An Alternative Approach to Wind Power Generation Using Piezoelectric Material

G. R. Ahmed Jamal*, S. M. Lutfur Rahman, M. Masud Rana, S. A. S. Nafis, M. Monjurul Huda, Salma Nazia Rahman

Department of Electrical and Electronic Engineering, University of Asia Pacific, Dhaka, Bangladesh

Abstract

In this work, we present an alternative way for producing clean energy from wind without using the turbine based conventional windmill. The core idea of this alternative proposal is to convert wind pressure into electric power using piezoelectric material. The conversion set up is discussed here according to the proposed method. At first, wind flow is converted into electric power through some piezoelectric transducers. Super capacitors were connected in parallel to the output of each piezoelectric transducer so as to store the produced electric energy. Using analog adder circuit, output of these parallel piezoelectric disc- super capacitor arrays are added and amplified. The final output was stored in a rechargeable low power 5 V DC battery. Significantly high amount of power can be generated in this process using larger number of piezoelectric discs. If properly designed, it can be better than the conventional windmill as it does not require rotating a turbine and thus can work at any wind speed. The proposed method can open the door of a relatively new way of generating clean energy from wind which is the most available source around us during both day and night.

Keywords

Clean Energy, Wind, Electrical Power, Piezoelectric Material

Received:May 20, 2015

Accepted: June 17, 2015

Published online: July 15, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Producing electric power from renewable, sustainable and green sources of energy become one of the most important issues in power sector worldwide. Till now, generation of electric power largely depends on fuel. In fuel based power generation, heat is generated from fuel combustion which is used to produce electricity through mechanical rotation. Depending on the types of fuel combustion chambers, gas, coal, diesel, uranium or other types of fuels are used to produce electricity. As there is limited reserve of these fuels in any particular geographical area of the earth So, it is very natural that it will decrease gradually and we cannot depend on these sources for arbitrarily long period. Besides, fuel combustion is directly responsible for huge amount of CO2 emission everyday and thus harmful for the environment. So, searching is on for renewable sources of electric power that can meet the demand of future. Sunlight and air have already been proved as potential sources for electric power and contributing in power generation through solar cell and windmill [1-3].

In a conventional windmill, wind is used to rotate turbine to convert wind energy into electricity. Electricity from wind power through windmill was first demonstrated in 1887 and since then the use of wind power is rapidly increasing all over the world. Though wind power is more or less consistent in an area in different years but it varies significantly within a single year as wind flow is directly linked with seasonal changes. Thus, for consistent output it should be used along with other sources of power so as to meet the demand throughout the year. It is reported that Denmark generated around 40% of its electricity from wind in 2014 [4], and now wind power is used in the electricity grids of more than 80 countries around the world [5]. As of June 2014, estimated wind power capacity was 336 GW, and at present at least 4% of total electricity usage throughout the world is being supplied from wind energy that is increasing every year [6].

Wind turbines are gaining popularity day by day as a way of generating clean energy which results increasing number of wind farms in different countries. However, wind turbine and related set up are heavy in weight as well as expensive. Besides, wind turbines generate low frequency vibrations and cause aesthetics problem in residential areas due to which many residents expressed their lack of interest on proposed wind farm near their areas. Hence, alternative way for producing clean energy from wind without using the turbine can be a good solution. Converting wind pressure into electric power using piezoelectric material can be a potential alternative solution.

Piezoelectricity means pressure induced electricity. In certain solid materials (like crystals and few ceramics) charge is accumulated due to mechanical stress. When pressure or stress is applied, linear electromechanical interaction between the mechanical and the electrical state occurs in these crystalline materials which results the piezoelectric effect. This is how electrical charge is internally generated in these materials from an applied mechanical pressure [7].

The capacity of piezoelectric materials to receive any pressure and to convert that into electric signal attracted many researchers who tried to implement circuits and systems for converting pressure and vibrations into electric power [5-11]. DARPAworked on a Energy Harvestingresearch project in the United States which includes generation of electricity in battlefield by inserting piezoelectric materials beneath the soldiers' boots [8,9]. However, this process was found to have an impact on the body and caused discomfort while walking. Laying down piezoelectric materials under every key of a mobile unit or computer keyboards was another similar idea [10]. In every key stroke, consequent pressure creates the charge on piezoelectric material. Similar energy generating ideas include producing the electric energy from movements of people in train stations, bus terminals, foot over bridge or any such public places [9,11] by laying piezoelectric materials under tiles or floor mats in those places. A similar idea was used in some night clubs of Europe where crystals were laid underneath the dance floor to generate electricity by which they could power their strobes and stereos [12]. Vibrations from industrial machineries or from the machines in a gymnasium can also be used to generate electric power to charge batteries for backup supplies or for low power microprocessors and wireless radios by suitably placing piezoelectric materials with these machines [12-14]. All these reports show the potential of piezoelectric materials in producing usable electrical power. It can be noted that, all these possible applications utilize the sensitivity of piezoelectric materials to any kind of pressure or vibration.

