Effect of Machining Mode of Notch on Fatigue Crack Growth and Fractured Surfaces

M. Benachour1, *, N. Benachour1, 2, M. Benguediab3

1Ingeniery of Mechanical Systems and Materials Laboratory, Mechanical Engineering Department, Faculty of Technology, University of Tlemcen, Tlemcen, Algeria

2Department of Physic, Faculty of Sciences, University of Tlemcen, Tlemcen, Algeria

3LMSR Laboratory, Mechanical Engineering Department, University of Sidi Bel Abbes, Sidi Bel Abbes, Algeria

Abstract

The present’s paper shows the effect of machining mode of the notch on fatigue crack growth and fractured surfaces. This investigation is conducted on 2024 T351 age hardening Al-alloy used extensively in aeronautic structures. The fatigue tests are conducted on four points bending according to ASTM method E399. Notches are produced by milling and electric discharge machining (EDM). The fatigue test is led to constant amplitude loading at R=0.1. The results show that the fatigue life is affected by machining method. A significant increase is shown in fatigue life for notch specimen machined by milling comparatively to the notch machined by EDM method. Additionally a reduction of fatigue crack growth rate (da/dN) is obtained by using milling process for machining notch. This finding is attributed to the presence of compressive residual stress at notch. The examination in various areas of the rough surface is carried out on SEM. The study of these fracture topographies shows the various mechanisms developed during the fatigue crack growth.

Keywords

Fatigue Crack Growth, Al-alloy, Fractography, Milling Mode, EDM, SEM

Received: August 8, 2015

Accepted: August26, 2015

Published online: September 2, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

The fatigue behavior of mechanical components depends strongly on the surface microstructure as well as on the stress condition in the surface region. Various techniques are used to the study of fatigue behavior [1]. At least half of all mechanical failures are due to fatigue [2]. Many works have suggested between 50 and 90 percent of all mechanical failures are fatigue failures [3,5]. The process of fatigue is characterized by three stages: (1) Crack initiation; (2) Stage I, as long as the crack and the crack tip plastic zone are contained within a few grains (Fig 1; (3) In stage II, the size of the plastic zone at the crack tip contains many grains and the macro scale crack propagates perpendicular to the loading direction; see figure 1, if the loading is proportional [6]. Suresh et al. [7] have highlighted the influence of the grain structure and slip characteristics in aluminum alloys. The occurrence of persistent slip band is beneficial to the fatigue crack growth properties via intrinsic and extrinsic mechanisms.

The important metal used in aerospace structures is the aluminum alloy 2024 T351 and many authors have studied this material [8-12] and consider different effects (load effect, residual stress, environment, corrosion…etc) on fatigue crack growth and correlation between fatigue striations and crack growth rate da/dN.

A systematic study has been made of the fractography of high stress low cycle fatigue of two high strength aluminum alloys, 2024 T351 and 7075 T6 by Cina and Kaatz [13]. The existence of the fine ridges could not be explained in stage I or stage II situations adjacent to the free surface. Newman [14] studies the closure-free load ratio effects for aluminum and explains the correlation between fatigue crack growth and closure, and the fatigue striations. Rodrigues et al. [15] compare the fatigue crack growth resistance and crack closure behavior of two aluminum alloys such as 2024 and 8090 by using the crack growth rate curves and fractography examination in CT specimen where the level of crack closure is 50% for 8090. This works study the morphology of fatigue crack growth in stage I and II after fatigue crack growth and explains the fatigue fractography of the V-notch specimen where the notch is obtained by milling machining and EDM.

Figure 1. Stage I and II crack growth process in polycrystalline material [6].

2. Experimental Procedures

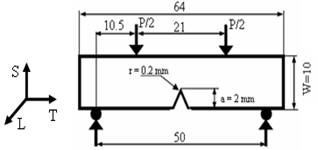

The experimental study was performed on 2024 T351 Al-alloy. The chemical composition of studied material is presented in Table 1 and mechanical properties at room temperature are reported in Table 2. Bars with a rectangular section 10´10 mm2 in 2024 Al-alloy were loaded under four point bending as shown in Fig 2. Fatigue tests were performed on servo-hydraulic testing machine MTS810 in "Centre des Matériaux d’Evry- Mines Paristech". V-Notchs of specimens were machined by two methods such as milling process and EDM method.

