Study the Pomegranate's Peel Powder as a Natural Inhibitor for Mild Steel Corrosion

Sahib Mohammed Mahdi*

Materials Engineering Department, Engineering College, Al-Mustansiriya University, Baghdad, Iraqi

Abstract

A pomegranate peel powder used as corrosion inhibitor for mild steel in 5%HCl and 5%H2SO4 solutions. This investigation was done in two methods, one by calculating corrosion rate using weight loss process, for different exposure times (168,336,504 and 672 hrs). And the other by using electrochemical test, by soaking the pomegranate peel powder in 5%HCl and 5% H2SO4 for variant times (72,168 and 336 hrs). The results show that pomegranate peel powder is a good natural inhibitor for mild steel in dilute strong acids for limited period.

Keywords

Pomegranate Peel, Mild Steel, Inhibitor, Corrosion, Potentiostat, Weight Loss

Received: June 16, 2015

Accepted: July 3, 2015

Published online: July 22, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Corrosion is the deterioration of metal by chemical attack or reaction with its environment. It is a constant and Continuous problem, often difficult to eliminate completely. Prevention would be more practical and achievable than complete elimination [1]. The study of steel corrosion phenomena has become important particularly in acidic media because of the increased industrial applications of acid solutions. Among the acid solutions, mineral acids including H2SO4 and HCl are the most widely used acids [2-9]. Corrosion control of metals is of technical, economical, environmental importance. The use of inhibitors is one of the best options of protecting metals and alloys against corrosion. The environmental toxicity of organic corrosion inhibitors has prompted the search for green corrosion inhibitors as they are biodegradable, do not contain heavy metals or other toxic compounds. As in addition to being environmentally friendly and ecologically acceptable, plant products are inexpensive, readily available and renewable [10-17]. Investigations of corrosion inhibiting abilities of tannins, alkaloids, organic, amino acids, and organic plant interest. The term ‘‘green inhibitor’’ or ‘‘eco-friendly inhibitor’’ refers to substances that are biocompatible such as plant extracts since they are of biological origin [12, 18-20]. Plant extract is low-cost and environmental safe, and so the research about plant extract as the corrosion inhibitor has received more attention. Recently, many extracts from plant leaves have been investigated as good corrosion inhibitors of steel. [21]. To be fully effective all inhibitors require to be present above a certain minimum concentration. In many cases the corrosion that occurs with insufficient inhibitor may be more severe than in the complete absence of inhibitor [22, 23]. Pomegranate fruit is consist of three parts: the seeds (about 3% of the weight of the fruit); the juice (about 30% of the fruit weight); and the peels which include the husk and interior network membranes [24, 25]. There are many uses for pomegranate peels, such as in medicine [26], which can help to be used as corrosion inhibitors in acids environments.

2. Experimental

The weight loss, electrochemical Tafel test method, optical and SEM examination with EDX test were used in order to observe the pomegranate peel powder effects on mild steel samples corroded in 5% H2SO4 and 5% HCl concentrations mediums at room temperatures.

2.1. Materials

The chemical composition of the Mild steel samples is list in table (1). Flat samples are used for weight loss tests, whereas cylindrical samples are used for electrochemical tests. Powder of dry pomegranate peel are added to 5% HCl and 5% H2SO4 concentrations mediums at room temperatures.

Table 1. The chemical composition of the mild steel samples.

| C% | Si% | S% | P% | Mn% | Ni% | Cu% | Cr% | Fe% |

| 0.17 | 0.02 | 0.01 | 0.01 | 0.43 | 0.04 | 0.05 | 0.02 | Rem. |

2.2. Weight Loss Measurements

Weight loss (W) experiments were carried out using flat mild steel samples with dimensions (25 X 50 X 2 mm). These samples are electrolyte cleaned and abraded with emery paper of 1000#. Each sample is weighted (Wi) using Balance KERN , Type ABS 120-4 with accurately of four digit before immersing in 250 ml of 5%HCl and 5%H2SO4 With and without 40 gm / litter of dry pomegranate peel grounded in coffee grinder. Exposure times were for (168, 336, 504, 672) hours at room temperature. The samples were taken out water wash, cleaned using fretting with tissues, then drying and weighting (Wf). The weight loss has been calculated using the following equations,

![]() (1)

(1)

Where W = weight loss in mg/cm2,

Wi and Wf are samples mass before and after corrosion in mg, and

A = sample surface area in cm2(neglecting the thickness area).

The inhibitor efficiency (h) has been calculated for each period of time using the general efficiency equation as below

h% ![]() (2)

(2)

Where h% = inhibitor efficiency percent,

Wcorr = weight loss in mg/cm2 without pomegranate peel, and

Wp = weight loss in mg/cm2 with pomegranate peel added for the same exposure time for Wcorr.

