Fourier Transform in the Application of Power Plants Pipelines Defect Detection

Saeedreza Ehteram1, *, Seyed Zeinolabedin Moussavi2

1Control Expert of Wind Powerplants Engineering Department, MAPNA Electric & Control, Engineering & Manufacturing (MECO), Karaj, Iran

2Electrical and Computer Engineering Faculty, Shahid Rajee Teacher Training University, Lavizan, Tehran, Iran

Abstract

Determination of power plants pipelines defects is an important task in industry. This study provides a simple way to classify these defects by the use of neural network also FT (Fourier Transform) is applied to have an analysis based frequency domain and data reduction on MFL (Magnetic Flux Leakage) database. The network receives in input a matrix of defects that are derived from a simulator formula that will be explained in follow. The aim of this research approach is the audit ability for safe or non safe material in pipelines and provides a binary output for indicating whether defect is recognized or not. The network proposed is MLP (multilayer perceptron) with strictly local connections. The first layer performs local linear operations, while the second has a non linear functionality. Result shown that this procedure could be used as an appropriate solution for pipelines defect detections.

Keywords

Fourier Transform, Non-Destructive Testing, Magnetic Flux Leakage, Multilayer Perceptron

Received: March 10, 2015 / Accepted: March 21, 2015 / Published online: May 28, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Pipelines are subject to be damaged by many kinds of defects which could not be observed by normal inspection, they are harmful to power plant system, because at least that they can cause the loss of efficiency.

The use of Neural Networks (NN) for the improvement of the defect detection of the pipeline systems has received bigger attention in the last years [1,2].The adjustments of the parameters used in these controllers are determined through a linear model of the system around a nominal operation point. Some techniques such as adapted control have been proposals as solution for better defect detection [3, 4 and 6]. However, the most of adapted controls is based on parameters identification on the system model and its specifications. Also this paper presents a model of defects that are commonly affect pipeline systems [7,8,9,18,22].In this paper two steps for the purpose of defect detection are proposals: MLP - Multi Layer Perceptron and FT Fourier Transform Analysis. The use of neural network with parameters adjusted - table 1- prepares an accurate decision on defect or non defect purpose. at the rest of this paper collection and application of NDT database, formulation, feature extraction, recognition, classification, the employed algorithm and experimental results are discussed.

If we have a discussion to what is done before and the current approach, we would observed some of published researches that are based on the analytical model of MFL signals from magnetic charge [18-22]. But for an exception, reference [24] is just discussed a single defect. The often encountered practical situation of two adjacent defects is also discussed only by Uetake and Saito [24], but their study is limited to slots with parallel walls, of a maximum of 4mm in length. With regards to this effort that considered a multiple defect case. The proceeding numerical modeling of MFL phenomena is exposed by Lord and co-workers [24, 25, and 26]. In oppose of the significant progress made in this area to include non-linear material properties [27, 28 and 29], a quantitative relationship between magnetic leakage field and defect length has not been clearly specified. Furthermore, numerical modeling involves a direct MFL approach, since it includes predefined defect geometries and material characteristics. Calibration of the MFL signals in terms of defect depth has been studied both through finite element modeling [25, 26, 27, and 29] and through analytical methods based on dipolar magnetic charge [26,30]. Two of the numerical analysis studies [25,29] correctly predicted that the amplitude of the normal MFL signals Component increases with defect depth, and that the separation between the extreme MFL values is directly proportional to the Defect length.

In this paper, with regards to previous works, a new simple algorithm is applied that could determine defects with various shapes. For problem of encountering different kinds of defects we initializes different defects with five classes which each of them tries to learn a defect with determined characteristics. These features are an estimate of two large groups of defects.

To convey the weakness and strength points of this paper, it could be mentioned that FT provides a frequent domain analysis on database by which more details of the data could be engaged to algorithm computations regards to other compression methods. In this way an exact domain could be applied on the database in FT compression block. For have a comparison with the PCA method as a compression block, not an exact boundary could be applied on the pure database matrix in the PCA method some eigens are applied that may not be really essential on the algorithm decision result but also some strength points ofPCA could not be unseen [37]. However this paper provides FT as an appropriate feature extraction and compression unit right before of decision unit.

2. Database Preparation

The database of the experimental MFL signals that is employed in this project is from Applied Magnetic group (AMG) in the department of physics from Queens in Canada. This database concludes signals of MFL that measured from outside and Inside of a power plant flow pipeline. Details of this database will lead to both un annealed and annealed data plots of increasing dent depths from 3mm to 7mm, resulting in a total of 10 plots for each one.

