Assessment of Physico-Chemical Parameters for Humic Acids Adsorption on Alumina

Chrisdel Chancelice NDJEUMI1, 2, 3, *, Andrada MĂICĂNEANU2, Jean Baptiste BIKE MBAH1, Ghislain Arnaud MOUTHE ANOMBOGO1, 2, 3, Richard KAMGA1

1Laboratoire des Matériaux et Chimie Industrielle Inorganique, ENSAI – University of Ngaoundere, Ngaoundere, Cameroon

2Department of Chemical Engineering, Babeș-Bolyai University, Cluj-Napoca, Romania

3Department of Environmental Sciences, ISS – University of Maroua, Maroua, Cameroon

Abstract

The purpose of this study was to investigate the potential use of alumina as adsorbent for humic acids removal from water. The main parameters that influence the adsorption of humic acids were highlighted by means of an experimental design based on Hadamard matrix. It was found that pH is the most important physico-chemical parameter, while particle size and porosity are the main adsorbent property that influences the adsorption efficiency. The optimum conditions to remove 99% of humic acids from solution at 25ºC are: pH 6.0, alumina particle size < 100 μm and pore size of about 15.9 nm. The kinetic modelling of experimental data showed that the process is better described by the pseudo-second-order kinetic model.

Keywords

Humic Acids, Adsorption, Experiment Design, Alumina, Kinetic Modelling

Received: April 9, 2015

Accepted: May 1, 2015

Published online: May 25, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Humic acids (HA) are chemically heterogeneous compounds having different types of functional groups (–COOH, –NH2, –OH, Ar–OH), at different proportions and configurations. In fact, humic acids are complex mixture of organic components derived from soils or produced within surface water and sediments by biological and chemical processes (Kazpard et al. 2006; Hizal and Apak 2006).

Humic substances are involved in most problems encountered in water treatment process. They lead to water colour, to formation of carcinogenic chlorinated organic compounds during disinfection, to membrane fouling during filtration, give taste and odour and biological regrowth in the distribution networks (Edwards and Amirtharajah 1985. Pourret et al. 2007 ; Davranche et al. 2004). Therefore several methods have been proposed for removal of HA and other unwanted substances from aqueous solution. The most widely used methods are coagulation/UV light radiation (Wendong et al. 2014), ozonation (Daizo et al. 2009), photo-Fenton process (Hideyuki et al. 2009), coagulation/flocculation (Gurusamy et al. 2008) and filtration on membrane (Suksaroj 2006). These classical methods are ineffective to ensure a complete removal of humic substances. They are usually completed with techniques such as microfiltration and adsorption. Adsorption has attracted much attention for removing HA from water (Wilbulswas et al. 1998; Lacey et al. 1997) because it is a very effective separation process to eliminate pollutants present even at trace levels. However, many of these works were performed on the principle of one variable at time. This type of experiment does not permit an accurate determination of the weight of each parameter on adsorption efficiency.

The purpose of this study was to investigate the use of alumina as a model adsorbent for the removal of HA from water. The experimental work includes the assessment of factors influencing the adsorption of HA on alumina by means of an experimental design (Hadamard matrix). The adsorption kinetics of HA on alumina under various conditions was also investigated and an adsorption mechanism was proposed.

2. Material and Methods

2.1. Material

HA were extracted from the soil sediment of the Nyong River, in the Mbalmayo city (3.51° N; 11.5° E) in Cameroon. Extraction was made according to the method described by Thurman and Malcom (1981) and modified by Jung et al. (2005). The sediment fractions of size d ≤ 100 μm was used for this purposes. This fraction was obtained by crushing the initial sediment and sieving the resulting powder through a 100 μm mesh sieve.

Characteristics of HA were described by Sieliechi et al. (2008). In short, analysis of elementary composition of HA of the Nyong river shows that they have a pedogenic origin due to C/N ratio value equal to 14.03. These are substances where aromatic and hydrophobic characters are predominant (H/C ratio of 0.08). Hydrophobic character is confirmed by the low values of the O/C ratio (0.84) and (O+C)/N (25.8). The potentiometric titration of Nyong HA gives the total exchangeable proton value of 2.7 meq g-1 (Sieliechi et al. 2008).

