Effect of Temperature and Hydrostatic Pressure on Films Based on MWCNT

A. A. Babaev1, *, R. K. Arslanov1, P. P. Khokhlachev1, T. R. Arslanov1, A. K. Filippov2, E. I. Terukov3

1Amirkhanov Institute of Physics, Daghestan Scientific Center, Russian Academy of Science, Makhachkala, Russia

2"PLASMAS" Limited Company, Saint-Petersburg, Russia

3Ioffe Physical-Technical Institute, Russian Academy of Science, Saint-Petersburg, Russia

Abstract

We present a study on the electrical behavior of polymer composites based on multi-walled carbon nanotubes (MWCNT) under the application of temperature and hydrostatic pressure. An unstable behavior of the composite film structure upon cyclic heating has been observed. It has been found that the resistivity has maxima at T ≈ 340 and ≈420 K, which are responsible for intrinsic defects. The current–voltage characteristics have been studied in the stationary and pulsed modes at different temperatures. Our observations also show that pressure-induced a structural change of the MWCNT to an ellipsoid shape at P~1.5 GPa, a measurement that correlates rather well with theoretical predictions. By direct and reverse high-pressure measurements of resistance, as well as current-voltage characteristics, we have identified reversibility of electrophysical properties.

Keywords

Multi-Walled Carbon Nanotubes, High Pressure, Currient-Voltage Characteristics

Received: April 8, 2015

Accepted: April 26, 2015

Published online: May 22, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Carbon nanotubes are materials that have received large attention since their discovery in 1991 [1]. The ideal nanotube form is obtained by rolling a graphene layer into a cylinder with a predefined orientation of the regular hexagons with respect to the nanotube axis, where the carbon atoms are located at the hexagon vertices. On the other hand, multi-walled carbon nanotubes can be formed by embedding pristine nanotubes with different chirality, giving rise to different electric response [2]. The large diversity of physical and chemical properties of multiwall nanotubes is obtained by combining different radii single nanotubes, a possibility that offers a large set of potential applications in various fields of science and nanotechnology. For example, the encapsulation of 3d metals (Co, Fe) nanowires in multi-walled carbon nanotubes (MWCNT) has attracted much attention as for the case of spintronics [3-5].

The carbon nanotubes films possess excellent properties, such as a low density, flexibility, and a high specific area. As expected, they will be useful for various advanced applications such as supercapacitors, sensor panels, solar cells, random access memory, etc [6-9]. These examples show that carbon nanotubes find a variety of applications and that the conductivity of carbon nanotubes films is the dominating parameter for the work of various devices. Therefore, the production of thin films with a high conductivity is a subject of intensive studies. Despite significant efforts to obtain highly conductive thermally stable films, the interpretation of the dependence of the conductivity of the CNT structure on the composite assembling structure and the results of studying the temperature dependence of the resistivity are ambiguous and depend on the method of fabrication of carbon nanotubes and their modifications.

High-pressure investigation of MWCNT probes the sensibility of their electrical [10,11] and mechanical [12] response to this external field. Due to their unique elastic behavior [13], polymer composites based on MWCNTs are of particular interest aspressure sensors, with resistance-pressure hypersensitivity between few kPa [14-16] to MPa ranges [17,18]. In the case of single-walled carbon nanotubes (SWCNT), application of high pressure (about few GPa) leads to important structural changes, which cause a radial deformation and symmetry breaking towards an elliptical shape [19]. It has been shown in SWCNT that a linear elasticity response is observed up to 1.5 GPa at room temperature, and in a triangular nanotube lattice, the deformation up to 4 GPa is reversible, beyond which the nanotube lattice is destroyed [20]. Unlike to SWCNT, the structure of MWCNT can be stable under higher pressures. Theoretically, this behavior can be explained in the framework of a continuum elastic approximation, where a large number of concentric walls undergo elastic deformation at the critical pressure PC~1 GPa, above which circular shape of the cross-section becomes radially corrugated [21,22]. On the other hand, experimental studies on MWCNT show response up to 20 GPa, using diamond anvil cells [15]. In this regards, hydrostatic pressure provides an ideal condition to investigate the structure elasticity, as well as electrical properties of MWCNT.

