Effect of the Unmodified and Modified ZnO Nanoparticles on the Mechanical and Antibacterial Properties of Silicone Rubber Using in Medical Applications

Noor Hadi Aysa1, *, Mohamed Hamza Al-Maamori2, Nehad Abdul Ameer Al-Maamori3

1Clinical and Laboratory Science Department, College of Pharmacy, Babylon University, Babylon, Iraq

2College of Material Engineering, Babylon University, Babylon, Iraq

3College of Science, Babylon University, Babylon, Iraq

Abstract

The aim of the present study is to establish the synthesis of the antibacterial prosthetic liner using with artificial limb mediated zinc oxide nanoparticles and the evaluation of their mechanical properties and antibacterial activity. So we used ZnO (modified and unmodified) nanoparticles to prepare silicone rubber nanocomposites using in the production of the prosthetic liner that being antibacterial and prevent any infection may occur. With the addition of (1, 2, 3, 4, and 5 pphr (part per hundred rubber)) of ZnO (unmodified and modified) nanoparticles it was noted that as, the concentration of both types of ZnO nanoparticles increase, tensile strength, tear resistance, elongation, modulus, hardness, compression, and specific gravity decrease. Composites contain modified ZnO nanoparticles still has higher mechanical properties than that contains unmodified ZnO nanoparticles the work suggested to use little amount of nanoparticles to get better mechanical and antibacterial properties because the propagation of nanoparticles near the surface of the nanocomposites prepared.

Keywords

ZnO, Nanoparticles, Antibacterial Properties and Nanocomposites

Received: July 26, 2015

Accepted: August 9, 2015

Published online: August 19, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Nanoparticles are of great scientific interest as they are effectively a bridge between the bulk material and atomic or molecular structures. The properties of materials change as their size approaches the nanoscale and as the percentage of atoms at the surface of a material becomes significant [1]. In order to reach a homogenous dispersion of the nanoparticles within silicone rubber, the use of a coupling agent is necessary to modify the surface of the nanoparticles to get the better mechanical properties and antimicrobial efficiency also to avoid aggregation of the particles during the preparation and production of composites this leads to the increase of the size of the particles due to the aggregation, which in turn influences the diffusion and the mechanical and antimicrobial properties[2], these properties is based on the diffusion of the particles from the bulk of the rubber to the surface where the antimicrobial agent interacts with the microorganism cells[3]. Filling polymers with nanoparticles leads to significant improvements in their mechanical properties. Such improvements depend strongly on the type of the filler and the way in which the filling is conducted [4]. So our work tends to use modified ZnO nanoparticles that prevent any agglomeration can occur within the matrix and then produce better mechanical and antibacterial properties.

2. Materials and Methods

1g of starch (as nutrient medium) was weighed correctly and mixed with 20 g of liquid silicone rubber 4305, the second step that is adding unmodified and modified ZnO nanoparticle at different ratio (1, 2, 3, 4, and 5) % for different samples then poured in circular templet has the diameter of 20 mm and thickness of 3 mm. After that the sample be ready for testing the mechanical properties according to the ASTM mentioned beside each test (tensile strength ASTM D412 Die C[5], tear resistance ASTM 624 Die B[6], elongation ASTM 412 Die C[5], modulus ASTM D412 Die C[5], hardness ASTM 2240[7], compression ASTM D395[8], and resilience ASTM1054[9]). Then two bacteria which cause skin infection was implanted on the sample prepared previously. The kinetic of bacteria growth rate was determined by a method that is based on the culturing bacterial with samples by using the loop and put it on the surface of the samples containing the best characteristics studied and containing a small proportion of the modified zinc oxide nanoparticles. Covering the disposable dates using para film to prevent pollution. The media were incubated at 37 °C for one week. Staphylococcus aureus and Pseudomonas areoginosa were used to test the sample prepared against the bacteria growth. The results were taken by considering the zone of growth of the bacteria. Antibacterial activity was evaluated by measuring the diameter of the growth zone around the sample.

