Model of the Microcomposite Structure of the Internal Areas of Carbon Fibres

Belov Petr A.*, Kobetz L. P.

"New Materials, Composites and Nanotechnologies" Engineering Research and Education Center, Bauman Moscow State Technical University, Moscow, Russia

Abstract

Specification of the carbon fibres (CF) model is proposed to the development of the Mileyko-Litvinov concept of the microcomposite structure of CF. A classical model defines the CF structure in the form of a fibrillar shell filled with microcomposite. Its matrix represents amorphous carbon of uncertain nature, and the filler - fibrils, with graphite crystallites as its main structural elements. The proposed model is different from the already known models due to accounting for the existence of pores – together with the two known phases of microcomposite – axially oriented fibrils and amorphous (matrix) carbon. It has been established that there are two fundamentally different types of pores: flat and spherical. The flat pores are limited by the surface areas of fibrils and matrix carbon, between which there is no adhesive interaction. The spherical pores are formed by the gaseous products of pyrolysis and carbonisation of CF during the molding stage of the filament. The following experimental data is referenced below in support of the complex four-phase microcomposite structure of the internal areas of the filament.

Keywords

Carbon Fibres, Nano Composites, Defects, Porosity/Voids, Multiscale Modeling

Received: July 25, 2015

Accepted: August 14, 2015

Published online: August 26, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

One of the first models of the CF structure, developed on the basis of dark-field electron microscopy [1], [2]. In this model, the main element of the structure, determining the strength and modulus of elasticity of the fiber is graphite-like the band-shaped fiber of infinite length. Their different degree of curvature determines the so-called moire effect in dark-field microscopy. Transverse load fibrils pass through chaotic their location.

According to the ideas developed in these works, high modulus CF consists of two phases, each of which contains turbostratic graphite-belt-and three-dimensional graphite inclusions. One of these phases consists of a wide, thick belt with a more pronounced axial orientation, the other is from a more narrow and less oriented twisted tapes fibrils. Both phases contain numerous microcracks and other defects. A detailed scheme designed by Barnet F. R. and M. Noor K. [3], in which the less oriented fibrils occupy the inner part of the fiber, more focused and committed are localized in the shell.

Developed in the 70-ies of the last century structural models consider mainly only one element of carbon fiber – graphite tape, microfibril, fiber, crystal (more graphite-like crystal), which, according to prevailing views, almost the entire volume. Indeed, the undisputed today is the fact that the content of graphite tapes, their primary orientation is fully determined by the elastic characteristics of the fiber. The set of these "parquet" tapes forms a bundle with turbostratic nanostructure, in which the basal plane parallel and tilted at different angles with respect to each other.

The most vulnerable side of the developed models is the mechanism of transmission of external loads on fibrils and its redistribution in the amount of fiber. In many models it provide passable tape turbostratic carbon moving from one pack to another, thus linking neighboring fibrils together.

Some researchers in the distant 70-ies found in CF disordered (disordered) amorphous phase. So, Tyson S. N. [4] the method of small-angle x-ray scattering revealed a phase in carbon (PAN) fibers, determined its relative abundance and density. According with these data, the amorphous carbon in the hydrocarbon, formed in the fibers in sufficient quantities, does not form a continuous phase, and is in the form of individual inclusions between the fibrils. His burnout leads to the formation of nanomaterialien porous structure of the closed type. Thus, the model for the structure of carbon fibers, published by Tyson, the closest to microcomposites hypothesis developed in various research centers in subsequent years. Although, as in other models of the structure of those years, the transfer of stress from the fibrils of the fibril Tyson is carried out mainly at the expense of anadromous stripe layered structures [5] turbostratic carbon.

A classical concept of Mileyko-Litvinov for microcomposite structure of CF [6, 7] is as follows: CF filament is a fibrillary shell with a high concentration of fibrils, filled with microcomposite, a matrix of which represents amorphous carbon of unknown structure, where fibrils serve as fillers. In average, carbon fibrils are 0.1–0.5mkm thick and have a complex structural hierarchy. Regardless of the various models of the possible internal structure of the fibrils, it can be stated that on the surface of the fibrils, there are areas of both amorphous (generally, structurally distinct from the "matrix") and crystalline, "graphitic" carbon with a wide range of poly-conjugated (graphene) fragments.

For the development of such concept, a microcomposite structure of the CF filament "filling" should be specified by two important elements. The first element – flat inter-phase pores formed on the surface where matrix carbon contacted the fibrils. The second element – spherical pores formed by the gaseous products of the pyrolysis and carbonisation of CF during the molding stage of the filament. The CF porosity is directly related to the quality of plastics at their base. Inaccessible (locked) porosity influences the level of the mechanical characteristics of tensile CF and composites, the accessible (open) porosity influences the adhesive strength of both fibre and matrix and, respectively, the resistance of the composite to interlayer shift and compression. The highest level of porosity is in the carbon fibres produced from hydrocellulose and, to a lesser extent, in the polyacrylonitrile (PAN) CF.

