Effect of Heat Treatment on the Optical Properties of Spinel ZnFe2O4 Thin Films

M. Vishwas1, *, K. Narasimha Rao2

1Department of Physics, Government Science College (Autonomous), Bangalore, India

2Department of Instrumentation and Applied Physics, Indian Institute of Science, Bangalore, India

Abstract

Zinc ferrite (ZnFe2O4) thin films were synthesized on glass and quartz substrates by the sol-gel method. The influence of annealing temperature and microwave irradiation on the optical properties of ZnFe2O4 thin films was investigated. The optical transmittance decreased with increase of annealing temperature. The optical band gap energy of the ZnFe2O4 thin films was estimated at different annealing temperatures by the Tauc’s method. The optical band gap energy increased with annealing temperature. The film thickness decreased with increase of annealing temperature and refractive index increased with annealing temperature.

Keywords

ZnFe2O4, Thin Films, Optical Properties, Band Gap Energy, Microwave Irradiation

Received: July 10, 2015

Accepted: July 22, 2015

Published online: August 2, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

In recent years, researchers paid special attention to spinel ferrites due to their unique physical and chemical properties and technological applications such as magnetic materials [1-4], photocatalysts [5] and gas sensors [6,7] etc. They are represented by the formula AB2O4. Zinc ferritesare the inorganic compounds of zinc and iron with the general formula of ZnxFe3-xO4. There are various methods of preparation of zinc ferrite thin films, of which the sol-gel method [8] is more advantageous than others. The optical properties of oxide thin films vary with annealing temperature [9-12]. Li et al. [13] reported the optical properties of TiO2 thin films and TiO2/ZnFe2O4 composite films prepared by r.f. magnetron sputtering. They observed red shift of the absorption edge of ZnFe2O4/TiO2 composite films in comparison with TiO2 thin films. Khorrami et al. [14] reported the synthesis and structural studies of ZnFe2O4 nanoparticles prepared by the sol–gel auto-combustion method. Liang and Hsia [15] reported the deposition and characterization of ZnFe2O4 thin films on yttria stabilized zirconia (111), SrTiO3 (100), and Si (100) substrates, by RF magnetron sputtering at 650oC. They reported the magnetic, structural and morphological studies of the ZnFe2O4 thin films. The morphology of the films differed with the substrates used for deposition.

In this paper, the effect of annealing temperature and microwave irradiation on the optical properties such as optical transmittance/reflectance, optical band gap energy and refractive index of the ZnFe2O4 thin films prepared by the sol-gel method are reported.