3. Results and Discussion

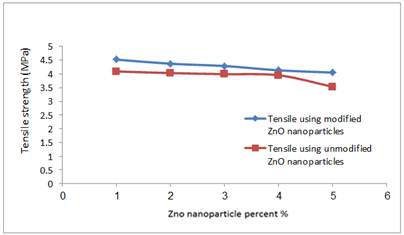

With the addition of both modified and unmodified ZnO nanoparticles it was noted that as, the concentration of both types of ZnO nanoparticles (modified and unmodified) increase, tensile strength decrease. Addition of modified ZnO still has high mechanical properties such behavior can explain that modified ZnO nanoparticles will increase the contact surface area between rubber chains, thus will give a rigid structure with better tensile strength (4.5 MPa). While in high quantities of both types of ZnO will happen aggregate in rubber matrix. This results in poor dispersion that weakens the bond between chains and decrease the tensile strength. This result agrees with reference [10-12] as shown in the figure 1:

Figure (1). Effect of ZnO modified and unmodified nanoparticles on the tensile strength of recipe.

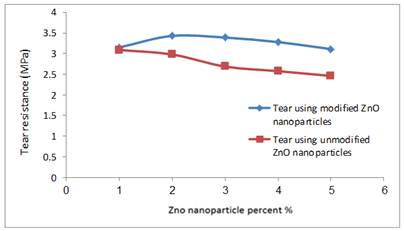

Figure (2). Effect of ZnO modified and unmodified nanoparticles on the tear resistance of the recipe.

Tear property is related to the tensile property. So that, tear resistance increase with small quantities of both of the ZnO modified and unmodified nanoparticles, as shown in figure 2. For the same reason as previously mentioned in the case of tensile property that the particles will uniformly distributed between rubber chains and increase the mechanical bond between them. This lead to better tear resistance. In case of increasing the quantity of both types of nano ZnO, tear resistance decreases. The tear resistance decreases due to irregular distribution of nano ZnO nanoparticles in rubber matrix and aggregate between chains. This is in agreement with previously reported by Jorgen and Mary [11].

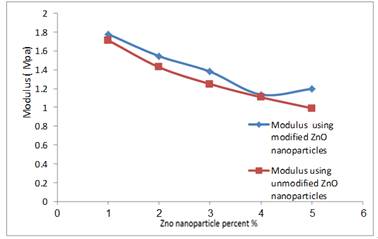

According to the figure 3 It's shown that ZnO nanoparticles does not show resistance to matrix molecule's orientation in the direction of applied force results in slipping of rubber chain in the direction of applied force and lowering modulus of elasticity. This result agrees with that of [6]. From Figure 3, it can be seen that the Young modulus decreased with the increase of ZnO modified and unmodified nanoparticles that’s belong to a high ZnO loading, means that the composites will not be able to withstand greater loads and the recipe tends to brittle as ZnO increases this behavior is similar to a result reported by [12].

Figure (3). Effect of ZnO modified and unmodified nanoparticles on the modulus of the recipe.

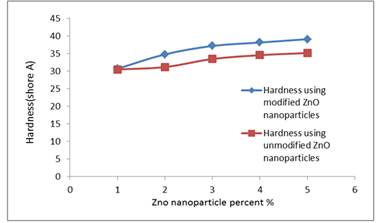

Figure (4). Effect of ZnO modified and unmodified nanoparticles on the hardness of the recipe

Figure 4 shows hardness property increases with small quantities of both of the ZnO modified and unmodified nanoparticles. Because zinc oxide acts as a filler that it strengthens the recipe and makes it resistant to the applied forces. The ZnO modified and unmodified nanoparticles may serve as physical crosslinks due to physical or chemical interactions involving filler and rubber. The filler can physically be entrapped in the rubber and share in the load-bearing process in the matrix leads to higher hardness which is considered to be due to the overall effect of crosslinking of polymer network. Polymer-filler interactions which may be physical and chemical and formation of occluded rubber give high hardness value and this agrees with that reported by Ahmed et-al [13].