2.3. Electrochemical Measurements

Figure 1. The electrochemical experiments setup.

The electrochemical measurements were carried out for the same environments, with cylindrical specimens of 4.5 cm2 surface area. The potentiostat instrument used for electrochemical corrosion measurement (tafel test) is of A Gamry Series G300 Potentiostat built in a Computer. The tests were applied in to two types connection, one of three electrodes connections (working electrode + working sense, reference electrode and counter electrode), and with two electrode connections (working electrode+ working sense and counter electrode + reference). The reference electrode was saturated Calomel reference electrode and graphite rod was used as a counter electrode. All experiments were carried at room temperature, and using Gamry workframe software for recording experiment data. Recorded Data were analyzed with Gamry Echem Analyst software. Figure (1) is clarifying the experiment setup for all tafel tests. The inhibitor efficiency percent is calculated by using equation (2), for the Gamry Echem Analyst too.

2.4. Microscopic Test

The surface of test specimen was examined with optical microscope and VEGA3 SEM with oxford instrument EDX detector. The images were for the tested specimens with and without cleaning; they are to identifying the existence of the pomegranate compounds on the surface.

3. Results and Discussion

The results have been records for each test and been discussed to evaluate its effect.

3.1. Weight Loss Measurmenets

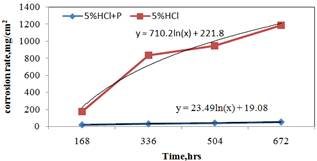

Figure (2) show the relationship between the corrosion rate in mg/cm2 versus exposure time in hours in case of immersing mild steel specimens in 5%HCl medium with and without pomegranate peel powder.

Figure 2. The relationship of corrosion rate with exposure time for 5%HCl with and without pomegranate peel powder (P).

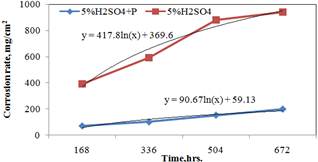

It is distinct that the corrosion rate is decreased at considerable form and the equation of each curve is obtained using microsoft excel program. Fig.(3) show the relationship of corrosion rate in mg/cm2 with exposure time in hours of mild steel specimens in 5%H2SO4 medium with and without pomegranate peel powder, the corrosion rate is decreased when pomegranate peel added, also the equation for each curve is obtained. The variations in values of two curves in the two figures demonstrate that there is great change take place in corrosivity of the media due to presence of pomegranate peel powder, but the values in the curves equations shows that the corrosion rate of steel sample in 5%HCl is double of that in 5%H2SO4, whereas it is opposite in case of pomegranate adding. Which mean that the pomegranate peel powder more inhibit in HCl acid than in H2SO4 acid. Table(2) shows the pomegranate peel efficiency, when added to 5%HCl and 5%H2SO4 mediums, it is clear that the efficiency of pomegranate peel in HCl acid is better and stable for the periods of the test than in H2SO4 acid.

Figure 3. The relationship of corrosion rate with exposure time for 5%H2SO4 with and without pomegranate peel powder(P).

Table 2. The pomegranate peel inhibiter efficiency using weight loss test.

