A Brief Review of Application of Laser Biotechnology as an Efficient Mechanism for the Increase of Biomass for Bio-energy Production Via Clean Thermo-Technologies

Obid Tursunov*, Jan W. Dobrowolski

Faculty of Mining Surveying and Environmental Engineering, AGH University of Science and Technology, Krakow, Poland

Abstract

Bio-energy production from biomass sources has been attracting world-wide research in renewable energy field to comprehensively understand bio-energy development, considering energy crisis in majority of the developing and developed countries. This paper illustrates the results of up today research studies that investigated biomass resources and their bio-energy potential. Additionally, among various alternative sources of energies, biomass has drawn enormous attention as feedstock for clean energy production. Hence, this paper also illustrates the application of environmentally-friendly laser biotechnology for more efficient increase of plant’s biomass in areas under unfavorable environmental condition for bio-energy production via alternative clean technologies such as pyrolysis/gasification. Pyrolysis is the degradation of macromolecular materials with heat in the absence of oxygen, and gasification is a process that converts biomass or fossil fuel based carbonaceous materials into carbon monoxide (CO), hydrogen (H2), carbon dioxide (CO2) and possibly hydrocarbon molecules such as methane (CH4). They have both applied and analytical aspects. The development of advanced fast pyrolysis and gasification process for bio-energy (biofuel, biogas and biochar) production has gained much attention in the last decade, because they offer convenient and applicable way to convert biomass into bio-yield and value-added products.

Keywords

Laser Biotechnology, Biomass, Bio-Energy, Municipal Solid Waste, Pyrolysis, Gasification, Catalyst

Received:June 15, 2015

Accepted: June 29, 2015

Published online: July 15, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Currently, the world is facing unique and daunting environmental challenges. These include global warming, climate change, an emerging global crisis in water availability and water pollution, loss of biodiversity and long-term damage to ecosystems, pollution of the atmosphere, waste production and disposal, impacts of chemicals use and toxic substance disposal, damaged aquatic ecosystems, and land degradation and deforestation (Tursunov and Dobrowolski, 2015).

The fundamental challenge that humanity encounter in this century is the conversion of a society based on consumption controlled only by demand and market forces into a sustainable society based on realistic needs and care for natural resources. The mankind should pass on from a destructive and wasteful attitude towards the environment to one which respects the mother Earth as the only limited and sensitive resource. The depletion of fossil fuels and natural resources will come sooner or later and this is prognosticated for many years now, but our society should not wait until then, and we need to develop and discover eco-technologies able to provide the necessary amount of energy and products needed by our society in the spirit of conservation of natural resources.

Several green and eco-friendly technologies are already developed and applied world-wide to produce renewable energy. Most of them use the sun energy directly or via energy carriers as the main energy source. In any green energy technology, there are several key aspects. Among them the most important are: efficiency in energy conversion, energy storage until consumption, carbon foot print, wastes generated and environmental impact (Tursunov et al, 2015). However, much attention has been paid to biomass conversion technologies into bio-energy. Accordingly, nowadays a lot of research studies are focused on investigation a proper technology for more efficient biomass production. Application of environmentally friendly laser biotechnology could be applied for more efficient increase of biomass for bio-energy production by using different clean or –bio technologies. Moreover, effective reclamation and an efficient biomass production in deteriorated areas as contribution to sustainable development of different areas (Dobrowolski et al, 2012b). Wide-scale application of laser biotechnology could contribute to decrease concentration of green-house gases and primary prevention of climatic change and also to progress in renaturalisation of the rivers regions, increase of water retention and prevention against flood incidents (Dobrowolski et al, 2012a).

Due to empirically selected algorithms of laser biotechnology is an efficient mechanism for increase of biomass production in deteriorated areas, hence pyrolysis can be used as a clean thermo technology to convert a biomass sources into valuable products. Pyrolysis of biomass (municipal solid waste (MSW), agricultural crops, woods etc.) refers to its thermal decomposition by heating in an inert atmosphere. Under these conditions, the biomass decomposes into solids (bio-char), water, gases composed of carbon dioxide (CO2), carbon monoxide (CO), hydrogen (H2) and hydrocarbons (HC) as well as myriad organic molecules (Tursunov, 2014). Therefore the gaseous product stream contains both condensable and non-condensable aerosols and vapours. Bio-oil is the liquid product condensed from the gaseous outlet stream. Upon analysis of the liquids from pyrolitic process, major portions are water and tar, and other compounds such as methanol, acetic acid, acetone, phenols, aldehydes, and esters. Because of the wide range of liquid products that may be formed, pyrolysis is perhaps the only process (technology) that can produce the most valuable chemicals and industrial feedstock from among all thermal conversion processes (Tursunov et al, 2015).

