Effect of Polypropylene Fiber on Properties of Mortar

Salahaldein Alsadey*

Faculty of Engineering, Department of Civil Engineering, Bani Waleed University, Beni Walid City, Libya

Abstract

Keywords

Mortar, Polypropylene Fiber, Cement, Compressive Strength

Received: June 9, 2016

Accepted: July 1, 2016

Published online: July 27, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Mortar is a very adaptable building material, but it is not very green and this effect comes mainly from the effect of the chemical composition in Portland cement. Portland cement provided the early hardness to speed mortar used in projects. On other hand, Portland cement concrete industry has grown astronomically in recent years. In addition, concrete is known a simple material in form but with a very compound internal nature. In contrast to its internal complexity, durability, and economy of concrete have made it the most often used construction material in the world. This paper describes the rational basis for the use of cement mortars in construction applications today. Research used to show these properties will also be identified and discussed.

Fiber-reinforced is mortar containing fibrous material which increases its structural properties. It has short discrete fibers that are uniformly distributed and randomly oriented. Fibers include steel fibers, glass fibers, synthetic fibers and natural fibers – each of which lend varying properties to the mortar. In addition, the character of fiber-reinforced mortar changes with varying mortars, fiber materials, geometries, distribution, orientation, and densities. However, the use of fiber reinforced mortar has increased in building structures to improve the toughness, flexure strength, tensile strength, impact strength as well as the failure mode of mortar. It has also been known that addition of fibers in mortar has little or no effect on the compressive strength. Fiber–reinforced concrete is becoming an increasingly popular construction material due to its improved mechanical properties over unreinforced concrete and its ability to enhance the mechanical performance of conventionally reinforced concrete. Fiber reinforcement is one of the most important modification methods to alter the brittle nature of plain concrete. Fibers are generally used as resistance of cracking and strengthening of concrete. In this paper an experimental study is made on the utilization of plastic waste in concrete cubes with addition percentage ranging from 0% to 3% [1].

The use of fibers in cement-based materials may considerably enhance the toughness, impact resistance, durability and reduce the cracking in concrete [2]. The main weaknesses of incorporating the fibers are the loss of workability and the increased difficulty of casting. This status may lead to an insufficient workability and high volumes of entrapped air in mortar, which cause reduction in its strength and durability [3]. The modern concrete can be designed to have the high flowability, whereby the term ‘flowability’ suggests that the concrete is able to flow in the congested reinforcement areas and fill complicated formwork without segregation [3,4]. Additionally, the repaired mortar applied to concrete is usually hard to consolidate well; therefore, the said mortar with high flowability may bring considerable advantages to the narrow mould system [5].

The cracks in cement composites are inevitable. There are two types of cracks. One is formed when the stress exceeds the strength of cement composites; the other is formed in the plastic stage and caused by external temperature, relative humidity, and loss of moisture due to wind [6]. Adding polypropylene fibers to the cement composites is an effective method of preventing crack formation [7]. The dispersion of the fibers in the wet mixture and their bonding with the mortar can reduce bleeding, prevent cracks, and increase the strength of the mortar [8]. Sanjuan et al. [9] suggested that polypropylene fibers can improve the properties of the mortar and also restrict plastic shrinkage cracks. Banthia and Gupta [9] showed that the more the fiber content is, the greater the crack-resistance of the mortar is. Ward and Li [11] suggested that fiber forms influence the properties and workability of the mortar, while Singh et al. [12] indicated that polypropylene fibers have excellent bonding, and can greatly improve the properties of the mortar.

In recent years, the production process of polypropylene fibers is very mature; costs have been reduced, and many types of polypropylene fibers are available. Adding fibers to cement composites can form an excellent composite material, and it is widely utilized in civil engineering. Many studies have indicated that the fiber content is one of the most important factors of the strength of mortar and concrete [13,14,15], but few papers have addressed the influence about the forms, strength, fineness, and dispersion of fiber [10,14], etc. This paper consequently investigates the mechanical properties of mortar which containing four types of polypropylene fibers and plastic shrinkage cracking.

By far the best advantage of using polypropylene fibers is that they offer significant cost reduction and benefits associated with processing as compared to other synthetic fibers. Polypropylene fiber has a considerably low cost to the other fiber-types. However, a polypropylene fiber leads to an improved potential for crack control, although the volumetric density is high. As a result, the polypropylene fiber content has to be reduced to a certain level. Optimizations of mechanical and conductivity properties can be achieved by different types and sizes of fibers, such as in the case of polypropylene fiber.