The aim of this work is to study and reveal specific features of the resistivity and the current–voltage characteristics at different temperatures of composite films obtained by modified direct spinning based on MWCNT and the 95%/5% polymer in the process of cyclic heating in the temperature range of 300–450 K. We also report a resistance measurement and current-voltage characteristics (I–V) of polymer composites based on MWCNT under hydrostatic pressure up to 9 GPa at room temperature.

2. Experimantal

2.1. Samples Fabrication

MWCNT has been fabricated by plasma arc, with an average tubes length 100–200 nm, outer diameters of 10–20 nm, and intrinsic diameters of 1.2–3.5 nm. Then, they have been embedded in a polymer composite matrix (Teflon lacquer LF-42). By using the plasma arc method, we increases the nanotubes yield. A yield deposit is about 100 g/hr on the anode and the graphite conversion to MWCNT is up to 100%. Preliminarily, MWCNT were purified from micro impurities of Ni and Fe, using HNO3 acid. To deplete the presence of vacancies and impurities, MWCNT were treated in a high-frequency plasma discharge at 40 MHz and power electric discharge of 0.01-0.1 W/cm3under Ar pressure in the range of 0.2-1.13 Torr during 300 seconds [23]. After the purification process, the MWCNT were introduced into a liquid composition of the polymer matrix in a ratio of MWCNT/polymer – 95/5 mas.%. The polymer was chosen so that the melting temperature happens to be higher than of 500 K (decomposition temperature is 630K).The specific volume resistance is 109 Ohm´m with electrical strength 11-17 kV/mm [20]. As the substrate, any organic or inorganic material can be used; e.g. paper on which the film MWCNT/polymer thickness is equal to 30 mm. The temperature dependences of electrical resistivity of MWCNT are given in early works [25-27].

2.2. Temperature and High-Pressure Measurements

The temperature was measured by a copper–constantan thermocouple with a diameter of 0.1 mm. The temperature dependence of ρ was studied using the four-probe method in the dynamic mode at a constant heating rate of ≈35 K/h on an Sh-300 combined device and a 6517A Keithley electrometer. The current–voltage characteristics were studied in the stationary and pulsed modes.

In order to investigate the high-pressure electrical properties of MWCNT placed on the selected organic substrate, we have deposited two contacts, which is secured by thin insulator film (mica) by using a clamping method or contact paste. The measurements of the resistance R and I–V characteristics were carried out on three different samples, with dimensions 300 ´150 mm2 at room temperature and during loading and unloading pressure. For creating this high pressure, we have used a unique Toroid type high-pressure cell to guarantee an isotropic response [28]. Hydrostatic pressure was produced by a pressure-transmitting medium of 4:1 ethanol-methanol in the anvil cell. Pressure within the working cell was monitored by a manganin gauge that we use to calibrate our pressure measurements. The absolute accuracy of the electrical measurements was about 3%.