Producing electric power from wind through conversion of wind pressure using piezoelectric materials can be a potential alternative of turbine based wind power. New York design firm Atelier DNA devised a concept namely Windstalk which they developed as a potential project to generate clean energy from wind for a city of Abu Dhabi [15]. In that proposed Windstalk concept 1,203 carbon fiber reinforced resin poles was used that stand 55 meters high. They are attached to the ground in 10 and 20 meters diameter concrete bases. A stack of piezoelectric ceramic discs are packed with the 30 cm diameter poles narrowing up to a diameter of 5 cm from base to the top. Electrodes are connected by cables between the discs that run the length of each pole – alternatively for odd and even electrodes. So, unlike conventional windmill that relies on the wind to turn a turbine, current is generated here through the electrodes due to compression on the stack of piezoelectric discs.

The Windstalk project is only a proposal so far. The designers haven’t yet determined the optimal shape for the stalks. Nevertheless, it is estimated that the overall electricity output of the concept would be comparable to that of a conventional wind turbine array.

The objective of this paper is to demonstrate experimentally an alternative way of wind power generation through conversion of wind pressure into electric power using piezoelectric materials without using any turbine. The mechanism and experimental set up of our proposed way of producing small amount of electric power will be discussed. At first, small amount of electricity will be generated directly from wind pressure through an array of piezoelectric discs. The resultant electric energy from a number of crystals can be summed up and processed further through some circuit set-up to produce and store usable DC electric power for later use.

2. Method and Results

A number of piezoelectric transducers collected from acoustic-electric guitars (as shown in Fig. 1(a) are used for conversion of wind flow and associated pressure into electric energy. As these types of piezoelectric transducers are small enough, the produced voltage across the transducer using normal air flow and associated pressure is also very small. In this experiment, a small electric blower was used as wind source for indoor (as shown in Fig 1(b). As the corresponding

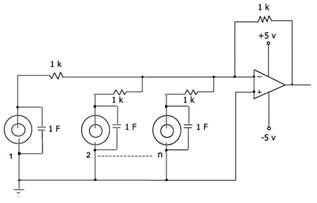

generated voltage at the output of piezoelectric disc is in ac form and noisy in nature, so a 1 Farad supercapacitor is used in parallel to the piezoelectric transducers for both filtering and storing the produced electric energy, as shown in Fig. 2. Supercapacitor, also known as Electrical double-layer Capacitor (EDLC), is a relatively new technology [16,17]. Compared with other capacitors, supercapacitors are of higher capacitance values per unit volume along with having greatest energy density. With their high capacitance values, supercapacitors are bridging the gap between capacitors and batteries. 100 F Supercapacitors can be considered as an alternative to batteries in applications where the importance of power delivery trumps depends on total energy storage. Because of higher farad values, supercapacitors can be charged very quickly while discharge slowly. This quick charging characteristics is helpful for storing momentarily generated piezoelectric output due to wind pressure. On the other hand, as it discharges slowly, electric energy remain stored in it for a longer time than usual capacitors. Consequently, multiple supercapacitor outputs can be added easily.