2. Experimental Work

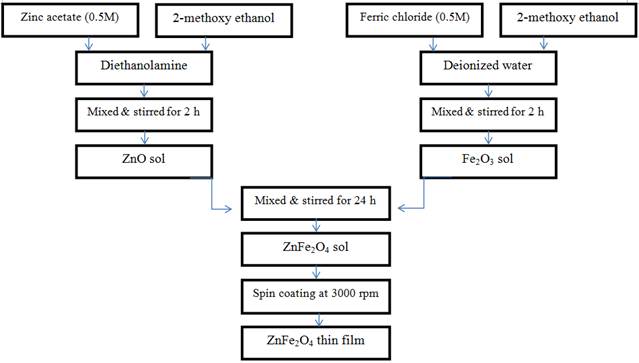

ZnO and Fe2O3 sols were prepared using zinc acetate dihydrate and ferric chloride hexahydrate as the precursor materials, respectively and deionized water and 2-methoxy ethanol were used as the solvents. Diethanol amine was added as a stabilizing agent. The preparation of ZnFe2O4 sol was reported previously [8]. A flow chart for the preparation of ZnFe2O4 thin films is shown in Fig. 1. Glass and quartz substrates (dimensions: 2.5 x 2.5 x 0.1 cm3) were cleaned by ultrasonic bath followed by isopropyl alcohol and washed with soap solution and rinsed with deionized water. Then the substrates were dried in air for 10 minutes. A few drops of ZnFe2O4 sol was placed on pre-cleaned glass and quartz substrates and spin coated at 3000 rpm for 40 seconds. The ZnFe2O4 films obtained were dried in air and annealed in a furnace from 80 to 800oC for 2 h in air. The spinel structure of ZnFe2O4 was formed after annealing the samples at 500oC for 2 h in air as confirmed from XRD studies [8]. Then the films were subjected to optical characterization using UV/VIS/NIR spectrophotometer (Ocean Optics, USA).

3. Results and Discussions

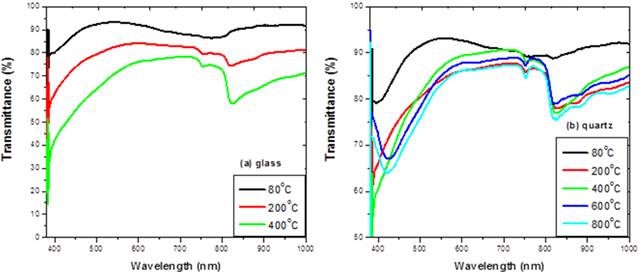

The optical transmittance spectra of ZnFe2O4 thin films deposited on glass substrates annealed at different temperatures is shown in Fig. 2 (a). The optical transmittance of ZnFe2O4 thin films annealed at 80oC showed higher transmittance (>90%) in the visible region. The transmittance of the films decreased with increase of annealing temperature. This is due to the evaporation of the solvent present in the films and increase of porosity of the films. The transmittance decreased with increase of annealing temperature from 200 to 400oC.

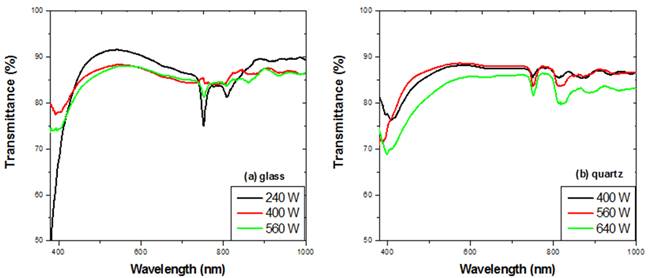

Fig. 2 (b) shows the optical transmittance spectra of ZnFe2O4 thin films deposited on quartz substrates. The optical transmittance decreased with increase of annealing temperature from 80 to 200oC. With further increase of annealing temperature, the films showed increased transmittance in the visible region. Fig. 3 (a) and (b) show the optical transmittance spectra of ZnFe2O4 thin films deposited on glass and quartz, respectively microwave irradiated at different powers from 240 to 640 W for 10 minutes.

The optical transmittance decreased with increasing the irradiation power from 240 to 400 W on glass substrates and the transmittance was almost constant for the films irradiated at 400 and 560 W. The optical transmittance of ZnFe2O4 thin films deposited on quartz was less than 90 % in the visible region after microwave irradiation as shown in Fig. 3 (b). The transmittance was almost same for the films irradiated at 400 and 560 W and the transmittance decreased to ~85 % after irradiation at 640 W.

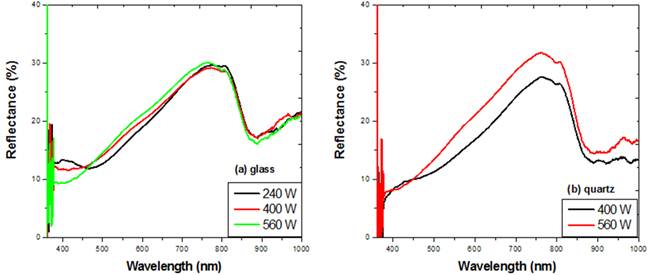

Fig. 4 (a) and (b) show the optical reflectance spectra of ZnFe2O4 thin films deposited on glass and quartz substrates, respectively microwave irradiated at different powers from 240 to 560 W. It has been observed that, the variation of optical reflectance with irradiation power was lesser than that of quartz substrate. The reflectance maxima was approximately 30% for glass substrate at different powers, while in the case of quartz substrate the optical reflectance increased from 27 to 32 %, approximately with increase of power from 400 to 560 W, respectively.