3. Analytical Model of MFL Defects

If a material is magnetized near saturation, the MFL field generated by a subsurface flaw can be described as follows:

![]() (1)

(1)

Where m is the dipole moment per unit length this is measured as follows:

![]() (2)

(2)

Where h bar is the plank coefficient, Ha is the applied magnetic field that is 1 Tesla [6] and a is the radius of the defect [7,8]. If the MFL on the surface of a sample is calculated, the variable y is constant and is equal to the depth h of the defect So the magnitude of h could specify the depth of defect. As mentioned above, it is not necessary to get physical information, like size or position of the defect. If the unknown system and material properties are defined in p=2h(m-2Haa2) and q=h2 parameters we obtain so the following simple fitfunction for the MFL on the surface of a sample could be illustrated as below:

![]() (3)

(3)

In the developed device the signal is measured by induction coils and for this reasons the measured signal is the derivative in x direction times the velocity of f(x) of measuring device. With regards to the previous equation, the MFL signal becomes as below. In this relation we try to calculate the rate of measured signal in time. So with acknowledge of velocity, that is rate of measuring device distance in time, and by timing this term to deviation off(x), we could reach to rate of delta f to delta t that is rate of depth in time.

![]() (4)

(4)

On the assumption that the velocity is constant, a new parameter P can be defined as:

![]() (5)

(5)

in this paper defects with radius of 0.0015m and 0.002m are mentioned with depth of 0.003m till 0.006m.

4. Feature Extraction

FT is a well-known statistical technique for feature extraction. Each M N MFL signal in the training set was row concatenated to form MN vector xk. Given a set of training signals {xk}, k=0, 1, NT the mean vector of the training set was obtained as [31].

![]() (6)

(6)

Fourier Transform is a familiar frequent domain analysis which exposed its input area to a frequent domain area. data reduction in this area could be done by decision on low, moderate or high frequent components. Fourier-related transform that is used in this paper refers to the discrete Fourier transform (DFT). DCTs are equivalent to DFTs of roughly twice the length, operating on real data with even symmetry (since the Fourier transform of a real and even function is real and even. The DCT, is often used in signal processing, especially for lousy data compression, because it has a strong energy compaction property because most of signals information concentrated in a few low-frequency components of the DCT [32]. This function is mathematically explained below so that the low frequent components in table 1 refer to this concept.

![]() (7)

(7)

5. Recognition of Defects

The recognition of power plants flow pipeline corrosion defects in this paper includes pre-processing and classification analysis. The former can be accomplished by recognizing and classifying typical features of signals from magnetic flux signals in types of mathematical forms. An approach is to classifying and performing a liable decision. For this reason, these are a both Multilayer Perceptron (MLP) neural networks however other procedures like Learning Vector Quantization (LVQ) [10], Self Organized Machine (SOM) [10] are approaches for classification. In this work multilayer perceptrons are applied with sigmoid transfer function and back propagation algorithm.

6. Classification for Recognition

According to construction of combiners, they are all made of learning process. Therefore to have different combiners different ways of training is essential. The process of learning is based on many ways such as: different ways to show inputs, samples for learning, training process, differ consulting technologies although in this task many theories are offered but each of them should due to some results:

1. The first requirement is that each expert has high level of performance and independently in deciding feature.

2. Expert has an arithmetic mathematics table to refer this point as strong point of each expert.

Classifying is done by many ways such as: multilayer perceptron,(MLP), radial basis function (RBF), k-mean etc.

This paper presents MLP for classifying. MLP means multi layer perceptron. Classifying is done by neural networks such as MLP.

Fundamental work of MLP is to changing weights between layers and each layer has (m) nodes. Number of input nodes is depended on dimension the database. Amount of nods located in hidden layer are subject to change by complicated rate of the expert. In this paper an approach is shown in follows that specifies the number of each layer this equations for this reason is earned experimentally but the result of this employment is satisfied. In training situation the weights are subject to change until reaching the best weights. The number of training situations is determined by the number of epochs it is kept done until fewer mistakes appear in output.

In this algorithm a classifier named MLP is employed. this expert is learned by a same set of database and the result of classification is disposed in table1.

7. Employed Algorithm

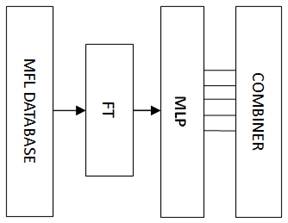

Figure 1. Devised algorithm.

