Impact of Nano Materials on the Durability of Asphalt Stabilized Soil

Saad Issa Sarsam*, Abeer Husain

Department of Civil Engineering, College of Engineering, University of Baghdad, Baghdad, Iraq

Abstract

Settlement of road way embankment at grade separation intersections, and highway bridge abutments is a widespread problem in Iraq. Typical subgrade soil usually used for embankment construction by Mayoralty of Baghdad was investigated. The aim of this work is to study the effect of Nano-materials additives such as Lime, coal fly ash, and Silica fumes on the durability of asphalt stabilized soil in terms of (freezing-thawing) cycles and (heating-cooling) cycles The optimum fluid content was 15% (6% cutback asphalt + 9% water). The optimum Nano-materials content requirement was determine by using repeated indirect tensile strength test. The optimum Nano-materials was (2%) for each of lime, and silica fumes. The failure criteria was a target permanent deformation. The reduction in deformation was (47.6%, 8%) for lime and silica fumes specimens respectively. Durability of asphalt stabilized soil, mixed with optimum Nano-materials in terms of (freezing-thawing) cycles and (heating-cooling) cycles was investigated by using repeated indirect tensile strength test. The variation in rate of deformation among various Nano materials was detected. Tensile strength was increase by (6.6% and 39.6%) when (2%) of silica fumes or lime were implemented respectively. Punching shear for asphalt stabilized soil increases by (47.4%) when (2%) lime was added, while it decrease by (10.5%) when (2%) of silica fumes was added. However, the percentage of losses in weight for the specimens exposed to durability test increases with increment of durability cycles.

Keywords

Nano Materials, Durability, Cutback Asphalt, Punching Shear, Repeated Indirect Tensile Strength, Sub Grade

Received: July 5, 2015

Accepted: July 18, 2015

Published online: July 28, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

The subgrade layer must be strong to resist shear failure, tensile stresses and have adequate stiffness to avoid and resist excessive pavement deformation. Available fill materials do not always meet these requirement and may require improvement of their engineering properties, soil stabilization with liquid asphalt may be an alternative to improve the stability, adhesion and waterproofing properties which are desired for embankment construction purpose. The aim of this research work is to study the effect of Nano-materials additives such as Lime, coal fly ash, and Silica fumes on the durability of asphalt stabilized soil in terms of (freezing-thawing) cycles and (heating-cooling) cycles by using repeated indirect tensile strength test. The strength properties such as indirect tensile strength and punching shear strength, and accumulation of deformation under repeated indirect tensile strength test will also be investigated. Such tests are considered as good representative of the actual stresses that embankment usually practice under vehicles load. Research work on the durability of asphalt stabilized soil is scares and scatter, [1] assessed the durability of asphalt stabilized Gypseous soil by using emulsion asphalt. It was stated that after exposing the specimens to cycles of (Heating – cooling), the undrained shear strength increased up to 10 cycles then decreased with further increased number of cycles. The angle of internal friction showed irregular variation (decreased at 10 cycles and then increased). Cohesion increased at 10 cycles then decreased with increased number of cycles at both (soaked and unsoaked condition), while for samples exposed to (freezing – thawing) cycles, angle of internal friction took irregular variation and increased at 10 cycles and then decreased (unsoaked condition); cohesion decreased with increased number of cycles. [2,3] Studied the effect of using additives such as lime and cement on extrusion value, volume change and water absorption of asphalt stabilized soil mixture under dry and absorbed condition. It was concluded that the dry extrusion value of soil cut-back mixture with additives (lime, cement) increases with increasing curing time, but under absorbed condition, when lime was added, extrusion value could not be obtained and the specimen collapsed in water. While when cement was implemented, higher extrusion value at all curing periods could be obtained. Water absorption and volume change reduces by using cement as additive to soil cutback mixture while increases when lime was used as additive. [4] Studied stabilization of Nasiriya collapsible soil using combination of emulsified and additives. It was stated that when lime was implemented as additive, (Cc) of asphalt stabilized soil mixed with lime decreases by (83%), while the reduction in coefficient of permeability for the same mixture was (89%). Coefficient of volume compressibility decreases by (86%) and CBR value increases about (98%) for same mixture. [5] Estimated the self-cementing fly ashes as a sub-grade stabilizer for Wisconsin soils. A laboratory-testing program was conducted to evaluate the mechanical properties of fly ash alone, and also to evaluate how different fly ashes can improve the engineering properties of a range of soft sub-grade soil from different parts of Wisconsin, substantial increase in the CBR was achieved when soils were mixed with fly ash. Unconfined compressive strength of the soil-fly ash mixtures increased with increasing fly ash content. [6] Studied the improvement of Gypseous soil characteristics using cutback asphalt and lime. The maximum dry unit weight decreases and the optimum fluid content increases as the cut back asphalt increases. Additional decrease in collapse potential was observed as the percentages of lime added increases. [7] Evaluated the wet-dry and freeze-thaw durability of different low plasticity clayey soils treated with both class F and C fly ash. Although the unconfined compressive strength values of the compacted soil-fly ash mixtures were high and satisfactory, the wet-dry and freeze-thaw durability tests results exhibited a weight loss of more than 14% indicating that the mixtures failed in durability test. [8] Recommends durability assessment in terms of (Freezing-thawing) cycles and (heating-cooling) cycles for stabilized soil as a part of the design criteria.

2. Materials and Methods

2.1. Subgrade Soil

The soil used in this research was taken from Al-Taji, 20 km north of Baghdad city. A shovel was used to remove the top soil (30 cm) and soil was obtained from depth of (0.3m-0.75m), then the soil was stored in plastic bags and transported to the laboratory. This soil represents typical subgrade soil usually used for embankment construction by Mayoralty of Baghdad.