In the this paper, we highlight the efficiency of environmentally-friendly laser biotechnology for biomass growth at contaminated areas, as well as other advantages of this application in environmental engineering. Additionally, we illustrate the possible use of biomass and the organic fractions of MSW biomass as an energy resource through a process of pyrolysis with various catalysts.

2. Application of Laser Biotechnology

2.1. Complementary Role of Laser Biotechnology in Environmental Engineering

One of the most promising alternatives to meet the increasing demands of the human population for energy sources is the production of bio-energy from biomass of plants. According to Dobrowolski et al. (2012a) laser stimulation can be used for a more efficient soil reclamation, wastewater treatment process, increment of bioremediation abilities and increment of energetic and food crops. Results of experiments showed that laser stimulation caused an increase of plant biomass and greater uptake of trace and biogenic elements from contaminated water and soil. Application of laser stimulation of different species of plants, soil bacteria and fungi in environmental biotechnology was introduced by Dobrowolski in 1978, for the optimization of bioremediation processes, e. g. removal of pollutants from sewage and soil reclamation as well as for increase of biomass production by plants cultivated in polluted soils (Dobrowolski, 2000; Dobrowolski, 2001).

Laser stimulation enables to optimize natural biological processes by optimal phenotype expression and better adaptation to different contaminants of the natural environment, including more efficient bioremediation of some elements. Moreover, laser biotechnology opens a new perspective of reclamation not only for different industrial regions, but also in areas with great amount of salt in the soil or soils contaminated by petrochemical pollutants (Dobrowolski, 2012a).

Depending on the applied algorithm for stimulation with coherent light, there could be an increase of accumulation of essential elements by the irradiated plants, decrease of the intake of some toxic metals (e.g. Pb, Cd – as contribution to primary prevention of nutritional health hazard) and using different algorithm enhancement of bioacummulation of toxic elements in such plants as willow Salix sp, duckweed Lemina minor, common reed Phragmites australis, elephant grass Miscanthus sp, Virginian mallow Sida hermaphrodita (Dobrowolski et al, 2004a; Dobrowolski et al, 2012a).

2.2. Effect of Laser Biotechnology on Plants

Research conducted by Dobrowolski et al. (2012a) on industrial plants cultivated on postindustrial areas showed that increase in iron content (in comparison with control group) and the lower level of lead (0.95 μg g-1 in the control group, 0.50 μg g-1 in the experimental group) and copper concentration (4.05 μg g-1 in the control group, 3.65 μg g-1 in the experimental group) was accompanied by higher dry biomass of the potato tuber.

Increase of zinc in flax seeds was observed in the experimental groups in comparison with the control group (469.20 μg g-1 versus 97.00 μg g-1) respectively (Dobrowolski and Zielinska-Loek, 2002; Dobrowolski, 2000; Dobrowolski and Rozanovski, 1998). Additionally, changes on concentration of some elements in the biomass of the irradiated plants were observed by Dobrowolski’s team, especially in experimental groups irradiated as cuttings before cultivation with the argon laser during field experiments with willow in reclaimed areas (Dobrowolski, 2000).

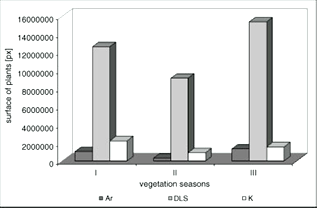

Fig. 1. Increase of duckweed surface (in pixels) during three vegetation seasons (I, II, III) in experimental groups (K – control group, DLS – laser diode (660 nm), Ar – argon laser (514 nm) (Dobrowolski et al, 2012a).

Dobrowolski et al. (2012a) obtained optimal parameters of laser stimulation for the experimental duckweed group (DLS) irradiated with red laser diode of wavelength 660 nm, power 20 mW and irradiation time three times for 3 sec. The plants irradiated with laser diode emitting red light showed the highest increase in biomass production compared to control group of duckweed, viability, better adaptation and resistance to unfavorable environmental conditions like low or high temperature and water deficiency. This effect was maintained during subsequent vegetation seasons without repetition of the laser stimulation (Fig. 1). Increase on the surface area of duckweed is related to biomass production.

