Recycling of Organic Waste Using Eudrilius Eugeniae- a Stategy for Kitchen Waste Management

Okareh O. T.1, *, Oloye T. O.1, Taiwo L. B.2

1Department of Environmental Health Sciences, Faculty of Public Health, University of Ibadan, Ibadan, Nigeria

2Institute of Agricultural Research & Training, Obafemi Awolowo University, Ibadan, Nigeria

Abstract

Improper management of organic waste in Nigeria constitutes one of the major health risks to the public. Vermicomposting has been identified to be a potential technique for the efficient management of organic wastes. However, little is known about vermicomposting and its usefulness in Nigeriia. This study was therefore designed to assess the effectiveness of Eudrilius eugeniae in the management of organic waste. Fresh kitchen wastes were collected, shredded and mixed with cow dung from an abattoir in a ratio 2:1. Samples were analysed for physicochemical parameters; pH, Organic Carbon (OC), Nitrogen (N), Phosphorus (P) and Potassium (K) using American Public Health Association (APHA) Method. Six kilogramme of the waste mixture was precomposted and vermicomposted using earthworms of the species Eudrilius eugeniae for 2 months. Vermicomposting parameters; temperature (0C) and Moisture Content MC (%) were determined weekly. Eudrilius eugeniae and vermicompost were harvested and weighed. Vermicompost (VC) was analysed for physicochemical parameters. The pH, proportions of OC, N, P, K and Carbon-Nitrogen (C-N) ratio of the waste mixture were: 5.6, 20.2 %, 0.9 %, 0.1 %, 0.3 %, and 23.4 respectively. The mean temperature and proportion of MC of the vermicomposting process were 25.6 ± 8.30C and 54.1 ± 5.9% respectively. An odourless, granular and homogenous vermicompost of 2.8 kg was obtained. The pH, proportions of OC, N, P, K and C-N ratio of vermicompost were: 7.3, 11.3 %, 1.3 %, 2.0 %, 2.5 % and 8.8 respectively. The optimum temperature, reduction in organic carbon, carbon: nitrogen ratio and the high mineralization of nitrogen showed that verrmicomposting is an environmentally acceptable and economically viable technique for recycling organic waste (kitchen waste) into vermicompost.

Keywords

Eudrilius Eugeniae, Recycling Organic Waste, Vermicomposting, Kitchen Waste, Cow Dung

Received: April 9, 2015

Accepted: April 25, 2015

Published online: May 27, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Over the last few years the problem of efficient disposal and management of organic wastes has become more rigorous due to rapidly increasing population, intensive agriculture and industrialization. Production of large quantities of organic waste all over the world poses major environmental (offensive odors, contamination of ground water and soil) and disposal problems (Edwards and Bater, 1992). Therefore, the disposal of different types of wastes has become very important issue for maintaining healthy environment.With the need to divert increasing amounts of organic waste from landfill, more emphasis needs to be placed on composting suitable wastes such as kitchen waste and animal waste in addition to botanical waste. There is enormous potential to transform these types of wastes into high specification compost products, especially now that in-vessel composting systems and other innovative methods of stabilising and maturing waste, such as vermicomposting, are becoming established.

Vermicomposting technology using earthworms as versatile natural bioreactors for effective recycling of organic wastes to the soil is an environmentally acceptable means of converting waste into nutritious composts for crop production. vermicomposting has been reported to be a viable, cost-effective and rapid technique for the efficient management of the organic wastes (Logsdson, 1994). Vermicomposting could be an adequate technology for the transformation of organic waste into valuable products (Elvira et al., 1997). Vermicomposting as a principle that originates from the fact that earthworms during the process of feeding, fragment the substrate thereby increasing its surface area for further microbial colonization (Chan and Griffiths, 1988). During this process, the important plant nutrients such as nitrogen, potassium, phosphorus and calcium present in the feed material are converted through microbial action into forms that are much more soluble and available to plants than those in the parent substrate (Ndegwa and Thompson, 2001) while the worms themselves provide a protein source for animals feeds (Hartenstein, 1981).

The role of earthworms in the breakdown of organic debris on soil surface and soil turn over process was first highlighted by Darwin (1881). The ability of earthworms to consume a wide range of organic residues such as sewage sludge, animal wastes, crop residues, and industrial refuse has been fully established (Mitchell et al., 1980; Edwards et al., 1985; Chan & Griffiths 1988; Hartenstein & Bisesi 1989). In the process of feeding, earthworms fragment the waste substrate, enhance microbial activity and the rates of decomposition of the material, leading to a composting or humification effect by which the unstable organic matter is oxidized and stabilized. The end product, commonly termed vermicompost and obtained as the organic wastes pass through the earthworm gut, is quite different from the parent waste material.

