Effect of Temperatures on Dissolution Performance of Scrap Lead Paste in Sodium Citrate Solution

Chunxia Gong1, 2, *, Yanjuan Chen1, Lifang Zhang1, Bo Wang1, Mingxue Fang1, Qun Chen1, Duyou Wang1

1Zhejiang Tianneng Battery (Jiangsu) Co., Ltd., Shuyang, Jiangsu, China

2School of Chemistry and Chemical Engineering, Southeast University, Nanjing, China

Abstract

People should appear arrhythmia, renal failure, convulsions, coma and even death if blood lead levels were more than 1000 mg/L. Lead impacts the body's nervous system and blood system significant. And in recent years, lead poisoning events occurred frequently. Therefore, it is very important for survival of human to research the properties of heavy metal lead. In this paper dissolution performance of scrap lead paste has been researched in sodium citrate solution at differenttemperature (20~80 ºC). The pH values of filtrate were all higher than 7 but lower than 7.51. 0.057~0.168 g sodium citrate was consumed by scrap lead paste per gram at 20~80 ºC. 0.575~1.815 g solid materials were residue, lowest at80 ºC. 10.677~24.404g·L-1lead in filtered liquor was tested, lowest at50 ºC. Dissolution rates of scrap lead paste were 9.544~17.883 %, also lowest at50 ºC.

Keywords

Dissolution Performance, Scrap Lead Paste, The pH, Temperature

Received: April 9, 2015 / Accepted: April 26, 2015 / Published online: May 15, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Our society and technology have more and more development and our living standard has been continuously improved, however, the resources also been unceasingly consumed, and the environmental problem has been increasingly serious. Energy and environmental protection have become two hot issues.

People should appear arrhythmia, renal failure, convulsions, coma and even death if blood lead levels were more than 1000 mg/L. Lead impacts the body's nervous system and blood system significant. And in recent years, lead poisoning events occurred frequently. Therefore, it is very important for survival of human to research the properties of heavy metal lead.

At present, lead acid battery has become the one kind of widespread used second batteries for the advantages of simple construction, reliable performance, lower price, easy getting of raw materials, convenient to use, and many other advantages1-2. It is mainly used as power source for automobile start and as auxiliary power supply for illumination, mintype electrombile and UPS3-5. Lead acid battery has become a primary consumption product all over the world; however, it also has become the mainly resources of lead renewable. Lead as a kind of highly toxic heavy metal, recycling and reusing it from the scraped lead acid battery is very important in environmental view.

When charging, the cathode material of lead acid battery turns into PbO2 and anode material turns into Pb. While discharging, the cathode and anode electrode active materials all turn into PbSO4. The reactions of materials when discharging are as follows,

Cathode reaction, PbO2 + HSO4− + 3H+ + 2e−→PbSO4 + 2H2O

Anode reaction, Pb + HSO4−→PbSO4 + H+ + 2e−

Overall reaction, Pb + PbO2 + 2H2SO4→PbSO4 + 2H2O

The manufacturing processes of lead acid battery mainly include exploiting and transformation of resource, preparation of material for battery and assembling of battery. Among the process of preparation of material and assembling of battery, especially the process of preparation of electrode, plenty of lead pastes will fall off as scrap lead pastes. Cyclic utilization of scrap lead paste is a significance measure which should reduce the batteries production fee and environmental pollution of heavy metal lead. The scrap lead paste mainly contains PbSO4 and PbO2. Therefore, desulphurization methods for scrap lead paste are important among cyclic utilization of scrap lead paste. The mainly desulphurization methods are Pyrometallurgy 6-7 and Hydrometallurgy method 8. Among Hydrometallurgy method, the flow desulfurization agent will be usually used: Carbonate 9-10(RSR11-12 and USBM13 technologies use (NH4)2CO3 as desulfurization agent, CX-EW14 technology uses Na2CO3 as desulfurization agent); NaOH 15-16; NaCl-HCl 17; citric acid-sodium citrate (C6H8O7·H2O-Na3C6H5O7·H2O)18-22; sulfate-reducing bacteria (CX-EWS technology)23and so on.

At this stage, many researchers used sodium citrate hydrometallurgy18-22 to dope with scrap lead paste; therefore, dissolution performance of scrap lead paste at different temperature in sodium citrate aqueous solution is very important for doping with scrap lead paste.

2. Experimental

The sodium citrate aqueous solutions which the concentration was 10 percent were prepared as follows: 16.7 ml of Na3C6H5O7×2H2O (30%) were constant volume to 50 ml by deionized water.

Experimental process was as follows: 5 g of scrap lead paste was added into 50 ml Na3C6H5O7×2H2O aqueous solution under vigorous stirring. Stirred for 5 min at different temperature (20~80 °C) in air atmosphere, filtered and washed for three times, then dried at 60 °C. The volume, pH value of filtrates and the masses of filter cakes were write down. Filtrates were diluted 2000 times then the concentrates of Pb2+ in filtered liquor was tested used atomic absorption spectroscopy (AAS). The dissolution rates of scrap lead paste(r) were calculated by follow pattern.