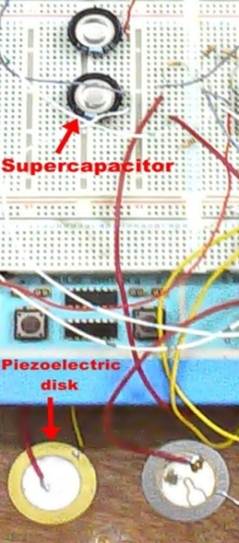

In our proposed method, at first, wind flow originated from the blower that hit the surface of piezoelectric disc was used to produce small electric energy at the terminal of piezoelectric transducer. A 1 farad supercapacitor (rated 5.5 volt) is placed in parallel to the terminal of piezoelectric transducer to store this small energy. An array of transducer-supercapacitor parallel set up was constructed and LM 324 Op Amp adder was used to add the output voltages of each pair of this array, as shown in Fig. 2. In our experiment, at first we tested the circuit with single and double Piezoelectric disk, as shown in Fig. 3 (a). We measured the output with supercapacitor and without super capacitor. We observed that when wind pressure is applied from blower, without super capacitor, the output is 0.29 V - 0.43 V for single piezoelectric disk and 1.18 V - 1.2 V for double piezoelectric disk. But if we use supercapacitors in parallel with piezo then output become 0.44 V - 0.48 V for single piezoelectric disk and 1.49 V - 1.54 V for double piezoelectric disk. If more piezo are added, then output also increased. In this way, output voltage of around 6 V can be found from 10 such transducers-supercapacitors parallel set up. This output can be used to charge a 5 V rechargeable DC battery to store the produce power to be used later. More transducers-supercapacitors parallel set up will result higher voltage but in that case corresponding biasing voltage of LM 324 Op-Amp IC need to be increased, else the adder output will exceed the highest saturation voltage of the IC. For faster charging of battery, number of adder IC can be increased so as to increase the total output current drawn by the load (in this case, the rechargeable battery is the load). The complete circuit set up for 10 piezoelectric transducers-supercapacitors parallel array along with other necessary components is shown in Fig. 3(b). A plane soft board is used to house the full set up which can be placed in rooftop to work at normal wind flow. Higher output voltage can be achieved at the output of adder by increasing the number of transducers-supercapacitors parallel stages before the Analog adder stage.

(a)

(b)

Figure 1. (a) Metal disk with attached piezoelectric disk of diameter 2.5 cm, as used in this work (b) An electric blower used as source of wind for this work.

Figure 2. Circuit set up for wind energy to electrical power conversion.

(a)

(b)

Figure 3. (a) Piezoelectric disc paired with supercapacitor (b) The complete experimental set up of the conversion unit using 10 piezoelectric disc-supercapacitor pairs.

A diode can be placed in the direction of Adder output to rechargeable battery in the circuit shown in Fig. 2 so as to prevent the discharging of the battery when there is not enough wind to produce the minimum voltage required at the adder output to charge the rechargeable battery. In the absence of adequate wind flow or pressure, output of the adder circuit may goes below 5 V and the battery will try to discharge by flowing current in reverese direction. The diode is placed to stop this reverse flow of current from battery so that it only take charge from the Adder output and cannot get discharged in the absence of sufficient output.

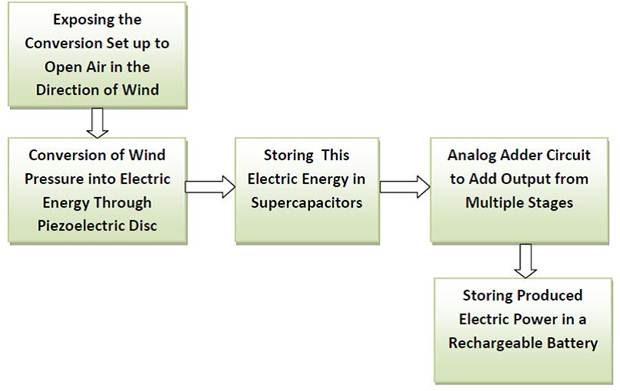

The overall conversion process can be summerized in the block diagram shown in Fig. 4. It is important to note that, though this experiment was carried out to add output from 10 transducers-supercapacitors parallel set up, but it can be extended to higher number until the Op amp reaches its output saturation voltage. Even if the adder circuit output is limited by the op amp output saturation voltage, but final output can be raised to higher voltage using voltage multiplier circuit so as to charge a rechargeable DC battery of higher voltage rating. In that case, the output current will be reduced and the battery will require more time to be fully charged.

3. Further Improvement

The generated electric power in this proposed method can be significantly improved in a number of ways. Good and large diameter piezoelectric disc can be used to get higher conversion efficiency. This can reduce the number of stages from the circuit set up shown in Fig. 2, because lesser number of transducers-supercapacitors parallel set up will be able to produce same output voltage. This will also increase the overall efficiency of the conversion circuit. If this project can be tested in coastal area where there is heavy wind flow then the output will be much better. More efficient conversion circuit may be designed to increase the efficiency. Increasing number of piezoelectric disc will also increase the total generated output Electric power. In fact, theoretically, the more the number of piezoelectric disc the higher the generated power. Hence, if millions of piezoelectric disc mounted in a plane platform that is vertically placed on a coastal area or a heavy wind region, then in this way significantly high amount of power can be generated.

Fig. 4. Block diagram of the full process of generating and storing electrical power from wind energy.

