Distribution Channels Management in Different Regions

Andrii Galkin*

Transport Systems and Logistics Department O. M. Beketov National University of Urban Economy in Kharkiv, Ukraine

Abstract

This paper develops a model for calculating distribution channel functioning efficiency in different regions. Author examined parameters and factors which impact on channel’s choice and change. Replacement any of them impact on channel efficiency in time period. In such conditions, the various aspects of distribution system for each region should be decided in the operation, logistics, economics and marketing levels. Consider costs for liquidation, reorganization and functioning of these channels. For channel performance evaluation author proposes to use investment indicators. Studying improves approach for distribution channel management which include project analysis and logistics methods for efficiency calculations in long term period.

Keywords

Regions, Investments, Project, Logistics, Channel, Distribution

Received: March 16, 2015

Accepted: April 2, 2015

Published online: April 6, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Production delivery in the consumption sphere is one of the important trade functions that take place in the commercial companies. Rational management is important in goods distribution processes. Logistics tools are effecting on the choice of distribution channel delivery mechanism for different regions. The sales channels choice is one of the key decisions for the company.

2. Distribution Channel Characteristics

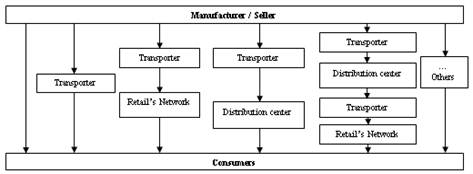

Choice of logistics channel (LC) is influencing on the distribution processes efficiency. The LC is linearly ordered by participant’s characteristics that perform logistics operations to bring material flow from one participant to another or to the final user (Oklander, 2005; Larina, 2005). An example of the distribution channels is presented on fig. 1 (Oklander, 2005; Anykyna, 2003; Kal'chenko, 2003; Hadjinsky, 2013).

Fig. 1. Material flow’s distribution channels scheme.

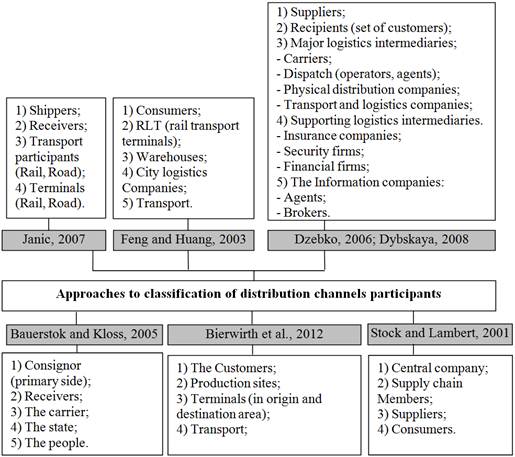

Fig. 1 shows different ways of selling. LC consists of different participants: manufacturers (seller), consumer (buyer) and logistics agents, storages, services organizations and others. References analysis reveals the different approaches to the classification of LC participants Fig. 2.

Fig. 2. Approaches to classification of distribution channels participants.

3. Methods Analysis

LC organizational construction may vary (Mirotin and Tashbayev, 2002), depending on the: enterprises size, extent activities, management concepts, material consumption and economics. Selecting a particular distributor, carrier, insurer, forwarder, banker, etc. use different methods (Nerush, 2007; Lukynskyy, 2003; Ponomarev, 2003; Roslavtsev, 2010; Shapiro, 2006) such as: peer review, methods of operations research and others. These methods do not take into account the enterprise specifics, logistics and marketing strategies, they reflect the distribution channels functioning without the cost of funds and set out to organize the LC. Episodic LC functioning in different regions become to make decision about managing distribution channels in different service areas in long term.

4. Results

LC may be viewed as stages of a business plan: identification, preparation (planning), analysis, implementation, operation, after the project audit. Alternative projects analysis in the business implementation is an important step of identification. Different project identifications enable the alternative income analysis and economic profit (Roslavtsev, 2010; Vorkut, 2002), which can be obtained at different distribution channels in organization and planning. The LC selection consists of the various factors that can be divided into external: state, economy, region, political situation, demographic and legislative factors, technological and technical availability of the channel, level of logistics technology, material flow‘s characteristics. The LC efficiency depends on many factors, which can be written as:

![]() (1)

(1)

where ![]() - factors of influencing on the LC choice;

- factors of influencing on the LC choice;

Replacement any of these factors will change efficiency of the channel or make it impossible to use in some time periods:

![]() , (2)

, (2)

It is important to note that liquidation, reorganization and functioning of LC may have additional costs:

![]() , (3)

, (3)

where ![]() - The total cost for LC functioning, USD.