Polypropylene fibers have been widely used for the reinforcement of cementitious materials to improve the toughness and energy absorption capability of matrix [17]. They were found to be extremely effective in reducing free plastic shrinkage, in retarding first crack appearance and in controlling crack development [18]. Although effectiveness of Polypropylene fibers in shrinkage cracking, impact resistance and ductility of cement matrices has been proved by many researchers, effect of Polypropylene fibers on compressive and flexural strength is not quit clear [19]. Studies have shown that there can be little or no chemical adhesion between the fiber and matrix as a result of their chemical inertness [20]. It seems that smooth surface of Polypropylene fibers intensifies this effect. Moreover, it has been suggested that the presence of Polypropylene fibers in cement paste results in the formation of a water film at the interface of fiber and matrix called wall effect. Due to greater mobility of calcium ions in a water environment, portlandite (calcium hydroxide) macro crystals can easily grow and make the transition zone more pores [21]. This phenomenon has a negative impact on the bond between fiber and matrix. It is clear that in order to utilize the maximum strength of the fiber and improve the composite properties, it is essential to enhance the interfacial bond of Polypropylene fibers.

By utilizing techniques such as multiple reactor configurations, polymerizing other gases such as ethylene or butane in conjunction with propylene to form copolymers, using special additives to control crystalline, etc., different types of polypropylene resins can be produced.

Advantages of Polypropylene Fibers:

a. Polypropylene is a light fiber, is the lowest of all synthetic fibres.

b. Excellent chemical resistance.

c. Low-cost of polypropylene fiber inexpensive compared to other synthetic fibers.

d. Polypropylene fiber easy to process compared to other synthetic fibers.

e. Good antistatic character as well as wide availability and Low cost.

In the present paper, test specimens were prepared for studying the effect of polypropylene fibers on the mechanical properties of normal strength mortar. The tests conducted included determining the compressive strength of hardened mortar with different volume fractions of the polypropylene fiber.

2. Aim of Study

The aim of this investigation is to study the effect of polypropylene fiber on the compressive strength of cement mortar. However, due to the brittleness of mortar, it is suggested to reinforce this mortar with fibers, thus enhancing its properties.

3. Materials and Mixed Proportions

A. Materials Used and Properties

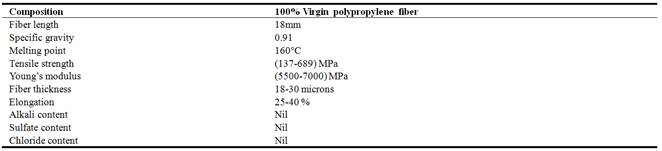

The experimental investigation was carried out in the Concrete Laboratory of the faculty of Engineering University of Bani Waleed. The cement used in mortar mixtures was the ordinary Portland cement type I manufacture in Zlitan. The fine aggregate was sea sand, with a fineness modulus of 2.86 and maximum size of less than 5 mm, water. High performance (18 mm) polypropylene fiber was used in this investigation. This fiber shows a micro reinforcement manufactured from (100%) polypropylene. It was brought from Sikca Company for Construction Chemicals. Polypropylene fiber complied with requirements of ASTM C1116-1997, Type ΙΙΙ [21]. It was stored under cover away from heat sources. Table (1) shows the physical and technical properties of polypropylene fiber.

Table 1. Physical and Technical Properties of Polypropylene Fiber.

B. Mix Proportions and Mixing Method

Four mortar mixes were prepared using the water-cement ratio as 0.50. The sea sand was used as fine aggregate. The mix design of the control mix (M1) was carried out according to the absolute volume method given by the ACI 211.1 [23] to achieve the criteria of flowing cement mortar. The polypropylene fiber of the volumetric fractions 0.5, 1 & 1.5% were used to prepare mixes: M2, M3 & M4, respectively. Each batch of mortar was produced in a pan mixer. At first, cement, sand, water were added to the mixer and mixed for 3 minutes. Then the polypropylene fiber was disseminated to prevent any agglomerates of fibers and the mixture was further mixed for other 3 minutes.

C. Casting and Compaction

According to ASTM C192-88 [24], after mixing process, the mix was immediately poured into moulds by means of a scoop. Casting of the samples was carried out in two layers; each layer was compacted by using a small steel bar. The complete compaction was determined by appearance of a film of cement mortar on the top and the air void was no longer appearing. After compaction, the top surfaces of specimens were trowelled level for obtaining smooth surface.

D. Curing

After casting, all specimens were kept under nylon sheets inside the laboratory for (24±1) hours to assure a humid air around the specimens and to prevent fast evaporation of water from the specimens, and then they were demoulded and cured until they were tested. All specimens prepared for compressive was stored in tap water tanks until testing age of 28 days.

