental study is made on the utilization of plastic waste in concrete cubes with addition percentage ranging from 0% to 3% [2].

2. Research Significance

Recycled plastic bottles are the most widely used plastic material in the world for manufacturing secondary products such as cold drinks or water bottle and beverage bottles etc. However, plastic bottles are commonly thrown away after a single use, which contributes to significant environmental problems. Therefore, methods to recycle plastic bottle waste have been examined in order to improve plastic bottle recycling applications. The use of plastic fibers recycled from plastic bottles waste in construction projects has been actively studied. Plastic bottle fibers can be utilized to effectively reduce shrinkage strain and to enhance the ductility of concrete, especially to mitigate the inherent shrinkage problem of concrete.

Plastic bottles which are used is become a waste after use and create environmental problems. Large amount of plastic waste produced very year. Recycle and reused of plastic require vast manpower and processing cost thus the very small amount of plastic recycled and reused and rest going into landfills, incinerators and dumps. Here author suggested the use of these plastic bottles pieces in a concrete as a plastic fiber to improve the properties of concrete. Use of plastic has a dual advantage cost of material is low also it solve the problem of disposal of plastic up to some extent.

3. Plastic Bottle Waste Collection and Method of Flake

Plastic bottle were collected from plastic waste in Libya such as plastic waste of packed water and cold drinks water bottle were flake into 18 micron and length 18 mm. Table 1 shows the plastic waste properties in this is study.

Table 1. The physical properties of the plastic waste.

| Properties | Plastic bottle |

| Specific gravity | 0.8 |

| Absorption% | < 0.2 |

| Color | Transparent and green , black and white |

| Shape | Angular |

4. Materials and Experimental Methods

The experimental investigation was carried out in the Construction Materials Laboratory of the Faculty of Engineering at Bani Waleed University Libya. Concrete mixes containing ordinary Portland cement, sea sand, crushed coarse aggregate, water, and different percentage of plastic bottle waste content were studied. The used ordinary Portland cement satisfies the ASTM requirements. Locally sea sand was used, which had specific gravity of 2.66 and its grading fell within ASTM. Crushed coarse aggregate had specific gravity of 2.70. The sieve analysis of coarse aggregate is carried out according to ASTM. The fibrillated plastic bottle waste was used as fiber. Three identical concrete mixes having different percentage of plastic bottle waste content were used in this investigation. The same mix, which is obtained according to BS, was used through the all investigation. The water cement ratio (w/c) was 0.6%. A total of 21 specimens were used for compression test. The concrete cubes with dimensions of 150 × 150 × 150 mm were compression tested at 28 days from initial casting with a maximum load capacity of 3000 KN. The compressive strength of each specimen type was determined by averaging three specimen strength values.

5. Results and Discussion

5.1. Effect of Plastic Bottle Waste on Workability of Plastic Bottle Waste Concrete

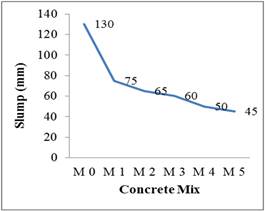

From the slump results obtained plastic bottle waste fiber have a significant decrease in slump compare to the results in plain concrete. This might due to the fact that plastic bottle fiber was different in geometry composition. In conclusion, slump test could not be considered as a suitable test to assess the workability of the concrete. This is due to the stiffening effects of the plastic bottle fiber which eventually influence the results of the slump test. The difference between the slump values of the control mix, between plain concrete and plain concrete with the addition of plastic bottle fiber is 55 mm. For addition of 1% of fiber contents, the difference in slump of fiber reinforced concrete without plastic bottle fiber and with the addition of plastic bottle fiber are 65mm, 70mm, 80mm, and 85mm for percentage of addition plastic bottle fiber 1.5%, 2%, 2.5% and 3% respectively.