Regards to related applications [1, 2 and 12], a frequent analysis is applied to MFL database. Also the pre-processing to the crude data is done in this step. this section is discussed and as a brief it contains extracting different kinds of defects from physical formulation and normalization then a class perform a decision on the its inputs, combination of decision on the out puts of FT block with different parameters are combined is in combiner block to achieve an appropriate decision. In his approach, 05 output classes recognize as 05 different classes of defects and for reduction of dimension of inputvector, 10 components are selected by FFT. result by different MLP parameters are collected in table 1.

8. Results and Discussions

With an overview on result o classifications in this area [1-3], a simple algorithm is proposed for defect detection in Non-destructive testing by MFL signals. An analytical model is employed to account defects of power plants flow pipelines. That was to have an appropriate MFL profile with the defect dimension along an impregnating magnetic field. The efficiency of the model was confirmed through experimental results in MFL defect detection that is discussed in historical discussion [37-39]. A clear advantage of the method presented here is the low number of parameters that have to be considered. For the reason of fast and facility of simulation, FFT is applied to perform a frequent domain analysis on database. The result of all are shown and discussed in table 1. Top accuracy rate in ten times running are recorded and we think could show the efficiency of the mentioned algorithm. It should be exposed that each results in table 1, is the average result of 10 times running of learning phase of network and the type is percent of accuracy.

Table 1. Results.

| Classes | MLP CONFIGURATION | |||||

| Type | 10-04-05 | 10-05-05 | 10-07-05 | 10-08-05 | 10-09-05 | 10-10-05 |

| Full FT Components | 70 | 73.3 | 80.1 | 95 | 66 | 37 |

| Odd components | 50 | 46 | 47.7 | 88 | 86.1 | 88 |

| Even components | 38 | 31.2 | 55 | 59 | 48 | 31.2 |

| High freq. components | 90 | 79 | 66 | 79 | 61.3 | 41.3 |

| Moderate | 45 | 43.3 | 16 | 55 | 21.7 | 37 |

| Low freq. Components | 10 | 17.5 | 19.5 | 14.2 | 57.5 | 27.4 |

References

- Saeedreza Ehteram, "BELBIC - An Intelligent Controller based defect detection of power plants flow pipeline from MFL signals". The 3rd Conference on Thermal Power Plant IPG011- October 18-19, 2011 Amirkabir University of Technology, Tehran, Iran.

- Saeedreza Ehteram, Alborz Rezazadeh Sereshkeh, Seyed Zeinolabedin Moussavi, Ali Sadr, Ali Akbar Jalali, Utilizing a Pattern Recognition Controller and Linear Discriminate Analysis for MFL Defect Detection. JCIT 4(2009), pp.11-19.

- A. Bergamini, Nondestructive testing of stay cables, IABSE conference on cable-supported bridges(2001), pp. 31213.

- A. Bergamini, Nondestructive testing of stay cables field experience in South East Asia, Third World conference on structural control vol2.(2002), pp. 1057064.

- M. Afzal and S. Upda, Advanced signal processing of magnetic flux leakage data obtained from seamless steel pipeline, NDT&E Int (2002) (7), pp. 44957.

- P. Ramuhalli, L. Udpa and S.S. Udpa, Electromagnetic NDE signal inversion by function-approximation neural networks, IEEE Trans Magnetics (2002) (6), pp. 363364.

- R.R. da Silva, S.D. Soares, L.P. Caloba, M.H.S. Siqueira and J.M.A. Rebello, Detection of the propagation of defects in ressurized pipes by means of the acoustic emission technique using artificial neural networks, Insight 48 (2006) (1), pp. 451. Full Text via Cross Ref. View Record in Scopus Cited By in Scopus (3).

- C Mandache, B Shiari and L Clapham"Defect separation considerations in magnetic flux leakage inspection" Insight Vol 47 No 5 May 2005 pp.

- D.E. Bray, Nondestructive evaluation (revised ed.), CRC Press, Boca Raton, FL (1997).

- R. Christen, A. Bergamini and M. Motavalli, Three-dimensional localization of defects in stay cables using magnetic flux leakage methods, J Non Destructive Eval 22 (2004) (3), pp. 9301.

- Martin Golz, David Sommer," The Performance of LVQ Based Automatic Relevance Determination Applied to Spontaneous Biosignals, KES 2006, Bournemouth, UK, October 9-11, 2006. Proceedings, Part III, Lecture Notes in Computer Science, Springer Berlin / Heidelberg, 2006. pp. 1256-1263.