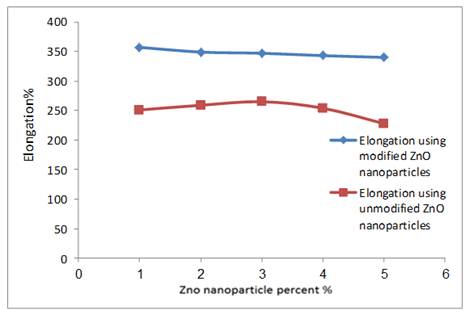

It was noted that for both of the ZnO modified and unmodified nanoparticles have the same behavior that both tend to increase the hardness of the recipe. The elongation property decreases with the addition of nano ZnO as figure 5, because the rubber is highly stretching so that when the very fine particles fill the spaces, it will restrict the movement of chains due to the diffusion of very fine ZnO nanoparticles through the rubber chains which are responsible for riveting the rubber chain and then decrease elongation property and this agrees with research [14-15].

Figure (5). Effect of ZnO modified and unmodified nanoparticles on the elongation of the recipe.

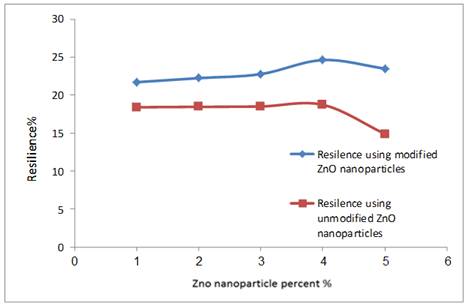

Figure (6). Effect of ZnO modified and unmodified nanoparticles on the resilience of the recipe.

Figure (6) shows decreases in the rebound resilience with the addition of ZnO modified and unmodified nanoparticles. The deterioration in resilience is most probably related to the presence of agglomerates at higher filler concentration. As expected, the addition of the ZnO increased the stiffness of the silicone rubber SR gradually with increasing filler content forming excess material works on decreases resilience force

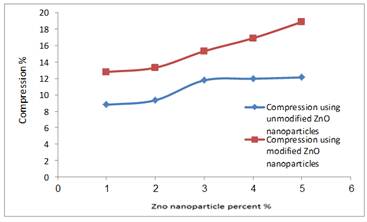

Increased ZnO content results in reduction in crosslink density of silicone rubber composites due to the dominant of the filler-filler than filler-matrix interaction and this may be the cause of lower compression set properties shown in the figure 8, such increase in deformation after load removal is similar to that reported by [16].

Figure (7). Effect of ZnO unmodified and modified nanoparticles on the compression set of the recipe.

Figure (8). The test of bacterial growth on the surface of the final recipe.

The bacterial growth after incubation for a week at 37 C˚ according to the procedure stated by [17] shows negative results which reflect the ability of zinc oxide to prevent the bacterial growth, in the best knowledge of presenting author, these results are reported for the first time.

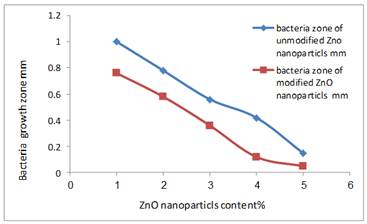

Figure 9 shows by increasing Zno nanoparticles content the bacteria growth zone, decrease that is ZnO nanoparticles has the ability to penetrate the bacteria cell walls and cause damage to its cytoplasm leading to bacteria inhibition. This ability increase by increasing the nanoparticles content the same is reported by [18].

Figure (9). Effect of ZnO unmodified and modified nanoparticles on the Bacteria growth zone.

4. Conclusion

Adding modified zinc oxide nanoparticle produced higher mechanical properties than that of using unmodified nanoparticles.

Using small amount of both (modified and unmodified) is preferred in preparing nanocomposites to avoid nanoparticles aggregation.

Silicone rubber-ZnO nanoparticle composites shows a resistance to bacterial growth that is used safely in medical applications.