2. Separation of Internal and External Porosity

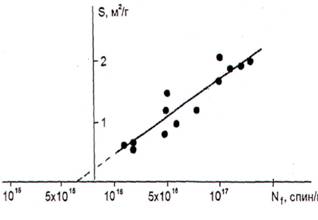

By using the [8] EPR method, CF chemical activity was researched in various modes of thermal treatment of its surface. It resulted in obtaining a linear dependence of the accessible specific surface on the number of paramagnetic centres (PMC) – see picture 1. During extrapolation of such linear dependence on the small values of the accessible specific surface area, it becomes apparent that the largest portion of PMC does not refer to the accessible specific surface. Notably, in a physical sense, in a carbon fibre, PMC largely represent nano defects with uncompensated electron density or the broken chemical bonds. In the extreme case of an isolated bond, it can be interpreted as dislocation or vacancy. Generally, broken bonds must be localized on the shores of internal cracks and inaccessible, closed pores, or on the edges of the graphite crystallites.

Picture 1. Dependence of the specific surface on the concentration of paramagnetic centres in carbon fibre VMN-4, oxidised in various modes.

Naturally, it can be stated that the ratio

![]() (1)

(1)

defines as the number of paramagnetic centres localised on the inaccessible surface of the internal defects. That is, the number of PMC on the surface of the internal surface of cracks and pores. Due to the linear nature of the obtained ratio:

![]() (2)

(2)

where ![]() is the value of the reverse of the surface concentration of PMC. Therefore, it can be stated that the surface concentration of PMC is the same for both accessible and inaccessible surfaces. By following this statement, one can calculate the total surface area of the internal defects:

is the value of the reverse of the surface concentration of PMC. Therefore, it can be stated that the surface concentration of PMC is the same for both accessible and inaccessible surfaces. By following this statement, one can calculate the total surface area of the internal defects:

![]() (3)

(3)

Thus, the area of the accessible and inaccessible surface of the pores in the CF filament can be separated.

3. Working Hypotheses on the Nature of Accessible Porosity

Further specification of the structure of inaccessible porosity is based on two equally valid hypotheses regarding its nature.

According to the first hypothesis, inaccessible porosity can be explained by the bubbles of gaseous products of carbonisation and their obstructed diffusion to the surface of a filament in the process of thermal oxidation of the PAN-precursor and subsequent carbonisation. Let us call it a hypothesis of spherical pores.

The second hypothesis explains that inaccessible porosity is caused due to the lack of adhesion between the conjugated sections of the matrix carbon and crystallite part of the surface of the fibrils. The conjugated sections of those phases form two non-interacting shores of the inter-phase crack which can be called, according to Bikerman, an [9] "unbonded patch." Let us call it a hypothesis of flat pores. Both hypotheses have their pros and cons, which will be discussed in the sections below.

4. The Hypothesis of Spherical Pores

The work researched [8] a kinematic model of the process of thermal oxidation of the rough surface of CF. Major outcome of the work was a conclusion that, in the course of thermal treatment of the defect-free (non-porous) uneven CF, at the end of the thermal treatment, the CF surface becomes perfectly cylindrical. Such a conclusion contradicts experimental facts. Regardless of duration of the thermal treatment, the surface remains porous/rough, even though parameters of the roughness vary from the original. The hypothesis of spherical pores explains such an effect with the fact that with the burning of any layer of final thickness, the CF surface demonstrates burnouts of the internal pores from the surface side. Concentration and distribution of the pores, opened by burning, by size, will be determined by the AFC (Amplitude Frequency Characteristic) profilograms for the current time.

The hypothesis of flat pores may explain such an effect since the basic structural element of CF is a folded tape [7] consisting of an alternation of the basal planes of the graphite crystallite (located at the angle to the axial orientation of the fibre) and the amorphous carbon linking them throughout a single fibril. Combined into long chains by the irregular carbon of extraordinary strength, these flat graphite fragments form nanoroughness by virtue of its regular amorphous-crystalline structure.

5. The Hypothesis of Flat Pores

The work [10] researched a surface structure of various CF, a relative surface share of the crystalline and amorphous phases and its influence on the adhesive properties of the CF surface with respect to the epoxy matrix. Major outcome of the work was a conclusion that the graphene surface portion has extremely low adhesion properties, whereas the carbon matrix and that portion of the graphite crystallite surface, located on the edges of graphene, have high adhesive properties. By assuming that the surface of even a single fibril, as an amorphous crystalline formation, can also be divided into parts with similar properties, the following may be concluded: the graphene portion of the fibril surface contacting the matrix carbon pushes it away. That is why the contacting portions of the matrix carbon and the graphene part of a fibril form two isolated (to be more specific, mutually repulsing) shores of the inter-phase crack, which can be called an "unbonded patch." By utilizing data contained in this work, a total unbonded area can be determined and compared with the value calculated according to formula (3). Furthermore, this hypothesis explains a lack of the "relict" gas in the filament, so that the flat pores due to the apparent mutual repulsion of the surfaces, unlike the spherical, allow effective drainage of gases from the filament interior to its surface.