4. Conclusion

Wind is the most available resource around us during day and night. Producing electricity from wind is an increasingly popular way of getting clean electric energy. In a conventional windmill, wind is used to rotate turbine to convert wind energy into electricity. In this work, an alternative way is presented for producing clean energy from wind without using the turbine. The core idea of this alternative proposal is to convert wind pressure into electric power using piezoelectric material. The conversion set up of producing small amount of electric power from wind flow is discussed here according to the proposed method. Wind flow is converted into electric power through some piezoelectric transducers. Super capacitors were connected in parallel to the output of each piezoelectric transducer so as to store the produced electric energy. Using analog adder circuit, output of these parallel piezoelectric disc- super capacitor arrays are added and amplified. The final output was stored in a rechargeable low power 5 V DC battery. This power can be used later to drive small loads like charging a mobile or low power LED bulbs. In this indoor project, we used artificial air from an electric blower to create pressure on piezoelectric element, and thus only a small amount of power is generated here. But, the proposed set up will equally work at outdoor on a heavy wind area because of the same basic mechanism of conversion of wind energy into electric energy through piezoelectric element and the corresponding generated output power can be significant. If properly designed, it can be better than the conventional windmill that uses turbine and thus requires a minimum speed of wind to rotate the turbine in order to generate electric power. The conventional electro-magnetic generator used in the windmills always has some cogging torque which restricts their operation above certain cut-in wind speed. Thus, it cannot generate power from wind always despite the availability of wind. Besides, using turbine has some other disadvantages also. But, when we use the proposed method of conversion of wind energy into electric energy through piezoelectric discs, speed is no longer the main issue. Electrical power will be generated from this set up even during low speed of wind, though in that case the generated amount of power will be lesser than that produced from high speed of wind due to obvious pressure difference. The proposed method can also be better than the solar energy, which is another popular renewable source, but active in generating electric power only for a portion of the day and remains inactive at night or dimmed daylight. But, wind energy is more or less available during day and night at varying speeds and hence generation of power won’t stop at night. The proposed method can open the door of a relatively new way of generating clean energy from wind, which is the most available source around us. The proposed idea is especially helpful in the coastal area of any country where there are heavy wind flow and conventional electricity is not that much available.

References

- A. Zahedi, "Solar photovoltaic (PV) energy; latest developments in the building integrated and hybrid PV systems",Renewable Energy, Elsevier,Volume 31, Issue 5, Pages 711–718, April 2006.

- David Ginley, Martin A. Green and Reuben Collins. "Solar Energy Conversion Toward 1 Terawatt", MRS Bulletin, 33, pp 355-364, 2008.

- Tony Burton, Nick Jenkins, David Sharpe, Ervin Bossanyi, "Wind Energy Handbook", John Wiley & Sons-Technology & Engineering, May 2011.

- Web: http://www.energinet.dk/EN/El/Nyheder/Sider/Vindmoeller-slog-rekord-i-2014.aspx\

- Web:REN21(2011)."Renewables 2011: Global Status Report"(PDF). p. 11.

- Web Online:http://www.wwindea.org/wwea-publishes-half-year-report-2014/pp. 1-8

- Robert John Littrell, "High Performance Piezoelectric MEMS Microphones", Dissertation of Doctor of Philosophy (Mechanical Engineering), The University of Michigan, 2010.

- Takeuchi M, Matsuzawa S, Tairaku K, Takatsu C. Piezoelectric generator as power supply for RFID-tags and applications, Proc. IEEE Ultrasonics Symposium, New York City, USA, pp. 2558–2561, 28–31, October 2007.

- T. Dikshit, D. Shrivastava, A. Gorey, A. Gupta, P. Parandka, S. Katiyal, "Energy Harvesting via Piezoelectricity", proceedings of the 4th National Conference; INDIACom-2010, 25 – 26 February, 2010.

- Roundy S., Wright P. K. and Rabaye J., "A. study of low level vibrations as a power source for wireless sensor nodes", Computer Communications 26, pp. 1131–1144, 2003.

- Richard, Michael Graham"Japan: Producing Electricity from Train Station Ticket Gates". TreeHugger. Discovery Communications, LLC. August 2006.

- U. K. Singh and R. H. Middleton, "Piezoelectric power scavenging of mechanical vibration energy", Australian Mining Technology Conference, 2-4, pp. 111-118, October 2007.

- Steven R. Anton and Henry A. Sodano, "A review of power harvesting using piezoelectric materials (2003-2006), Smart Materials and Structures 16, 2007.

- Y. C. Shu and I. C. Lien, "Analysis of power output for piezoelectric energy harvesting systems", Smart Materials and Structures 15, pp. 1499-1512, 2006.

- http://atelierdna.com/masdarwindstalk/

- George H. Barbehenn, "Supercapacitor Charger and Ideal Diode for Power Supply Ride-Through Systems", LT Journal of Analog Innovation, pp. 15-19, January 2012.

- Donghwa Shin, Younghyun Kim, Jaeam Seo, Naehyuck Chang, Yanzhi Wang and Massoud Pedram, "Battery-Supercapacitor Hybrid System for High-Rate Pulsed Load Applications", Design, Automation & Test in Europe Conference & Exhibition, 14-18 March, 2011