Selective Catalytic Reduction of Nitrogen Oxide by Ammonia over Copper-Hydroxyapatite Catalysts Prepared in Organic Medium

Jihene Jemal1, Carolina Pettito2, Gérard Delahay2, Zouheir Ksibi1, Hassib Tounsi3, *

1Department of Chemistry, Faculty of Sciences, Tunis, Tunisia

2Institute Charles Gerhardt, National School of Chemistry, Montpellier, France

3Department of Materials Engineering, National School of Engineers, Sfax, Tunisia

Abstract

Copper loaded hydroxyapatite catalysts have been prepared in organic medium by reaction/evaporation and impregnation methods and have been tested in the selective catalytic reduction of NO by NH3. The catalyst characterizations showed the presence of CuO and Cu2O particles deposited on the surface of the carrier in different environments and sizes. Compared to the catalysts prepared by ion exchange and impregnation in aqueous medium method, the ones prepared in organic medium are less efficient in the selective catalytic reduction of NO by NH3.

Keywords

NH3-SCR, NO, Cu(acac)2, Cu-HAp

Received: August 13, 2015

Accepted: August 20, 2015

Published online: August 27, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

It is well recognized that the use of Diesel and lean burn engines decreases the fuel consumption and thereby reduces the emissions of dioxide carbon, CO2. Unfortunately, the elimination of nitrogen oxides (NOx: NO + NO2) cannot be achieved easily in these engines because of the presence of an excess of oxygen in their emissions. One of the main technologies proposed for NOx reduction in Diesel and lean burn engines exhausts was the Selective Catalytic Reduction (SCR). This process was originally developed for stationary emission sources, using ammonia (NH3) as reducing agent (NH3-SCR) [1]. However, it soon turned out to be a promising technology for the NOx removal in automobile applications as well [2]. Urea was used as ammonia vector agent because it is safer and can be easily transported ‘‘on board’’. The urea solution is injected in a controlled way into the exhaust line, where it is thermally decomposed into NH3 and CO2. The ammonia then reacts selectively with NOx under lean conditions, giving N2 as the final product [3-4]. Various SCR catalyst technologies, namely vanadia, iron zeolite and copper zeolite are in commercial use today [3-5]. Copper-zeolite has the best low temperature deNOx performance with no or little NO2 in the gas [4]. However, it is susceptible to sulfur poisoning and demonstrates a lack of hydrothermal stability at temperature above 300°C. Recently, small-pore copper zeolites such as Cu-CHA and Cu-SAPO-34 have demonstrated superior hydrothermal stability and selectivity at low temperatures which make them the preferred catalysts for high-performing system [6-8]. For copper deNOx catalysts, it is generally assumed that dispersed oligomers or bulky CuO species are active in the region of low temperatures, while isolated Cu2+ cations catalyze the reaction at higher temperatures [1,3].

We reported previously [9-12] that hydroxyapatite (Ca-HAp) has a great capacity to disperse copper oxide on its surface. Therefore, it has been shown that the highly dispersed CuO clusters on the surface of Ca-HAp have excellent catalytic properties in the NH3-SCR of NO at low temperature range. Thus, the aim of this work was to evaluate the catalytic behavior of Cu-HAp catalysts where copper was introduced by reaction/evaporation and impregnation using copper (II) acetylacetonate (Cu(acac)2) as precursor. This method was used in order to avoid exchange and, thus to promote the formation of copper oxide aggregates highly dispersed on Cu-HAp support.

2. Experimental

2.1. Preparation of Support and Catalysts

The Hydroxyapatite (Ca-HAp) powder was prepared by an aqueous precipitation method using (NH4)2HPO4 and Ca(NO3)2·4H2O as starting materials and ammonia solution for pH adjustment [13]. For the catalysts prepared by reaction/evaporation method in organic medium, 1g of Ca-HAp was added to 50 mL of organic solvent (chloroform or toluene) under stirring for 1hour. The appropriate amount of Cu(acac)2 was dissolved in 50 mL of organic solvent and then drop-wise added to the slurry containing the Ca-HAp. After 24 hours of reaction, the solvent was removed by evaporation under vacuum. For the impregnated sample, 2 g of Ca-HAp was mixed with 10 mL of organic solvent (chloroform or toluene) containing the desired amount of copper. All the solids were dried at 70°C and then calcined in air (10°C. min-1) at 500 °C for 2 hours. For the catalysts prepared by ion exchange in solution and impregnation in aqueous phase, more details about the experimental data can be found in references [9,10]. The obtained catalysts were called Cu(x)-HApEW, Cu(x)-HApIW, Cu(x)-HApRE and Cu(x)-HApI with x the copper amount in wt.% and EW for exchange in water, IW for impregnation in water, RE for reaction/evaporation in organic phase and IO for impregnation in organic phase. Letters T and C were added in the end of each catalyst which referred to Toluene and chloroform, respectively. In table 1 we reported the preparation conditions, chemical analyses, BET surface area (SBET) and mean pore diameter (ø) of Cu(x)-HAp catalysts.