Proper time of exposure to selected wavelength and energy density of coherent light is able to stimulate the growth rate of plants and reclamation of deteriorated regions, the biomass production as well as bioremediation of selected toxic metals from contaminated soil and waste water treatment in hydro-botanic plants (Dobrowolski et al, 2004b).

According to Dobrowolski and Zielinska-Loek (2002) laser photostimulation of inoculums of selected fungi could also be a supporting factor of stimulation of moulds living in mycorrhiza and adaptation of the infected roots of seedlings to contaminated soil. Proper photostimulation of inoculums of selected moulds and bacteria could also accelerate biodegradation of some organic pollutants of water and soil.

Referring to laser stimulation of different species of plants for better adaptation to the contamination of soil with petroche mical pollutants: Dobrowolski et al. (2012b) carried a research study on the application of laser biotechnology for the enhancement of the biodegradation of hydrocarbons as a result of using an adequate algorithm of photostimulation of inoculums of fungi selected from soil contaminated by petrol pollutants for a long time. The increase of the biomass production on energy plantations as a result of laser photostimulation of plants cultivated in suboptimal environmental conditions (e.g. on contaminated soil) as well as application of similar method for increase of biomass production in hydro-botanic wastewater treatment plants, promotion low carbon energy production and sustainable development could be recommended for large-scale application. Thus, application of Eco-friendly laser biotechnology could contribute to a better bioremediation of contaminated land and water and to the development of biomass production as a source of renewable bio-energy.

Further application of clean thermo technologies (e.g. pyrolysis or gasification) could be an efficient mechanism to convert a biomass produced in the result of laser photostimulation to bio-energies like bio-gas, bio-fuel, bio-oil, bio-char, syngas, methane and etc.

3. Biomass Conversion Technologies

3.1. Products from Pyrolysis/ Gasification Processes

Long term research experiences emphasize that pyrolysis is one of the alternative methods for municipal solid waste treatment, and it offers more benefits from scientific and economic point of view. During the pyrolysis process, organic matter thermally decomposes in an environment that is devoid of any oxygen. A heat source is required for the pyrolysis process, yet no heat source is needed for gasification, inasmuch this process is self sustaining thermally. When both gasification and pyrolysis processes occur at the same time, the gasification combustion reaction is able to provide the heat source needed for the pyrolysis process to execute the reactions. In this process no heat source outside of the gasification process is needed for pyrolysis (Tursunov, 2014). Under these conditions, the biomass decomposes into gases composed of carbon oxides, solids (char), water, hydrogen and hydrocarbons as well as myriad organic molecules. The gaseous product stream therefore contains both condensable and non-condensable aerosols and vapours. Bio-oil is the liquid product condensed from the gaseous outlet stream.

Radlein and Quignard (2013) quoted that woody biomass is composed generally of cellulosic and lignin polymers along with various extractives together with a small amount of inorganic matter. The products of its thermal decomposition of biomass are determined principally by the relative proportions of the various components along with the decomposition temperature. For instance, it is well known that the three principal components of woody biomass, cellulose, hemicelluloses and lignin, show substantially different weight-loss profiles (i.e. different temperatures of maximum rate of weight loss) at the same heating rate on thermal gravimetric analysis (TGA).

Pyrolysis basically proceeds by multiplicity of serial and parallel reactions with a wide range of activation energies. The same is also true for minor components like bark, extractives and proteins. Consequently, the spectrum of products is critically dependent on the biomass heating rate and final temperature. It should be considered that the temperature of the decomposing biomass is not necessarily coincident with that of the pyrolysis vessel.

Piskorz et al. (1986) showed that the predominant functional groups present in bio-oil were carbonyl, phenolic and carboxylic. These groups are distributed between those products originating from the cellulosic components of the biomass and those nascent from lignin. The former are mostly soluble in water while the latter are mostly insoluble. Addition of adequate water to a single-phase bio-oil generally results in separation of a "heavy tar" fraction that was identified as originating largely from the lignin component of biomass (Radlein et al, 1987) also called pyrolytic lignin.

Broido and Kilzer (1963) first called attention to the great sensitivity of the pyrolytic decomposition pathways of cellulose to immensely small amounts of inorganic impurities (< 0.1%) which expressly alter the degradation characteristics of cellulose. Particularly, they promote the destruction of anhydrosugars to smaller fragments with accompanying formation of char. Moreover some inorganic constituents, in particular alkaline salts, can greatly accelerate char formation. For instance, it has been found that even a few ppm of sodium salts can increase the char yield from the pyrolysis of pure crystalline cellulose by a factor of greater than 10 (Radlein and Quignard, 2013).

