Design and Analysis of an Automobile Exhaust Muffler

P. Srinivas*, Venkata Ramesh Mamilla, G. Lakshmi Narayana Rao,

Sowdager Moin Ahmed

Department of Mechanical Engineering, QIS Institute of Technology, Ongole, Andhra Pradesh, India

Abstract

Present day engines are required to have more engine power and are also required to meet the strict pollution standards. In an automobile the exhaust muffler plays an integral role in reducing the sound of the automobile, as well as the ride itself. In order to maintain a desired noise and comfortable ride, the modes of a muffler need to be analysed. Here dynamic modal analyses were carried out to determine the mode shapes, stresses and deformations of exhaust muffler using CAE analysis.

Keywords

Design, Analysis, Automobile, Exhaust Muffler

Received: June 17, 2016

Accepted: July 6, 2016

Published online: July 21, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Mufflers are installed within the exhaust system of most internal combustion engines, although the muffler is not designed to serve any primary exhaust function. The muffler is engineered as an acoustic sound proofing device designed to reduce the loudness of the sound pressure created by the engine by way of acoustic quieting.

For the majority of such systems, however, the general rule of "more power, more noise" applies. Several such exhaust systems that utilize various designs and construction methods:

Ÿ Vector muffler - for larger diesel trucks, uses many concentric cones, or for performance automotive applications, using angled baffles to cause exhaust impulses to cancel each other out.

Ÿ Spiral baffle muffler - for regular cars, uses a spiral-shaped baffle system

Ÿ Aero turbine muffler - creates partial vacuums at carefully spaced out time intervals to create negative back pressure, effectively ‘sucking’ the exhaust out of the combustion cylinder.

2. Literature Review

Although the first works on this subject are more than 10 years old, the study of heat transfer in automotive exhaust systems has only recently attracted the importance it deserves due to its key role in the design of modern exhaust after-treatment systems. Such studies are today important for better understanding of these systems and, thus, being able to influence under body heat transfer, transient cold-start warm-up of the catalytic converter, thermal ageing of the converter, or the regeneration behaviour of diesel particulate traps etc.

Experimental investigation of the heat transfer rates in exhaust ports was initially aimed at supporting thermodynamic engine cycle models, especially for engine turbocharger matching applications [6]. Those experimental findings were exploited in the computer model developed by Frank [7], who also simulated manifold heat transfer by employing classical correlations applicable to curved pipes. Meitner and Sorenson [8], on the other hand, based on the experimental results of Sachdev [9], presented a comprehensive model covering also heat transfer in takedown pipes. Both models focused, however, mainly on the temperature variation during single engine operating cycles. Pattas et al. studied the thermal response behaviour of diesel exhaust systems equipped with a particulate filter [4]. Zhang et al. Developed a model computing the steady state temperature distribution in exhaust systems with single wall and with double wall, air gap insulated piping [10]. Recently, one-dimensional transient models covering a variety of exhaust system designs have been presented [3, 11, 12], presenting a model that was able to simulate real world heat transfer in exhaust systems of gasoline car sand is extensively employed in CAE investigations [3]. The experimental acquisition of useful data for the estimation of heat transfer rates and their application in the optimized design of various exhaust configurations forms the subject of the present paper

3. Working of Exhaust Muffler

Engine generates lots of pulsating noise as its exhaust valves open up to release highly pressurized gas. These thousands of little sound bursts per minute travel quickly down the exhaust pipe, and the noise bounces around to add up into a loud and potentially very annoying sound. The key, then, is to find a way to minimize this sound level before it exits the exhaust system.

3.1. Tuning Engine Noise

Mufflers are mounted in line with your exhaust pipes, typically towards the very end before the exhaust tips. They feature a series of perforated tubes or baffled chambers which are designed to tune and minimize your engine's sound output. As noise comes into the muffler, the sound waves bounce around against the baffles, creating opposing sound waves that cancel each other out. And much like an acoustical engineer designing an instrument or a concert hall, muffler manufacturers know how to "tune" the baffles and chambers to create a desired sonic effect. So whether you want to cut as much sound as possible or get a focused sound with an amplified growl range, there's a performance muffler out there for you.

3.2. Back Pressure

Engine exhaust back pressure is defined as the exhaust gas pressure that is produced by the engine to overcome the hydraulic resistance of the exhaust system in order to discharge the gases into the atmosphere. For this discussion, the exhaust back pressure is the gage pressure in the exhaust system at the outlet of the exhaust turbine in turbocharged engines or the pressure at the outlet of the exhaust manifold in naturally aspirated engines.