- The total cost for LC functioning, USD.

![]() – Capital expenditure on establishment, reorganization and liquidation inside the LC, USD.

– Capital expenditure on establishment, reorganization and liquidation inside the LC, USD.

![]() – Operating costs in the LC, USD.

– Operating costs in the LC, USD.

![]() – Taxes in the LC, USD.

– Taxes in the LC, USD.

![]() – Loans cost in the LC, USD.

– Loans cost in the LC, USD.

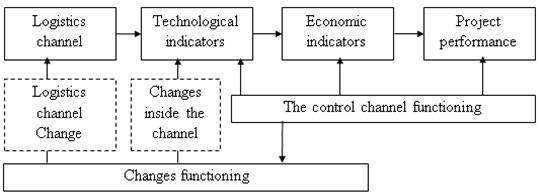

Management functions are important in identification of distribution channel functioning efficiency. An important step of planning is working out of business plan (project) for the distribution channel implementation (Vorkut, 2002; Roslavtsev, 2010). Business plan can provide each LC calculation of technological, economical, project’s performances, Fig. 3. Other management functions are also important. Organization technologies make an impact on project’s performances. Control system indicates changes through time periods of functioning.

Fig. 3. Diagram of logistics channels management.

LC selection should base on all performances inside and outside of it. For example, the decision to use or not to use distribution center, the decision to use their own or hired transport, decision about the number of participants in the LC, the decision to use or own wage distribution centre, the number of distribution centres, leading to changes in capital and operating costs, expenses loans and taxes in each distribution channel version. The vehicles number, delivery time, driver’s number, vehicle’s capacity, storage size, retailers destination and their number, service level, supply level and other technological indicators are influenced on changing inside channel. For example, an increasing in the stock’s value may change channel system using compositions to direct technology "just in time".

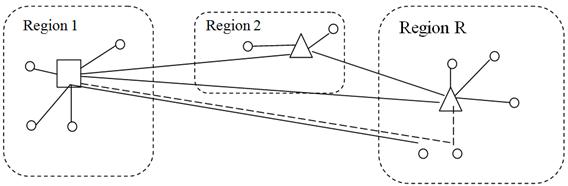

LC options development and analysis provide ability to use not only own logistics system elements but also hired participants. Main purpose of using hired participants is costs reduce. In such cases, distribution centres can be used. Distribution centre accumulates various received goods nomenclature, sells them, and get profits portion from the combined sales. Goods suppliers are able to sell their products over the wide consumers range. Different LC provides material flow for different regions, you can see on fig. 4.

Fig. 4. Logistics channels for different regions:

![]() – Manufacturer;

– Manufacturer; ![]() – Distribution Center (Dealer);

– Distribution Center (Dealer); ![]() – retailer; ––– –– – functioning LC; – not functioning LC.

– retailer; ––– –– – functioning LC; – not functioning LC.

Based on the relationship (1) and (2) it should be noted that some LC in some regions cannot function. The existence of several distribution channels simultaneously raises the questions about the synergistic effect with their service. Several LC service will allow more vehicles efficient usage and separate fixed costs (Roslavtsev, 2010): driver’s salaries, overhead costs for the vehicles repair and maintenance, the loan cost between all LC.

Solving the LC problem provides to control parameters of these channels in real time. LC managing options may include: L – the LC links number; Lq – the LC relationship character; M – LC participants number; X – impacts factors; Q – the material flow amount; Qn – the material flow amount moving through the logistics channel N; N – LC number, R – regions numbers. The indicators that characterize the channel results may include: net present value and payback period which includes different risks in distribution channel.