2.2. Physical Properties and Chemical Composition of Subgrade Soil

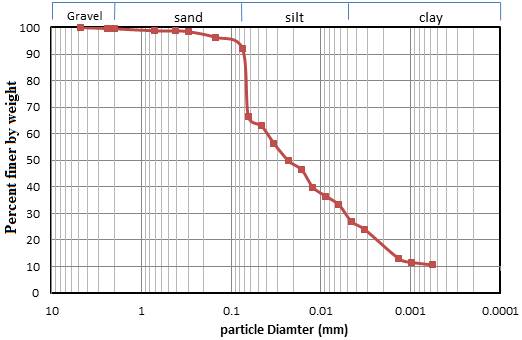

Physical test on the soil include particles size distribution, Atterberg limit, and compaction characteristics. Chemical teste were conducted. Table 1 shows the physical properties and chemical composition of the soil. Fig.1. shows the grain size distribution of the subgrade soil.

Table 1. Physical properties and chemical composition of the used soil.

| Physical properties | Specification | Test results |

| Liquid limit% | (ASTM D-4318) | 35.75 |

| Plastic Limit % | 23.1 | |

| Plasticity Index % | 12.6 | |

| Maximum dry density | (ASTM D690-00a) Standard proctor | 17.7 kn/m3 |

| Optimum water content% | 15% | |

| Unified classification system | CL | |

| AASHTO classification system | A-6(12) | |

| ASTM classification system | 7% sand, 63% silt, 30% clay | |

| Coefficient of curvature | 1.706 | |

| Coefficient of uniformly | 66.67 | |

| Collapse Index | 1.81% (slightly collapse soil) | |

| % Total soluble salt (T.S.S) | 6.02 | |

| % Organic content | 0.945 | |

| % Total (CaCo3) | 33.50 | |

Fig. 1. Grain size Distribution of subgrade soil.

2.3. Lime

Hydrated lime was obtained from southern cement state company in Karbala, it was manufactured according to Iraqi Specification (No.207/2002). The properties of lime are given in Table 2.

2.4. Silica Fumes

It was manufactured by Wacker Silicon Company in Germany as fluffy powder, and obtained from local market. The properties of silica fumes are shown in Table 2.

2.5. Coal Fly Ash

Coal fly ash (class F) was implemented in this work, it was obtained from local market. The physical properties of coal fly ash are presented in Table. 2. On the other hand, Fig. 2 shows the representative samples of (Lime, fly ash and Silica fumes).

Table 2. Properties of Nano materials.

| Nano material type | Lime | Silica fumes | Coal Fly ash |

| Chemical formal | Ca(OH)2 | SiO2 | Fly ash (F) |

| Passing sieve No.200 | 100% | 100% | 100% |

| Specific surface area (m2 /kg) | 4404 | 20000 | 2940 |

| Density (g/cm3) | 2.211 | 2.623 | 1.04 |

| Appearance | White powder | Light gray powder | Dark gray powder |

Fig. 2. Nano Material used in this research.

2.6. Cutback Asphalt

The Properties of medium curing cut-back (MC-30) manufactured at AL-Dora refinery according to (ASTM D-2027), (AASHTO-M82-75) are obtained from the refinery and listed in the table 3.

Table 3. Properties of Cut-back Asphalt (as per Dora refinery).

| Grade | MC-30 |

| Viscosity(CSt)@60 ˚C | 30-60 |

| Flash point (C.O.C) ˚C (min) | 38 |

| Water% V(max) | 0.2 |

| Residue from distillation to 360 ˚C % V(min) | 50 |

| Test on Residue from Distillation | |

| Penetration @25 ˚C (100g,5sec,0.1mm) | 120-250 |

| Ductillity@25 ˚C (cm)(min) | 100 |

| Solubility in Tri-chloro ethylene % wt. (min) | 99.0 |

3. Testing

3.1. Determination of Optimum Nano Materials Requirement

The optimum cutback asphalt content and fluid content that were suitable for all geotechnical properties of the soil such as direct shear test, one-dimensional compression test and unconfined compression test were determined, it was found as (6%) and 15% by weight of dry soil respectively, the details were published elsewhere,[9]. The optimum content of Nano-material of lime, fly ash and silica fumes was assessed using Repeated Indirect Tensile Strength test.

3.1.1. Specimen’s Preparation

The pulverized and homogenous soil passing No.10 sieve was oven dried at temperature of (100 ˚C) to constant weight. The optimum fluid content (6% asphalt cut-back+9% water) and the target maximum dry unite weight of soil (17.7 kn/m3) that was found through standard compaction test were selected for preparation of specimens. Nano-material such as lime, fly ash and silica fumes, passing sieve No.200 were mixed with dried soil at deferent percentage (0.5%,1.5% and 2%)by weight of dry soil by hand for two minutes to ensure the homogeneity of mixture, then water was added and mixed thoroughly by hand for three minutes until the water dispersed through mixture, thereafter cutback asphalt was added to mixture and mixed by rubbing the mixture between palms for five minutes, so that the mixture had homogenous character and proper coating of soil particles with asphalt occurred. The mixture was allowed to aeration for two hours at room temperature (20±5 ˚C). The compaction mold used in this test is 10 cm in diameter and 7.5 cm in height, filter paper was placed at the bottom of the mold, the mixture was placed into the mold and compacted statically, after that, the specimen was extracted from the mold and allowed to curing for (8)days before test. The procedure of the prepeartion of specimens was shown in Fig.3, 4, 5. While Fig.6 shows part of the prepared specimens.

Fig. 3. Aeration process.

Fig. 4. Moulding process.

Fig. 5. Static compaction.