Fig. 1. Flow chart for the preparation of ZnFe2O4 thin films by the sol-gel method.

Fig. 2. Optical transmittance spectra of ZnFe2O4 thin films deposited on (a) glass and (b) quartz substrates annealed at different temperatures in air.

Fig. 3. Optical transmittance spectra of ZnFe2O4 thin films deposited on (a) glass and (b) quartz substrates microwave irradiated at different powers.

Fig. 4. Optical reflectance spectra of ZnFe2O4 thin films deposited on (a) glass and (b) quartz substrates microwave irradiated at different powers.

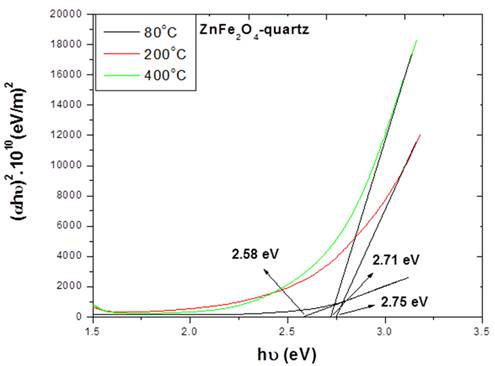

Fig. 5. Optical band gap energy estimation of ZnFe2O4 film deposited on quartz substrate annealed at 80, 200 and 400 oC in air.

Fig. 5 shows the estimation of direct optical band gap energy of ZnFe2O4 thin films deposited on quartz substrates annealed at different temperatures in air by Tauc’s method [16].

The absorption coefficient (α) of the films was calculated using the relation

α = (1/t) ln(1/T) (1)

where t is the film thickness and T is the percentage of transmittance. The optical band gap energy values of the ZnFe2O4 film annealed at 80, 200 and 400 oC were found to be 2.58, 2.75 and 2.71 eV, respectively. Hence the blue shift was observed with increase of annealing temperature. The film thickness was estimated by the envelope method [16] and found to be 147, 129 and 112 nm for the sample annealed at 80, 200 and 400oC, respectively. The refractive indices of the ZnFe2O4 film annealed at 80, 200 and 400 oC were found to be found to be 1.873, 1.921 and 1.953, respectively estimated by the envelope method [17]. The increase of refractive index of ZnFe2O4 film with annealing temperature is due to the densification of the film.

4. Conclusions

Optically transparent and uniform ZnFe2O4 thin films were successfully deposited onto glass and quartz substrates by the sol-gel spin coating method. The films exhibited very high optical transmittance in the visible region. The transmittance decreased with annealing temperature and microwave irradiation and the optical band gap energy increased with annealing temperature. The refractive index of the films increased with increase of annealing temperature. The ZnFe2O4 thin films obtained are suitable for spintronic applications.

Acknowledgements

The authors are thankful to Prof. K. Rajanna, Chairman, Department of Instrumentation and Applied Physics, Indian Institute of Science, Bangalore for his support and encouragement.

References

- Ehrhardt, H., Campbell, S. J. and Hofmann, M. (2003), "Magnetism of the nanostructured spinel zinc ferrite," Scripta Materialia, 48 (8), 1141–1146.

- Kundu, A., Upadhyay, C. and Verma, H. C. (2003), "Magnetic properties of a partially inverted zinc ferrite synthesized by a new coprecipitation technique using urea," Physics Letters A, 311 (4-5), 410–415.