Table 1. Chemical composition of (wt%).

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni | Pb |

| 0.105 | 0.16 | 3.97 | 0.45 | 1.5 | 0.05 | 0.11 | 0.018 | 0.02 | 0.056 |

Table 2. Mechanical properties.

| E (GPa) | sY0.2 (MPa) | UTS (MPa) | A (%) |

| 74 | 363 | 465 | 22.1 |

Fatigue crack growth (FCG) tests were performed using closed-loop servo-hydraulic testing machine "MTS 810" with 100 KN load capacity under applied constant amplitude sinusoidal wave loading at the frequency of 10 Hz and fixed stress ratio (R= 0.1). Specimens are subjected to the bending fatigue tested used by many researcher. Stress intensity factor for V-notch bent specimen is expressed in reference work [16]. In fatigue tests, we note the length of the crack (mm) versus number of cycles N (a=f(N)). Secant method was used for modelling fatigue crack growth rates. The calculation is done using two pairs of adjacent measures (ai, Ni) and (ai+1, Ni+1).

Figure 2. V-Notch specimen in four points bending fatigue test.

3. Results and Discussion

3.1. Metallographic Analysis

Figure 3. Microstructure of aluminium alloy 2024 T351 (a) T-S direction, (b) L-S direction.

Figure 3 (a, b) shown the microstructure of aluminum alloy 2024 T351 respectively of (T-S) and (L-S) areas relative to transversal (T), longitudinal (L) and short transversal (S) directions indicated on figure 2. This microstructure is obtained by polarized light microscopy. The specimen underwent a polishing up to 10 mm followed by an electrolytic attack for one minute duration. The microstructure shows that the size of the grains is significant, which will influence the fatigue behavior. This influence can be noticed at the beginning in crack nucleation stage.

3.2. Fractography Fatigue Crack Growth

The knowledge of the cracking process is an important and considerable practical way in order to better include/understand the origins of a great number of fracture in service. The fractography observations are of an importance issue as well for the comprehension of micro mechanisms governing the propagation as for the examination of the parts broken in service. The observations carried out with the SEM highlighted the details of the mechanisms of the fracture and the micro-mechanisms which occur during the fatigue crack growth. It’s enabled us to analyze the morphology of the crack tip and to try to explain the phenomenon of crack closure.

In figure 4, we show the morphology of pre-crack at ![]() , when the fracture is crystallographic. This is due to existence of residual stress induced during the machining of the V-notch. At

, when the fracture is crystallographic. This is due to existence of residual stress induced during the machining of the V-notch. At ![]() , the fractography show the regular fatigue striation, this depend to the duration of fatigue cycle. The direction of striations is different of any grains who explain the granular fracture and the difference of stress and their directions in crack tip. The micro crack is present in several directions to the applied load (figure 5). The SEM observations in figures 4 and 5 show the stage I of fatigue fracture.

, the fractography show the regular fatigue striation, this depend to the duration of fatigue cycle. The direction of striations is different of any grains who explain the granular fracture and the difference of stress and their directions in crack tip. The micro crack is present in several directions to the applied load (figure 5). The SEM observations in figures 4 and 5 show the stage I of fatigue fracture.

Figure 4. SEM examination in pre-crack at ![]() .

.

Figure 5. SEM examination in pre-crack at ![]() .

.

Figure 6. SEM examination at constant amplitude loading (R=0.1/ ![]() ).

).

Figure 7. Effect of machining mode on fatigue life.

At constant amplitude loading (![]() ), figure 6 shows the fatigue striations. Theses striations are inclined and not parfaitely orthogonal to fatigue crack direction. The short cracks are present. Fig 6 shows also several types of striations to knowing the ductile striations and the fragile striations. The phenomenon of crack closure is characterized by the striations present on fracture surface during the fatigue test and distance between two striations. Before the fracture of the specimen, the apparition of cupules and ductile striations prove the final ductile fracture by fatigue at

), figure 6 shows the fatigue striations. Theses striations are inclined and not parfaitely orthogonal to fatigue crack direction. The short cracks are present. Fig 6 shows also several types of striations to knowing the ductile striations and the fragile striations. The phenomenon of crack closure is characterized by the striations present on fracture surface during the fatigue test and distance between two striations. Before the fracture of the specimen, the apparition of cupules and ductile striations prove the final ductile fracture by fatigue at ![]() .

