Drying Sewage Sludge Using Microwave Technology - Modern Method and Energy Efficiency

Emilian-Narcis Riti-Mihoc*, Emil Riti-Mihoc, Dan Porcar

Faculty of Materials and Environmental Engineering, Department Environmental Engineering and Sustainable Development Entrepreneurship, Technical University of Cluj-Napoca, Cluj-Napoca, Romania

Abstract

This paper presents new experimental results regarding energy efficiency of the treatment in microwave field of the sludge from wastewater treatment plants. Research was based on comparing by drying in heat convection and drying by heating in the microwave field. Are presented the results of experiments, and the phenomena occurring in the two types of drying analyzed. The final results highlights the energy efficiency of drying in microwave field compared to convective drying.

Keywords

Sewage Sludge, Wastewater, Microwave Treatment, Energetic Efficiency, Drying Sludge

Received: February 29, 2016

Accepted: March 19, 2016

Published online: December 27, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

According to the study "Environmental, Economic and Social Impacts of use of sewage sludge on land" commanded by DG Environment of the European Commission, carried out by the company Milieu Ltd and WRC, resulting an average of sludge 25 kg dry solid / capita / year, in the European Union [11]. So in the whole European Union in 2018 production is estimated at 12.5 million t dry solid /year, the equivalent of over 13 billion m3 wet sludge/year. These huge amounts of sludge raises big management problems and handling. Thus, there are several concerns at European and global level to reduce sludge quantities handled. The main method to reduce the volume of sludge is drying. But we find that this current production of sludge, drying methods, e.g. natural drying on sand is not effective and requires large spaces, and the thermal drying, classical, requires high energy. Therefore, a new drying technology that minimizes energy consumption, it must be developed [1] [2] [3] [5] [7].

The microwave drying was analyzed as an alternative to the convective drying, was analyzed in terms of process efficiency due to the different nature of the heating phenomena [6].

To determine the efficiency of drying of sludge in microwave field compared to conventional drying by heat input from an external source, the experiments ware made with two dimensions of samples, namely samples of mass 30 g respectively 40 g [7].

In the process of drying in microwave field we determined that drying to be at maximum 1000 W power and minimum power at 100 W.

In the process of conventional drying, the enclosure was made in an oven with the temperature in the workspace set at 200±5°C. I used for determinations, sludge from the line of treatment from WWTP Cluj-Napoca, taken immediately after centrifugal filtration and mechanical dewatering being taken under the same conditions for both cases [8].

2. Description of Experiments

2.1. Equipment Used

For the drying of the sludge in microwave field we used: laboratory stand for the thermal processing in microwave field with a resonant chamber, digital equipment for temperature monitoring with thermocouple immersion type sensor M 4011, electronic balance type KERN PCB and microwave transparent plastic containers for samples, the maximum working temperature a 180°C [7] [10].

For conventional drying we used to heating: Oven, type Memmert VO 500, with the following characteristics [8]:

• Voltage / frequency power: 230 (±10%) V; 50/60 Hz.

• installed power: 2400 W;

• working temperature +20°C ... +200°C;

• Working chamber dimensions: 545x465x400 mm; 100 l.

2.2. Procedure for Drying in the Microwave Field

• Samples preparation;

• Determining of initial mass of the samples;

• Put the samples in the chamber, closing and adjusting the power and time of exposure to microwaves.

• Let the samples to cool below 35°C;

• Weighing the samples.

2.3. Procedure for Conventional Drying

• Samples preparation;

• Determining of initial useful mass of the evidence;

• Heating the oven to the temperature;

• Put the samples in the oven and mentaining the prescribed drying time;

• Let the samples to cool below 35°C;

• Weighing the samples.

Preparation of the samples had three phases: weighing the empty containers, filling containers with sludge and final weighing, the difference will determine the correct amount of sludge contained.

The weighing was done individually for each sample using the electronic balance.

The exposure time was adjusted in both cases minute by minute up to 10 minutes. In the case of oven drying after 10 minutes the drying was continued step by step from 5 to 5 minutes.

For each set of measurements were prepared three samples for each time exposure.