3. Results and Discussions

3.1. Effect of Temperature on the Resistivity of MNCNT

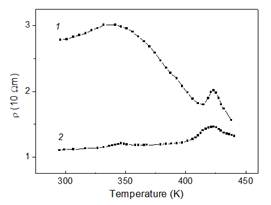

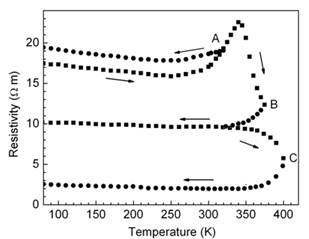

Figure 1 presents the results of studying the temperature dependence of ρ of composite films produced on paper. The measurements were performed on seven samples. On the first heating (curve 1) of the composite in the range T = 300–450 K, a reduction in ρ is observed. Against the background of the reduction in ρ, two expressed maxima at T ≈ 340 and ≈420 K were observed. The annealing of the composite at a constant temperature in the range T ≈ 310–360 and ≈410–425 K leads to a slow decrease in ρ and, in the range T ≈ 360–400 ≈ 425–450 K to a decrease in ρ from 3 to 10% until reaching the quasistationary state for about 40 min. The identical processes are observed in composites formed without paper, in which the resistivity is lower. It should be noted that, in original studies, we did not observe maxima of ρ, because the heating rate was high [26]. During the first heating in the range T = 77–300 K, a gradual small reduction in ρ was observed (Fig. 2). In this temperature range, the cyclic cooling and heating leave ρ practically unchanged. At T > 300 K, the ρ increases, reaching the maximum at T ≈ 340 K, and then decreases to T ≈ 410 K. On cooling from 400 to 340 K, ρ of the composite decreases and the metallic conductivity is observed, and, on cooling from 340 to 77 K, ρ slightly increases. The further temperature heating–cooling cycling in the range of 77–400 K varies ρ along a curve without In order to reveal the reasons of the maximum of ρ at T ≈ 420 K, we studied multilayered graphite (deposit) with different thicknesses of 0.2 and 1.7 mm with pressed contacts on the butt-ends. In 0.2 mm thick graphite, an expressed maximum of the resistance (R) at T = 420 K is observed as in MWCNT films, and, in 1.7-mm-thick graphite, the maximum of R is blurred and displaced to 450 K, probably, due to an increase in the concentration of intrinsic defects. Although graphite is a semi_metal, its resistivity decreases with an increase in temperature. As a rule, graphite has no perfect structure. Typical defects of the crystal structure are stacking faults and defects in layers. We assume that, by analogy, MWCNTs also have structural defects responsible for the maximum of ρ at T ≈ 340 K. In order to study the conductivity of the samples and the behavior of the contacts, we measured the current–voltage characteristics in the temperature range of 300–500 K in the stationary and pulsed modes. In the whole range of the applied voltages, the current–voltage characteristics are purely linear. The measured slopes of the curves correlate well with the temperature variations in ρ. The measurements in two directions of the current confirm the identity of the current–voltage characteristics and good ohmic behavior of the contacts. In the pulsed mode, the resistivity of the composite as a function of temperature on heating the sample by the current flowing through it was studied. A rectangular voltage pulse regulated in the amplitude (up to 500 V) and duration (102–104 μs) was applied, which caused the heating of the sample at a certain choice of these parameters. We noticed that, at a given amplitude of voltage, the current through the sample varied, depending on the temperature range in which the measurements were performed. At room temperature, as a result of selfheating, the current through the sample gradually decreased at a given constant voltage, which confirms the increase in the resistance of the sample at room temperature and higher up to T ≈ 340 K

Figure 1. Temperature dependence of the resistivity of the MWCNT composite films: (1) the first heating and (2) the second heating.

Figure 2. Temperature dependence of the resistivity of 20-μ-thick composite films during reversible heating and cooling (A, B, C) Cooling to different temperatures.

and, in the range T ≈ 340–400 K, an increase in the current was observed. It should be noted that, nowadays, there is no theory enabling one to describe the specific features of the electric properties of CNTs in a wide temperature range from a unique physical interpretation. The resistivity of nanomaterials has a wide scatter: for nanotubes, from a few μΩ to a few MΩ, depending on the diameter, the type of conduction, the number of layers, and the concentration of carriers, which proves to be maximum at the Dirac point. The observed maxima of ρ (the transition from metallic to semiconductor character of conduction), probably, are responsible for intrinsic defects. Nanotubes are not perfect, and their surface may contain pentagons and heptagons. The defectiveness of nanostructures is caused by the presence of impurities of metallic catalysts used in the synthesis of carbon nanomaterials and by amorphous carbon, sorbed gases, attached radicals with oxygen, and topological defects. Multilayered carbon nanotubes possess electric properties similar to the properties of quasitwo-dimensional graphite [29], and the sort of the defects depends on the nanotube production technique [30]. Carbon atoms in nanotubes have triple coordination and, therefore, nanotubes are conjugated systems in which three of four valence electrons of each carbon atom form sp2-hybrid orbitals and localized C–C σ-bonds and the fourth one participates in the formation of a delocalized π-system like in graphite. These π-electrons are weakly bound to their atoms, so they participate in the charge transfer in the system