Later, it was highlighted that de-mineralization of the biomass, especially the removal of alkali cations, can lead to very large increases in organic liquid yields, with enhanced formation of anhydrosugars (Scot et al, 2000). However, besides the added expense of demineralization by acid treatment, the viscosity of the sugary bio-oil is also much higher leading to operational complications in tar recovery.

3.2. Catalytic Activity in Pyrolysis Process

According to Blasi (2008), the catalytic pyrolysis process of MSW as a biomass source can be divided into two steps:

Primary pyrolysis termed MSW decomposition. This step is a thermochemical decomposition of MSW with production of water, tar, char and volatiles. In this process, temperature is the most important parameter influencing the product yields distribution. This step could perform at a lower temperature ~300oC, and last until a temperature of 700oC or even higher. As the pyrolysis temperature increases, the moisture inside the MSW particles evaporated first, then thermal degradation and devolatilization of dried portion of the particles take place, and the volatile species gradually evolve out from the particles surface and undergo further pyrolysis.

The second step secondary reactions of tar cracking occur at higher temperatures (>400 oC). The basic secondary reactions of tar cracking and shifting include decarboxylation, decarbonylation, dehydrogenation, cyclization, aromatization, and polymerizing reactions, which are given in order of increasing pyrolysis severity (e.g., increasing temperature). Part of vapors (mainly heavy oil fraction) are absorbed by the active surface of the catalyst, and then cracked to light vapors. The light vapors then undergo series reactions such as deoxygenation, cracking to form H2O, CO2, CO, alkanes, alkenes and aromatic hydrocarbons. These reactions would result in a decrease of tar vapors and increase of gas and water yields. When all of the volatile species are removed from the solid, a residue of char is left.

According to (Tursunov, 2014; Tursunov et al, 2011; Tursunov et al, 2015) temperature and the presence of catalysts are among the most important parameters that influenced the product yield from this process. Studies had also found that maximum pyrolytic oil can be obtained in the temperature range of 400 and 550oC. Due to the secondary reactions, the pyrolytic oil yield decreased parallel with gas amount increasing as temperature operated over 500oC.

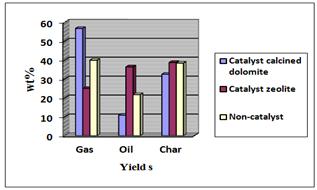

Experimental studies by Tursunov (2014) indicates that MSW pyrolysis experiments at the reactor temperature of 750 °C with zeolite and calcined dolomite were carried out to study the influence of the catalysts on product yields (gas, oil and char) from pyrolysis process which is presented in Table 1 and Fig. 2 respectively. There was a remarkable increase in gas yield from 24.98 wt% with zeolite to 56.67 wt% with calcined dolomite. The oil yield decreased significantly from 36.35 wt% with zeolite to 10.88 wt% with calcined dolomite. It was because that the low oil yield resulted from oxygen removal to water, CO2 and CO, from coke formation on the catalysts and from a significant increase in gas yield due to catalysis (Tsai et al, 2007). The char yield resulted 38.66 wt% with zeolite and 32.44 wt% with calcined dolomite. Furthermore, the details of the materials balance calculation at different reactor temperatures over the range of 200–750 C were presented in Table 1. The overall material balance had a closure of ~99.99%.

Table 1. Product yields and recovery from catalytic (calcined dolomite and zeolite) pyrolysis of MSW at 200-750 oC reactor temperature (Tursunov, 2014).

| Type of MSW pyrolysis | Gas (wt %) | Oil (wt %) | Char (wt %) | Recovery (wt %) |

| Catalytic (calcined dolomite) | 56.67 | 10.88 | 32.44 | 99.99 |

| Catalytic (zeolite) | 24.98 | 36.35 | 38.66 | 99.99 |

| Non-catalytic | 39.91 | 21.72 | 38.36 | 99.99 |

Recovery = Gas + Oil + Char

Fig. 2. Comparison of the overall gas, char and oil yield components of catalytic (calcined dolomite; zeolite) and non-catalytic pyrolysis (Tursunov, 2014).

Thus, pyrolysis product yields profile confirmed that the catalysts promote depolymerization processes to yield a strong decomposition (low solid yield) or a strong liquid phase cracking (low liquid yield), and hence a higher hydrogen formation, since this gas was formed from liquid cracking (Vassilatos et al, 2009).