2. Methodology

The household organic wastes selected for this study were majorly kitchen waste excluding salty or cooked food and cow dung. The kitchen wastes were collected from the selected food canteens within University College Hospital, Ibadan Oyo State. Fresh cow dung was collected from Bodija Abattoir, Ibadan after it has been confirmed that the cows are free of any form of sickness, treatment or immunization.

The earthworms used for this study Eudrilius eugeniae were collected from the muddy and marshy areas of botanical garden in University of Ibadan, by digging, and hand sorting using hand trowel. Eudrilius eugeniae were identified to species level at the Department of Zoology and the remaining earthworms that does not belong to the required species were discarded.

The wastes collected from the canteens consisted of fresh vegetable waste, plaintain peels, green peas waste, yam peels, and cabbage wastes. The kitchen wastes were shred to increase its surface area and were mixed properly to ensure a homogenous composition.

Cow dung and the shredded kitchen waste were mixed in a ratio 1:2 on dry basis. A grab sample of the waste mixture was taken to the laboratory for physico-chemical analysis. Two kilogram of the waste mixture was bagged and sealed in black polythene bags and were left under the sun for fourteen days. This was done to avoid exposure of worms to high temperature during the initial thermophilic stage of composting. On the 15th day, the waste mixtures were opened, air dried and tested for worm acceptability.

Worm acceptability was conducted by introducing two adult Eudrilius eugeniae into a small quantity of moistened precomposted waste and was monitored for the survival of worms and appearance of worm casts. After two days, the sample was accepted as palatable (i.e. with casts and surviving).

The vermicomposting process took place underneath the rear staircase of Ajose Building after formal permission has been taken and approved. In the vermicomposting process, three locally made earthen pots A, B, C, (3.5 kg, 3 kg, 3 kg respectively) and each of size (13 cm height and 19 cm diameter) with holes drilled around it to enhance adequate aeration and proper drainage of excess water. These pots were selected for this study because they are locally made, cheap and easy to get, it has the ability to conserve moisture and protection from light. The pots were covered with 2 mm wire mesh to prevent migration of the worms.

About 1.5 kg of precomposted waste (dry weight) was weighed into each pot and moistened with about 1 litre of water but not wet because much water kills the worms and less water chase them away. Thirty (30) adult earthworms Eudrilius eugeniae weighing 38 g, 40 g, and 45 g was inoculated into pot A, B, and C respectively. The pots were covered to protect the vermicomposting bed from pests and direct light. The vermicomposting beds were moistened on a regular basis with 0.25 litre of water to ensure adequate moisture. The temperature of the vermicomposting bed were taken by piercing a compost thermometer into the middle of the vermicomposting bed, and sample were also drawn and taken to the laboratory for pH and moisture content determination at different intervals of 0, 7, 14, 21, 28, 35, 42, 49 and 56 days. The 0 day refers to the initial day of the vermicomposting. On the 60th day moistening was stopped. Vermicomposting was stopped after three days and worms were harvested by hand sorting according to Svendson (1955) and the sorted worms were weighed. The vermicompost from pots A, B, and C was then combined to form a bulk sample. Vermicompost was air dried for four days and passed through 2 mm sieve. Sample was taken to the laboratory for physico-chemical analysis.

The limitation of this study lies principally on the effect of Eudrilius eugeniae exposure to sunlight. these organisms tends to migrate from the pot when exposed to sunlight or when the biomass is not adequately moistened. The experiment therefore, require an environment devoid of sunlight and the organic mixtures frequently and adequately moistened.

Gold Standards Adopted for the Management of the Organic Waste

The gold standards used for this study included:

i. Eudrilius eugeniae species selectivity / sorting method.

ii. Eudrilius eugeniae acceptability test.

iii. Kitchen wastes sream exclusion and inclusion criteria.

iv. Health status of animals (cows) that produce the dungs used for the study.

v. Quality of the vermicompost (NPK).

3. Results

3.1. Physico-Chemical Characteristics of Waste Mixture (Raw Biomass)

The physical analysis of the raw biomass for the vermicomposting process revealed a heterogenous waste mixture of 6 kg (weight), composed of plaintain peels, yam peels, vegetable wastes, cabbage wastes, green peas and cowdung with a pH value of 5.6 and electrical conductivity of 1105 µs/cm.