Table 1. Chemical analyses, BET surface area (SBET) and mean pore diameter (ø) of Cu(x)-HAp catalysts.

| Catalysts | Preparation method | Copper precursor | Solvent | Cu. (wt%) | SBET (m2/g) | ø (nm) |

| Ca-HAp | Precipitation | - | Water | - | 44 | 34 |

| Cu(1.33)-HApRET | Reaction + evaporation | Cu(acac)2 | Toluene | 1.33 | 47 | 30 |

| Cu(1.45)-HApIT | Impregnation | Cu(acac)2 | Toluene | 1.45 | 50 | 46 |

| Cu(1.66)-HApRET | Reaction + evaporation | Cu(acac)2 | Toluene | 1.66 | - | - |

| Cu(2.32)-HApIC | Impregnation | Cu(acac)2 | Chloroform | 2.32 | 49 | 43 |

| Cu(2.98)-HApREC | Reaction + evaporation | Cu(acac)2 | Chloroform | 2.98 | 47 | 35 |

| Cu(4.22)-HApREC | Reaction + evaporation | Cu(acac)2 | Chloroform | 4.22 | 44 | 37 |

| Cu(1.12)-HApEW [10] | Ion exchange | Cu(NO3)2 | Water | 1.12 | 34 | 17 |

| Cu(2.98)-HApEW [10] | Ion exchange | Cu(NO3)2 | Water | 2.98 | 32 | 28 |

| Cu(1.37)-HApIW [11] | Impregnation | Cu(NO3)2 | Water | 1.37 | 46 | 14 |

| Cu(1.86)-HApIW [11] | Impregnation | Cu(NO3)2 | Water | 1.86 | - | - |

2.2. Characterization Techniques

Elemental analyses were performed by "Service Central d’Anlayse" of the "Centre National de la Recherche Scientifique; CNRS" in Vernaison FRANCE (www.sca.cnrs.fr). The textural properties of the samples were determined by adsorption and desorption of N2 at -196 °C, using Micromeritics ASAP 2020. Samples were degassed for 12 hours at 250 °C before adsorption. The BET method was used to determine the specific surface area whereas the mean pore size and volume were estimated using the Barret-Joyner-Halenda (BJH) approximation. The XRD patterns were obtained by Bruker D8 Advance diffractometer operating with Cu Kα (λ = 0.15418 nm) at room temperature (RT). Powder patterns were collected at a rate of 5°.min-1 from 5 to 60° 2θ with a step size of 0.02°. The redox properties of the catalysts were studied by temperature-programmed reduction method (H2-TPR). The experiments were carried out with a Micromeritics AutoChem II Chemisorption Analyser using H2/Ar (5/95, v/v) gas at a total flow-rate of 30 cm3.min-1 and by heating the samples from RT to 500°C (10°C. min-1). In each case, 0.051 g of the catalyst was previously activated at 550°C for 30 min under air, and then cooled to RT under the same gas. The TPR with H2/Ar (5/95, v/v) was then started and the thermal conductivity detector monitored continuously H2 consumption. The NH3-SCR reaction was performed in a continuous-flow fixed-bed quartz reactor under atmospheric pressure. An aliquot of the catalyst (0.022 g) was introduced in the reactor, heated up to 550°C for 1 h under nitrogen flow and cooled to room temperature. The catalytic tests were carried out in a temperature programmed surface reaction (TPSR) from 25 to 550 °C at 10°C. min-1. The following gas composition (400 ppm NO, 400 ppm NH3, 8% O2, balanced with Helium) was used for NH3-SCR of NO. The outlet gases from the reactor were analyzed continuously by sampling on line to quadruple mass spectrometer (Pfeiffer Omnistar) equipped with Channeltron and Faraday detectors (0-200 amu) and following the masses: NO (30), N2 (14, 28), N2O (28, 30, 44), NH3 (17, 18), O2 (16, 32) and H2O (17, 18).