3.1.2. Specimens Testing

Pneumatic repeated load system (PRLS) shown in Fig.7 was implemented to determine the optimum percentage of Nano-material (lime, fly ash and silica fumes). Uniaxial compressive repeated loading was applied on the specimen which was centred on the vertical diametrical plane between the two parallel loading strips (12.7 mm) wide as shown in Fig.8. Such load assembly applies indirect tensile stress on the specimen in the form of rectangular wave with constant loading frequency of (60) cycles per minutes. A heavier sine pulse of (0.1) sec load duration and (0.9) sec rest period is applied over test duration. Specimens were stored in the chamber of the testing machine at room temperature (20±5 ˚C), dial gage of the deformation reading was set to zero before test start and the pressure actuator was adjusted to the specific stress level equal to 8 bar (800 KPa). A digital video camera was fixed to capture dial gage reading, the specimen was covered with rubber sheet of 1.5 mm thickness at the diametrical plan to control and limit the loading pulse. This could simulate the field conditions where the asphalt concrete layers controls the loading on the subgrade beneath. The test was continued for 30 minutes, upon completion of test, the recording was terminated and the specimen was removed from the test chamber.

Fig. 6. Part of the prepared specimens.

Fig. 7. PRLS.

Fig. 8. Test assembly.

The impact of Nano material percentage and type on the accumulated permanent deformation was assessed. The average of three sample of each percentage and type of Nano-material was calculated and considered for analysis as recommended by [10]. Total of 30 specimens were prepared and tested.

3.2. Durability Testing for (Freezing-Thawing) and (Heating-Cooling) Cycles

Practical frost criteria and temperature sensitivity are necessary to quickly check the susceptibility of the asphalt stabilized subgrade soil to environment. Durability test in terms of (Freezing-thawing) cycles and (heating-cooling) cycles were conducted according to the procedure that was provided by [8].

3.2.1. Specimens Preparation

The specimens were prepared by mixing the oven dried soil passing No.10 sieve with the optimum Nano material percentage, and optimum fluid content (6%asphalt cut-back+9% water), then the mixture was allowed to aeration for two hours at room temperature (20±5 ˚C). The mixture was placed in mold and compacted to the target maximum unite weight of (17.7 kn/m3) that was found through standard compaction test, then the specimens was extracted from the mold and allowed to curing for (8) days. After completing curing time, specimens were divided into four groups, the first group of specimens were stored in deep freezer for (6) hours at a temperature of (-10 ˚C) and then subjected to thawing at room temperature (20±2 ˚C) for (6) hours. This processes represented one cycle of (freezing – thawing), which requires 12 hours. The specimens were subjected to 10, 20, and 30 cycles of (freezing- thawing). Fig. 9 shows part of specimens in the freezing process.

The Second group of specimens were stored in refrigerator for (6) hours at a temperature of (+5 ˚C) and then subjected to heating at room temperature (20±2˚C) for (6) hours. This processes represented one cycle of (heating-cooling), which requires 12 hours. The specimens were subjected to 10, 20 and 30) cycles of (heating-cooling). Fig. 10 shows part of specimens in the heating process.

The third group was stored at room temperature (20±5 ˚C) for 30 minutes then was subjected to indirect tensile strength determination. The fourth group was also stored at room temperature (20±5 ˚C) for 30 minutes then was subjected to punching shear strength determination. Fig.11, and 12 shows the indirect tensile strength (ITS) and the double punching shear test assembly.

Fig. 9. Freezing cycle.

Fig. 10. Heating cycle.

Fig. 11. ITS test.

Fig. 12. Punching shear.

3.2.2. Specimens Testing

Pneumatic repeated load system (RPLS) as explained above was used to determine the impact of (freezing-thawing cycles) and (heating-cooling cycles) on the accumulated permeant deformation of the specimens for the first two groups of specimens.

3.3. Indirect Tensile Strength Test

The indirect tensile strength test is used to determine the tensile properties of the (soil +6% cutback asphalt+ optimum Nano- materials additives) mixture which can further be related to the cracking properties of the pavement, higher tensile strength corresponds to a stronger cracking resistance. Tensile strength is difficult to measure directly because of secondary stress induced by gripping specimens so that it may be pulled a part, indirect tensile strength test was measured following the procedures of ASTM [11]. The specimen of the third group was centred on the vertical diametrical plane between the two parallel loading strips (12.7 mm) wide. Vertical compression load at rate of (2) inch/min (50.8 mm/min) by versa tester machine was applied until the dial gage reading reached the maximum load resistance and the specimen shows failure. The indirect tensile strength was calculated using eq.1. [11].

ITS=![]() (1)

(1)

Where:

ITS= indirect tensile strength (kPa).

P= maximum load resistance at failure, N.

T= thickness of specimen immediately before test, mm.

D= diameter of specimen, mm.

3.4. Double Punching Shear Test

Soil mostly fails in shear, there are three type of shear failure, General shear failure, local shear failure, and Punching shear failure. The type of failure that will occur in soil due to vertical load will depend upon the type of soil, punching shear failure occur in soil if it is very soft cohesive soil, failure pattern is not easy to observe and load deformation curve is very steep.

The specimen of the fourth group was centred on the horizontal diametrical plane between two metal cylinder (50 mm) in diameter and (50 mm) in height. Vertical compression load at rate of 2 inch/min (50.8 mm/min) by versa tester machine was applied until the dial gage reading reached the maximum load resistance and the specimen exhibit failure. Punching shear stress was calculated using eq.2, [12,13].

![]() (2)

(2)

Where:-

![]() =punching shear stress (kPa).

=punching shear stress (kPa).