Table 1. Chemical characteristics of the waste mixture (raw biomass)

| Parameters | Unit | Values |

| Calcium (Ca) | % | 0.44 |

| Magnesium (Mg) | % | 0.41 |

| Sodium (Na) | % | 2.18 |

| Organic Carbon (C) | % | 20.16 |

| Nitrogen (N) | % | 0.86 |

| Phosphorus (P) | % | 0.12 |

| Potassium (K) | % | 0.25 |

| Sulphate (SO4) | % | 2.54 |

| Iron (Fe) | % | 0.43 |

| Maganese (Mn) | mg/Kg | 132.00 |

| Zinc (Zn) | mg/Kg | 104.50 |

| Lead (Pb) | mg/Kg | 42.00 |

| Copper (Cu) | mg/Kg | 11.50 |

| Nitrate (NO3) | mg/Kg | 7.29 |

| C: N | 23.44 |

The proportions of Organic carbon, Nitrogen, Phosphorus, Potassium and Carbon-Nitrogen (C-N) ratio of the waste mixture inputted into vermicomposting process were: 20.2%, 0.9%, 0.1%, 0.3%, and 23.4 respectively. Other chemical characteristics of the waste mixture are shown in Table 1.

3.2. Temperature, pH, and Moisture Content of Vermicomposting Process

3.2.1. Temperature (0) of Vermicomposting Process

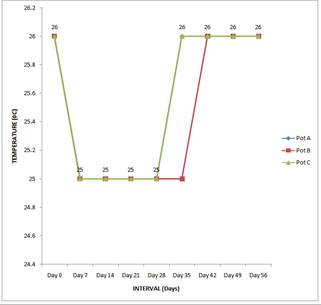

The mean temperature at which vermicomposting process occurred was 25.6 ± 8.30C. Table 2 showed the observed mean temperature in each vermicomposting pot A, B, and C. The highest temperature, 26.00C was observed in the three pots and least was 25.00C which was also observed in the three pots. Figure 1 shows the observed temperature in the pots during vermicomposting process.

Figure 1. Observed temperature in the pots during vermicomposting process.

Table 2. Observed temperatures in vermicomposting pot A, B, and C

| Temperature (0C) | Pot A | Pot B | Pot C |

| Mean | 25.50 | 25.50 | 25.50 |

| Maximum | 26.00 | 26.00 | 26.00 |

| Minimum | 25.00 | 25.00 | 25.50 |

3.2.2. Ph of Vermicomposting Process

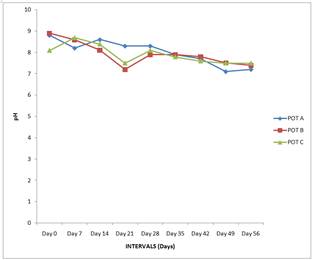

The mean pH at which vermicomposting process occurred was 8.0 ± 0.5. Table 3 shows the observed mean pH in each vermicomposting pot A, B, and C. Pot B has the highest pH value of 8.9 while pot A has the least pH value of 7.1. Figure 2 shows the observed pH in the pots during vermicomposting process.

Figure 2. Observed pH in the pots during vermicomposting process.

Table 3. Observed pH in vermicomposting pot A, B, and C

| pH | Pot A | Pot B | Pot C |

| Mean | 7.95 | 8.15 | 8.10 |

| Maximum | 8.80 | 8.90 | 8.70 |

| Minimum | 7.10 | 7.40 | 7.50 |

3.2.3. Moisture Content (%) of Vermicomposting Process

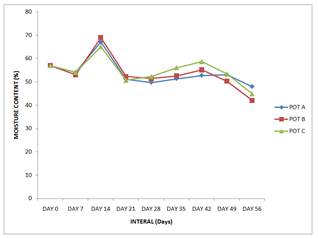

The mean moisture content level of the vermicomposting process was 54.1 ± 5.9%. Table 4 showed the mean moisture content level in each vermicomposting pot A, B, and C. The highest moisture content level 69.0% was observed in pot B and the least moisture content level 42.1% was also observed in pot B. Figure 3 shows the observed moisture content in the pots during vermicomposting process.

Figure 3. Observed moisture content (%) in pots during vermicomposting process

3.3. Physico-Chemical Characteristics of Vermicompost

At the end of vermicomposting, an odourless, granular and homogenous vermicompost of 2.8 kg was obtained with a pH value of 7.3 and electrical conductivity of 1345 µs/cm.