3.2. Effect of Hydrostatic Pressure on the Resistance of MNCNT

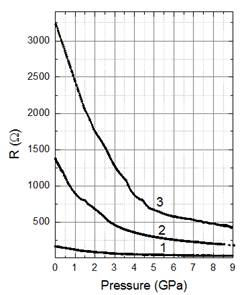

Figure 3 shows the logarithmic change of the electrical resistance as function of the loading pressure for the three polymer composites samples. Initial resistance R0 at atmospheric pressure is 164 W, 1364 W and 3226 W for samples 1, 2 and 3, respectively. It is noticed that as the pressure goes up 9 GPa, all samples show a similar decrease in R. This R reduction under pressure (hence increase in the electrical conductivity) is typical in MWCNT, as already reported in the measurements up to 18 GPa [10], and 20 GPa [11], as well as at kPa pressures for carbon black [31], even under uniaxial compression. The average aspect ratio for R/R0, in kW samples, 1 and 2 is about 7 times and for Wsample, 3, is 5 times.

Figure 3. The reversible pressure dependence of resistance for different samples MWCNT

Conventionally, we can distinguish two regimes on the pressure dependence with respect to R: (1) there is a significant linear decrease of R with respect to the applied pressure up to P» 1 GPa (2) a quasi-stationary state that corresponds to small changes in the resistance above 4 GPa. At the same time, there is an interesting feature between the pressure interval (1) and (2), where the observed changes may indicate the pressure-induced structural transition at the PC, where changes in the circular shape of the nanotube walls occur. This behavior has been observed in all studied samples above region (1), in agreement with theoretical predictions for the MWCNT [21,22]. However, the appearance of this feature between different samples indicates a small spread of the pressure values around 1 GPa. For example, as can be seen from Figure 1 (curve 2) this feature is observed around 1.5-2 GPa.

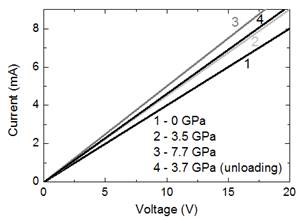

Figure 4. I-V characteristics for the sample 2 at several fixed pressures.

The changes in the electric resistance linear behavior for the composite are accompanied by the deformation of the nanotube walls and further application of pressure leads to quasi-stationary state about 4 GPa with weakly R dependence. It is noticed that after the system passes region II, R does not exhibit a dramatic change, suggesting that there is no nanotube destruction up to 9 GPa. Comparatively, the R depletion with respect to pressure loading in the compositeis qualitative different for the increasing behavior observed in MWCNT networks/poly (dimethylsiloxane) (PDMS) composites at the MPa level pressures [17].

The important aspect, which guarantees the use of the proposed polymer composite as pressure sensing device, is the reversibility of electrical and elastic properties [32]. As literature results demonstrate, a perfect elasticity and sensitivity is observed at low applied pressures [14,15,17,18]. Therefore, in the ideal case, the linear characteristics of resistance-pressure should be expected. Notwithstanding, for MWCNT networks/(PDMS) the relative resistances seems to demonstrate a larger curvature under pressure due to flexibility of the PDMS matrix and have been almost recovered to its original value when pressure is removed [17]. For a hydrostatic pressure sensor based on carbon sphere–polyvinyl alcohol composites, the linear behavior of relative conductance and relative capacitance were limited only up to 150 kPa as reported by Machado et al. [15]. In order to improve sensing linearity Wang et al. proposed that the carboxyl radical could effectively affect the homogeneous distribution and alignment of the MWCNT in the polymer matrixes [18]. Our results in Figure 1 show the resistance-pressure dependence for sample 3, which are retraced after pressure unloading from a pressure of 9 GPa. Herewith we have observed no hysteresis phenomena. Compared with ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure, a moderate hysteresis has been observed on the resistance-pressure response [14]. We note that the reverse high-pressure measurement has been performed in relaxation mode of press, i.e. pace of unloading pressure taken more time than loading. With an artificial acceleration in the unloading process, the probability of breaking the contacts is increased. The measurements performed on the other samples show analogous reversibility of R. Additionally, the pressure unloading has been conducted in the regions I and II, where a complete restoration of the electrical properties is observed. Therefore, we have demonstrated that polymer composites based on MWCNT may be a promising candidate for high-pressure sensor. However, additional measurements, as response time,cycling stability and temperature-stable sensing will need to be performed to further out the important working variables.