| Efficiency for HCl by weight loss | Efficiency for H2SO4 by weight loss | ||

| Exposure time, hours | Efficiency, h | Exposure time, hours | Efficiency, h |

| 168 | 88.2% | 168 | 81.9% |

| 336 | 96% | 336 | 82.9% |

| 504 | 95.4% | 504 | 82.6% |

| 672 | 95.4% | 672 | 78.7% |

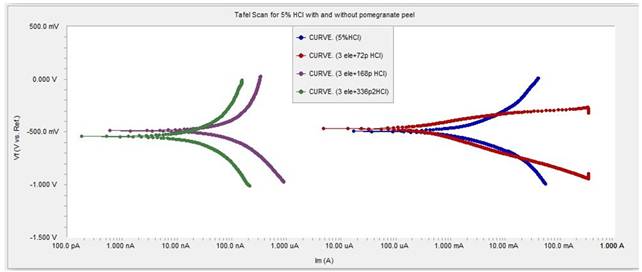

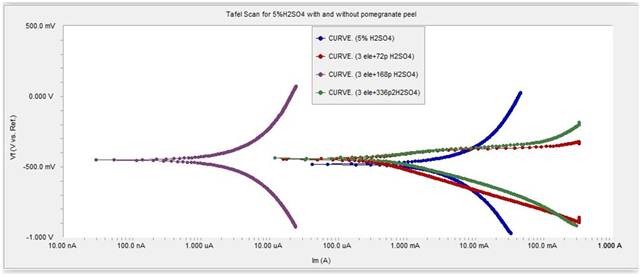

3.2. Electrochemical Measurements

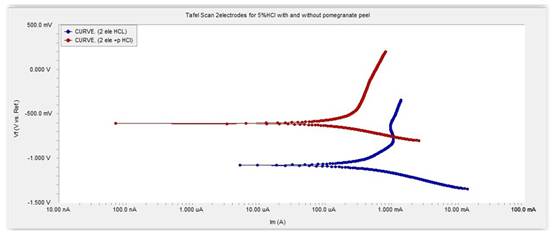

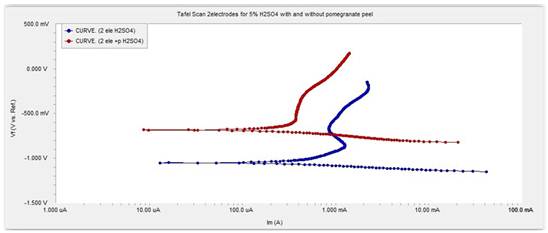

Using Gamry instrument Series G300 Potentiostat built in a Computer for electrochemical tafel tests in two cases, one with three electrodes connection and the other with two electrodes connection. Electrochemical kinetic of a corroding metal can be characterized by determining at least three polarization parameters, such as current density (icorr), corrosion potential (Ecorr), and Tafel slopes (ba and/or bc). Then the corrosion behavior can be disclosed by a polarization curve (E vs. log i). This is an accelerated electrochemical process for determining corrosion rate, that has an advantage over the corrosion rate determined by weight loss since the latter is a time consuming process. Fig. (4) shows the tafel scan curves of the cylindrical specimens in 5%HCl with and without pomegranate peel powder of three electrodes test. The solution of pomegranate peel powder in 5%HCl is prepared for various time of soaking (72,168 and 336 hours). This test is done for clarifying effect of solution aging. Fig, (5) shows the tafel scan curves of 5%H2SO4 with and without pomegranate peel powder. The test and solutions prepared in the same way as for HCl solution. Figs. (4) and (5) shows high decrease in corrosion rate after 72hrs of pomegranate peel soaking in two acids, but there are a distinct decrease in corrosion rate, for one week (168hrs) of pomegranate peel soaking in two acids. The pomegranate peel appears to suspend the acids activity. But at 336hrs of pomegranate soaking the activity of the 5%H2SO4 began to return, while it is still efficient in 5%HCl. That is mean the existence of pomegranate peel is active for both 5% dilute acids for 168hrs, and loss most efficient in 5%H2SO4 within two weeks. Table (3) show the values of tafel curves parameter of both 5%acids with and without pomegranate peel addition. These parameters are calculated by the Gamry Echem Analyst software. This table show that the corrosion rate in mpy of 5%H2SO4 is much higher than of 5%HCl , and tafel parameter (Ecorr, bC, bA) are about to be close each others. Where table (4) show the efficiency of pomegranate soaking in 5%HCL and 5%H2SO4 using the corrosion rate of table (3) in mpy. The results of two electrodes test are shown in figures (6) and (7) for 5%HCl and 5%H2SO4 with and without pomegranate peel powder respectively. Two-electrode experiments measure the whole cell, that is, the sense leads measure the complete voltage dropped by the current across the whole electrochemical cell: working electrode, electrolyte, and counter electrode. It is clear that the potential difference between the 5%HCl and with pomegranate peel added to 5%HCl (fig.6) are high, this is the same for 5%H2SO4 with and without pomegranate peel (fig.7), which mean that the curves with high potential (with pomegranate peel added) are more passive than the lower potential (5%HCl and 5% H2SO4). The two electrodes curve behavior like the E-I curve of passive metals.

Figure 4. Show tafel curves for electrochemical experiments of 5%HCl with and without pomegranate peel (P) addition for varying times.

Figure 5. Show tafel curves for electrochemical experiments of 5%H2SO4 with and without pomegranate peel (P) addition for varying times.