3. Results and Discussion

3.1. Catalytic Performance of the Catalysts in the NH3-SCR of NO

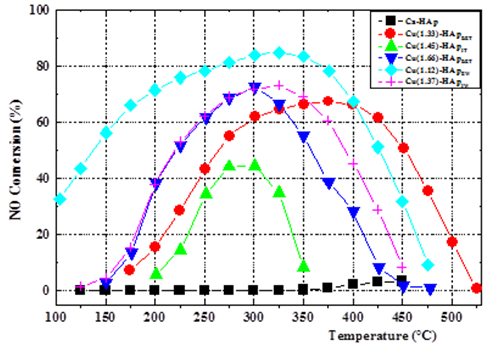

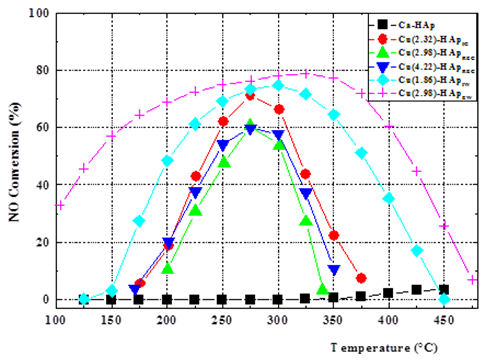

The NO conversion profiles of the support Ca-HAp and the different Cu(x)-HAp catalysts are presented in Fig.1 and Fig.2. The reduction of NO by NH3 in presence of an excess of O2 proceeds according to the standard reaction (1):

4NO + 4NH3 + O2 → 4 N2 + 6H2O (1)

The introduction of copper to Ca-HAp, which is inactive for NO reduction, produces marked changes in the catalytic behavior. For Cu(x)-HAp catalysts, the NO conversion increases with the temperature, reaches a maximum and then decreases more slowly. This behavior reveals a competition between two reactions. The first correlated to NO reduction to N2 and the second to NH3 oxidation into NO or/and N2O by the oxygen present in the reaction mixture as shown in reaction (2), (3) and (4).

4NH3 + 3O2 → 2 N2 + 6H2O (2)

2NH3 + 2O2 → N2O +3H2O (3)

4NO + 4NH3 + O2 → 4 N2O + 6H2O (4)

As can be seen in figure 1, the catalysts prepared by reaction/evaporation method in toluene (Cu(1.33)-HApRET and Cu(1.66)-HApRET) exhibited appreciable NO conversion over a broad temperature range. For Cu(1.66)-HApRET, which is active at low temperatures, the NO conversion is about 12% at 175 °C, reached 72 % at 300 °C and then decreased progressively to 0% at 450 °C. Whereas, Cu(1.33)-HApRET is more active at high temperatures than Cu(1.66)-HApRET with more broader activity window. Indeed, Cu(1.33)-HApRET is still active at 450°C with NO conversion about 50%. Cu(1.45)-HApIT catalyst, prepared by impregnation, is the least active among all catalysts with NO conversion about 45% at 300°C. On the other hand, the catalysts Cu(1.66)-HApRET and Cu(1.37)-HApIW prepared by different methods exhibit nearly the same NO conversion profiles at temperature below 300°C. On the other hand, Cu(1.12)-HApEW catalyst prepared by ion exchange in water efficiently operated in the low temperature region, whereas, Cu(1.33)-HApRET is the most active catalyst above 400 °C.

The comparison of NO conversion of catalysts prepared in chloroform is reported in figure 2. These catalysts are less active than those prepared in water and toluene. Surprisingly, the most active catalyst was Cu(2.32)-HApIC, which is prepared by the impregnation method. The NO conversion started around 175°C (5%), reached 71% at 275°C and then decreased progressively to 7% at 375°C. It seems that, the use of chloroform as organic medium does not help to obtain well dispersed copper oxide on the surface of Ca-HAp.

Figure 1. NH3-SCR of NO in oxidizing atmosphere of the Ca-HAp and Cu(x)-HAp catalysts prepared in toluene. TPSR protocol: ramp = 6°C. min-1; flow rate = 100 cm3 min-1, catalyst mass = 0.022g , [NO] = [NH3] = 400 ppm, [O2] = 8% balanced with He.