Further experiments on the I–V characteristics provide additional confirmation of the reversibility of the electrical properties of the proposed polymer composite. In contrast to the effects of low pressure [17] the linear I–V characteristic for sample 2 is observed for all the considered pressure range (Figure 4). As it has been shown for MWCNT arrays, the behavior of the I-V characteristics does not change with low applied pressure [33]. The slopes of our I-V curves are in good agreement with the results of R(P) (Figure 1). Moreover, the measurements of I–V characteristics at loading and unloading pressure again suggest the reversibility of electrophysical properties, as well as it shows good ohmic contacts behavior (see the lines at 3.5 GPa and at 3.7 GPa).

4. Conclusion

(1) It was established that the resistivity ρ is stable upon cyclic heating and cooling of MWCNT composite films in the temperature range T = 77–300 K. (2) It was found that the resistivity ρ has maxima at T = 340 and 420 K, which are responsible for structural defects in MWCNTs and the deposit, respectively. The maximum of ρ at T = 340 K is unstable. (3) The value of ρ can be controlled by annealing of composite films at T > 300 K.

(4) In the entire range of applied voltages, the current–voltage characteristics are purely linear, and the measured slopes of the curves are in good correlation with the temperature variations in ρ.

The resistance and I–V characteristics of polymer composites based on MWCNT under high-pressure up to 9 GPa are studied. We found that for an aspect ratio of R/R0»7 a very high resistance response, of the order of kW is observed. The observed features on R(P) in the area P~1.5 GPa suggest the existence of a structural transition at PC, above which the deformation of circular shape nanotube walls occurs and becomes an ellipsoid, in agreement theoretical predictions. A quasi-stationary state is observed above 4 GPa with no evidence of nanotubes destruction. Experiments conducted at the unloading mode show excellent reversibility of the electrophysical properties of polymer composites based on MWCNT.

Acknowledgements

This work was supported by the RAS Presidium Program P.34 "Matter at high pressures"

List of Notations

MWCNT – multi-walled carbon nanotubes

SWCNT – single-walled carbon nanotubes

T – Temperature in (K)

P – Pressure in (GPa)

R – Resistance in (W)

r – Resistivity in (Wm)

I-V – current–voltage characteristics

References

- Iijima, S. (1991) Nature (London) 354, 56-58.

- Charlier, J. - Ch.,Blase, X. and Roche, S. (2007) Reviews of Modern Physics. 79, 677-732.

- Mühl, T. Elefant, D.,Graff, A.,Kozhuharova, R. ,Leonhardt, A. Mönch, I. Ritschel, M. Simon, P.,Groudeva-Zotova S.and Schneider, C.M. (2003) Journal of Applied Physics 93, 7894-7896.

- Zhao, B., Mönch, I., Vinzelberg, H. Mühl T. and Schneider, C. M. (2002) Applied Physics Letters 80, 3144-3146.

- Thamankar, R. Niyogi, S.,Yoo, B.Y.,Rheem, Y.W.,Myung, N. V.,Haddon, R.C. and Kawakamia, R.K. (2006) Applied Physics Letters 89, 033119-3.

- M. Kaempgen, C. K. Chan, J. Ma, Y. Cui, and G. Gruner, Nano Lett. 9, 1872 (2009).

- M. W. Rowell, M. A. Topinka, M. D. McGehee, H. J. Prall, G. Dennler, and N. S. Sariciftci, Appl. Phys Lett. 88, 233506 (2006).

- C. Feng, K. Liu, J. S. Wu, L. Liu, J. S. Cheng, and Y. Y. Zhang, Adv. Funct. Mater. 20, 885 (2010).

- M. Zhang, S. L. Fang, A. A. Zakhidov, S. B. Lee, and A. E. Aliev, Science (Washington) 309, 1215 (2005).

- Monteverde, M.,Garbarino, G.,Núñez-Regueiro, M.,Souletie, J.,Acha, C.,Jing, X.,Lu, L.,Pan, Z.W.,Xie, S.S. and Egger, R. (2006) Physical Review Letters 97, 176401-4.