- Hiroshi Wakuya, Hiroyuki Harada, Katsunori Shida "An architecture of self-organizing map for temporal signal processing and its application to a Braille recognition task" Wiley Periodicals, Inc. Syst Comp Jpn, 38(3): 62- 71, 2007.

- Saeedreza Ehteram, Seyed Z. Moussavi "Semantic Supervised clustering to land Extraction on satimage database" journal of Global engineering , science and technology (GESTS), Seul korea March 2007, pp.117-125.

- Saeedreza Ehteram, Ali Sadr, Seyed zeinolabedin Mousavi "Rapid face recognition by regional feature extraction ", INISTA 2007 conference Istanbul Turkey20 23 June2007, pp. 262-269, 2007.

- R. Ebrahimpour, S. R.Ehteram, E. Kabir, "Face Recognition by Multiple Classifiers, a Divide-and-Conquer Approach ", Lecture Note in Computer Science (LNCS), vol. 3686, pp. 225-232,September 2005.

- R. Ebrahimpour, Seyed Zeinolabedin Moussavi, and Saeedreza Ehteram "Multiple Binary Classifier Fusion (MBCF) in Application of Satimage Database" IASTED from proceeding (522) Applied Simulation and Modeling 2006-Greece.

- Y. Chung Bang, L. Jong Won, K. Jae Dong and M. Kyung Won, Damage estimation method using committee of neural networks, Proceedings of the SPIE—the international society for optical engineering vol. 5047 (2003), pp. 26374.

- Qi Jiang, Qingmei Sui, Nan Lu, Paschalis Zachariades, Jihong Wang.Detection and estimation of oil gas pipeline Corrosion defects "http://corporate.coventry.ac.uk/conten.

- Dobmann G and H╫ller P 1980 Research Techniques in Nondestrucrive testing R. S. Sharp (New York: Academic) vol IV, pp.399.

- Shcherbinin V E and Pashagin A I 1972 Defektoskopyia pp.8742.

- Forster F 1986 NDT Int. 19 33.

- Edwards C and Palmer S B 1986 J. Phys. D: Appl. Phys. 196pp.573.

- Mandal K and Atherton D L 1998 J. Phys. D: Appl. Phys. 31 pp.32117.

- Uetake I and Saito T 1997 NDT & E Int. 30 pp.371.

- Hwang J H and Lord W 1975 J. Testing Eval. 3 pp.21.

- LordWand Hwang J H 1977 Br. J. Non-dest. Testing 19 pp.148.

- Lord W, Bridges J M, Yen W and Palanisamy R 1978 Mater.Eval. 36 pp.464.

- Atherton D L and Daly M G 1987 NDT Int. 20 pp.235.

- Patel U and Rodger D 1995 IEEE Trans. Magn. 31 pp.2170.

- Altschuler E and Pignotti A 1995 NDT & E Int. 28 pp.350.

- Philip J, Rao C B, Jayakumar T and Raj B 2000 NDT & E Int. 33 pp.2895.

- M.Turk, A.Pentland Eigenfaces for Recognition", Journal of Cognitive Neuroscience, vol. 3, pp. 71-86, 1991.

- Duda, R.O. and Hart, P.E., Pattern Classification and Scene Analysis, John Wiley & Sons, 1973.

- Ken cabeen, peter gent."Image compression and the discrete cosine transform" math45 collage of Redwoods, pp1,2.

- S. Chandrasekaran, B.S. Manjunath, Y.F. Wang, J. Winkeler, and H. Zhang,An Eigensapce update algorithm for image analysis,", to appear in the journal Graphical Model and Image Processing, 1997.

- M.R. Jamali , A. Arami, M. Dehyadegari, C. Lucas, Z. Navabi, Emotion on FPGA: Model driven approachESWA 3156 No. of Pages 10-20 Oct. 2008.

- "PCA and MLP Combination in the Application of Power Plants Flow Pipelines Defect Detection" Saeedreza Ehteram, Seyed z Moussavi, ARTIFICIAL INTELLIGENCE AND APPLICATIONS 08/2014.

- "Simple Classification of mathematical simulated defects of Power plants pipelines" Saeedreza Ehteram, Borzoo Afkham, Seyed z Moussavi, Non-Destructive Testing 05/2013.

- "DEFECT DETECTION OF POWER PLANTS FLOW PIPELINES BY A COMBINATION OF NEURAL NETWORKS" Saeedreza Ehteram, Borzoo Afkham, British Academic Journals 12/2012.