Stock alumina samples of different particle size and texture available in our laboratory were used as adsorbent. Their characteristic has been described in detail elsewhere (Kamga et al. 2000). In short there are pure aluminas of Al2O3 content greater than 99%. Their BET surface areas and mean pores diameter are 227 m2 g-1 and 8.7 nm; 153 m2 g-1 and 14.4 nm; 142 m2 g-1 and 15.9 nm for ALCATA, Al3993R and Al4192E respectively.

2.2. UV-Visible Analysis

UV-Visible analysis was carried out using a Spectronic Genesystm 2PC spectrophotometer. A 1 cm optical path quartz cell was used. Distilled water was used as reference. The amount of HA in solution was determined by measuring the absorbance at the maximum wavelength of 254 nm. Calibration curve was made by measuring the absorbance of HA solutions of known concentrations.

2.3. HA Adsorption Experiments

The adsorption experiments were performed in batch mode in 100 ml Erlenmeyer flasks by mixing 4 mg adsorbent and 10 ml HA solution (25.8 mg L-1). The mixture was shacked at 50 cycle min-1 in thermostated water batch for the desired time. The mixture was then centrifuged at 3500 rpm for 15 min and the remaining HA in the supernatant solution was determined as described in section 2.2.

The relative amount of HA adsorbed per gram of adsorbent was expressed as:

![]() (1)

(1)

where, C0 and C are the initial and time t concentrations of HA, respectively, m is the mass of adsorbent, and V is the volume of HA solution.

2.4. Experimental Design: Hadamard Matrix

It has been reported in the literature that numerous factors can influence humic acids adsorption from solution (Davis and Gloor 1981; Zhou et al. 1994; Gu et al. 1995; Dubey et al. 1996; Arnarson and Keil 2000). Some of them are contact time, adsorbent to solution ratio, temperature, pH, adsorbent particle size, composition and texture. To assess key parameters for better adsorption efficiency, Hadamard matrix was used (Goupy 1990). For the experimental design variation domains of usual adsorption from solution parameters (pH, temperature, particle size and adsorbent to solution ratio) were determined by kinetic studies. Factor levels used for two level experiment design are listed in Table 1. The response function was the amount of HA adsorbed per gram of adsorbent.

With 4 factors, Hadamard matrix designs require eight experiment combinations.

Table 1. Factors level used in two level experiment design.

| Factors | Code value | Low level (-1) | High Level (+1) |

| pH | X1 | 4 | 10 |

| Temperature (°C) | X2 | 25 | 60 |

| Particles size (d) (μm) | X3 | 315 < d < 500 | d < 100 |

| Amount of adsorbent (g) | X4 | 2 | 8 |

Each experiment was carried out in triplicate. Microsoft Excel 2007 and Statgraphics plus software were used to analyse the obtained data.

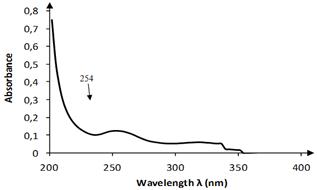

3.1. Characterisation of HA

HA absorption spectrum is show in Figure 1. This spectrum presents a wide absorption band at wavelengths ranging between 245 and 260 nm with a maximum absorption at 254 nm. This result is similar to that of Gossart (2001), which found that the adsorption band of synthetic HA lied between 260 and 300 nm. The difference between two spectra is probably linked to the origin of the two samples.

Figure 1. Absorption spectrum of HA.

3.2. Effect of Some Parameters onto HA Adsorption

During the adsorption experiment, absorbance of supernatant solution was determined. Subsequently, the humic acids concentration was calculated from calibration curve. The equation of the calibration curve obtained was: A=0.161C + 0.0019, with R2 = 0.997, where C is humic acids solution concentration (g L-1) and A the absorbance.

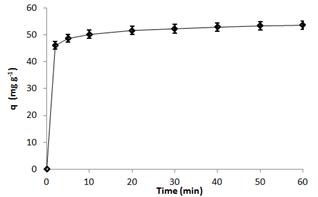

3.2.1. Contact Time

It was observed that the humic acids adsorption is very fast in the first minutes and then stabilizes after 10 minutes (Fig. 2). Indeed, beyond this period it was not observe any more notable variation of the adsorbed quantities. This result shows that adsorption of HA on alumina is faster than the adsorption of the HA on activated carbon. Unai et al. (2009) found that the time required for adsorption of humic acids on activated carbon to reach the equilibrium lied between 50 min to 3 h. This could be attributed to the difference in texture and chemical groups present on the surface of alumina and activated carbon.

Figure 2. Adsorption kinetics of HA onto ALCATA of d < 100 µm, (pH = 11.7, temperature 25°C).