![]()

r, dissolution rate; c, concentrates of Pb2+ in filtrates; V, volume of filtrates; m, mass of scrap lead paste.

3. Results and Discussion

3.1. The pH Value of Filtrates

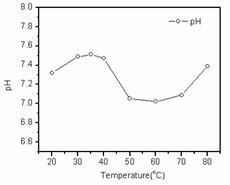

The pH curve of filtrates at 20~80 °C was shown in fig 1. It shows that pH values of filtrates all higher than 7 but lower than 7.51 after dissolved by Na3C6H5O7×2H2O at different temperature. Therefore, filtrates are neutral after dissolved by sodium citrate at 20~80 °C.

Fig 1. The pH curve of the filtrates at 20~80 °C

3.2. Mass of Sodium Citrate Consumed by Scrap Lead Paste per Gram

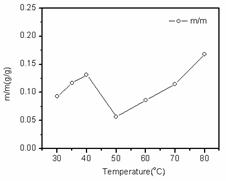

Fig. 2 shows the mass of sodium citrate was consumed by scrap lead paste per gram at 20~80 °C. They were from 0.0571 g to 0.1680 g; the mass of sodium citrate be consumed by scrap by lead paste per gram was lowest as 0.0571 g at 50 ºC. Therefore, a dissolution rate of scrap lead paste was lowest at 50 ºC in sodium citrate solution.

Fig 2. Mass of sodium citrate consumed scrap lead paste per gram at 20~80 °C

3.3. Percentages of Solid Remaining in Sodium Citrate

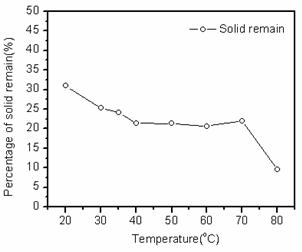

Fig. 3 shows the percentages of solid remaining in 10% sodium citrate aqueous solution at 20~80 °C. The percentages of solid remaining were from 9.657% to 30.93% doped with 10% sodium citrate aqueous solution at 80~20 °C. It shows a decrease of the percentages of solid remaining with higher the solution temperatures.

Fig 3. Percentages of solid remaining at 20~80 °C in 10% sodium citrate aqueous solution

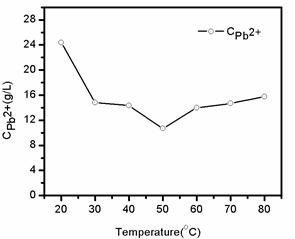

3.4. Concentrations of Pb2+in Filtrates

Fig. 4 shows the concentrations of Pb2+ in filtrates at 20~80 °C in 10% sodium citrate aqueous solution. The concentrations of Pb2+ in filtrates at 20~80 °C in 10% sodium citrate aqueous solution were from 10.677 to 24.404 g·L-1. It was lowest at 50 ºC as 10.677 g·L-1. Therefore, a dissolution rate of scrap lead paste was lowest at 50 ºC in 10% sodium citrate aqueous solution. This result was consistent with the result of fig 2.

Fig 4. Concentrations of Pb2+in filter liquor at 20~80 °C

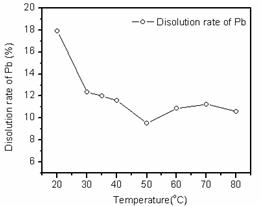

3.5. Dissolution Rates of Scrap Lead Paste

Fig. 5 shows the dissolution rates of scrap lead paste at 20~80 °C in 10% sodium citrate aqueous solution. The dissolution rates of scrap lead paste at 20~80 °C in 10% sodium citrate aqueous solution were from 9.544 % to 17.883 %, lowest at 50 ºC as 9.544 %. Therefore, a dissolution rate of scrap lead paste was lowest at 50 ºC in 10% sodium citrate aqueous solution. This result was also consistent with the results of fig 2 and fig 4.

Fig 5. Dissolution rates of scrap lead paste at 20~80 °C in 10% sodium citrate aqueous solution

4. Conclusions

Filtrates were all neutral after dissolved by 10% sodium citrate aqueous solution at 20~80 °C. 0.057~ 0.168 g sodium citrates were consumed by scrap lead paste per gram. Concentrations of Pb2+ (10.677 ~ 24.404 g·L-1) in filtered liquor was lowest at 50 ºC as 10.6772 g·L-1. The dissolution rates of scrap lead paste in 10% sodium citrate aqueous solution at 20~80 °C were from 9.544% to 17.883%. A dissolution rate of scrap lead paste was lowest at 50 ºC in this sodium citrate aqueous solution. These dissolution performances of scrap lead paste in 10% sodium citrate aqueous solution are very important for the survival of human to research the properties of heavy metal lead.

Acknowledgements

We would like to thank the help of Bin Wang, Yu Cheng and Hui Zhang in Zhejiang Tianneng battery (Jiangsu) Co., Ltd. and Jinxi Chen in School of Chemistry and Chemical Engineering, Southeast University.