P= applied load, N

A= cross-sectional area, mm2

a= radius of punch, m

b=radius of specimen, m

h=height of specimen, m

4. Discussion of Test Results

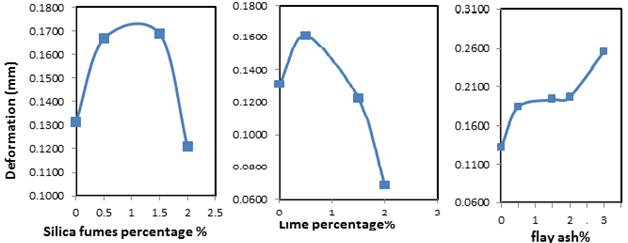

4.1. Optimum Lime Content

The repeated indirect tensile strength test shows that the permanent vertical plastic strain is measured as a function of the number of load application at stress level equal to (800Kpa) (8bar) and at room temperature (20±5 ˚C). Three percentage of Lime were tried (0.5%, 1.5%, and 2%) by dry weight of soil, the average of three sample for each lime percentage was calculated and considered for analysis. The minimum amount of initial and accumulated deformation can be obtained from this test and used as a base to determine the optimum percentage of Nano-material. Fig. 13. Present the impact of lime content on permanent micro strain under repetition of indirect tensile stress. it can be observed that the strain decrease with increasing lime content until it reach to optimum lime of (2%) by weight of the soil. This behaviour may be attributed to the role of possible chemical reaction of lime additive with soil, and improvement of the cementation which results in increment of the soil particles bond. This leads to increase the strength of specimens and decrease the strain under repeated load as compared with asphalt stabilized soil mixture without additive. Finally 2% lime was considered as optimum.

4.2. Optimum Silica Fumes Content

Fig.13. Present permanent micro strain – number of repeated indirect tensile stress relationship of stabilized soil with (6%) cutback asphalt mixed with silica fumes of (0.5%, 1.5%, and 2%) by weight of dry soil. The initial and permanent strain increase with increasing silica fumes content up to 2%.

This behavior may be attributed to that silica fumes consist of very fine vitreous particles with surface area (20000 m2/kg). Because this extreme fineness and high silica fumes content, it is highly effective Pozzolanic materials when added to soil mixture. It acts in bonding between particles and also block off the mixture voids, thus tends to increase the strength of specimens and decrease the strain under repeated load as compared with asphalt stabilized soil specimens without additive.

Fig. 13. Relationship between permanent micro strains and number of repetition.

4.3. Optimum Coal Fly Ash Content

Coal fly ash class F was implemented as additive, its impact on the strength of asphalt stabilized soil mixture was assessed using repeated indirect tensile strength test. Fig.13. Present permanent micro strain- No. of repeated indirect tensile stress relationship for asphalt stabilized soil mixed with Coal fly ash class F of (0.5%, 1.5%, 2%, and 3%) by weight of dry soil. The micro strain on the y-axis represent the net strain which is obtained from subtracting initial strain from the cumulative strain at each load repetition. This will indicate high strain at early stages of loading which will be reduced as load repetitions proceeds.

Class F coal fly ash produces cementation compounds that bind the soil particles and thereby achieve the desired stabilization. Coal fly ash have certain amount of free lime (CaO) less than (10%) available to react with clay mineral to further stabilize or alter the soil properties, while the low surface area of fly ash (2940 m2/kg) is not sufficient to block off the mixture voids. This behavior may be attributed to that the fly ash class F is not acting as good Pozzolanic materials to improve the strength of soil mixture under repeated load, however, the variation in the behavior of different percentages of fly ash was not significant. Such behavior agrees well with [14,15]. Fig.14. Shows the impact of various Nano additives on the deformation under repeated indirect tensile stress. Table 4 summarises the effect of additives content on the deformation of asphalt stabilized soil mixtures. Finally, it can conclude that the optimum lime or silica fumes content was (2%) by weight of the soil, while the fly ash class F could not improve the properties of asphalt stabilized soil. It was decided to terminate further investigation on this type of fly ash.

Fig. 14. Effect of Nano additives on the deformation of asphalt stabilized soil specimens.

Table 4. Effect of Nano additives content on the deformation of asphalt stabilized soil.

| Mix type | Deformation (mm) | % change in deformation |

| Soil+6% cutback asphalt | 0.1313 | |

| Soil+6%cutback asphalt+0.5% lime | 0.1606 | +22.3 |

| Soil+6%cutback asphalt+1.5% lime | 0.1222 | -6.9 |

| Soil+6%cutback asphalt+2% lime | 0.0688 | -47.6 |

| Soil+6% cutback +0.5% silica fumes | 0.1667 | +26.96 |

| Soil + 6% cutback +1.5% silica fumes | 0.1688 | +28.56 |

| Soil + 6%cutback +2% silica fumes | 0.1208 | -7.996 |

| Soil+6%cutback sphalt+0.5% fly ash | 0.1844 | +40.44 |

| Soil+6%cutback sphalt+1.5%fly ash | 0.1938 | +47.61 |

| Soil+6%cutback sphalt+2%fly ash | 0.1969 | +49.96 |

| Soil+6%cutback sphalt+3%fly ash | 0.2560 | +95.21 |

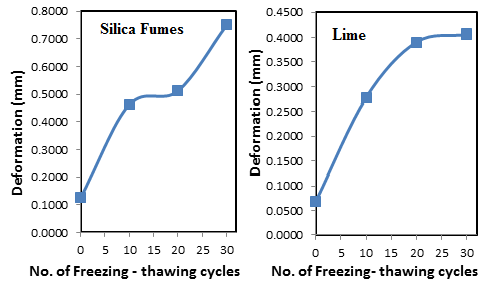

4.4. Freezing-Thawing Cycles Test

Fig.15. Shows the behavior of the asphalt stabilized soil mixed with silica fumes and lime, it was observed that the deformation of specimen increases with increasing number of durability cycles as compared with specimens before cycles. This behavior may be attributed to that during the process of soil mixture freezing, the volume of the remaining fluid content of specimens was increased as a result of the freezing, and this will cause micro cracks and loss of strength.