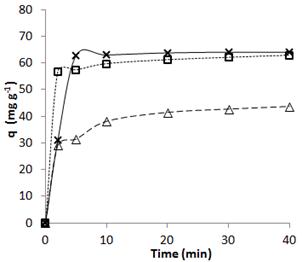

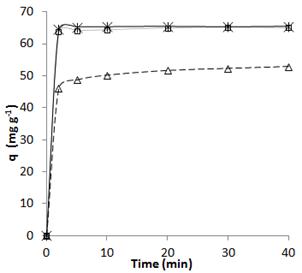

3.2.2. Textural Properties of Alumina

The removal of HA with ALCATA alumina of different particle sizes showed that the removal rate increased as the particle size decreases (Fig. 3-a). Equilibrium was reached in about 7 minutes for particles size lower than 200 µm, more than 20 minutes for particle size greater than 315 µm. The amount of HA adsorbed at equilibrium is 65.2 mg g-1 for smallest particle size and 38.4 mg g-1 for highest particle size alumina.

The lower adsorption capacity of high particle size adsorbent may be attributed to the fact that HA have to diffuse inside the bulk of large particles before adsorption occur. These phenomena explained why time to reached equilibrium is greater for larger particle than for smaller ones. This difference cannot be attributed to texture. It has been shown that particle size did not affected adsorbent surface area and porosity (Kamga et al. 2000). Also not all the adsorption sites of large particles are available for adsorption. This phenomenon was also observed by Kamga et al. (2000) for the adsorption of dye from solution.

Adsorption of HA is faster on large pores alumina (Al3993R and Al4193E) than small pores alumina (ALCATA). The time required to reaches equilibrium is 5 min for large pore alumina and more than 10 min for small pore alumina (fig. 3-b). Moreover, the amounts of HA adsorbed at equilibrium on Al3993R and Al4193E are greater than the amount adsorbed on ALCATA. By changing the pore size diameter from 8.7 nm to 15.9 nm, the amount adsorbed increased from 63 m g-1 (80.2% removal) to 87.3 mg g-1. This difference in HA adsorption efficiency cannot be attributed to adsorbent surface area as ALCATA has higher surface areas than the two other alumina. It is probably due to the fact that HA diffuse more easily inside large pore alumina and higher amount of HA accumulate in large pore alumina.

(a)

(b)

Figure 3. Adsorption kinetics at 25°C, pH 6.0 of HA onto ALCATA of (a) different particle size d < 100 µm ( ![]() ), 200 < d < 315 (

), 200 < d < 315 ( ![]() ), 315 < d < 500 (

), 315 < d < 500 (![]() ) and (b) different pores diameter 15.9 nm (

) and (b) different pores diameter 15.9 nm ( ![]() ), 14.4 nm (

), 14.4 nm ( ![]() ), 8.7 nm (

), 8.7 nm (![]() ).

).

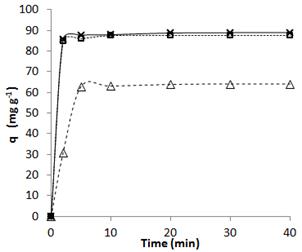

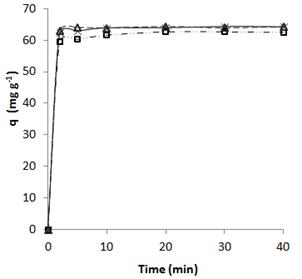

3.2.3. Effect of Physico-Chemical Parameters

Adsorption kinetic of HA on ALCATA alumina of particle size < 100 μm at different pH values (6, 8 and 11.7) for initial HA concentration of 25.8 mg L-1, at 25ºC are shown in Fig. 4-a. The kinetic curves at pH 8.0 and pH 6.0 are overlapped. It was observed that pH has little effect on the equilibrium time. Indeed, this time is of approximately 5 minutes at pH 6.0 and 8.0, and 10 minutes at pH 11.7. The amount of HA adsorbed at equilibrium is 65.2 mg g-1 at pH 6.0 and 8.0. This amount drops to 50.2 mg g-1 when pH increases from 6.0 to 11.7. At high pH the functional groups of humic acids (i.e. –COOH, –NH2, –OH, A–OH) and those of alumina (Al–OH) are negatively charged, therefore they repel each other. Furthermore at high pH, there is competition between HA and –OH group on alumina. This result also reveals that adsorption of HA onto alumina involved at least three mechanisms, i.e. electrostatic bonding, surface complexation and molecular sieved interaction. This phenomenon was also explained by Jianwei and Yanhui (2012) for the adsorption of HA onto unmodified zeolite.