4. Test Methods

a. Flow Table Test for Consistency of Mortar Mixes:

The amount of water required for standard consistency of plain mortar or fiber reinforced mortar was determined by the flow test. Flow table was prepared according to ASTM C1437-01 [28] for use in tests of hydraulic cement. The amount of mixing water was sufficient to produce a flow of (100±10) mm expressed as a percentage of the original diameter of the flow mould. The required amount of water for standard consistency of mortar was expressed in terms of (w/c) ratio.

b. Compressive Strength Test:

Compressive strength tests were conducted on a (50×50×50) mm mortar cubes according to the B.S. 1881 Part116: 1983 [25] by using 3000 kN capacity, ELE Digital Electric testing machine. The cube specimens were left in the moulds for 24 hours at 25±2°C. The loading rate used in the test was 0.3 MPa/sec. The test was conducted at ages of (28) days and three specimens were tested at each mix.

5. Results and Discussion

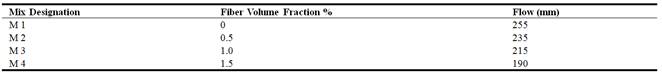

A. Effect of Polypropylene Fiber on Workability

The effect of fibers on the flow of the four mortar mixes is highlighted in Table (2). It is easy to note that the inclusion of polypropylene fiber in cement mortar reduces the flowing ability. On the other hand; a higher amount of polypropylene fiber makes loss flowability. In summary, the effect of polypropylene fiber on either the flowing or working capacity is much less than the references cement mortar.

Table 2. The Workability Results for All Mortar Mixes.

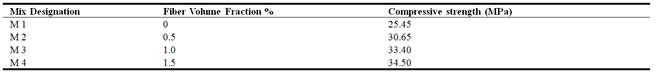

B. Effect of Polypropylene Fiber on Compressive Strength

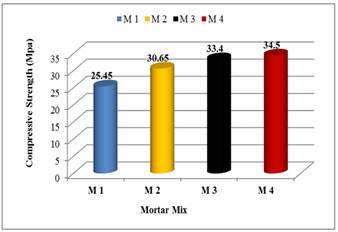

From Table (3) and figure 1, when polypropylene fibre was used, the increase in the compressive strength of the cement mortar reinforced with polypropylene fiber was up to 20.43% compared with that of the reference mortar. This result was obtained from the low volume fraction of polypropylene fiber up to 0.5% used in the mix (M2). The use of 1.0% of polypropylene fiber used in the mix (M3) increases the compressive strength up to 31.34% compared with that of the reference mortar. Alternatively, the compressive strength of the cement mortar with polypropylene fiber volume fraction increased significantly compared to the reference mortar. It is observable that the increase of the compressive strength by using 1.5% volume fraction of polypropylene fiber (M4) would increase the compressive strength up to 35.56%, as opposed to the reference mortar. This condition can be rooted from the improvement in the mechanical bond strength when the fibers allow the ability to delay the micro-crack formation and arrest their propagation afterwards up to a certain extent [26-27]. The comparison between control mortar mix with the different volume fraction of polypropylene fiber used in this study shows that there is significant enhancement of compressive strength. This is again due to the increase of mechanical bond strength.

Table 3. The Compressive Strength Results for All Mixes.

Figure 1. Compressive strength of Polypropylene Fibre.

6. Conclusion

This study has investigated the behavior of mortar reinforced to improve the mechanical properties. On the basis of the results of this work, the following conclusions may be deducted:

A. The use of polypropylene fiber affects the workability of fiber reinforced mortars; Polypropylene fibers produce harsh mixes significantly.

B. The use of polypropylene fiber increase the compressive strength when fiber volume fraction exceeds (0.5%) by about (30.65%), (33.40%) for (1%) and (34.50%) for (1.5%) volume fraction of polypropylene fiber.

Acknowledgement

The author would like to express gratitude to the students of Civil Engineering for their continuous support during experimental work.

References

- Salahaldein Alsadey (2016) "Effect of Polypropylene Fiber Reinforced on Properties of Concrete". Journal of Advance Research in Mechanical and Civil Engineering.

- F. Burak, S. Turkel & Y. Altuntas "Effects of steel fiber reinforcement on surface wear resistance on self-compacting repair mortar", Cem. & Conc. Comp.; 29, 2007, pp.391-396.

- L. Gang,K. Wang & T.J. Rudolphi "Modeling reheological behavior of highly flowable mortar using concepts of particle and fluid mechanics", Cem. & Conc. Comp.; 30, 2008, pp.1-12.

- H.Okamura, & M.Ouchi "Self compacting concrete", J. Adv. Concr. Technolgy, 1(1); 2003, pp.1-15.

- K.H. Khayat, R. Morin "Performance of self-consolidating concrete used to Repair parapet wall in Montreal", Proceedings of the first north American conference on the design and use of self-consolidating concrete, 2002, pp. 475-481.