The proportions of OC, N, P, K and C-N ratio of vermicompost were: 11.3 %, 1.3 %, 2.0 %, 2.5 % and 8.8 respectively. Table 5 showed the other chemical characteristics of vermicompost obtained at the end of vermicomposting.

Table 4. Moisture content observed in vermicomposting pot A, B, and C.

| Moisture Content (%) | Pot A | Pot B | Pot C |

| Mean | 57.56 | 55.57 | 54.99 |

| Maximum | 67.14 | 69.02 | 65.08 |

| Minimum | 48.01 | 42.12 | 44.89 |

Table 5. Chemical characteristics of vermicompost

| Parameters | Unit | Values |

| Calcium (Ca) | % | 3.49 |

| Magnesium (Mg) | % | 0.44 |

| Sodium (Na) | % | 0.83 |

| Organic Carbon (C) | % | 11.25 |

| Nitrogen (N) | % | 1.26 |

| Phosphorus (P) | % | 2.04 |

| Potassium (K) | % | 2.50 |

| Sulphate (SO4) | % | 3.93 |

| Iron (Fe) | % | 148.90 |

| Maganese (Mn) | mg/Kg | 277.00 |

| Zinc (Zn) | mg/Kg | 66.89 |

| Lead (Pb) | mg/Kg | 40.00 |

| Copper (Cu) | mg/Kg | 37.00 |

| Nitrate (NO3) | mg/Kg | 14.28 |

| C: N | 8.79 |

4. Discussion

4.1. Physical and Chemical Characteristics of Waste Mixture (Raw Biomass)

A heterogenous waste mixture of about 8kg consisting of cow dung, vegetable waste, plantain peels, yam peels, cabbage waste and green peas waste has a pH of 5.6. The pH of the waste mixture is slightly acidic and it falls within the optimum pH range of 5- 9 for vermicomposting as reported by Griengo et al, (2008). This is also in agreement with Guerrero (2004), that Eudrilius eugeniae grows well in an environment with a pH of 5-9.

The Nitrogen, Phosphorus, Potassium (NPK) values of the waste mixture is low as shown in Table 1. Although, there is no standard NPK value for organic waste used for vermicompoting, chemical characteristics of the waste mixture depend on its component. The Carbon : Nitrogen (C: N) ratio of the waste mixture is 20:1. This is a reflection of the waste components and does not fall within the C: N ratio range of 25:1 to 30:1 for vermicomposting according to Rostami et al., (2010). This is because the bacteria involved in composting digest carbon twenty five to thirty times faster than they digest nitrogen.

4.2. Temperature, PH and Moisture Content of Vermicomposting Process

4.2.1. Temperature Observed During Vermicomposting Process

The mean temperature observed in the three vermicomposting pots A, B, and C was 25.6 ± 8.30C and the minimum and maximum temperature observed during the vermicomposting process was 250C and 260C respectively. This is in agreement with Rostami et al (2009a) who stated that a temperature range around 150C and 250C is more appropriate for vermicomposting. This is also supported by the study of Nagavallema et al., (2004) which stated that earthworms should be released into organic residue at a temperature around 250C. Also, according to study of Griengo et al, (2008), Eudrilius eugeniae has a preference for a temperature of not more than 300C and cannot tolerate extended temperature below 160C. They further stated that highest maturation and cocoon production was obtained between 220C and 250C. The temperature observed in the vermicopmosting pots may be due to the passage of adequate air into the pots through the holes around the earthen pots used.

4.2.2. PH Observed during Vermicomposting Process

The minimum and the maximum pH observed in the three vermicomposting pots A, B, and C during vercomposting process conform to the studies of Griengo et al, (2008) and Guerro, (2004). They observed that the optimum pH for vermicomposting and the growth of Eudrilius Eugeniae is between 5 and 9. This is unlike thermophilic composting, occurring at a narrow pH between 7 and 8.

4.2.3. Moisture Content Observered During Vermicomposting Process

The mean, minimum and maximum moisture content values observed during vermicomposting process and in the three vermicomposting pots A, B, and C were in agreement with the observation of Griengo et al., (2008) of moisture content below 60% but different from the observation of Palsania et al., (2008) of 75 ± 5% and Rostami et al., (2010a) of 65% to 75% as the suitable moisture content range for vermicomposting. The difference in the moisture content observed during this study could be as a result of the time of sample collection prior to or before moistening and the organic residue vermicomposted. However, vermicomposting activities were optimum in the pots during this study. This might have been enhanced by the conserving nature of the local earthen pots used for the process because earthworm’s survival depends solely on a moist but not wet environment.