.

During fatigue tests, the fatigue life was evaluated for two specimens when the notches are machining respectively by milling and electro-erosion. Figure 7, shows the effect of machining mode on fatigue life. The fatigue life in milling notches was affected; this effect was due to the presence of residual stress.

4. Conclusion

The fatigue crack growth resistance is used for the aluminum alloy 2024 T351 on the four bending test specimen where the notch is obtained by milling and EDM. The metallographic examination used, to show the grain size. The grain size effect is signaled for the crack nucleation (pre-crack situation). The fractography examination of different surface fracture shows different situations. Pre-crack and unbalance of the stresses in crack tip marked by the disposition of the fatigue striations and the existence of crystallographic fracture. The propagation with constant amplitude reflects the existence of the regular fatigue cracks striations. On fracture surface appear the short cracks or secondary crack. Finally of rupture, the presence of the cupules shows the ductility by fatigue before rupture. Machining of the V-notch by milling induced a compressive residual stress a round crack front and the fatigue life is longer comparatively to electro-erosion machining.

Acknowledgments

The authors gratefully acknowledge the technical support from the Centre des Matériaux d’Evry – Mines ParisTech, France. The authors also with to express their gratitude to Professor emeritus A. Pineau and Professor B. Tanguy for fruitful discussions and assistance in fatigue crack growth tests

References

- Stanzl-Tschegg, S.E., Mayer, H., 2001, Fatigue and fatigue crack growth of aluminium alloy at very high numbers of cycles. International Journal of Fatigue, Vol. 23, S231-S237, 2001.

- D.W. Hoeppner, "Industrial Significance of Fatigue Problems", ASM Handbook, Fatigue and Fracture, vol. 19, p 1, 1996.

- R. Wanhill, S. Barter, L. Molent. "Fatigue failure analyses for metallic aircraft components". International

- C. Bathias, A. Pineau, "Fatigue of Materials and Structures: Fundamentals". ISTE - J. Wiley, 2010.

- C.R. Brooks, A. Choudhury. "Failure analysis of Engineering Materials". McGraw-Hill, 2001.

- Sanders, Jr Th., Staley, J.T., 1978, Fatigue and microstructure. ASM, Metals Park, Ohio, p 467.

- Suresh S, Vasudevan AK, Bretz PE. Mechanisms of slow fatigue crack-growth in high-strength aluminum alloys - role of microstructure and environment Metall Trans A 1984;15:369-379.

- Mahmoud, S., Lease, K., 2004, Influence of R on effective stress range ratio and crack growth. Engineering Fracture Mechanics, Vol. 22, N° 06, pp 915-926.

- Mayon, G., 2005, A unified a (DK+.Kmax)1/2 crack growth models for aluminum 2024 T351, International Journal of Fatigue, Vol. 27, pp 629-638, 2005.

- Srivastava, Y.A., Garg, S.B.L., 2004, Influence of R on effective stress range ratio and crack growth. Engineering Fracture Mechanics, Vol. 22, N° 06, pp 915-926.

- Rodopoulos, C.A., Choi, J. H., De Los Rios, E.R., Yates, J.R., 2004, Stress ratio and the fatigue damage map - Part II: The 2024 T351 aluminum alloy. International Journal of Fatigue, Vol. 26, pp 747-752.

- Benguediab, M., 1989, Study of the fatigue crack growth under reduced loading spectra, Thesis D.Sc in Materials Science, Higher National School of Mechanics and Aerotechnics-Poitiers University, France.

- Cina, B., Kaatz, T., 1979, A systematic study of the fractography of fatigue in high strength aluminum alloys. Fatigue & Fracture of Engineering Materials and Structures 2 (1), 85–95, 1979.

- Newman, J.A., 2000, The Effects of load ratio on threshold fatigue crack growth of aluminum alloys. Doctorate of Philosophy in Engineering Mechanics - Virginia.

- Rodrigues, E.M., Matias, A., Godefroid, L.B., 2005, Fatigue crack growth resistance and crack closure behavior in two aluminum alloys for aeronautical applications. Materials Research, Vol. 8(3), 287-291.

- M. Benachour, A. Hadjoui, M. Benguediab, N. Benachour, Effect of the amplitude loading on fatigue crack growth, Procedia Engineering, vol. 2, pp. 121-127, 2010.