- Tang, D.S., Bao, Z.X., Wang, L.J.,Chen, L.C.,Sun, L.F.,Liu, Z.Q.,Zhou, W.Y.,Xie, S.S.,(2000) Journal of Physics and Chemistry of Solids 61 1175-1178.

- Whitby, R.L.D., Gun’ko, V.M., Fukuda, T., Maekawa, T. (2010) Carbon 48, 3635-3658.

- Reich, S.,Thomsen, C. and Ordejón, P. (2002) Physical Review B 65, 153407-4.

- Pan, L.,Chortos, A.,Yu, G.,Wang, Y.,Isaacson, S.,Allen, R.,Shi, Yi.,Dauskardt R. and Bao, Zh. (2014) Nature Communication 5:3002 doi: 10.1038/ncomms4002

- Machado, W.S., Athayde, P.L., Mamo, M.A., van Otterlo, W.A.L., Coville, N.J., Hümmelgen, I.A. (2010) Organic Electronics 11 1736-1739.

- Fung, C.K.M., Zhang, M.Q.H., Chan, R.H.M.,Li,W.J.(2005)IEEE MEMS 2005, 251-254. (doi: 10.1109/MEMSYS.2005.1453914).

- Hu, C.H.,Liu,C.H.,Chen, L.Z.,Peng, Y. C. and Fan, S.S.(2008) Applied Physics Letters 93, 033108-3.

- Wang, P.,Geng, Sh.,Ding, T. (2010)Composites Science and Technology 70 1571-1573.

- Tangney, P., Capaz, R.B., Spataru, C.D., Cohen M.L. and Louie, S.G. (2005) Nano Letters 5, 2268-2273.

- Tang, J., Qin, L.-Ch., Sasaki, T., Yudasaka, M., Matsushita, A. and Iijima, S. (2000) Physical Review Letters 85, 1887-1889.

- ShimaH. and Sato, M. (2009) Physica Status Solidi A 206, 10, 2228-2233.

- Shima, H.,Ghosh, S.,Arroyo, M., Iiboshi, K., Sato, M.(2012) Computational Materials Science 52 90-94.

- A.K. Filippov, M.A. Fedorov. (2003)4-th International Conference on Electromagnetic Processing of Materials. EPM, 14-17 October, Lion, France, 131.

- A.K. Filippov, V.N. Pak. (2007) International Workshopon Fullerenes and Atomic Clusters. IWFAС, July 2-6, St.Petersburg, Russia, 211.

- Babaev, A.A., Khokhlachev,P.P.,Nikolaev,Yu.A., Terukov,E.I., Phreydin,A.B., Filippov,R.A., FiloppovA.K., Manabaev,N.K.(2012) Inorganic Materials. 48, 1124-1127.

- Babaev, A.A., Khokhlachev,P.P.,Nikolaev,Yu.A., Terukov,E.I., Phreydin,A.B., Filippov,R.A., FiloppovA.K., Manabaev, N.K..(2011) Journal Perspektivnye materially 13. 846-850.

- Babaev, A.A., Khokhlachev, P.P., Nikolaev, Yu.A., Terukov, E.I., Phreydin, A.B., Filippov, R.A., FiloppovA.K., Manabaev, N.K.(2012). Izvestiya RAN. Seriya Fizicheskaya, 76, 7, 961-964.

- Khvostantsev, L.G., Slesarev, V.N., and Brazhkin, V.V. (2004). High PressureResearch 24, 371-383.

- S. Kotosonov and V. V. Atrazhev, JETP Lett. 72 (2), 53 (2007).

- D. N. Weldon, W. J. Blau, and H. W. Zandlbergen, Chem. Phys. Lett. 241, 365 (1995).

- Sánchez-Gonzáleza, J.,Macías-Garcíaa, A.,Alexandre-Francob, M.F.,Gómez-Serrano, V. (2005) Carbon, 43, 741-747

- Ma, M.D., Liu, J. Z., Wang, L., Shen, L., Xie, L., Wei, F., Zhu, J., Gong, Q., Liang, J. and Zheng, Q. (2010) Physical Review B 81, 235420-5.

- Singh, L.T. and Nanda, K.K. (2012) AIP Advances 2, 022103-7.