Figure 2. NH3-SCR of NO in oxidizing atmosphere of the Ca-HAp and Cu(x)-HAp catalysts prepared in chloroform. TPSR protocol: ramp = 6°C. min-1, flow rate = 100 cm3 min-1, catalyst mass = 0.022 g , [NO] = [NH3] = 400 ppm, [O2] = 8% balanced with He.

The light-off temperatures at 50% of NO conversion (LOT50) were used as an issue to compare the efficiency of the prepared catalysts in the NH3-SCR of NO. It can be seen from Table 2, that the catalysts prepared by ion exchange in water; Cu(2.98)-HApEW and Cu(1.12)-HApEW; have the lowest LOT50. The use of organic solvent displaced the LOT50 to high temperatures. Indeed, for Cu(1.12)-HApEW the LOT50 is about 136°C, while for Cu(1.33)-HApRET, it is about 265°C and decreased to 222°C for Cu(1.66)-HApRET. The increase of LOT50 can be related to the nature of copper oxide species. We have shown previously that highly dispersed CuO clusters that are easily reduced were responsible for the activity in the low temperature range [9,10].

Table 2. The maxima of NO conversions obtained (with the related temperatures) and the light-off temperature (T50) of the different Cu-Hap catalysts.

| Catalysts | NO Conv (%) | T max (°C) | LOT50 (°C) |

| Cu(1.33)-HApRET | 67 | 375 | 265 |

| Cu(1.45)-HApIT | 44 | 300 | - |

| Cu(1.66)-HApRET | 73 | 300 | 222 |

| Cu(2.32)-HApIC | 71 | 275 | 236 |

| Cu(2.98)-HApREC | 61 | 275 | 256 |

| Cu(4.22)-HApREC | 60 | 275 | 243 |

| Cu(1.12)-HApEW [10] | 85 | 325 | 138 |

| Cu(2.98)-HApEW [10] | 78 | 325 | 136 |

| Cu(1.37)-HApIW [11] | 72 | 325 | 219 |

| Cu(1.86)-HApIW [11] | 74 | 300 | 202 |

3.2. Characterization of Cu(x)-HAp Catalysts

3.2.1. Chemical Analysis

The chemical analysis of the synthesized Ca-HAp host structure shows a calcium deficient with a Ca/P close to 1.55 (Ca wt.% = 38.40 and P = 19.16). Acidic and basic properties of the Ca-HAp can be correlated to the Ca/P atomic ratio, basic properties arising from an excess of Ca2+ and acidic properties from a deficiency of Ca2+. Therefore, our calcium deficient Ca-HAp contains on its surface mainly P–OH groups of an acidic nature (2.6 groups. nm-2) which acts as sorption sites [14]. On the other hand, it has been shown that copper (II) acetylacetonate can react with either acidic OH groups or a basic OH groups for any metal oxide surface [15]. When acidic, surface OH groups are present, the Cu(acac)2 reacts with the proton to form a blue color mononuclear surface-grafted Cu(acac). However, the basic surface OH groups form deep purple μ-methoxy dinuclear copper acetylacetonate complex. In our case, we obtained blue color catalysts which could indicated the formation of the mononuclear surface-grafted Cu(acac) on Ca-HAp as shown in reaction (5):

(Cu2+)(acac-)2 + (H+)(-O-P) → (Cu2+)(acac-)-O-P + Hacac (5)

The further calcination in air at 500 °C for 2 hours might decompose the mononuclear copper complexes and form dispersed copper oxide [15].

3.2.2. Textural Parameters

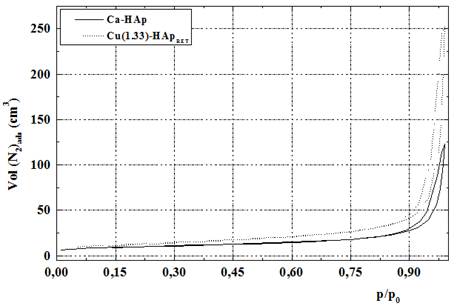

From the results of SBET and mean pore diameter (ø), the textural properties were well preserved after the introduction of copper. The slight increase in SBET and mean pore diameter for the catalysts prepared by impregnation and ion exchange in organic medium is most likely due to the much larger surface area of the as-deposited small copper oxide particles. By comparing the catalyst Cu(1.45)-HApIT and Cu(1.37)-HApIW prepared with impregnation technique in two different mediums (with almost the same copper content and SBET value) the decrease of the mean pore diameter of Cu(1.37)-HApIW suggests that copper oxide were entrapped in the mesoporous matrix. While, for Cu(1.45)-HApIT catalyst the textural analysis indicates that the copper species are probably well dispersed on the surface of the support.