The kinetic of HA removal by ALCATA of particle size < 100 μm at different temperatures (25°C, 45°C and 60 °C) at pH = 6.0, for initial HA concentration of 25.8 mg L-1, (Fig. 4-b) shows that temperature does not influence the adsorption of humic acids on alumina. The time to reached equilibrium remains at 5 min and the amount of HA adsorbed is almost the same whatever the temperature and contact time. The amount of HA adsorbed at equilibrium is 63.2 mg g-1.

(a)

(b)

Figure 4. Adsorption kinetics of HA onto ALCATA, d < 100 µm, at (a) different pH values, pH 6.0 ( ![]() ), pH 8.0 (

), pH 8.0 ( ![]() ), pH 11,7 (

), pH 11,7 (![]() ) and (b) different temperatures 25°C (

) and (b) different temperatures 25°C ( ![]() ), 45°C (

), 45°C ( ![]() ) , 60°C (

) , 60°C (![]() ).

).

3.3. Modelling of Adsorption Kinetic

The adsorption data were analysed using two kinetic models, mainly pseudo-first-order and pseudo-second-order (Ho et al. 2000) models. The respective linear equations of pseudo-first-order and pseudo-second-order model are respectively:

![]() (2)

(2)

![]() (3)

(3)

where, qe and q are the amount (mg g-1) adsorbed at equilibrium and at time t, respectively, k1 and k2 are the respective pseudo-first- and pseudo-second-order kinetic constants.

The experiment data does not fit pseudo first order model, as the correlation coefficient for the ![]() vs.

vs. ![]() plots, for all the considered adsorbents where lower than 0,700. Table 2 presents the correlation coefficient for the

plots, for all the considered adsorbents where lower than 0,700. Table 2 presents the correlation coefficient for the ![]() vs.

vs. ![]() plots, and the kinetic constant

plots, and the kinetic constant ![]() . The experiment data fit very well the pseudo-second-order model. Therefore it can be concluded that the adsorption of HA occurred probably in two steps. The first step is solute transfer from solution to the adsorbent surface and the second step is the interaction between the solute and the adsorbent. This second step leads to effective removal of HA from solution.

. The experiment data fit very well the pseudo-second-order model. Therefore it can be concluded that the adsorption of HA occurred probably in two steps. The first step is solute transfer from solution to the adsorbent surface and the second step is the interaction between the solute and the adsorbent. This second step leads to effective removal of HA from solution.

Table 2. The pseudo-second-order rate constants for HA adsorption.

| Parameters | Values | Pseudo-second-order | |

| pH | 6.0 | 70.06 | 0.999 |

| 8.0 | 64.83 | 0.999 | |

| 11.7 | 37.50 | 0.999 | |

| Particle size | d < 100 µm | 14.90 | 0.997 |

| 100 < d < 200 µm | 32.42 | 0.999 | |

| 315 < d < 500 µm | 12.59 | 0.998 | |

| Porosity | Ø = 8.7 nm | 14.90 | 0.995 |

| Ø = 14.4 nm | 8.49 | 0.999 | |

| Ø = 15.9 nm | 8.19 | 0.999 | |

3.4. Mechanism of HA Adsorption on Alumina

Alumina possesses Brönsted and Lewis acidic sites. Those sites react with phenolic, carboxylic and amine functional groups of HA.

For Brönsted sites, the reactions could be:

![]()

![]()

![]()

For the Lewis sites, we could have:

![]()

![]()

![]()

At high pH, HO- ions react with the alumina Brönsted sites. Therefore the second adsorption scheme does not occur and the reduction of amount of HA adsorbed is observed. Furthermore HO- ions react with phenolic and carboxylic group of HA to yield Ø-O- and RCOO- ions.

Other adsorption mechanism could involve intermolecular forces, namely van der Waals and hydrogen bonding.

3.5. Dominants Factors

The Hadamard matrix was used to seek parameters that significantly influence the adsorption process. Table 3 presents the results of the Hadamard matrix assessment for the HA adsorption on alumina. Multiple regression analysis equation obtained is as follows:

Y = 6.5 + 5.5·X1 + 3·X2 + 14.5·X3 – 3.5·X4 (4)

with a correlation coefficient, R2, of 0.8563.