2.4. Working Parameters

The conditions and the operating parameters were as follows:

• Sample size: - sets of samples with a weight of 30 g, and 40 g, (the measurement error of: ±0,5 g);

• Time of exposure in microwave field minute by minute up to ![]() minutes. In the case of oven drying was continued step by step from 5 to 5 minutes;

minutes. In the case of oven drying was continued step by step from 5 to 5 minutes;

• Power of the magnetron (microwave field power) was 1000 W and 100 W.

• measuring precision of the sample ±0,001 g;

3. Processing and Results Interpretation

On the basis of these measurements was calculated, the mass variation of the samples after the treatment in microwave field, the weight loss relative to the initial mass of the sample and the mass percentage loss.

To compare the speed of drying, in two variants, I calculated the relative humidity as the ratio of mass of the sample at a time and dry solids content of the sample.

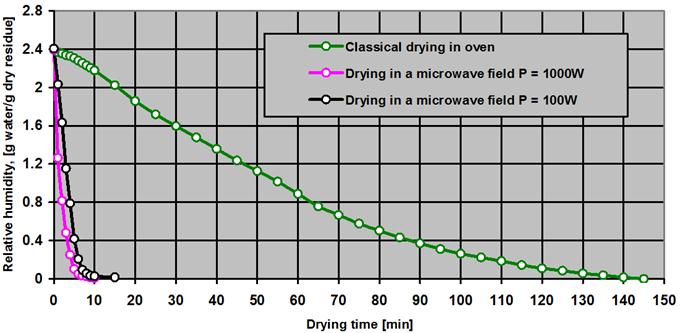

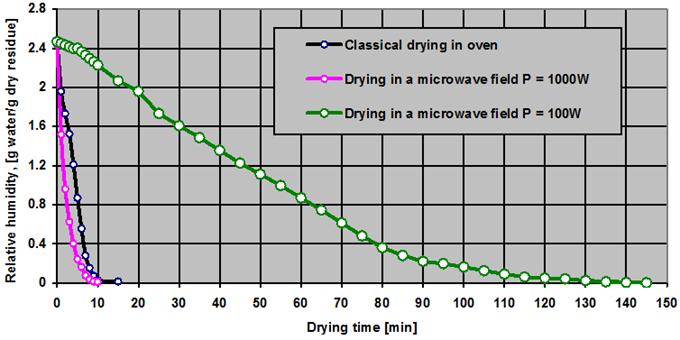

On the basis of the measured values and calculated are plotted the curves of drying for the sawage sludge in an oven and in the microwave field, depending on the power of the microwave field, the drying time and the mass of samples (Figure 1 and 2).

From drying curves for indirect heating (convection) in oven, it can be see that at the beginning of heating, water molecules from the surface were easily evaporated with the heat transfer to the sample. This drying period at a constant rate (described by linear slope of the drying curve) continued as long as the rate of diffusion of water molecules within the sample of sludge, is as fast as the rate of evaporated water.

It can be seen that the drying process has slowed gradually as the amount of water molecules transferred to the surface, by diffusion started to fall and humidity at surface decreased. So the amount of moisture removed during this period was relatively small, and the duration and heat consumption were high. This inefficiency encountered to the convective drying was caused by low thermal diffusivity and low capillary forces from sludge.

Figure 1. Drying curves of samples weighing 30 g, compared oven and in the microwave field at P = 1000 W maximum power and 100 W minimum power.

Figure 2. Drying curves of samples weighing 40 g, compared oven and in the microwave field at P = 1000 W maximum power and 100 W minimum power.

As shown in the figures 1 and 2, drying in the microwave field, is more efficient than to convective heating. Thus, from the experimental data, it show that, during the drying in the microwave field the humidity was reduced significantly in a relatively short time. In fact, in less than 10 minutes, the humidity has dropped below 5 ÷ 6 %, compared with duration of up to 150 minutes the case of convection drying, in preheated oven at 200°C. If the heating temperature of the oven is lower, this duration may increase several times.