Acknowledgment

I'm grateful to the department of microbiology in the college of medicine and Dr. Samah Ahmed at the college of pharmacy at the Babylon University for their help to me to test the organism which was obtained from college of medicine and used for the study at the college of pharmacy.

References

- Ravindra P. Singh, Vineet K. Shukla, Raghvendra, S. Yadav, Prashant K. Sharma, Prashant K. Singh, Avinash C. Pandey, Biological approach of zinc oxide nanoparticles formation and its characterization, Advanced Materials Letters, Vol. 2 No.4, pp.313-317, 2011.

- Wang. Z. L, "Nanostructures of zinc oxide", Materials Today; 7(6): 26-33, 2004.

- Awwad Ak. M., Nidà M. Salem, Amany O. Abdeen, Biosynthesis of Silver Nanoparticles using Olea europaea Leaves Extract and its Antibacterial Activity, Nanoscience and Nanotechnology, Vol.; 2(6) 164-170, 2012.

- Harish K Handral, Prashanth Kumar Jha, Shruthi SD. Pharmacognostic and phytochemical studies on the leaves of Murraya koenigii L Spreng. Pharmacophore; 1 3: 231- 238, 2010.

- ASTM-D412. Standard Test Methods for Rubber Properties in Tension,American Society for Testing and Materials. ASTM Designation:Annual Book of ASTM Standards, Philadelphia. 1981.

- ASTM D 624, Standard test method for tear strength of conventional vulcanized rubber and thermoplastic elastomers thermoplastic elastomers. Annual Book of ASTM Standards;2000

- ASTM D 2240. Standard test method for rubber property - Durometerhardness, Annual Book of ASTM Standards, Philadelphia, 2005.

- ASTM-D395-03, Standard Test Methods for Rubber Property—Compression Set, 2008.

- ASTM 1054. Standard test method for rubber property – compression set. Philadelphia: Annual Book of ASTM Standards; 2008.

- Demjen Z, Pukanszky B, Nagy Jr J., Possible coupling reactions of functional silanes and polypropylene, Polymers;40:1763–73, 1999.

- Jorgen S. B., Mary C. B., Mechanical behavior of particle filled elastomers, Rubber Chem. Technol., Vol. 72, pp. 633–656, 1999.

- Fadil Abbas.H.Al-Husnawi, A Study of the Effect of Zinc oxide on Physical Properties of NR/SBR Blends, Thesis M.Sc., University of Kufa, 2014.

- Ahmed A., Mohd D., and Abdullah I., Mechanical Properties of Filled NR/LLDPE Blend, Iranian Polymer Journal , Vol 13, No.3, 2004.

- Ramirez I., Jayaram S., Cherney E.A., and Gauthier M., Study of Laser Ablation and Mechanical Properties of Silicone Rubber Nanocomposites, University of Waterloo, Proc. ESA Annual Meeting on Electrostatics, Paper B3, 2008.

- Hanim, H., Zarina, R., M.Y. Ahmad Fuad, Z.A. Mohd. Ishak and Azman Hassan, The Effect of Calcium Carbonate Nanofiller on the Mechanical Properties and Crystallisation Behaviour of Polypropylene, Malaysian Polymer Journal (MPJ), vol: 3, No.12, p 38-49, 2008.

- Mostafa A., Abouel-Kasem A., Bayoumi M. R., and Sebaie M. G., Effect of carbon black loading on the swelling and compression set behavior of SBR and NBR rubber compounds, Materials & Design, vol. 30, no. 5, pp. 1561–1568, 2009.

- Mancuso, D. N., Goiato, M. C., Dekon, S. F. & GenariFilho, H., Visual evaluation of color stability after accelerated aging of pigmented and nonpigmented silicones to be used in facial prostheses, Indian J Dent Res, 20, 77-80, 2009.

- Polyzois, G. L., Tarantili, P. A., Frangou, M. J. &Andreopoulos, A. G., Physical properties of a silicone prosthetic elastomer stored in simulated skin secretions, J. Prosthet Dent, 83, 572-7, 2000.