4.3. Physical and Chemical Characteristics of Vermicompost

The earthworms, Eudrilius Eugeniae used in this study modify the physical and chemical characteristics of the waste mixture. The final vermicomposts were odour free, granular and homogenous as shown in plate 4.1 and 4.2 and decreased in weight. pH and electrical conductivity of vermicompost was higher than that obtained from the waste mixture. The pH of the waste mixture increased from acidic to neutral. This is in agreement with Nagavallemma et al., (2004) who observed the pH of vermicompost to be around 7. Possible contributions to the near neutral pH of vermicompost may be the secretion of NH4+ ions and the activity of calciferous glands in earthworms.The calciferous glands contain carbonic anhydrase which catalyse the fixation of CO2 as CaCO3, thereby preventing the fall in pH (Kale et al., 1982). Ndegwa and Thompson (2000) also reported that shift in pH values may be due to N and P mineralization and conversion of the organic material into intermediate of organic acids. Pramanik et al (2007) also postulated that decomposition of organic matter leads to the formation of ammonium (NH4+) and humic acids. The combined effect of these two oppositely charged groups actually regulates the pH of vermicompost leading to a shift of pH towards neutrality or acidity.

Electrical conductivity (EC) of vermicomposts was higher than initial waste mixture. The EC reflects the salinity of any material and it is a good indicator of the applicability and utility of vermicompost for agricultural purposes. This increase in EC might have been due to release of different mineral ions, such as phosphate, ammonium, potassium etc. (Kaviraj and Sharma, 2003). These results are corroborated by Wong et al. (1997) who stated that increase in EC might have been due to the loss of weight of organic matter and release of different mineral salts in available forms (such as phosphate, ammonium, potassium).

The weight of vermicompost was reduced by about 65.6% through the voracious activities of the earthworms. This is in agreement with Mistra (2010) who stated a reduction of vegetable market waste through the action of Eudrilius Eugeniae by 62.22 %. This is also supported by Nagavallemma et al (2004)’s report that earthworms can consume various organic wastes and reduce the volume by 40-60 %. Each earthworm eats waste equivalent to its body weight and produces cast equivalent to about 50 % of the waste it consumes in a day.

The manurial value of vermicompost depends on several factors viz., nature of feed substrate, aeration, moisture, temperature and earthworm species used in the process. Hence it is essential to specify various physicochemical characteristics, such as pH, electrical conductivity, organic carbon, Nitrogen, total Phosphorus, Potassium, metal content etc. to quantify the dynamics of vermicomposting process as shown in Table 5.

Calcium (Ca) content was higher in vermicompost than in the waste mixture. Garg and Kaushik (2005) have also reported a significant increase in calcium content during vermicomposting of industrial wastes spiked with other organic waste. They have reported that earthworms drive the mineralization process and convert a proportion of calcium from binding form to free forms, resulting in its enrichment in worm casts. Nagavallemma (2004) also reported increase in calcium content (1.18-7.61). This contradicts the reduction in Calcium content reported by Sharma at al (2011).

Organic carbon reduced by 44.20 % in vermicompost. The combined action of earthworms and microrganisms may be responsible for organic carbon loss from the waste mixture in the form of CO2. This agrees with the report of Kaviraj and Sharma (2003) of 20-45 % reduction in Total Organic Carbon during vermicomposting of municipal or industrial waste. Similar observations have been reported by Prakash and Karmegam (2010) during vermicomposting of sugar industry waste and also by Yadav and Garg (2010) during vermicomposting of cow dung, poultry droppings and food industrial sludge employing Eisenia fetida. Inoculation of earthworms in decomposing organic waste material promotes biochemical degradation and their activity also promoted the colonization of decomposer communities of waste system, this is due to stable biological as well as chemical environmental conditions. Dominguez and Edwards (2004) has reported that earthworm fragments and homogenizes the ingested material through muscular action of their foregut and also adds mucus and enzymes to ingested material and thereby increases the surface area for microbial action, while microorganisms perform the biochemical degradation of waste material providing some extra-cellular enzymes within the worm’s gut. Thus combined action earthworms and microorganisms bring about carbon loss from the substrates in the form of CO2.