3.2.1. Back Pressure Limits

All engines have a maximum allowable engine back pressure specified by the engine manufacturer. Operating the engine at excessive back pressure might invalidate the engine warranty. To facilitate retrofitting of existing engines with DPFs, especially using passive filter systems, emission control manufacturers and engine users have been requesting that engine manufacturers increase the maximum allowed back pressure limits on their engines.

Table 1. VERT Maximum Recommended Exhaust Back Pressure.

| Engine Size | Back Pressure Limit |

| Less than 50 hp | 40 kPa |

| 50-500 hp | 20 kPa |

| 500 hpand above | 10 kPa |

Engine manufacturers are usually much more conservative on their back pressure limits. For example, diesel generator set engines from Caterpillar, Cummins, John Deere and DDC/MTU

3.2.2. Effects of Increased Back Pressure

At increased back pressure levels, the engine has to compress the exhaust gases to a higher pressure which involves additional mechanical work and/or less energy extracted by the exhaust turbine which can affect intake manifold boost pressure. This can lead to an increase in fuel consumption, PM and CO emissions and exhaust temperature. Increased backpressure may affect the performance of the turbocharger, causing changes in the air-to-fuel ratio-usually enrichment—which may be a source of emissions and engine performance problems. The magnitude of the effect depends on the type of the charge air systems. Increased exhaust pressure may also prevent some exhaust gases from leaving the cylinder (especially in naturally aspirated engines), creating an internal exhaust gas recirculation (EGR) responsible for some NOx reduction. Slight NOx reductions reported with some DPF system, usually limited to 2-3% percent, are possibly explained by this effect. Excessive exhaust pressures can increase the likelihood of failure of turbocharger seals, resulting in oil leak agent the exhaust system. In systems with catalytic DPFs or other catalysts, such oil leak can also result in the catalyst deactivation by phosphorus and/or other catalyst poisons present in the oil. All engines have a maximum allowable engine back pressure specified by the engine manufacturer. Operating the engine at excessive backpressure might invalidate the engine warranty. It is generally accepted by automotive engineers that for every inch of Hg of backpressure (that's Mercury – inches of Hg is a unit for measuring pressure) approximately 1-2 HP is lost depending on the displacement and efficiency of the engine, the combustion chamber design etc

3.3. Characteristics of Muffler

The design of a noise muffler incorporated into a pneumosystem. On the basis of the developed mathematical model transition processes in the pneumonia system were calculated with regard to a noise muffler installed so as to investigate the impact of the installed noise muffler on the speed of the pneumonia system’s operation.

The performance of a muffler is characterized using 3 different measures.

- Insertion loss, IL

- Transmission loss, TL

- Noise reduction, NR

Insertion loss is defined as "the ratio (in dB) between the acoustic power radiated at the outlet of a reference system and the system investigated, with both systems driven by the same source" [2] The reference is usually a straight pipe with the same length as the investigated system.

Transmission loss is defines as" the ratio (in dB) of the incident power to the power transmitted for a given termination" [2]. Normally a reflection free pipe. Noise reduction is defined as the "difference in sound pressure level (in dB) at two arbitrarily selected points in the exhaust pipe and tailpipe" [3], (upstream and downstream side of the muffler).In this work, transmission loss, TL, will be used as the measurement of the muffler performance.

3.4. Muffler Configuration

For the least noise it is always best to have two mufflers in series. The second muffler will absorb sound missed by the first muffler, and there will be some wave type noise cancelling in the tubing between the two mufflers. Ideally, the second muffler should do most of the silencing but even a small resonator at the end of the exhaust system will make a big difference.

3.4.1. Exhaust Outlet

The exhaust outlet should extend beyond the separate bumper found on MGBs and most vintage sports cars. This is because the curved inner surface of the bumper will reflect the exhaust noise back towards the car contributing to "droning" during cruising. Another alternative is to used turned down exhaust tips to keep the noise away from the bumper/reflector.