During thawing process, more voids formation will occur which resulted in increased deformation. When lime additive was implemented, the deformation increases up to 20 cycles of freezing- thawing, then the rate of increases decreases. This could be attributed to the fact that the Pozzolanic action of lime continues with time which controls the deformation. Such finding was in agreement with [16].

Table 5. Effect of number of (freezing-thawing) cycles on deformation of asphalt stabilized soil.

| Mix type | Deformation (mm) | Number of load repetitions | % change in deformation |

| 6%cutback asphalt+2% silica fumes | 0.125 | 1660 | |

| 6%cutback asphalt+2% silica fumes) exposed to 10 cycle | 0.569 | 1650 | +355 |

| 6%cutback asphalt+2% silica fumes) exposed to 20 cycle | 0.595 | 1610 | +376 |

| 6%cutback asphalt+2% silica fumes) exposed to 30 cycle | 0.750 | 21 | +500 |

| 6%cutback asphalt+2% lime | 0.069 | 1625 | |

| 6%cutback asphalt+2% lime)exposed to 10 cycle | 0.281 | 1630 | +307 |

| 6%cutback asphalt+2% lime)exposed to 20 cycle | 0.391 | 1630 | +467 |

| 6%cutback asphalt+2% lime)exposed to 30 cycle | 0.406 | 1625 | +489 |

Fig. 15. Effect of (freezing-thawing) cycles on the deformation of asphalt stabilized soil.

Table 5 shows the deformation and No. of load repetition for asphalt stabilized soil with optimum Nano-materials for Lime and silica fumes exposed to (0, 10, 20 and 30) cycles of (freezing-thawing) and (heating-cooling) after testing period of (30 minutes). It indicates the failure of silica fumes specimen at 30 cycles of freezing and thawing, while lime specimens sustained the tensile stresses throughout the testing cycles.

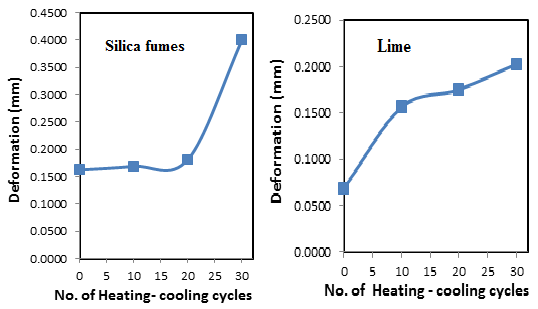

4.5. Heating-Cooling Cycles Test

This test was carried out for (0, 10, 20 and 30) cycles by heating the specimens at (20±2 ˚C) and cooling at (+5 ˚C) and then tested by applying repeated indirect tensile stress.

Fig. 16. shows the effect of number of (heating-cooling) cycles on the deformation of the asphalt stabilized soil mixed with silica fumes. Specimen’s shows no significant variation in deformation at 10 and 20 cycles, while the deformation was increased at cycle above 20, this behavior may be attributed to the limitation of Pozzolanic action of silica fumes which could sustain the strength.

The effect of lime additive was more pronounced after 10 cycles, it can be seen that the rate of increment in deformation decreases as the number of (heating-cooling) cycles increases. This may be attributed to the positive effect of heating on the chemical reaction of lime with the clay portion of the soil, the gain in strength continue with time. Such findings are further supported with the data listed in Table 6.

Fig. 16. Effect of (heating-cooling) cycles on the deformation of asphalt stabilized soil.

Table 6. Effect of number of (heating-cooling) cycles on deformation of asphalt stabilized soil.

| Mix type | Deformation (mm) | Number of load repetitions | % change in deformation |

| 6%cutback asphalt+2% silica fumes | 0.152 | 1660 | |

| 6%cutback asphalt+2% silica fumes)exposed to 10 cycle | 0.172 | 1635 | +13 |

| 6%cutback asphalt+2% silica fumes)exposed to 20 cycle | 0.181 | 1630 | +19 |

| 6%cutback asphalt+2% silica fumes)exposed to 30 cycle | 0.400 | 1620 | +163 |

| 6%cutback asphalt+2% lime | 0.069 | 1625 | |

| 6%cutback asphalt+2% lime)exposed to 10 cycle | 0.156 | 1575 | +127.18 |

| 6%cutback asphalt+2% lime)exposed to 20 cycle | 0.178 | 1595 | +154.36 |

| 6%cutback asphalt+2% lime)exposed to 30 cycle | 0.209 | 1605 | +195.2 |

Table 7. Indirect tensile strength value for asphalt stabilized soil.

| Mix type | Indirect tensile strength (MPa) | % change in(ITS) |

| Soil+6% cutback asphalt | 137.9 | |

| Soil+6% cutback asphalt+0.5%fly ash | 128.7 | -7.2 |

| Soil+6% cutback asphalt+1.5%fly ash | 110.1 | -20.2 |

| Soil+6% cutback asphalt+2%fly ash | 82.8 | -40 |

| Soil+6% cutback asphalt+0.5%silica fumes | 109.8 | -20.4 |

| Soil+6% cutback asphalt+1.5%silica fumes | 128.4 | -7 |

| Soil+6% cutback asphalt+2%silica fumes | 147.1 | +6.6 |

| Soil+6% cutback asphalt+0.5%lime | 165.5 | +20 |

| Soil+6% cutback asphalt+1.5%lime | 182.7 | +32.5 |

| Soil+6% cutback asphalt+2%lime | 192.6 | +39.6 |

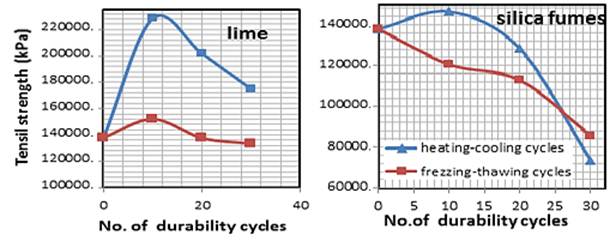

4.6. Impact of Nano Additives and Durability Cycles on Indirect Tensile Strength

The variation of indirect tensile strength of asphalt stabilized soil mixed with different percentage of Nano-materials additives are shown in Table 7. The tensile strength increase by (39.6%) when (2%) lime was added while its increase by (6.67%) when (2%) silica fumes was added.