- ACI Committee 308, Standard Practice for Curing Concrete (308R-92), ACI Manual Concrete Practice, American concrete institute, Farmington Hill, MI, pp. 10-16, 1997.

- Khaliq, W., and Kodur, V., "Thermal and Mechanical Properties of Fiber Reinforced High Performance Self-consolidating Concrete at Eleavated Temperatures," Cem. Concr. Res.,Vol. 41, No. 11, pp. 1112-1122, 2011.

- Kerans, R. J., and Parthasarathy, T. A., "Theoretical Analysis of the Fiber Pullout and Pushout Tests" J. Amer.Ceramic Soc., Vol. 74, No. 7, pp. 1585-1596, 1991.

- Sanjuan, M. A., Andrade, C., and Bentur, A., "Effect of Crack Control in Mortars Containing Polyethylene Fibers on The Corrosion of Steel in A Cementitious Matrix," ACI Mater., Vol. 94, No. 2, pp. 134-141, 1997.

- Banthia, N., and Gupta, R., "Influence of Polypropylene Fiber Geometry on Plastic Shrinkage Cracking in Concrete," Cem. Concr. Res.,Vol. 36, No. 7, pp. 1263-1267, 2006.

- Ward, R. J., and Li, V. C., "Dependent of Flexural Behavior of Fiber Reinforced Mortar on Material Fracture Resistance and Beam Size," ACI Mater., Vol. 87, No. 6, pp. 627-637, 1990.

- Singh, S., Shukla, A., and Brown, R., "Pullout Behavior of Polypropylene Fibers From Cementitious Matrix," Cem.Concr. Res., Vol. 34, No. 10, pp. 1919-1925, 2004.

- Barluenga, G., "Fiber-Matrix Interaction at Early Ages of Concrete with Short Fibers," Cem. Concr. Res.,Vol. 40, No.5, pp. 802-809, 2010.

- Wang, J. Y., Banthia, N., and Zahang, M. H., "Effect of Shrinkage Reducing Admixture on Flexural Behaviors of Fiber Reinforced Cementitious Composites," Cem. Concr. Compos., Vol. 34, No. 4, pp. 443-450, 2012.

- Soroushian, P., and Ravanbakhsh, S., "Control of Plastic Shrinkage Cracking with Specialty Cellulose Fibers," ACI Mater., Vol. 95, No. 4, pp. 429-435, 1998.

- Song, P. S., Hwang, S., and Sheu, B. C., "Strength Properties of Nylon-and Polypropylene Fiber-reinforced Concrete." Cem.Concr. Res., Vol. 35, No. 8, pp. 1546-1550, 2005.

- .Sun W., Chen H., Luo X., Qian H., The effect of hybrid fibers and expansive agent on the shrinkage and permeability of high performance concrete, Cement and Concrete Research, 2001, 31,595-601.

- Toledo Filho R.D., Sanjuan M.A., Effectof low modulus sisal and propylene fibers on the free and restrained shrinkage of mortars at early age, Cement and Concrete Research, 1999, 29, 1547-1604.

- Toutanji H.A., Properties of polypropylene fiber reinforced silica fume expansive-cement concrete, Construction and Building Materials, 1999, 13, 171-177.

- Linfa Y., Pendleton R.L., Jenkins C.H.M., Interface morphologies in polyolefin fiber reinforced concrete composites, Composite Part A, 1998, 29(A), 643-650.

- Holmer S.J., Vahan A., Transition zone studies of vegetable fiber-cement paste composites, Cement and Concrete Composites, 1999, 21, 49-57.

- SickaCompany, "Technical Data Sheet Catalogue".

- The American Concrete Institute (ACI 211.1-91) Standard P "Standard Practice for selecting Proportions for Normal,Heavyweight, and Mass Concrete ", ACI Manual of Concrete Practice 2000, Part 1: Materials and General Properties of Concrete.

- ASTM C230 "Standard Specification for Flow Table for Use in Tests of Hydraulic Cement ".Annual book of ASTM standard; 2002.PA, www.astm.org.

- ASTM C109 "Standard Test Method for Compressive Strength of Hydraulic Cement Mortars Using 50mm Cube Specimens ". Annual book of ASTM standard; 2002.

- E. T. Dawood & M. Ramli."Development of high strength flowable mortar with hybrid fiber"Construction and Building Materials Journal 2010, 24 (6), 2010, 1043–1050.

- B. Chen & J. Liu"Residual strength of hybrid-fiber-reinforced high-strength concrete after exposure to high temperatures"Cement & Concrete Research; 34, 2004. pp.1065-69.

- ASTM C192/C192M-02, "Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory", Annual Book of ASTM Standards, Vol.04.02, 2003; pp.126-133.