- Deng, H., Li, X., Peng, Q., Wang, X., Chen, J. and Li, Y. (2005), "Monodisperse magnetic single-crystal ferrite microspheres," Angewandte Chemie. International Edition, 44 (18), 2782–2785.

- Yao, C., Zeng, Q., Goya, G. F., Torres, T., Liu, J., Wu, H., Ge, M., Zeng, Y., Wang Y. and Jiang, J. Z. (2007), "ZnFe2O4 Nanocrystals: Synthesis and Magnetic Properties" J. Phys. Chem. C, 111, 12274-12278.

- Zhang, B., Zhang J. and Chen, F. (2008), "Preparation and characterization of magnetic TiO2/ZnFe2O4 photocatalysts by a sol–gel method" Res. Chem. Intermed., 34 (4), 375–380.

- Niu, X., Du, W. and Du, W. (2004), "Preparation and gas sensing properties of ZnM2O4 (M = Fe, Co, Cr)," Sensors and Actuators B, 99 (2-3), 405–409.

- Zhang, G., Li, C., Cheng, F. and Chen, J. (2007), "ZnFe2O4 tubes: synthesis and application to gas sensors with high sensitivity and low-energy consumption," Sensors and Actuators B, 120 (2), 403–410.

- Vishwas, M., Rao, K. N. and Raichur, A. M. (2015), "Fabrication and characterization of ZnFe2O4 thin film based metal-insulator-semiconductor capacitors" Int. Lett. Chem., Phy. and Astr., 50, 151-158.

- Vishwas, M., Rao, K. N., Phani, A. R. and Gowda, K. V. A. (2012), "Sol–gel synthesis and optical characterization of nano-crystalline ZnTiO3 thin films"J. Opt.,41(1), 60–64.

- M. Vishwas, Sharma, S.K., Rao, K.N., Mohan, S., Gowda, K.V.A. and Chakradhar, R.P.S. (2010), "Influence of surfactant and annealing temperature on optical properties of sol–gel derived nano-crystalline TiO2 thin films",Spectrochimica Acta Part A, 75, 1073–1077.

- Vishwas, M., Rao, K.N., Kareem, K.S. and Chakradhar, R.P.S. (2014), "Influence of annealing and SiO2 layer on structural, optical and electrical properties of hydrophobic ITO thin films prepared by activated reactive evaporation", J. NanoScience and NanoTechnology,2 (4), 475-479.

- Vishwas, M., Rao, K.N. and Chakradhar, R.P.S. (2012), "Influence of annealing temperature on Raman and photoluminescence spectra of electron beam evaporated TiO2 thin films", Spectrochimica Acta Part A, 99, 33–36.

- Li, G.H., Yang, L., Jin, Y.X. and Zhang, L.D. (2000), "Structural and optical properties of TiO2 thin film and TiO2 + 2 wt.% ZnFe2O4 composite film prepared by r.f. sputtering"Thin Solid Films, 368, 163-167.

- Khorrami, S., Gharib, F., Mahmoudzadeh, G., Sepehr, S.S., Madani, S.S., Naderfar, N. and Manie, S. (2011), "Synthesis and characterization of nanocrystalline spinel Zinc ferrite prepared by sol-gel auto-combustion technique", Int. J. Nano. Dim., 1(3), 221-224.

- Liang, Yuan-Chang and Hsia, Hao-Yuan (2013), "Growth and crystallographic feature-dependent characterization of spinel zinc ferrite thin films by RF sputtering", Nanoscale Research Letters, 8, 537-544.

- Vishwas, M., Rao, K. N., Phani, A. R., Gowda, K. V. A. and Chakradhar, R.P.S. (2012), "Optical, electrical and structural characterization of ZnO:Al thin films prepared by a low cost sol–gel method",Solid State Comm., 152, 324–327.

- Swanepoel, R. (1983), "Determination of the thickness and optical constants of amorphous silicon" J. Phys. E: Sci. Instrum., 16, 1214-1222.