This behavior may be attributed to that the presence of additives in the mixture, strengthens the bonding between the soil particles as it is a Pozzolanic material in addition to the strength which was provided by the binder (cutback asphalt), and as a result the mixture exhibit high resistance to tensile forces. On the other hand, fly ash sows negative impact on tensile strength. Similar findings were reported by [4].

Table 8. illustrates that after (heating-cooling) cycles for asphalt stabilized soil mixed with 2% lime, the indirect tensile strength change in the range of (+18.6%, +9.4%, -9.2%) for specimens of (10, 20 and 30) durability cycles respectively. While for asphalt stabilized soil mixed with silica fumes, the indirect tensile strength reduces in the range (-0.5%, -12.8%, -50%) for specimens of (10, 20 and 30) cycles respectively when compared with specimens without any cycles. This behavior may be attributed to the Pozzolanic action of Nano-materials additives used. Also it was observed that after (freezing-thawing) cycles for (soil+6%cutback asphalt+2%lime) mixture, the indirect tensile strength decrease in the range of (21.1%, 28.5%, 30.7%) for specimens of (10, 20 and 30) cycles respectively, while for (soil+6%cutback asphalt+2% silica fumes) mixture, the indirect tensile strength decrease in the range of(18.1%, 23.3%, 41.8%) for specimens of (10, 20 and 30) cycles respectively when compared with specimens without any cycles. The increment of tensile strength in case of lime treated specimens at heating- cooling cycles may be attributed to the positive effect of heating on the chemical reaction of lime with the clay portion of the soil. Fig.17. Summarises the impact of durability test on the indirect tensile strength.

Table 8. Influence of durability cycles on indirect tensile strength for asphalt stabilized soil.

| Mix type | Indirect tensile strength(MPa) | %change in ITS |

| 6% cutback asphalt+2%lime | 192.6 | |

| 6%cutback asphalt+2%lime exposed to 10 cycles of(heating-cooling) | 228.4 | +18.6 |

| 6%cutback asphalt+2%lime exposed to 20 cycles of(heating-cooling) | 201.8 | +9.4 |

| 6%cutback asphalt+2%lime exposed to 30 cycles of(heating-cooling) | 174.9 | -9.2 |

| 6%cutback asphalt+2%lime exposed to10 cycles of(freezing-thawing) | 152.1 | -21.1 |

| 6%cutback asphalt+2%lime exposed to20 cycles of(freezing-thawing) | 137.7 | -28.5 |

| 6%cutback asphalt+2%lime exposed to 30cycles of(freezing-thawing) | 133.4 | -30.7 |

| 6%cutback asphalt+2% silica fumes | 147.1 | |

| 6%cutback asphalt+2% silica fumes exposed to 10 cycles of (heating-cooling) | 146.4 | -0.5 |

| 6%cutback asphalt+2% silica fumes exposed to 20 cycles of (heating-cooling) | 128.2 | -12.8 |

| 6%cutback asphalt+2% silica fumes exposed to 30 cycles of (heating-cooling) | 73.5 | -50 |

| 6%cutback asphalt+2% silica fumes exposed to 10 cycles of (freezing-thawing) | 120.5 | -18.1 |

| 6%cutback asphalt+2% silica fumes exposed to 20 cycles of (freezing-thawing) | 112.9 | -23.3 |

| 6%cutback asphalt+2% silica fumes exposed to 30 cycles of (freezing-thawing) | 85.6 | -41.8 |

Fig. 17. Impact of durability test on the indirect tensile strength.

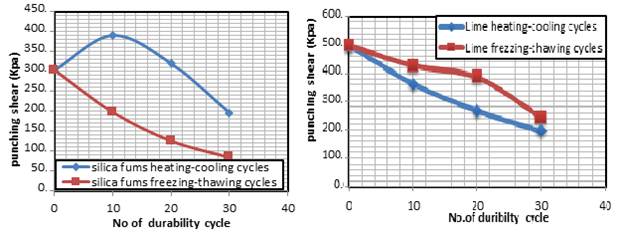

4.7. Impact of Nano Additives and Durability Cycles on Punching Shear Strength

Table 9. Illustrated the variation of punching shear strength of asphalt stabilized soil mixed with different percentage of Nano-materials additives. It was observed that the punching shear increases in the range of (15.8%, 21.1%, and 46.9%) for lime treated specimens as compared with untreated specimens. This behaviour may be attributed to the Pozzolanic action of lime additives with soil particles, which increases the bonding between soil particles. Other types of Nano materials additives (silica fumes and fly ash) exhibit negative impact on punching shear strength of asphalt stabilized soil. Such behaviour agrees with [1] work.