Table 3. Summaries of the response effects of Hadamard matrix.

| Experiment no. | Factor levels | Response Y | |||

| X1 | X2 | X3 | X4 | Amount of HA adsorbed | |

| 1 | + 1 | – 1 | – 1 | – 1 | 121.71 |

| 2 | – 1 | – 1 | – 1 | + 1 | 30.48 |

| 3 | – 1 | – 1 | + 1 | + 1 | 25.03 |

| 4 | + 1 | + 1 | + 1 | + 1 | 31.04 |

| 5 | – 1 | + 1 | – 1 | – 1 | 132.19 |

| 6 | + 1 | – 1 | + 1 | – 1 | 94.81 |

| 7 | + 1 | + 1 | – 1 | + 1 | 33.67 |

| 8 | – 1 | + 1 | + 1 | – 1 | 5.78 |

| Effect bi | 5.34 | 3.04 | 14.56 | - 34.91 | |

X1 = pH; X2 = Temperature; X3 = Particle size; X4 = Adsorbent amount

It was observed that, there is not interaction between parameters. Temperature has little effect on HA adsorption. This result is similar with that obtained from the kinetic study. Practical analysis shows that the pH of the solution influences significantly the adsorption process. Of course, kinetic studies reveal that at high pH (11.7) there is a 25% reduction of the amount of humic acids adsorbed. It was also noticed from the regression equation that high amount of adsorbent has negative effect on the amount of HA adsorbed per gram.

The similarity between the kinetic results and the Hadamard matrix assessment is due to the fact that parameters of the adsorption process are independent from each other.

Taking into consideration all the obtained results, we can conclude that, HA at 25.8 mg L-1 was best adsorbed in the following conditions: pH 4.0, adsorbent mass 2 g and particle size <100 mm.

4. Conclusion

Humic acids (HA) removal from aqueous solution was possible using pure alumina as adsorbent. Alumina can remove more than 96% of humic acids at 25ºC with 10 min necessary to reach equilibrium time. HA show high affinity for the alumina surface. The most efficient alumina for HA adsorption was that of small particle sizes and pore size content (there are in mesoporous range all of them). The kinetic studies reveal that adsorption of HA onto alumina follow the pseudo-second-order kinetic model. This imply that the adsorption mechanism include two main steps, namely diffusion of humic acids towards the adsorbent surface and then the interaction between HA and adsorbent, complexation reaction of HA on alumina. The main parameters that govern HA adsorption onto alumina are solution pH and adsorbent pore size.

References

- Arnarson, T. S., & Keil, R. G. (2000). Mechanisms of pore water organic matter adsorption to montmorillonite. Marine Chemistry, 71(3-4), 309-320.

- Daizo, I., Ahmed, H. A. D., Satoshi, K., Hideyki, K., Tohru, S., Tadaya, K., & Kiyohisa, O. (2009). Degradation of marine humic acids by ozone-initiated radical reactions. Chemical Engineering Journal,148, Issues 2–3, 15, 336–341

- Davis, J. A., & Gloor, R. (1981). Adsorption of dissolved organics in lake water by aluminium oxide. Effect of molecular weight. Environ. Sci. Technol., 15, 1223-1229.

- Davranche, M., Pourret, O., Gruau, G., Dia, A. (2004).Impact of humate complexation on the adsorption of REE onto Fe oxyhydroxide. Journal of Colloid and Interface Science, 277, 271–279.

- Dubey, V., Madhusudhanan, S., Nath, R., Rao, N., & Singh, B. (1996). Active carbon for removal of toxic chemicals from contaminated water. Carbon, 34 (3), 327-330.

- Edwards, G. A., & Amirtharajah, A. 1985. Removing color caused by humic acids, J. Am. Water Works Assoc., 77, (3), 50-57.

- Gossart, P., (2001). Contribution à l’étude des interactions de la matière organique des sols avec les métaux lourds : Etude structurale et analytique de molécules modèles. Thèse de doctorat soutenu le 18 Décembre 2001 à l’Université des Sciences et Technologies de Lille, 132 p.

- Goupy, J. L., (1990). Étude comparative de divers plans d’expériences.Revue de statistique appliquée tome 38, no4, 5-44.

- Gu, B., Schmitt, J., Chen, Z., Liang, & Mccarthy, J. F. (1995). Adsorption and desorption of different organic matter fractions on iron oxide. Geochimica et Cosmochimica Acta 59 (2), 219-229.