References

- S.M. Tabaatabaai, M.S. Rahmanifar and S.A. Mousavi, "Lead-acid batteries with foam grids,."[J]. Journal of Power Sources, vol.158, pp.879-884, 2006.

- Y. Chen, B.Z. Chen and X.C. Shi, "Preparation and electrochemical properties of pitch-based carbon foam as current collectors for lead acid batteries."[J]. Electrochimica Acta,.vol.53,.pp. 2245-2249, 2008.

- M.L. Soria, J. Valenciano and A. Ojeda, "Development of ultra high power, valve-regulated lead-acid batteries for industrial applications,."[J]. Journal of Power Sources,.vol.136, pp.376-382, 2004.

- D. Pavlov, G. Petkova, M. Dimitrov, "Influence of fast charge on the life cycle of positive lead-acid battery plates,."[J].Journal of Power Sources, vol.87, pp.39-56, 2000.

- C.H. Yeh, C.C. Wan and J.S. Chen, "Physical and electrochemical characterization of PbO2 electrode prepared at different H2SO4/H2O/PbO ratios."[J]. Journal of Power Sources, vol.101, pp.219-225, 2001.

- J. M. Jiang, "Situation and development trend of lead smelting technology at home and abroad."[J].Energy Saving of Non-Ferrous Metallurgy,vol.3, pp.4-8,2013.(in Chinese).

- S. K. Guo, A. P. He, A. Q. Liu, et al. "New pyrometallurgi-cal processes and equipment for smelting lead," [J]. Shanghai Nonferrous Metals,.vol.23, pp.20-23, 2002.(in Chinese).

- X.J. Sun, J.K. Yang, W. Zhang, et al. "Lead acetate trihydrate precursor route to synthesize novel ultrafine lead oxide from spent lead acid battery pastes," [J]. Journal of Power Sources, vol.269, pp. 565-576, 2014.

- X. Zhu, J. Yang, L. Gao, et al. "Preparation of lead carbonate from spent lead paste via chemical conversion,"[J]. Hydrometallurgy, vol.134-135, pp.47-53, 2013.

- X. Zhu, L. Li, X. Sun, et al. "Preparation of basic lead oxide from spent lead acid battery paste via chemical conversion,"[J]. Hydrometallurgy, vol.117-118, pp. 24-31, 2012.

- H.D. McDonald, "Method of recovering lead values from battery sludge,"[P]. United States Patent, 4229271. 1980-10-21.

- R.D. Prengaman. "Recovering lead from batteries,"[J]. Jom-Journal of the Minerals Metals& Materials Society, vol.47, pp.31-33, 1995.

- E.R. Cole, A.Y. Lee and D.L. Paulson, "Update on recovering lead from scrap batteries,"[J]. Journal of Metals, vol.37, pp. 79-83, 1985.

- M. Olper, P. Fracchia, "Hydrometallurgica1 process for an overall recovery of the components of exhausted lead-acid batteries,"[P].United States Patent, 4769116. 1988-9-6.

- W.P. Chen, J.S. Gong and Q.Z. Li, "Researeh on Proeess for Redueing PbO:Contained in Lead Baffery Serapwith Fe2+,"[J]. Journal of Hunan University, vol.22, pp.53-58, 1995. (in Chinese).

- W.P. Chen, "New Technology of Hydrometallurgical Recovering Lead from Waste Battery Slurry,"[J]. Journal of Hunan University, vol.23, pp.111-115, 1996 (in Chinese).

- D. Andrews, A. Raychaudhuri, "Frias C. Environmentally sound technologies for recycling secondary lead,"[J]. Journal of Power Sources, vol.88, pp.124-129, 2000.

- M. S. Sonmez, R. V. Kumar, "Leaching of waste battery paste components: Part 1. Lead citrate synthesis from PbO and PbO2," [J]. Hydrometallurgy, vol.95, pp.53-60, 2009.

- J. K. Yang, X. F. Zhu, W. C. Liu, et al. "Review of recovery technology for lead paste from spent lead acid battery," [J]. Mod Chem Ind, vol.29, pp.32-36, 2009.

- M.S. Sonmez and R.V. Kumar, "Leaching of waste battery paste components. Part 2: Leaching and desulphurisation of PbSO4 by citric acid and sodium citrate solution,"[J]. Hydrometallurgy, vol.95, pp.82-86, 2009.

- X. Zhu, X. He, J. Yang, et al. "Leaching of spent lead acid battery paste components by sodium citrate and acetic acid,"[J]. Journal of Hazardous Materials, vol.250-251, pp.387-396, 2013.

- D.N. Yang, J.W. Liu, Q. Wang, et al. "A novel ultrafine leady oxide prepared from spent lead pastes for application as cathode of lead acid battery,"[J]. Journal of Power Sources, vol.257, pp.27-36, 2014.

- M. Olper, M. Maccagni and C.J.N. Buisman, "Electrowinning of lead battery paste with the production of lead and elemental sulphur using bioprocess technologies,"[C]. proceedings of the LEAD~ZINC 2000 symposium, Pittsburgh Pennsylvania USA, Minerals Met&Mat Soc, pp.209-210, 2000.