Nitrogen (N) content was higher in vermicompost than in waste mixture. The increased Nitrogen content in vermicompost may also be due to the release of nitrogenous products of earthworm metabolism through the cast (excreta), urine as well as mucoproteins. Also because Eudrilius eugineae belongs to the merenephridial species, the casts would be more enriched with Nitrogen since the urine produced by septal nephridia is voided into the gut and discharged along with the casts (Padmavathiamma et al., 2008). Micro-organisms in the gut of earthworms, using mucus secreted from the gut epithelium as an energy source, may fix atmospheric Nitrogen in quantities that are significant for the earthworm metabolism and as a source of Nitrogen for plant growth (Padmavathiamma et al., 2008).

Similar observation was reported by Yadav and Garg (2010) of increase in Nitrogen content in the range of 1.6-3.6 folds during vermicomposting of cow dung, poultry droppings and food industrial sludge employing Eisenia fetida. Kaushik and Garg (2004) also reported 2.0–3.2-fold increase in Nitrogen during vermicomposting of textile mill sludge mixed with cow dung and wheat straw. Plaza et al. (2007) have reported that the nitrogen content of vermicomposts increase due to mineralization of Carbon-rich materials and, possibly, due to the action of Nitrogen-fixing bacteria. Decreases in pH may be another important factor in nitrogen retention by vermicompost which otherwise may be lost as ammonia at higher pH values. Increase in nitrogen content in the final product in the form of mucus, nitrogenous excretory substances, growth stimulating hormones and enzymes from earthworms have also been reported by Tripathi and Bhardwaj 2004.

According to Viel et al. (1987), loss in organic carbon might be responsible for nitrogen enhancement. Earthworms also have a great impact on nitrogen transformations in manure, by enhancing nitrogen mineralization, so that mineral Nitrogen may be retained in the nitrate form (Atiyeh et al. 2000). However, in general the final nitrogen content of compost is dependent on the initial Nitrogen present in the waste and the extent of decomposition (Gaur and Singh, 1995).

There was over 90% increase in phosphorus content of vermicompost. This is greater than 33.7-54% increase observed by Yadav and Garg (2010) and 1.3-1.5 fold increase in phosphorus content observed by Sangwan et al. (2010) in the vermicomposting of press mud. Le Bayon and Binet (2006) have reported that some amount of phosphorus is converted to more available forms partly by earthworm gut enzymes, i.e., acid phosphatases and alkaline phosphatases. Actions of phosphorus-solubilizing microorganisms present in earthworm’s casts may also be responsible for the release of phosphorus in vermicomposting (Prakash and Karmegam, 2010).

There was about 90% increase in potassium (K) content in vermicompost than in waste mixture. Acid production by the microorganisms seems to be prime mechanism for solubilizing the insoluble potassium. The Potassium content observed in this study was greater than the 39.5-50% increase observed by Yadav and Garg (2010). Suthar (2008) reported 104– 160% increase in potassium content during vermicomposting. Sangwan et al. (2010) have also reported an increase in K in vermicomposts after bioconversion of sugar industry waste. Kaviraj and Sharma (2003) have reported that enhanced number of micro-flora present in the gut of earthworms might have played an important role in the process and increased potassium content during vermicomposting process.

Nitrate (NO3) content was higher in vermicompost than in the waste mixture. Tripathi and Bhardwaj, (2004); Garg et al., (2006); and Jadia and Fulekar, (2008), reported that nitrogen is released by earthworms during formation of various metabolic products like growth stimulating hormones and dead tissues get attached to the available nitrogen during vermicomosting. Apart from this, pH has a significant role in concentration of Nitrate during vermicomposting. Neutral pH stabilizes the content of nitrates, while at high pH, nitrogen is lost as volatile Ammonia (Garg et al., 2006; Suthar, 2007).

The Carbon: Nitrogen (C: N) ratio of the waste mixture reduced from 23.4 to 8.8 after vermicomposting. This is in agreement with the reduction of 2.0-5.2 fold C: N reduction observed by Yadav and Garg (2010) The C: N ratio indicates the degree stabilization of a waste, as carbon is lost as CO2 during vermicomposting whereas nitrogen content is enhanced during this process and these factors contributes to the lowering of C: N ratio. The decrease in C: N ratio and relative increase in the total nitrogen of vermicomposts may also be due to the loss of dry mass in terms of CO2 as well as moisture loss by evaporation during vermicomposting (Viel et al., 1987).

Kitchen wastes, cow dung and Eudrilius eugeniae can be collected free from households / institutions, abattoirs and wetlands respectively. Only the pots used for the experiment were bought, even at costs that were relatively cheap and affordable, since they are produced locally. Therefore, adopting this technology will be cost-effective in the management of the organic waste.