6. Conclusion

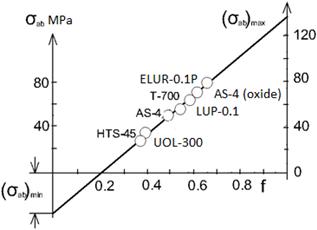

Development of the concept of the microcomposite structure of the CF filament. In opposition to the traditional dual-component model of CF filling, a quarto-component model of the same is proposed. Together with the traditional components – fibrils and matrix carbon, the model accounts for the existence of internal pores of two fundamentally different types. The first type, spherical pores, represent a product of degassing at the early technological stages of CF production. Experimental proof of their existence is the roughness of the CF surface at the end of thermal treatment of any duration [10]. The second type, flat pores, result from the absence of adhesion interaction of the flat graphene portion of the fibril and matrix carbon surfaces. Experimental proof of their existence is a linear dependency of the adhesion durability of CF and epoxide matrix on the share of the amorphous/graphene portion of its surface [10]. Construction of such dependency in this work became possible due to the quantitative determination of the shares of amorphous and crystalline phases on the CF surface, by using a special method involving spectroscopy of the combined light scattering (CLS). It was revealed that when the CLS spectrums were decomposed with the help of special computer software, integral intensity of the radiation scattering can be calculated separately on the orderly crystalline (IKP) and chemically inactive and amorphous (IAM), active surface fragments. Since the total activity of the CF surface ![]() is determined in relation to the shares of amorphous sections, it can be expressed by the following formula:

is determined in relation to the shares of amorphous sections, it can be expressed by the following formula:

![]() (4)

(4)

Picture 2. Dependence of durability during the inter-layer shifting of the CFRP based on various carbon fibres on the fCF.

Picture 2 demonstrates durability dependency during the inter-layer shifting of the CFRP (Carbon Fibre Reinforced Plastic), reinforced CF with various shares of amorphous carbon on their surface. The linear nature of such dependence demonstrates that the change durability parameter during shifting of the CFRP can be determined by a single parameter: either the fibre surface share taken by the active amorphous carbon, or the inactive graphene carbon; whereas, the specific concentration of the oxygen-containing functional groups, per surface unit, remains the same for all fibres. Mathematically, such dependency can be stated as follows:

![]() (5)

(5)

where: coefficient ξ = 172 MPa; ![]() – the initial value of durability with a shift of the epoxide CFRP, which equals 35 MPa. Based on the experimental data, the graphene portions do not become penetrated with epoxide bonding agents, and, when the matrix becomes solid as a result of shrinking, it peels off by forming "unbonded patches."

– the initial value of durability with a shift of the epoxide CFRP, which equals 35 MPa. Based on the experimental data, the graphene portions do not become penetrated with epoxide bonding agents, and, when the matrix becomes solid as a result of shrinking, it peels off by forming "unbonded patches."

References

- Diefendorf R.J., Tokarsky E. High-performance carbon fiber. // Polym. Eng. Sci. 1975, vol. 15, N 3, p. 150-159.

- Lemaistre C. W., Diefendorf R. J. Origin of structure in carbonized PAN (polyacrylnitrile) fibers. // SANPE Quart., 1973, vol. 4, N 4, p. 1-6.

- Barnet F. R., Noor M. K. Characterisation of carbon fibers by oxygen plasma etch. // Carbon Fibres (Platics and Polim. Conf. Suppl. N 6). The Plastics Institute, London, 1974, p. 32-43.

- Tyson C. N. Fracture mtchannisms in carbon fibres derived from PAN in the temperature range 1000-2800°C // J. Phys. D: Appl. Phys., vol. 8, 1975. Printed in Great Britain. C 1975.

- Fourdeux A., Perret R., Ruland W. General structurel features of carbon fibers // Carbon fibres (Plastics and Polym. Cont. Suppl.№5) The Plastics Institute, London, 1971, p.59-67.

- Kobetz L.P., Deev I.S. Carbon fibres: structure and mechanical properties. // Composites science and technology. V.57. 1997. p. 1571-1580.

- Litvinov V.B. and others "Structural and mechanical properties of highly durable carbon fibres," Composites and Nanostructures, 2011. № 3. Pgs. 36–50.

- Nelub V.A., Kobetz L.P., Malysheva G.V., Belov Petr A., "Research of the Physical and Chemical Properties of Carbon Fibre Surface the by Raman-Spectroscopy Method, Works II of the International Conference Global Science and Innovation, May 21-22, 2014 vol. II, pgs. 263–268.

- Bikerman J.J., The physical basis of wetting, Kolloid Z. and Z. Polymer [sic]. 1967. № 1. pgs. 52–56.

- Kobetz L.P., Nelub V.A., Belov Petr A., "Study of the Paramagnetic Absorption of Carbon Fibres and Polymer Composites on their Basis," Research Collection of the International Extramural Scientific-Practical Conference "Topical Questions of Education and Science," Russia, Tambov, 30 December 2013, section 13, pgs. 64–73.