Williams and Horne (1994, 1995) who pyrolyzed biomass in the form of wood in a fluidized bed and upgraded vapors with catalysts in a fixed bed downstream. Furthermore, the details of the materials balance calculation at different reactor temperatures over the range of 750–900°C is presented in Table 2. The overall material balance had a closure of ~ 94.40%.

Therefore, pyrolysis product yields profile confirmed that the catalysts promote depolymerization processes to yield a strong decomposition (low solid yield) or a strong liquid phase cracking (low liquid yield), and hence a higher hydrogen formation, since this gas was formed from liquid cracking.

Table 2. Product yields and recovery from catalytic pyrolysis of MSW at different reactor temperature (Williams and Horne, 1994; 1995).

| Temperature (°C) | Gas (wt%) | Oil (wt%) | Char (wt%) | Recoverya (wt%) |

| 750 | 43.42 | 34.55 | 18.53 | 96.50 |

| 800 | 64.84 | 16.06 | 16.53 | 97.43 |

| 850 | 75.63 | 7.71 | 15.42 | 98.76 |

| 900 | 78.87 | 5.13 | 14.92 | 98.92 |

| 900b | 44.07 | 37.98 | 15.86 | 97.91 |

a Recovery = Gas + Oil + Char

bPyrolysis process.

Dolomite is a suitable catalyst for the removal of hydrocarbons, which are evolved in the pyrolysis (gasification) of MSW. Dolomites increase gas yields at the expense of liquid products. With suitable ratios of MSW feed to oxidant, almost 100% elimination of tars can be achieved. The dolomite catalyst deactivates due to carbon deposition and attrition; however, dolomite is cheap and easily replaced (Tursunov et al, 2011). The main function of dolomite is to act as a guard bed for the removal of heavy hydrocarbons prior to the reforming of the lighter hydrocarbons to produce a product gas of syngas quality.

4. Conclusion

In the near future, bio-energy potential estimation from the perspective of the origination of biomass resources, particular attention should be paid to woody biomass due to its vast biomass potential, as well as its conversion and utilization techniques. Similar to the bio-energy use of MSW and wastes from animal husbandry to generate methane or synthetic gas (syngas), garbage in rural areas cannot be ignored, not only because of its great potential, but also because of its potential harm to ecological environment. This is especially significant in developing countries, where perfect garbage utilization and recycling system has not been established in proper way. From the perspective of effective use of biomass, quality evaluation of biomass and bio-energy is particularly essential.

This paper presented the efficiency of environmentally-friendly laser biotechnology for biomass growth at contaminated areas, as well as other bio-technological advantages of this application in environmental science. In addition, this paper illustrated the possible use of biomass and the organic fractions of MSW as an energy resource through a process of pyrolysis with catalysts. As biomass has been playing an important role in bio-energy production, above mentioned laser biotechnology opens new trends on more efficient biomass production for bio-energy production via alternative up today clean technologies such as pyrolysis or gasification. Furthermore, the utilization of biomass feedstock appears to be a genuine solution to sustainable production of clean energy carriers in the future.

References

- Blasi C.D. (2008) Modeling chemical and physical processes of wood and biomass pyrolysis. Prog. Energy and Combustion Science. Vol. 34, pp. 47-90.

- Bekcan S., Atar H.H., Beyaz A. (2009) Measurement of the effects of liquid fertilizers at the different level on duckweed (Lemina minor) growth using image analysis technique. J. Biotechnol Eq. Vol. 23, pp. 1205-1209.

- Broido A., Kilzer F.J. (1963) A critique of the present state of knowledge of the mechanism of cellulose pyrolysis, Fire Res. Abstr. Rev. Vol. 5, pp. 157.

- Dobrowolski J.W. (2001) Ecotoxicology, human ecology, laser biotechnology in primary prevention of environmental health hazard. J. Przeglad Lekarski. Vol. 58, pp. 7.

- Dobrowolski J.W., Sliwka M., Mazur R. (2012a) Laser biotechnology for more efficient bioremediation, protection of aquatic ecosystems and reclamation of contaminated areas. J. Chem Technol Biotechnol. vol 87. 1354-1359.

- Dobrowolski J.W., Budak A., Trojanowska D., Rymarczyk M., Macuda J. (2012b) Laser stimulation of Trichophyton mentagrophytes for the enhancement biodegradation of hydrocarbons. J. Environmental Engineering and Management. Vol 11, No. 10, pp. 1783-1788.

- Dobrowolski J.W. (2000) Perspectives of application of laser biotechnology in management of the natural environment. Polish Journal of Environmental Studies. Vol. 10 (Sup. 1), pp. 7-9.