5. Conclusion

This study was undertaken to explore the use of Eudrilius eugeniae in vermicomposting for the efficient management of organic waste and specifically kitchen waste.

The optimum temperature at which vermicomposting occured, pH and moisture content observed during the process suggest that verrmicomposting is an environmentally acceptable and economical valuable technique for recycling organic waste into vermicompost even at household level.

The physico-chemical characteristics of the initial waste mixture inputted and the efficient actions of Eudrilius eugeniae thereby enriching it, determined the physico-chemical characteristics of vermicompost obtained. Decomposition of the organic waste mixture as indicated by decrease in C: N ratio was enhanced in the presence of Eudrilius eugeniae.

An odourless, granular and homogenous vermicompost obtained was rich in important plant nutrients (NPK) and decrease in C: N ratio. The product can be used for horticultural and agricultural purposes because of its fertilizing value.

This technology therefore, can be adopted and use at household level for improved public health status and effective organic waste management.

References

- Atiyeh, R.M, S. Subler, C.A. Edwards, G. bachman, J.D. Metzger, and W. Shuster 2000. "Effects of vermicomposs and composts on plan growth inhorticultural container media and soil". In Pedo biologia, 44, pp. 579-590.

- Chan, P.L.S. and Griffiths, D.A. 1988 The vermicomposting of pre-treated pig manure. Biological Wastes, 24: 57-69.

- Darwin, C, 1881. The Formation of Vegetable Moulds through the Action of Worms. Murray Publications, London

- Dominguez, J., and Edwards, C.A., 2004. Vermicomposting organic wastes: a review. In: Hanna, S.H.S., Mikhail, W.Z.A. (Eds.), Soil Zoology for Sustainable Development in the 21st Century, Cairo, pp. 369–395.

- Edwards, C.A., Burrows,I., Fletcher, K.E. and Jones, B.A. 1985. The Use of Earthworms for Composting Farm Wastes. In JKR Gasser (Ed.) Composting Agricultural and Other Wastes; Elsevier, London and New York, pp: 229-241.

- Edwards, C.A. and Bater, J.E. 1992. The use of earthworm inenvironmental management. Soil Biology and Biochemistry;24:1683-9

- Elvira, C., Sampedro, L., Dominguez, J., Mato, S., 1997. Vermicomposting of wastewater sludge from paper-pulp industry with nitrogen rich materials. Soil Biol. Biochem. 29, 759–762.

- Garg, V.K., and Kaushik, P., 2005. Vermistabilization of textile mill sludge spiked with poultry droppings by an epigeic earthworm Eisenia foetida. Bioresour. Technol. 96, 1063–1071.

- Garg P, Gupta A. and Satya, S. 2006. Vermicomposting of different types of waste using Eisenia foetida: A comparative study. Bioresour. Technol. 97: 391–395.

- Griengo, S., Lumansoc, T., Organas, M.R., Willie Jones B Saliling, W.J.B., Gamido, J.S.B., and Ele, J.J.G. 2008.Evaluation of the operational characteristics of vermicomposting beds at the USM-based Regional Vermicompost and Vermimeal Production Center XII. USM R & D 16(2): 105-112

- Guerrero, R.D. 2004. Environmental Technology Compilation (ETC). Philippine Council for Aquatic and Marine Research and Development (PCAMRD)

- Hartenstein, R., 1981. Production of earthworms as a potentially economic source of protein. Biotechnol. Bioengg. 23, 1797–1811.

- Hartenstein, R. and M.S. Bisesi, 1989. Use of Earthworm Biotechnology for the Management of Effluents from Intensively Housed Livestock. Outlook on Agriculture, USA, 18: 72-76.

- Jadia, C.D. and Fulekar, M.H. 2008. Vermicomposting of vegetable waste: A biophysicochemical process based on hydro-operating bioreactor. Af. J. Biotechnol. 7: 3723-3730.

- Kale, R.D., Bano, K., Krishnamoorthy, R.V., 1982. Potential of Perionyx excavatus for utilization of organic wastes. Pedobiologia 23, 419–425.

- Kaushik, P. and Garg, V.K. 2004. Dynamics of biological and chemical parameters during vermicomposting of solid textile mill sludges mixed with cow dung and agricultural residues. J. of Bioresource Technology, 4: 203-209.

- Kaviraj, and Sharma, S. 2003 Municipal solid waste management through vermi composting employing exotic and local species of earthworms. Bioresource Technology; 90:169–73.

- Le Bayon, R.C., Binet, F., 2006. Earthworm change the distribution and availability of phosphorous in organic substrates. Soil Biol. Biochem. 38, 235–246.