Project’s invest consists of costs and revenues in a time period: investment costs in period t (![]() ) and total net cash flow in period t (NCF). Invest projects efficiency can be found by the net cash flow (NCF) calculating (Vorkut, 2002; Roslavtsev, 2010):

) and total net cash flow in period t (NCF). Invest projects efficiency can be found by the net cash flow (NCF) calculating (Vorkut, 2002; Roslavtsev, 2010):

![]() , (4)

, (4)

![]() – positive cash flow in t period, USD;

– positive cash flow in t period, USD;

![]() – positive cash flow in t period, USD;

– positive cash flow in t period, USD;

Researches have shown that the amount of costs and revenues depends on the material flow amount in the LC. Material flow volumes changes in the channel are dictated by changes one of the parameters:

Including managing options and formula (4) will have wide:

![]() , (5)

, (5)

The LC choice is determined by the invest indicator:

![]() ,(6)

,(6)

Where ![]() – The highest net cash flow indicator, USD;

– The highest net cash flow indicator, USD;

![]() – All net cash flow indicator, USD.

– All net cash flow indicator, USD.

Decisions on changes inside LC or replacement the channel at all must be acceptable in the long term. Therefore, the assessment of possible changes and solutions in LC has to be assessed by investment performance. The time for making changes has to be included into consideration.

5. Conclusions

Usage the methods and models of logistics channels management should be considered at different levels, such as: continent, state, region, area, city, district and others. The various aspects of distribution system for each region should be decided in the operation, logistics, economics, marketing and other levels. Logistic channel mechanisms for promoting individual material flow must be provided at the planning stage and project identification. One of the changing parameters can lead to efficiency varying inside the channel but change the distribution channel at all. Studying improves models and methods of distribution channel management which take into consideration project analysis and logistics methods for efficiency calculations.

Further studies will be focused on testing and modeling of the proposed approach and models to identify distribution channels regularities with different parameters.

References

- Oklander, MA (2005), Logistics: Textbook. – Kiev: Foreign Trade.

- Larina P.P. (2005), Logistics: Textbook. – Donetsk: Era.

- Anykyna B. A. (2003), Logistics: Textbook. 3rd ed., Rev. Moscow: INFRA-M.

- Kal'chenko A (2003), Logistics: Textbook. - Kiev: MBK.

- Hadjinsky A. (2013), Logistics: Textbook for High society. - Moscow: Marketing

- Stock, J. R., AND Lambert, D. M. (2001), Strategic Logistics Management, 4th Ed., Boston, Irwin / McGraw-Hill.

- Bauerstok and Kloss (2005), Logistics. Integrated supply chain, 2nd ed. – Moscow. – Olympus business.

- Dzebko, I. (2006), Economisty o logistice. Hand Book, Kharkiv: Center Consultation;

- Dybskaya V., Zaytsev E., Sergeyev V. and Sterligova A. (2008), Logistics, Moscow: Eksmo.

- Janic, Milan (2007) Modeling the Full Cost of an intermodal and Road Freight Transport Network, Transportation Research Part D: Transport and Environment, 12 (1): 33-44.

- Bierwirth, Christian and Kirschstein, Thomas and Meisel, Frank, On Transport Service Selection in Intermodal Rail/Road Distribution Networks (November 27, 2012). BuR Business Research Journal, Vol. 5, No. 2, pp.198-219, November 2012. Available at SSRN: http://ssrn.com/abstract=2185353

- Feng, C.M. and Huang, H.H. (2003) Modelling the intermodal logistics between intercity rail and city truck, Journal of the Eastern Asia Society for Transportation Studies, Vol. 5, 2313-2326.

- Mirotin L. and Tashbayev I. (2002), Systemic analysis in logistics. - M: Examination.

- Nerush U. M. (2007) Logistics. Moscow: Prospectus.

- Lukynskyy V. S. (2003) Models and Methods logistics. – St.Petersburg: Peter.

- Ponomarev V. (2003) Logistics: Training. guidances. - Kiev: Center teach.

- Roslavtsev D. (2010), Evaluating the effectiveness of solutions in the projects of modernization of logistic chains, East European Journal of advanced technologies, Volume 5, № 3 (47), available at: http://journals.uran.ua/eejet/article/download/3094/2897, Last accessed at 03.03.2015.

- Shapiro, J. (2006), Modeling of supply chain, St. Petersburg: Peter.

- Vorkut, T. (2002), Proektyvannya transportnogo obslugovyvannya v cepyah postavok: monograph, Kiev: NTU.