Figure 3 depicted the N2 adsorption-desorption isotherms of Ca-HAp and Cu(1.33)-HApRET samples. The isotherms exhibited typical type IV with H1 hysteresis loop according to IUPAC classification. The sharpness of the isotherms and the presence of hysteresis loop at p/p0 > 0.87 suggest that the tested catalyst is mostly mesoporous [8].

Figure 3. N2 adsorption-desorption isotherms of the carrier Ca-HAp and Cu(1.33)-HApRET catalyst.

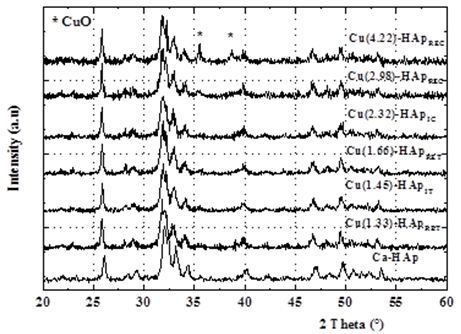

Figure 4. XRD patterns of different Cu(x)-HAp catalysts.

3.2.3. X-Ray Powder Diffraction Analysis

Figure 4 shows the XRD patterns of pure Ca-HAp and Cu(x)-HAp catalysts in the range of 20–60°C 2q. The observed positions of diffraction lines are in full agreement with the corresponding values reported for hexagonal Ca-Hap (PDF Ref. 09-0432). The crystallinity of Cu-HAp did not significantly change whatever the exchange methods. No detectable CuO crystallites superior to 4 nm at 35.5 °C (002) and 38.6 °C (111) were observed in all catalysts except for Cu(4.22)-HApREC catalyst. It seems that, CuO crystallites are either amorphous and/or well dispersed on Ca-HAp surfaces. For Cu(4.22)-HApREC, the increase of copper content leads to the sintering of CuO crystallites to size detectable by XRD.

3.2.4. Temperature-Programmed Reduction (TPR) Analysis

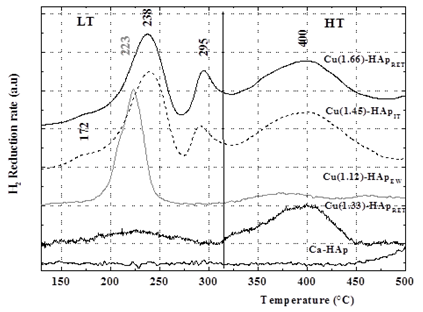

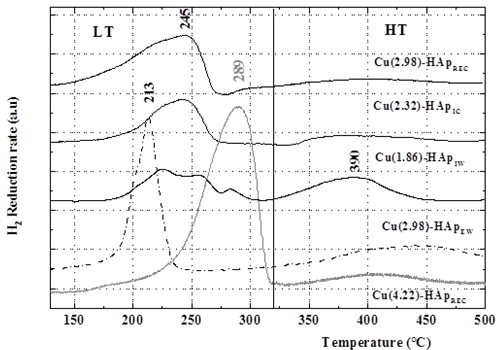

The H2-TPR profiles of Ca-HAp and Cu(x)-HAp catalysts prepared in different medium are reported in figures 5 and 6. As shown in our previous work [9-11], the support Ca-HAp profile shows three reduction peaks at 523°C, 645°C and 720 °C which can be related to the reduction of phosphates species. At temperatures below 450°C, the reduction f Ca-HAp did not interfere with the reduction of copper species. Thus, it seems reasonable to relate the H2-TPR signals of Cu(x)-HAp to copper species deposed on the surface of Ca-HAp which have different nature and reducibility. The reduction profiles of all Cu(x)-HAp catalysts can be divided into low temperature region LT (T ≤ 320°C) and high temperature HT (320 < T (°C) < 550). The broadness of the reduction peaks for the catalysts prepared in organic solvent compared to the ones prepared by ion exchange in water reveals that copper oxide particles are large in the former catalysts.