3.4.2. Exhaust Pipe Size

As a rule of thumb, a 2 inch dual exhaust is fine for a mild 215 engine, a 2 1/4 inch diameter is good for up to about 300 cubic inches, and while a 2 ½ inch exhaust is good for a highly tuned 350. A 3 inch exhaust is better for larger performance engines. In theory, using too large of an exhaust can decrease low end torque because the increased gas velocity of a smaller pipe helps scavenging. However, I doubt this is too strong of an effect, and probably header diameter and length is more important for scavenging. But with an old British car, ground clearance is limited and that is a good reason for not using too large of a pipe.

In any case, the largest piping is needed before the X or H pipe. As was explained earlier, the X or H pipe allows the exhaust pulses to use both exhaust pipes, while the pulses are restricted to only one pipe before the cross over connection. Also, the exhaust gases have cooled slightly by the time they reach the cross over and will take up slightly less volume, but the cross over connection is the main effect. Logically, then, a way to minimize ground clearance issues and retain many of the advantages of a large diameter exhaust is to make a custom crossover piece with larger diameter inlet than outlet pipes.

4. Design Considerations

Present day engines are required to have more engine power and are also required to meet the strict pollution standards. To improve exhaust system performance, many design specifications are required.

A chimney serves as an exhaust pipe in a stationary structure. For the internal combustion engine.

Ÿ It is important to have the exhaust system "tuned" (refer to tuned exhaust) for optimal efficiency.

Ÿ Also this should meet the regulation norms maintained in each country.

4.1. Design Calculations for Multiport Representation

A multi-port representation is a way of characterizing a duct system in the plane wave region with a matrix relation between its input and output state variables

y=G(1)

Where,

x is the input state variables,

y the output state variables

The plane wave region is frequencies below the first cut-on frequency for higher order modes, which for a circular duct can be calculated from

![]() (2)

(2)

4.2. Designing of Parts

The parts are designed on the solid workbench by referable conditions and respectable literatures.

Solid Works is mechanical design automation software that takes advantage of the familiar Microsoft Windows graphical user interface.

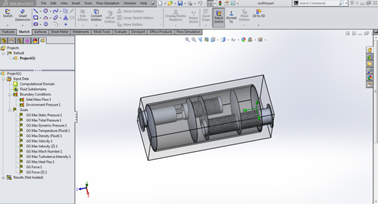

Fig. 1. Assembly of exhaust muffler.

5. Simulation

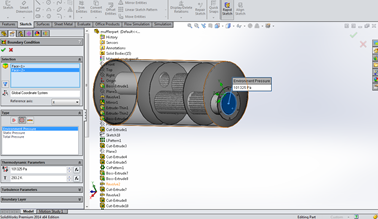

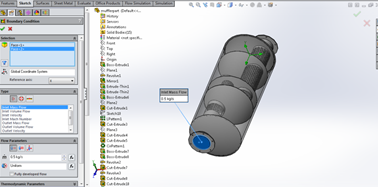

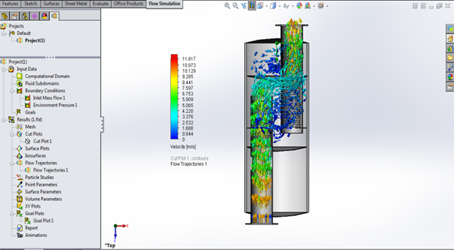

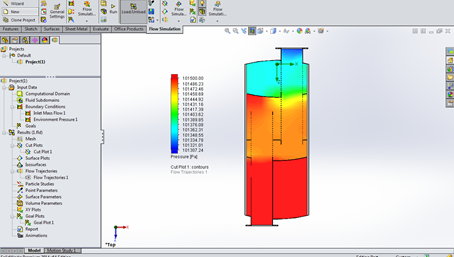

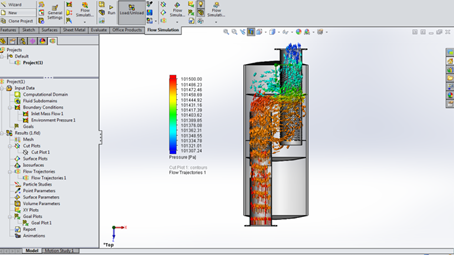

Solid Works Flow Simulation 2010 is a fluid flow analysis add-in package that is available for Solid Works in order to obtain solutions to the full Nervier-Stokes equations that golem the motion of fluids. Other packages that can be added to Solid Works include Solid Works Motion and Solid Works Simulation. A fluid flow analysis using Flow Simulation involves a number of basic steps that are shown in the following figures

Fig. 2. Flow Simulation.

Fig. 3. Simulation parts.