- Gurusamy, A., Lai-Yi, L., & Jiunn-Fwu, L. (2008). Adsorption of reactive dye from an aqueous solution by chitosan: isotherm, kinetic and thermodynamic analysis. Journal of Hazardous Materials, 152 (1): 337-346.

- Hideyuki, K., Maki, S., Satoshi, K., Tohru, S., Kiyohisa, O., & Yoshihiro, Y. (2009). Humic acid degradation in aqueous solution by the photo-Fenton process. Chemical Engineering Journal, 137(2), 225–230

- Hizal, J., & Apak, R. (2006). Modelling of cadmium (II) adsorption on kaolinite-based clays in the absence and presence of humic acid. Applied Clay Science, 32(3-4): 232–244

- Ho, Y. S., McKay, G., Wase D., & Foster C.F. (2000). Study of the sorption of divalent metal ions onto peat. Adsorp. Sci. Technol. 18 639-650.

- Jianwei, L., & Yanhui Z. (2012). Adsorption of humic acid from aqueous solution onto unmodified and surfactant-modified chitosan/zeolite composites. Chemical Engineering Journal,Volumes 200–202, 202–213

- Jung, A. V., Chanudet, V., Ghanbaja, J., Lartiges, B.S., & Bersillon, J. L. (2005). Coagulation of humic substances and dissolved organic matter with a ferric salt: an electron energy loss spectroscopy investigation. Water Res., 3849-3862

- Kamga, R., Kayem, G. J., & Rouxhet, P. G. (2000). Adsorption of gossypol cottonseed oil on oxides. Journal of colloid and interface science, 232, 198-206.

- Kazpard, V., Latirges, B.S., Frochot, C., d’Espinose, de la Caillerie, J.B., Viriot, M.L., Portal, J.M., Görner, T., & Bersillon, J.L. (2006).Fate of coagulant species and conformational effects during aggregation of a model of a humic substance with Al13 polycations. Water research, 40, 1965-1974.

- Lacey, A.L., Hayes, M.H.B., & Vaidyanathan, L.V. (1997). Preparation of iron pillared clays and their applications for sorption of humic substances. Humic Substances, Peats, and Sludges. Health and environnemental aspect, 219–225.

- Pourret, O., Davranche, M., Gruau, G., & Dia, A., (2007).Competition between humic acids and carbonates for rare earth elements complexation. Journal of Colloid and Interface Science 305, 25–31.

- Sieliechi, J.M., Lartiges, B.S., Kayem, G.J., Hupont, S., Frochot, C., Thiemed, J., Ghanbaja, J., D’Espinose, J.B., De La Caillerie, Barres, O., Kamga, R., Levitzg, P., & Michot L.J. (2008). Changes in humic acids conformation during coagulation with ferric chloride: Implications for drinking water treatment, Water research 42: 2111-2123.

- Suksaroj Chaisri, (2006).Nanofiltration et oxydation avancée de solutions de colorants. Application au traitement d’effluents de l’industrie textiles. Thèse de doctorat soutenu le 20 Mai 2006 à L’école doctorale de l’Université Montpellier II, 135p.

- Thurman, E.M., Wershaw, R.L., Malcolm, R.L., & Pinckney, D.J. (1981). Molecular size of aquatic humic substances. Organic Geochemistry 4, 27–35.

- Unai Iriarte-Velasco, Jon I. A´lvarez-Uriarte, Noemı Chimeno-Alanı´s, & Juan R. Gonza´ lez-Velasco, (2009). Evaluation of the Adsorption of Aquatic Humic Substances in Batch and Column Experiments by Thermally Modified Activated Carbons. Ind. Eng. Chem. Res., 48, 5445–5453

- Wendong, W., Wen, W., Qinghai Fan, Yabo, W., Zixia, Q., & Xiaochang, W. (2014). Effects of UV radiation on humic acid coagulation characteristics in drinking water treatment processes. Chemical Engineering Journal,Volume 256, 137–143

- Wilbulswas, R., White, D.A., & Rautiu, R. (1998). Removal of humic substances from water by alumina-based Al-hydroxy intercalated clays. Environmental Technology 19, 627–632.

- Zhou, J. L., Rowland, S., Mantoura, R. F. C., & Braven, J. (1994).The formation of humic coatings on mineral particules under simulated estuarine conditions - a mechanistic study. Water Research, 28, 571-579.