By comparing the experimental data we can see that, in the case of drying sewage sludge in the microwave field, the drying process may be reduced by 15 to 20 times, due the way of transfer of energy in a microwave field directly in all mass of sludge. This phenomena is explained by the fact that the energy of microwave field acting on the water molecules from inside of the sludge, which vibrates very quickly, with the frecvency of microewave field, so that the resulting heat is transferred directly to sludge without loss. By this process, the sludge was heated from the inside to outside, and the evaporation of water begins from the inside of sample to the outside. In fact at the beginning of the heating process was observed to the surface of the sample a pronounced wetting, a phenomena that was as much greater as the power of the microwave field was higher. This wetting is explained by the fact that the heating began from inside, and thus the vaporization temperature was reached fastest than to the outside, thus creating vapors producing an internal pressure which pushes the capillary water and mechanically linked water to the outside. At the same time produce a condensation vapors produced inside the sample, to the passing through the cool layers to the surface.

This is totally different from convective drying, which began heating from the outside of the sample, and the migration of water molecules to the surface was only by diffusion.

Whatever in the both cases, the volume ware greatly reduced, due to moisture loss.

An equation expressing the time from drying in microwave field, determined by algebraic regression based on drying curves can be expressed in according of the sludge humidity and the magnetron power output with relations:

![]() (1)

(1)

Where:

![]()

![]()

![]() - is moisture sludge

- is moisture sludge ![]()

Thus the relationship

![]() (2)

(2)

From the tangents of drying curves, which gives the values ![]() , can be determined values of the drying rate, wich can be obtained by calculation using equation (3).

, can be determined values of the drying rate, wich can be obtained by calculation using equation (3).

![]() (3)

(3)

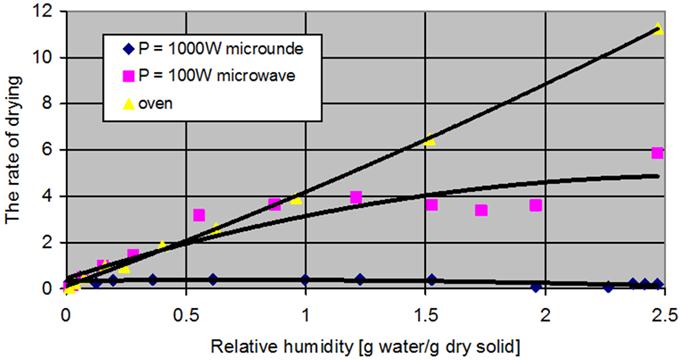

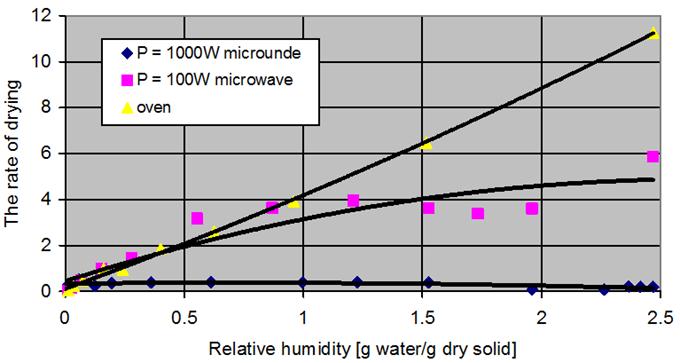

With these values were traced curves of the drying rates depending on the relative humidity (Figure 3 and Figure 4)

Figure 3. The rate of drying of the samples with a weight of 30 g compared to the conventional oven and the microwave field at the maximum power P = 1000 W and 100 W.

Curves of the drying rates show a significant difference between the rates of drying, in microwave field and convective drying techniques. For samples of 40 g may find that, for convective drying, average rate of drying for the period drying constant speed (up to a humidity of 5-6%) was approximately 0.2 gwater/min, and for drying microwave were 4 and respectively 2,6 gwater/min, to the power of 1000 W and respectively 100 W. The results indicated that the mass transfer, in the sludge was faster during drying in the microwave field compared to the convective

In the case of convective drying of sewage sludge on the surface is formed a hard layer which is substantially impermeable to the flow of humidity and slows humidity transfer. This layer is a barrier to the loss of humidity and is known as cementation. Temperature of the sample of sludge in this case was colder than the ambient temperature. Therefor a pressure gradient from the inside to the outside to accelerate the diffusion of humidity, was not present.

Figure 4. The rate of drying of the samples with a weight of 40 g compared to the conventional oven and the microwave field at the maximum power P = 1000 W and 100 W.