According to previous works [16-21] the reduction of CuO follows a direct reaction (equation 6); or sequential reduction as in equations (7a) and (7b):

CuO + H2 → Cu +H2O) (6)

2CuO + H2 → Cu2O +H2O (7a)

Cu2O + H2 → 2Cu + H2O (7b)

These reactions depend on the conditions of reduction, the CuO particle size and on the nature of the support [17]. It was shown that slow heating rates of unsupported CuO powder induced a direct reduction, while for faster heating an intermediate Cu2O phase appeared [16]. On the other hand, Kim et al. [19] established that the reduction of CuO is easier than the reduction of Cu2O which is expected from the lower apparent activation energy of CuO about 60.3 kJ.mol-1 while the value is 114.0 kJ.mol-1for Cu2O. Zhang et al. [18] found that the maximum rate of H2 consumption during the reduction of CuO occurs at 385 °C while Cu2O exhibits a peak in the rate of H2 consumption at 420 °C, together with a tail in the range from 469 to 590°C. According to Yamaguchi et al. [19] the reduction of CuO supported on ZSM-5 depends on CuO particle size; large particles displayed a direct reduction, whereas small particles did shows an intermediate Cu2O phase [20].

Figure 5. H2-TPR profiles of Cu(x)-HApM catalysts prepared in toluene. Conditions: H2/Ar (3/97 vol./vol.), flow rate = 30 cm3 min-1, ramp: 10°C min-1, catalyst mass = 0.051 g.

Figure 6. H2-TPR profiles of Cu(x)-HApM catalysts prepared in chloroform. Conditions: H2/Ar (3/97 vol./vol.), flow rate = 30 cm3 min-1, ramp: 10°C min-1, catalyst mass = 0.051 g. (Cu(4.22)-HApREC profile was divided by two for more clarity).

For the present catalysts, we think that the LT reduction profiles can be attributed to the reduction of CuO particles to Cu0 which are deposited on the surface of the carrier in different environment and size. The HT peaks should be related to the reduction of Cu2O particles. For example the reduction profile of Cu(1.33)-HApRET, contains a broad LT peak at 226 °C and HT peak at 400°C. Whereas, for Cu(1.66)-HApRET, a supplementary reduction peak appeared in the LT region around 295 °C which can be attributed to the reduction large particles of CuO.

Cu(1.45)-HApIT and Cu(1.66)-HApRET catalysts display a similar TPR curve constituted by two peaks at 230°C and 290°C for the LT range and a broad peaks at 400°C for the HT range. Surprisingly, Cu(1.45)-HApIT catalyst, prepared by impregnation, is the least active in NO conversion even though it has the same H2-TPR profile as Cu(1.66)-HApRET.

4. Conclusion

In this study, the influence of the preparation method on the NO–SCR by NH3 activity of different copper-Hydroxyapatite Cu(x)-HApM catalysts has been studied on presence of oxygen. The ionic exchange and impregnated catalysts in organic medium gives the less efficient catalyst in NO-SCR. The slight increase in SBET for the catalysts prepared in this medium is most likely due to the much larger surface area of the as-deposited small copper oxide particles. The catalyst characterizations by H2-TPR showed the presence of CuO and Cu2O particles deposited on the surface of the carrier in different environments and sizes. Compared to the catalysts prepared by ion exchange and impregnation in aqueous medium, the one prepared in toluene are less efficient in the selective catalytic reduction of NO by NH3.

References

- Pereda-Ayo, B.; De La Torre, U.; Illán-Gómez, MJ.; Bueno-López, A.; González-Velasco, JR.Role of the different copper species on the activity of Cu/zeolite catalysts for SCR of NOx with NH3. App. Catal. B., 2014, 147, 420-28.

- Heck, RM.; Farrauto, RJ.; Gulati, ST. 3rd Ed.; John Wiley & Sons, Inc., Hoboken, NJ, USA, 2009.

- Nova, I.; Tronconi, E. Urea-SCR Technology for deNOx After Treatment of Diesel Exhausts., Nova, I.; Tronconi, E (Eds) 2014.

- Johnson, TV.; SAE technical paper., 2009, 2009-01-0121

- Wilken, N.; Wijayanti, K.; Kamasamudram, K.; Currier, NW.; Vedaiyan, R.; Yezerets, A.; Olsson, L. Mechanistic investigation of hydrothermal aging of Cu-Beta for ammonia SCR. Appl. Catal. B., 2012, 111, 58-66.