- Logsdon G.1994. World wide progress in vermicomposting. Biocycle; 35(10),63-5.

- Misra, A.K. 2010. Role of Eudrilla Euginae to Convert Organic Bio-wastes into Vermicompost. Journal of Applied Sciences Research, 6(11): 1914-1917,

- Mitchell, M.J., Hornor, S.G. and Abrams, B.I. 1980. Decomposition of sewage sludge in drying beds and the potential role of the earthworm, Eisenia foetida. J.Environ. Qual, 9,373-8.

- Nagavallemma, K.P., Wani, S.P., Stephane, L., Padmaja, V.V., Vineela, C., Babu, R.M. and Sahrawat, K.L. 2004. Vermicomposting: Recycling wastes into valuable organic fertilizer. Global Theme on Agrecosystems Report no. 8. Patancheru 502 324, Andhra Pradesh, India: International Crops Research Institute for the Semi-Arid Tropics. 20 pp.

- Ndegwa, P.M., Thompson, S.A., and Das, K.C. 2000. Effects of stocking density and feeding rate on vermicomposting of biosolids Bioresource Technology 71:5-12.

- Ndegwa, P.M., and Thompson, S. A., 2001. Integrating composting and vermicomposting in the treatment and bioconversion of solids. Bioresource Technology 76:107-112.

- Padmavathiamma, P.K., Li, L.Y. and Kumari, U.R. 2008. An experimental study of vermi-biowaste composting for agricultural soil improvement Bioresource Technology 99; 1672–1681.

- Palsania, J., Sharma, R., Srivasstava, J., and Sharma, D. 2008. Effect of moisture content variation over kinetic reaction rate during vermicomposting process: Applied Ecology and Environmental Research 6(2): 49-61.

- Plaza, C., Nogales, R., Senesi, N., Benitez, E., Polo, A., 2007. Organic matter humification by vermicomposting of cattle manure alone and mixed with two-phase olive pomace. Bioresour. Technol. 9, 5085–5089.

- Prakash, M. and Karmegam, N. 2010. Vermistabilization of press mud using Perionyx ceylanensis Mich. Bioresour. Technol. 101, 8464–8468.

- Pramanik, P., Ghosh, G.K., Ghosal, P.K. and Banik, P. 2007. Changes in organic-C, N, P and K and enzyme activities in vermicompost of biodegradable organic wastes under liming and microbial inoculants. J. of Bioresource Technology, 98: 2485-2494.

- Rostami, R., Nabaei, A. and Eslami, A. 2009a. Survey of optimal temperature and moisture for worms' growth and operating vermicompost production of food wastes, Health and environment, 1(2), pp. 105- 112.

- Rostami, R., Nabaei, A., Eslami, A. and Najafi Saleh, H. 2010. Survey of E.Foetida population on pH, C/N ratio and process's rate in vermicompost production process from food wastes, Ofogh-e-Danesh, 35(52), pp. 93-98.

- Sangwan, P., Kaushik, C.P. and Garg, V.K. 2010. Vermicomposting of sugar industry waste (press mud) mixed with cow dung employing an epigeic earthworm Eisenia foetida. Waste Manage. Res. 28, 71–75.

- Suthar, S. 2007. Vermicomposting potential of Perionyx sansibaricus (Perrier) in different waste materials. Bioresour. Technol. 98: 1231-1237.

- Suthar, S., 2008. Bioremediation of aerobically treated distillery sludge mixed with cow dung by using an epigeic earthworm Eisenia fetida. Environmentalist 28, 76–84.

- Tripathi, G. and Bhardwaj, P. 2004. Comparative studies on biomass production, life cycles and composting efficiency of Eisenia fetida (Savigny) and Lampito mauritii (Kinberg). Biores. Technol. 92, 275– 283.

- Viel, M., Sayag, D. and Andre, L. 1987. Optimization of agricultural industrial waste management through in-vessel composting. In: de Bertoldi, M. (Ed.), Compost: Production, Quality and Use. Elsevier Appl. Sci., Essex, pp. 230–237.

- Wong, J.M.C., Fang, M., Li, G.X., Wong, M.H., 1997. Feasibility of using coal ash residue as co-composting materials for sewage sludge. Environ. Technol. 18, 563-568.

- Yadav, A., and Garg, V.K. 2010. Recycling of organic wastes by employing Eisenia fetida. Bioresour. Technol. (article in press), doi:10.1016/j.biortech.2010.10.083.