During the drying in microwave field the temperature inside the sample has come to the boiling point of water within one minute and created a large difference between vapor pressure from the inside and surface sludge sample. Thus, the transfer of moisture has been favorised by the the total pressure gradient, so the vapor and the capillary forces due to this pressure gradient forced humidity to migrate towards the surface due to the rapid formation of the vapor phase inside the sludge sample. When the material contains a lot of water, the water from upper layers is eliminated in liquid form due to the inside vapors pressure. During this period, the rate of moisture loss increased beyond "constant-rate", this time we can call the "circulation in liquid state", that not exist to the convective drying.

Drying process during the "constant-rate", lasts as long as the transfer of moisture from the interior to the surface is continuously to replace the water that being evaporated. Therefore, the time which the drying is done only by diffusion from humidity was much reduced.

In the case of drying in microwave field the phenomena of wetting of the surface, reduce the period of slowing the rate of drying and thus the performance of drying increases significantly. In general, using microwave of the great power, the efficiency of the process it might speed up with about 20 times, compared to the convective drying. For example, drying in microwave field, the temperature of 85°C in the sample of sludge was obtained in less than a minute, while the convective drying are needed approximately 150 minutes to achieve the same temperature, in this case the oven chamber temperature was maintained at 200°C.

4. Conclusions

Power generated by the magnetron of microwave is proportional to the pulse duration, so from the drying curves, by algebraic regression, was determined an empirical relationship to estimate the drying time required for a given humidity content, depending to the power generated by the magnetron.

It has been shown that the microwave drying of the sludge is much more efficient than the conventional methods, even if we consider only the drying time, but keep in mind that the heating in the microwave field does not supose the heating of the walls of the working chamber, as is for the conventional heating in the oven, this process I has a higher efficiency.

With the industrial application of this process for the treatment of sewage sludge, the energy consumption for drying can be greatly reduced as compared with conventional methods.

References

- Dan, V., Riti-Mihoc, E., Riti-Mihoc, E. N. - Thermal treatment of clearing sludge in microwave field, 4th Research / Expert Conference with International Participations "QUALITY" 2005 Fojnica, B & H, 2005.

- Dan V. - Contributions to study the process of heating and drying the molds using microwave energy PhD Thesis - Technical University of Cluj-Napoca, 2000.

- Dolande, J., Dana, A. - Temperature profiles in microwave heating of solids: a systematic study. Journal of Microwave Power and Electromagnetic Energy, Vol. 28, No. 2, p. 58-67, 2003.

- Gan, Q. - A case study of microwave processing of metal hydroxide sediment sludge from printed circuit board manufacturing wash water. Waste Management; 20:695–701, 2000.

- L iao, P. H., Wong, W. T. and Lo,K. V. - Release of phosphorus from sewage sludge using microwave technology, Natural Sciences and Engineering Research Council of Canada, 2005.

- Riti-Mihoc E. N., Riti-Mihoc, E., Porcar, D. - Mathematic Physical model of dimensioning system in the propagation of microwave "waveguide-sludge from wastewater treatment plants, 1st Annual International Interdisciplinary Conference AIIC 2013 24-26 April, Azores, Portugal Proceedings, European Scientific Journal, Special Issue, No. 3 June, 2013. ISSN: 1857-7881 (Print) ISSN: 1857-7431 (Online), pp. 82-90.

- Riti-Mihoc E. N., Riti-Mihoc, E., Porcar, D. – Research on Microwave Calcinations of Sewage Sludge, Metalurgia International, Special Issue No. 5, 2013, ISSN 1582-2214, pg. 139-142.

- Riti-Mihoc, E. N. - Studies and research on microwave field thermal processing sludge from sewage - PhD Thesis, Technical University of Cluj-Napoca, 2011.

- Riti-Mihoc, E. N., Riti-Mihoc, E., Fodor, M. - Experimental research on treatment of sludge settling in microwave field, VII National Conference "Professor Dorin Pavel - Romanian hydropower founder" Sebes 2007.

- Riti-Mihoc, E. N., Riti-Mihoc, E., Dan, V. - Stand for analyzing gas emissions from thermal processing in microwave field sludge settling, IX National Conference "Professor Dorin Pavel - founder of Romanian hydropower "Sebes, 2009.

- http://ec.europa.eu/environment/archives/waste/sludge/pdf/part_ii_report.pdf