- Wang, J.; Peng, Z.; Chen,Y.; Bao, W.; Chang, L.; Feng, G.In-situ hydrothermal synthesis of Cu-SSZ-13/cordierite for the catalytic removal of NOx from diesel vehicles by NH3. Chem. Eng. J., 2015, 263, 9-19.

- Wang, D.; Jangjou,Y.; Liu, Y.; Sharma, MK.; Luo, J.; Li, J.; Kamasamudram, K.; Epling, WS.A comparison of hydrothermal aging effects on NH3-SCR of NOx over Cu-SSZ-13 and Cu-SAPO-34.Appl. Catal. B., 2015, 165, 438-45.

- Petitto, C.; Delahay, G.Selective catalytic reduction of NOx by NH3 on Cu-SAPO-34 catalysts: Influence of silicium content on the activity of calcined and hydrotreated samples. Chem. Eng. J., 2015, 264, 404-10.

- Tounsi, H.; Djemel, S.; Petitto, C.; Delahay, G. Copper loaded hydroxyapatite catalyst for selective catalytic reduction of nitric oxide with ammonia. Appl. Catal. B., 2011, 107, 158-63.

- Jemal, J.; Tounsi, H.; Chaari, K.; Petitto, C.; Delahay, G.; Djemel, S.; Ghorbel, A. NO reduction with NH3 under oxidizing atmosphere on copper loaded hydroxyapatite;. Appl. Catal. B., 2012, 113, 255-60.

- Jemal, J.; Tounsi, H.; Djemel, S.; Pettito, C.; Delahay, G. Characterization and deNOx activity of copper-hydroxyapatite catalysts prepared by wet impregnation. Reac. Kinet. Mech. Cat., 2013, 109,159-65.

- Jemal, J.; Pettito, C.; Delahay, G.; Ksibi, Z.; Tounsi, H.Selective catalytic reduction of NO by NH3 over copper-hydroxyapatite catalysts: effect of the increase of the specific surface area of the support.Reac. Kinet. Mech. Cat., 2015, 114, 185-96.

- Heughebaert, JC: PhD Thesis, Institut National Polytechnique Toulouse, 1977.

- Tanaka, H.; Futaoka, M.; Hino, R.; Kandori, K.; Ishikawa, T.Structure of synthetic calcium hydroxyapatite particles modified with pyrophosphoric acid.J.Colloid.Interf.Sci., 2005, 283, 609-12.

- White, MG.; Catal Roy. Soc. Chem., 2005, 18, 72.

- Kim, JY.; Hanson, JC.; Frenkel, AI.; Lee, PL.; Rodriguez, JA. Reaction of CuO with hydrogen studied by using synchrotron-based x-ray diffraction.J. Phys. Condens. Matter., 2004, 16, 3479.

- Galvita, VV.; Poelman, H.; Rampelberg, G.; De, Schutter, B.; Detavernier, C.; Marin, GB.Structural and Kinetic Study of the Reduction of CuO–CeO2/Al2O3 by Time-Resolved X-ray Diffraction.Catal. Lett., 2012, 142, 959-68.

- Zhang, Y.; Drake, IJ.; Bell, AT.Characterization of Cu-ZSM-5 Prepared by Solid-State Ion Exchange of H-ZSM-5 with CuCl.Chem. Mater., 2006, 18, 2347-56.

- Kim, JY.; Rodriguez, JA.; Hanson, JC.; Frenkel, AI.; Lee, PL.Reduction of CuO and Cu2O with H2: H Embedding and Kinetic Effects in the Formation of Suboxides.J.Am.Chem. Soc., 2003, 125, 10684-692.

- Yamaguchi, A.; Shido, T.; Inada, Y.; Kogure, T.; Asakura, K.; Nomura, M.; Iwasawa,Y. In Situ Time-Resolved Energy-Dispersive XAFS Study on the Reduction Processes of Cu–ZSM-5 Catalysts.Bull.Chem.Soc.Jpn., 2001, 74, 801-08.

- Arous, W.; Tounsi, H.; Djemel, S.; Ghorbel, A.; Delahay, G. Selective catalytic reduction of NO by NH3 on Cu (II) ion-exchanged offretite prepared by different methods. Top.Catal. 2007, 42, 51-54.