- Dobrowolski J.W., Rozanowski B., Zielinska-Loek A., Sliwka M., Gowin K., Mazur R. (2004a) Perspectives of application of laser biostimulation for more bioremediation of soil and wastewater. International Conference on Bioremediation of Soil and Groundwater, Politechnika Slaska, Krakow, pp. 133-148.

- Dobrowolski J.W., Zielinska-Loek A. (2002) The laser photostimulation of willow cuttings planted alongside main roads and change of concentration of elements in the willow’s organs. Mengen und Spurenelemente. Friedrich-Schiller-Universitat, Leipzig. Vol. 21, pp. 334-340.

- Dobrowolski J.W., Rozanowski B. (1998) The influence of laser light on accumulation of selected macro-trace and ultra elements by some plants. Menegeund Spurenelemente. Friedrich-Schiller-Universitat, Jena. Vol. 18, pp.147-156.

- Dobrowolski J.W., Rozanowski B., Zielinska-Loek A., Sliwka M., Gowin K., Mazur R., Lewicki P., Zakrewska A., Slazak A. (2004b) Perspectives of application of laser biostimulation for more bioremediation of soil and wastewater. Intl Conference on Bioremediation of Soil and Groundwater. Politechnika Slaska, Krakow. p 133-148.

- Jakubiak M., Sliwka M. (2009) Research on effects of laser light stimulation on selected strains of energetic willow. Polish J. Environmental Studies. Vol. 18, pp. 123-127.

- Piskorz J., Radlein D., Scott D.S. (1986) On the mechanism of the rapid pyrolysis of cellulose, Journal Analytical Applied Pyrolysis. Vol. 9, pp. 121-137.

- Radlein D and Quignard A. (2013) A Short historical review of fast pyrolysis of biomass. Oil & Gas Science and Technology – Rev. IFP Energies nouvelles, vol. 68 No. 4, pp. 765 – 783.

- Radlein D., Piskorz J., Scott D.S. (1987) Lignin derived oils from the fast pyrolysis of poplar wood, Journal of Analytical Applied Pyrolysis. Vol. 12, pp. 51-59.

- Radlein D., Piskorz J., Scott D.S. (1992) Control of Selectivity in the Fast Pyrolysis of Cellulose, Proc. 6th EC Conference on Biomass for Energy, Industry and Environment, Athens, April 1991, Grassi G., Collina A., Zibetta H. (eds), Elsevier, pp. 643-649.

- Scott D.S., Paterson L., Piskorz J., Radlein D. (2000) Pretreatment of poplar wood for fast pyrolysis: rate of cation removal, Journal Analytical Applied Pyrolysis. Vol. 57, pp. 169-176.

- Tursunov O., Dobrowolski J. (2015) Addressing environmental issues and risks in Uzbekistan. Integrated Journal of Engineering Research and Technology. Vol. 2 (1), pp. 62-69.

- Tursunov O., Dobrowolski J., Nowak W. (2015) Catalytic energy production from municipal solid waste biomass: Case study in Perlis, Malaysia. World Journal of Environmental Engineering. Vol. 3, No. 1, pp. 7-14.

- Tursunov O. (2014) A comparison of catalysts zeolite and calcined dolomite for gas production from pyrlolysis of municipal solid waste (MSW). Elsevier Applied Science. Science Direct. J. Ecological Engineering. Vol 69, pp.237-243.

- Tursunov. O., Isa K., Ong. S. (2011) Review paper of catalyst (dolomite) analysis for MSW pyrolysis (gasification). International Postgraduate Conference on Engineering (IPCE). Perlis, Malaysia.

- Tsai W.T., Lee M.K., Chang Y.M. (2007) Fast pyrolysis of rice husk: Product yields and compositions. J. Bioresour. Technol. Vol.98, pp. 22-28.

- Vassilatos V., Taralas G., Sjöström K., Björnbom E. (2009) Catalytic cracking of tar in biomass pyrolysis gas in the presence of calcined dolomite. The Canadian Journal of Chemical Engineering. Vol. 70, Issue 5, pp. 1008–1013.

- Williams P.T., Horne P.A (1994) Characterisation of oils from the fluidised bed pyrolysis of biomass with zeolite catalyst upgrading. J. Biomass Bioenergy. Vol. 7, pp. 223-236.

- Williams P.T., Horne P.A. (1995) Analysis of aromatic hydrocarbons in pyrolytic oil derived from biomass. J. Anal. Appl. Pyrol. Vol. 31, pp. 15-37.