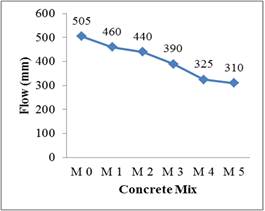

The Line graph (1a, 1b) below shows the results for the Flow table test conducted on plastic bottle fiber of different percentages of plastic bottle fiber. Lower Flow value indicates decrease the workability. The data for the Flow test are tabulated on the Table 2. The difference between the flow values of the control mix, which are plain concrete and concrete with the addition of plastic bottle fiber are 45 mm for 1% of plastic bottle fiber contents. For 1.5%, 2%, 2.5% and 3% of plastic bottle fiber contents, the difference in flow value for concrete without addition of plastic bottle fiber respectively 65 mm, 115 mm, 180 mm and 195 mm.

Table 2. Results Obtained From Slump and Flow Test.

| Mixture | Plastic Bottle Fiber Content% | Slump mm | Flow mm |

| M0 | 0 | 130 | 505 |

| M1 | 1 | 75 | 460 |

| M1 | 1.5 | 65 | 440 |

| M4 | 2 | 60 | 390 |

| M5 | 2.5 | 50 | 325 |

| M6 | 3 | 45 | 310 |

Figure 1a. Slump test results for various concrete mixes.

Figure 1b. Flow Table test results for various concrete mixes.

5.2. Physical Properties of Hardened Concrete

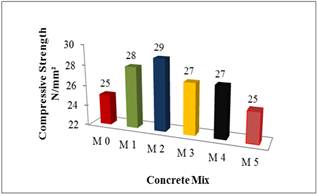

The 28 days compressive strength results were presented in Table 2. As shown in figure 2 the compressive strength of concrete goes on increasing with increase in percentage of plastic pieces (Plastic Bottle Fiber) but the rate of increasing compressive strength is only slight higher in strength with the addition of plastic bottle fibre. This low in strength is may be due reduction in bonding due introduction of plastic pieces. It is observed that the strength of concrete increases with the increase in the percentage of plastic bottle fiber. From 1% Up to 3% of plastic bottle fiber added the compressive strength of concrete of all concrete mix increases but beyond 3% decrease in the strength is observed compare to other percentage added. However, the maximum increase in the characteristic strength is observed in 1.5% added criterion for the concrete mix.

The effect of reinforcing plastic fibers in compression is quite often debated in the literature, since different studies report increases [3, 4, 5, 6], decreases [7, 8, 9] or no relevant effects [10, 11, 12] in the compressive strength of fiber-reinforced concretes and mortars, with respect to the unreinforced materials. The decrease of compressive properties has been explained due to the fact that highly deformable plastic fibers might assume the role of voids in the cementitious matrix when compressive forces are applied [7,8,9]. On the other hand, it has been shown that sufficiently stiff fibers can increase the lateral tensile strength of the composite material, leading to delayed compression failure [4,5,12].

Table 3. Compressive Strength of Concrete Prediction from Plastic Bottle Fibre after 28 Days.

| Mixture | Fiber Content% | Compressive Strength (N/mm2) |

| M0 | 0 | 25 |

| M1 | 1.0 | 28 |

| M2 | 1.5 | 29 |

| M3 | 2.0 | 27 |

| M4 | 2.5 | 27 |

| M5 | 3.0 | 25 |

Figure 2. Compressive strength Vs Plastic Fibres (%).

6. Conclusion

An investigation has been performed to study the usage of recycled plastic bottle waste on properties of concrete. The properties investigated were workability (slump and flow table), and compressive strength. The conclusion, which follow are drawn based on experimental results and observations presented earlier in the paper. These conclusions are of necessity specific to this study, being related to recycle plastic bottle waste, and environmental condition during testing, testing method, etc. Nevertheless, the findings of this investigation should provide a significant contribution towards the knowledge on the Utilization of waste materials on properties of concrete.

Ultimately the recycled plastic fibers used in this study appear to be much more effective in improving the mechanical qualities of cementitious products compared with recycled plastic fibers obtained from post-consumer textile carpet waste [12] and recycled PET fibers [13]. It is worth noting the environmental benefits related to the recycling of waste plastic bottles, especially considering that the reinforcement technique examined in the present work does not require energy consuming processes, such as material re-polymerization and extrusion. The plastic bottles just need to be collected, washed, and suitably cut to obtain reinforcing fibers, with substantial reduction of costs and energy consumption. Future extensions of the present research will deal with the multiscale mechanical modeling of materials incorporating plastic bottles reinforcements and other fibers/aggregates recycled from industrial waste. Based on the experimental result following points are summarized with regard to effect of plastic bottle fiber on the properties of concrete:

• Compressive strength of concrete is affected by addition of plastic bottle fiber and it goes on increasing the percentage of plastic increases addition of 1.5% of plastic in concrete causes about 16% increase in strength after 28 days curing.