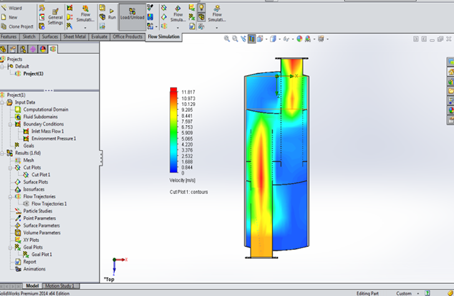

Fig. 4. Velocity Distribution.

Fig. 5. Detailed Velocity Distribution.

Fig. 6. Pressure Distribution.

Fig. 7. Detailed Pressure Distribution.

6. Conclusions

1. Double expansion chamber gives better results as compared to single expansion chamber. Transmission loss of double expansion chamber is 42.48 which is more than requirement and satisfactory.

2. Design and analysis of muffler guard is done in solid works.

3. Modelling of muffler is done with proper dimensions

4. Dynamic analysis is carried out to determine the mode shapes and stresses and deformations in the muffler using CAE analysis

7. Future Work

The muffler which we are going to create that is little big in size. So, in future the size of muffler can be minimize to a proper size which can be suitable for the motorcycle. Also there is a scope to calculate back pressure. Also because of reduction in size of muffler the manufacturing cost of muffler can also be reduce. Due to reduction in the muffler the requirement of space is also less.

References

- 2005,A.K.M.Mohumuddin, Mohd Rashidin Ideres and Shukari Mohad Hashim, Experimental study of noise and back pressure for silencer design characteristics, Journal of Applied Science5(7):1292- 1298,2005 ISSN 1812-5654.

- 2010, ChandrashekharBhat, S S Sharma, Jagannath K, N S Mohan, Sathisha S G, Design and Analysis of a Expansion Chamber Mufflers, World Journal Of Engineering, volume 7, supplement 3, 2010, ISSN: 1708-5284.

- 2010, Wang jie and Dong-pengVue. The Modal Analysis of Automotive Exhaust Muffler Based on PROE and ANSYS. 20IO 3rd International Conference on Advanced Computer Theory and Engineering (ICACTE). 2010 IEEE.

- 2010, Mehmet Avcu, ŞadiKopuz and Mehmet Teke. DIESEL ENGINE EXHAUST SYSTEM DESIGN, Journal of Naval Science and Engineering 2010, Vol. 6, No.1, pp. 39-58.

- 2011, Ying Li Shao. A Study on Exhaust Muffler Using a Mixture of Counter phase Counteract and Split-gas Rushing. © 2011 Published by Elsevier Ltd. Selection and/or peer-review under responsibility of [CEIS 2011].

- 2011, Shi wu, DongkaiJia, YuntongJia, Ke Wu. Structural Design and Testing Study of Truck Muffler. 2011 International Conference on Electronic &Mechanical Engineering and Information Technology ©2011 IE.

- 2011, Jun Chan and Xiong Shi.CFD Numerical Simulation of Exhaust Muffler. 2011 Seventh International Conference on Computational Intelligence and Security. © 2011 IEEE. DOI 10.1109/CIS.2011.321.

- 2012, 1M RAJASEKHAR REDDY & 2 K.MADHAVA REDDY. DESIGN AND OPTIMIZATION OF EXHAUST MUFFLER IN AUTOMOBILES International Journal of Automobile Engineering Research and Development (IJAuERD)ISSN 2277-4785 Vol.2, Issue 2 Sep 2012 11-21.

- 2012, HuaHUANGEJimin NI, Qianying DU, Nan XIE, Multi-objectives Optimization on Exhaust Muffler Based on DoE. 2012 Fourth International Conference on Computational and Information Sciences.©2012 IEEE DOI 10.1109/ICCIS.2012.189.

- 2013, Ehsan Sabah M. AL-Ameen. Experimental Test for Noise Attenuation in Gasoline Engine with Different Types of Mufflers Journal of Engineering and Development, Vol. 16, No.4, Dec. 2012 ISSN 1813-7822.

- 2013, Takashi Yasud,Chaoqun Wu, Noritoshi Nakagawa, KazuteruNagamura. Studies on an automobile muffler with the acoustic characteristic of low-pass filter and Helmholtz resonator. Applied Acoustics 74 (2013) 49–57. 2012 Elsevier Ltd.http://dx.doi.org/10.1016/j.apacoust.2012. 06.007.