Table 9. Punching shear strength for stabilized soil.

| Mix type | Punching shear (kPa) | % change in punching shear |

| Soil+6% cutback asphalt | 339.1 | |

| Soil+6% cutback asphalt+0.5%fly ash | 303.4 | -10.5 |

| Soil+6% cutback asphalt+1.5%fly ash | 213.5 | -37.0 |

| Soil+6% cutback asphalt+2%fly ash | 182.3 | -46.2 |

| Soil+6% cutback asphalt+3%fly ash | 160.6 | -52.6 |

| Soil+6% cutback asphalt+0.5%silica fumes | 212.8 | -37.2 |

| Soil+6% cutback asphalt+1.5%silica fumes | 266 .9 | -21.3 |

| Soil+6% cutback asphalt+2%silica fumes | 303.4 | -10.5 |

| Soil+6% cutback asphalt+0.5%lime | 392.6 | +15.8 |

| Soil+6% cutback asphalt+1.5%lime | 407.4 | +21.1 |

| Soil+6% cutback asphalt+2%lime | 498.2 | +46.9 |

Table 10. Effect durability cycles on punching shear strength of asphalt stabilized soil.

| Mix type | Punching shear (kPa) | %change in punching shear |

| 6% cutback asphalt+2%lime | 498.2 | |

| 6%cutback asphalt+2%lime exposed to 10 cycles of(heating-cooling) | 363.1 | -27.1 |

| 6%cutback asphalt+2%lime exposed to 20 cycles of(heating-cooling) | 266.9 | -46.4 |

| 6%cutback asphalt+2%lime exposed to 30 cycles of(heating-cooling) | 196.6 | -60.5 |

| 6%cutback asphalt+2%lime exposed to10 cycles of(freezing-thawing) | 426.6 | -14.7 |

| 6%cutback asphalt+2%lime exposed to20 cycles of(freezing-thawing) | 386.1 | -22.5 |

| 6%cutback asphalt+2%lime exposed to 30cycles of(freezing-thawing) | 243.6 | -51.1 |

| 6%cutback asphalt+2% silica fumes | 303.4 | |

| 6%cutback asphalt+2% silica fumes exposed to 10 cycles of (heating-cooling) | 390.3 | +28.6 |

| 6%cutback asphalt+2% silica fumes exposed to 20 cycles of (heating-cooling) | 319.8 | +5.4 |

| 6%cutback asphalt+2% silica fumes exposed to 30 cycles of (heating-cooling) | 196.3 | -35.3 |

| 6%cutback asphalt+2% silica fumes exposed to 10 cycles of (freezing-thawing) | 197.9 | -34.7 |

| 6%cutback asphalt+2% silica fumes exposed to 20 cycles of (freezing-thawing) | 125.8 | -58.5 |

| 6%cutback asphalt+2% silica fumes exposed to 30 cycles of (freezing-thawing) | 84.4 | -72.1 |

As demonstrated in Table 10, asphalt stabilized soil specimens treated with silica fumes show positive effect on punching shear after exposure to 10 and 20 cycles of (heating – cooling). While lime shows dramatic reduction in punching shear strength after exposure to both types of durability cycles. This may be attributed to the damaging effect of such cycles on the bonding power and particles interlock which was distracted by the durability cycles. Fig. 18 summarises the impact of Nano additives on punching shear strength.

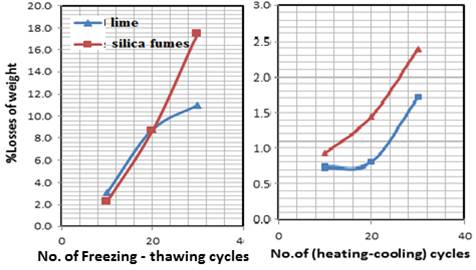

4.8. Impact of Nano Additives and Durability Cycles on Losses in Weight

When the moisture in the soil was frozen, the volume of water expands, so the pore size between soil particles increases and when it melts the pore sizes decrease. Thus, the (freezing-thawing) cycles and (heating-cooling) cycles will change the structure coupled between soil particles which will change the mechanical properties of soil such as density, strength. Table 11. Illustrates the variation in the percentage of losses in weight of asphalt stabilized soil after practicing durability test. It can be observed that the percentage of losses in weight increases with the increase in number of cycles. This behavior may be attributed to the continuous freezing of moisture, formation of ice crystals, and expansion of its volume which causes disintegration of the mix. The additives such as lime or silica fumes which exhibited Pozzolanic reaction with moisture occurred due to (freezing-thawing) cycles and (heating-cooling) cycles. This could lead to the abrasion of the external shell of the specimens, also the volatiles and moisture in soil mixture were evaporated with the progress of the curing periods. Lime treated mixes exhibit lower losses in weight at both of the durability cycles when compared to silica fumes even at higher number of durability cycles. Finally, it was demonstrated by Fig. 19 that the mixture of (soil+6% cutback asphalt) with optimum Nano-materials for lime and silica fumes meet the durability requirement from loss in weight point of view, and according to the manual of [8].

Fig. 18. Impact of durability cycles on punching shear strength.

Fig. 19. Impact of durability cycles on the percentage of loss in weight.

Table 11. Loss in weight of asphalt stabilized soil through durability test.

| Mix type | %Losses in weight |

| Soil+6%cutback asphalt+2%lime exposed to 10 cycles of(heating-cooling) | 0.7 |

| Soil+6%cutback asphalt+2%lime exposed to 20 cycles of(heating-cooling) | 0.8 |

| Soil+6%cutback asphalt+2%lime exposed to 30 cycles of(heating-cooling) | 1.7 |

| Soil+6%cutback asphalt+2%lime exposed to10 cycles of(freezing-thawing) | 3.1 |

| Soil+6%cutback asphalt+2%lime exposed to20 cycles of(freezing-thawing) | 8.8 |

| Soil+6%cutback asphalt+2%lime exposed to 30cycles of(freezing-thawing) | 11.0 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 10 cycles of (heating-cooling) | 0.9 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 20 cycles of (heating-cooling) | 1.4 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 30 cycles of (heating-cooling) | 2.4 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 10 cycles of (freezing-thawing) | 2.3 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 20 cycles of (freezing-thawing) | 8.7 |

| Soil+6%cutback asphalt+2% silica fumes exposed to 30 cycles of (freezing-thawing) | 17.5 |

5. Conclusions

Based on the testing program, the following conclusion could be drawn:

1. From the result of repeated indirect tensile strength test, it was found that the deformation of asphalt stabilized soil decreased by 47.6% and 8% when 2% of lime or silica fumes were added respectively. However, the variation in the deformation behavior of different percentages of fly ash was not significant, and increases with increment of coal fly ash content.