• Thus it is conclude that the use plastic bottle fiber can be possible to increase the strength of concrete.

• From the above discussion it is identified that the use of plastic bottle fiber can be possible to improve the properties of concrete which can act as a one of the plastic disposal method.

• The Super-plasticizer is necessary for higher grade to get required slump & workable mix.

Acknowledgement

The author would like to thankful to the entire researchers who have done excellent work for drawing attention towards possible disposal of plastic waste in concrete. Their efforts will really help in saving environment from plastic waste.

References

- Seyed Hamed and Younes Saberi (2014) "Study on the Effect of Polypropylene Fibers on Strength and Heat Resistance of Concrete". World Applied Sciences Journal 31 (5):767-770, 2014, ISSN 1818-4952.

- Salahaldein Alsadey (2016) "Effect of Polypropylene Fiber Reinforced on Properties of Concrete". Journal of Advance Research in Mechanical and Civil Engineering.

- Banthia N, Zanotti C, Sappakittipakorn M. Sustainable fiber reinforced concrete for repair applications. Construction and Building Materials 2014; article in press.

- Song PS, Hwang S, Sheu BC. Strength properties of nylon- and polypropylene fiber reinforced concretes. Cement and Concrete Research 2005;35(8):1546–1550.

- Nili M, Afroughsabet V. The effects of silica fume and polypropylene fibres on the impact resistance and mechanical properties of concrete. Construction and Building Materials 2010;24(6):927–933.

- Fraternali F, Ciancia V, Chechile R, Rizzano G, Feo L, Incarnato L, Experimental study of the thermo-mechanical properties of recycled PET fiber-reinforced concrete. Composite Structures 2011;93:2368–2374.

- Karahan O, Atis CD. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater Des 2011;32(2):1044–1049.

- Kim SB, Yi NH, Kim HY, Kim J, Song Y. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cement and Concrete Composites 2010;32:232–240.

- Fraternali F, Spadea S, Berardi VP. Effects of recycled PET fibres on the mechanical properties and seawater curing of Portland cement-based concretes. Construction and Building Materials 2014:61:293–302.

- Silva DA, Betioli AM, Gleize PJP, Roman HR, Gómez LA, Ribeiro JLD. Degradation of recycled PET fibers in Portland cement-based materials. Cement and Concrete Research 2004;35:1741–1746.

- Pereira de Oliveira LA, Castro-Gomes JP. Physical and mechanical behaviour of recycled PET fibre reinforced mortar. Construction and Building Materials 2011;25:1712–1717.

- Ozger OB, Girardi F, Giannuzzi GM, Salomoni VA, Majorana CE, Fambri L, Baldassino N, Di Maggio R. Effect of nylon fibres on mechanical and thermal properties of hardened concrete for energy storage systems. Materials and Design 2013;51:989–997.

- Fraternali F, Farina I, Polzone C, Pagliuca E, Feo L, On the use of R-PET strips for the reinforcement of cement mortars. Composites Part B – Eng 2013;46:207–210.

- ACI 544.1R (1996). State-of-the-Art Report on Fiber Reinforced Concrete, American Concrete Institute, Farmington Hills, Michigan.

- ACI Committee 544. 1982. State-of-the-Report on Fibre Reinforced Concrete, (ACI 544.1R-82), Concrete International: Design and Construction. 4(5):9-30, American Concrete Institute, Detroit, Michigan, USA.

- ACI Committee 544. 1989. Measurement of Properties of Fibre Reinforced Concrete, (ACI 544.2R-889).

- ASTM C192/C192M-02, "Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory", Annual Book of ASTM Standards, Vol.04.02, 2003; pp.126-133.

- British Standard Institution, BS 1881: Part 102 (1983). "Methods for Determination of Slump".

- British Standard Institution, BS 1881: Part 116 (1983). "Methods for Determination of Compressive Strength of Concrete Cube".