2. From the result of durability by using repeated indirect tensile strength test, it was found that for lime treated mixes exposed to (10, 20 and 30) cycles of (freezing-thawing), the value of deformation increases with increase in number of durability cycles in the range of (307%, 467% and 489%) respectively. While for specimens exposed to (10, 20 and 30) cycles of (heating-cooling), the value of the deformation increases in the range of (127%, 154%, and 195%) respectively as compared with specimens before any cycles.

3. From the result of durability by using repeated indirect tensile strength test, it was found that for silica fumes treated mixes exposed to (10, 20 and 30) cycles of (freezing-thawing), the value of deformation increases with increase in number of durability cycles in the range of (355%%, 376%, 500%) respectively. While for specimens exposed to (10, 20 and 30) cycles of (heating-cooling), the value of the deformation increases in the range of (13%, 19%, and 163%) respectively as compared with specimens before any cycles.

4. The value of indirect tensile strength increases by (6.6%) and (39.6%) when (2%) silica fumes or lime was added to the asphalt stabilized soil respectively. while it decreases by (40%) when (2%) coal fly ash was added to the mixture as compared with specimens without any additives.

5. The value of punching shear strength increases by (47.4%) when (2%) lime was added, while it decreases by (10.5%) and (52.6%) when (2%) silica fumes or (3%) coal fly ash were added to the mixture respectively as compared with specimens without any additives.

6. The values of indirect tensile strength and punching shear strength for asphalt stabilized soil specimens mixed with optimum Nano-materials additives such as lime and silica fumes, and exposed to (10, 20 and 30) cycles of (freezing-thawing) and (heating-cooling) decreases with increase in number of durability cycles.

7. The percent losses in weight for asphalt stabilized soil specimens mixed with optimum Nano-materials such as lime and silica fumes, and exposed to (10, 20 and 30) cycles of (freezing-thawing) and (heating-cooling) increases with increase in number of durability cycles.

References

- Jasim .A. L., (2015),"Assessing the Durability of Asphalt Stabilized Gypseous Soil Embankment". M. Sc. Thesis, Department of Civil Engineering, University of Baghdad.

- Prakash, S. and Sarsam, S., (1981), "Effect of Curing Time on Soil Cutback Mix for Faloga Soil" IRC, Indian Highways, Vol. 9, No. 10.

- Sarsam, S. I., (1979), "Soil-Cutback Mix for Base Course Construction in Some Parts of Iraq" M. Sc. Thesis, Department of Civil Engineering, University of Sulaimaniah.

- Al-Tai A. H, (2015),"Stabilization of Nasiriya Collapsible soil using combination of emulsified asphalt and additives". M. Sc. Thesis, Department of Civil Engineering, University of Baghdad.

- Acosta, (2002)," The use of cement or lime, fly ash in soil stabilization for road construction "reported In Germany, Vosteen. (sundoc.bibliothek.uni-halle.de/diss-online/06/.../t2.pdf )

- Al-Safarani, M.G, (2007)," Improvement Ability of Gypseous Soil Characteristics Using Cutback Asphalt and Lime" M. Sc. Thesis, Civil Engineering Department, University of Al – Mustansiria.

- Aldaood A., Bouasker M. Al-Mukhtar M., (2014) "Impact of wetting–drying cycles on the microstructure and mechanical properties of lime-stabilized Gypseous soils", Engineering Geology,Journal ISSN,Vol.174,23 May, P (11-21).

- US Army Corps of Engineers (1989) "Soil stabilization for pavement mobilization construction" EM 1110-3-137.

- Husain A. (2015) "Effect of Nano materials on the durability of asphalt stabilized soil", M.Sc. Thesis, Department of Civil Engineering, University of Baghdad.

- Sarsam S. I. and Ibrahim, S. W.,(2008),"Contribution of Liquid Asphalt in Shear Strength and Rebound Consolidation of Gypseous Soil" Engineering and Technology, Vol. 26, No. 4.

- Annual book of ASTM standard, (2011), Volume 04.03, American Society for Testing and Materials, West Conshohocken, USA.

- Jimenez RA (1974). "Testing for De-bonding of Asphalt from Aggregates". Transportation Research Record 515, TRB, National Research Council, Washington, D.C., pp. 1–17.

- Sarsam S (2007). "A study on aging and recycling of asphalt concrete pavement". University of Sharjah Journal of Pure & Applied Sciences, 4(2): 79-96.

- Onyelowe K. C and Okafor F. O., (2012)," A comparative review of soil modification methods ", ARPN Journal of Earth Sciences, vol. 1, No. 2, November.

- Olutaiwo, A. O., Adedimila, A. S., and Sidiq, U.,(2008), "An Examination of the Use of Liquid Asphalt Binders in Road Works in Nigeria" Journal of Engineering and Applied Sciences, Vol. 3, No. 1, (p 134-142).

- Yildiz.M and Soganci A.S., (2012),"Effect of freezing and thawing on strength and permeability of lime stabilized clays", Scientia Iranica 19(4).1013-1017.