Table 3. The value of parameters of Tafel test for 5%HCl and 5%H2SO4 with and without pomegranate peel(P) at different time of soak.

| Environment | Ecorr V | Icorr A | bC | bA | Corrosion rate, mpy |

| 5%HCl | -0.493 | 0.001060 | 0.1888 | 0.1905 | 107.3 |

| 72hr + HCl+P | -0.467 | 0.000208 | 0.1403 | 0.0934 | 21 |

| 168hr +HCl+P | -0.487 | 2.65E-07 | 0.7951 | 1.9416 | 0.027 |

| 336hr +HCl+P | -0.541 | 8.17E-08 | 0.8384 | 1.4423 | 8.3E-03 |

| 5%H2SO4 | -0.481 | 0.00352 | 0.439 | 0. 2198 | 357.5 |

| 72hr +H2SO4+P | -0.446 | 0.000321 | 0.1469 | 0.0645 | 32.6 |

| 168hr +H2SO4+P | -0.451 | 8.14E-06 | 0.8523 | 0.8993 | 0.83 |

| 336h r+H2SO4+P | -0.439 | 0.000153 | 0.0861 | 0.0445 | 15.6 |

Table 4. The inhibiter efficiency of pomegranate peel soaking in acids using electrochemical test.

| Efficiency for HCl by electrochemical test | Efficiency for H2SO4 by electrochemical test | ||

| Soaking time, hours | Efficiency, h | Soaking time hours | Efficiency, h |

| 72 | 80.4% | 72 | 90.8% |

| 168 | 99.9% | 168 | 99.7% |

| 336 | 99.9% | 336 | 95.6% |

Figure 6. Two electrode exterminate for 5%HCl with and without pomegranate peel (P).

Figure 7. Two electrode exterminate for 5%H2SO4 with and without pomegranate peel (P).

3.3. Microscopic Examinations

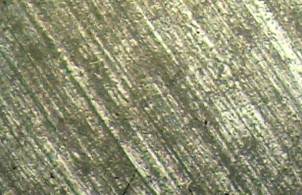

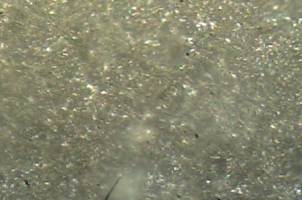

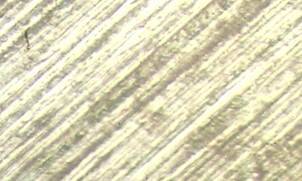

Figs. (8) and (9) show the structure of the specimens in 5%HCl without and with pomegranate peel respectively in optical microscope at magnification (X200). It is apparent there is a precipitate layer on the surface of the specimen immersed in acid with pomegranate peel solution, whereas no precipitate on surface specimen immersed in 5% HCl. The same things looks on the specimen in 5%H2SO4 without and with pomegranate peel, as seen in figs. (10) & (11).

Figure 8. Specimen structure immersed in 5%HCl at X200.

Figure 9. Specimen structure immersed in 5%HCl with pomegranate peel at X200.

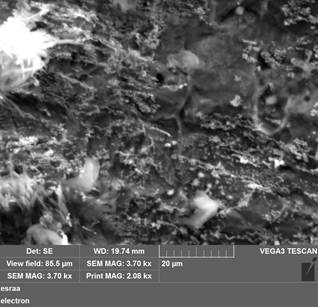

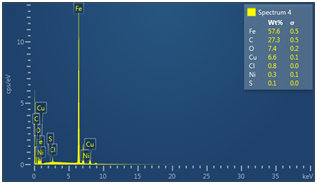

To get more information about the precipitate layer, fig(12) show the SEM examination for the specimen in solution of 5%HCl with pomegranate peel with magnification(X3700), it is clear that the precipitate layer like fibers coats on metal surface. EDX test of the layer (fig.13) show that presence of 27.3%wt of carbon and 7.4%wt of Oxygen, which mean that the phenolic compound[26] of the pomegranate peel is react with the acid, soften it and the acid activity is weaken. At the same time the precipitate layer acts as a hinder to acid solution, which causes the inhibitor behavior for the period of its endurance.

Figure 10. Specimen structure immersed in 5%H2SO4 at X200.

Figure 11. Specimen structure immersed in 5%H2SO4 with pomegranate peel at X200.

Figure 12. The image of specimen surface coated with reactant product of pomegranate peel powder with 5%HCl.

Figure 13. The EDX Spectrum test of the reactant product of pomegranate peel powder with 5%HCl.

4. Conclusion

The pomegranate peel powder is efficient inhibitor when added to dilute strong acids. That proves that pomegranate peel can be used as a natural inhibitor for mild steel in acids solutions. But this inhibitor is active for limited period. The pomegranate peel powder is insoluble in acid solutions, and its reactant products precipitate on metal surface, assisting to forms a protective layer on the surface of the metal.

References

- B. E. Amitha Rani and Bharathi Bai J. Basu," Green Inhibitors for Corrosion Protection of Metals and Alloys: An Overview", International Journal of Corrosion Volume 2012, Article ID 380217, 15 pages.

- Nabel A. Negm, Ahmad F. El Farargy, Emad A. Badr, Mohamad F. Zaki, "Corrosion Inhibition performance of polyethylene glycol/ polytriethanolamine inhibitors on corrosion of carbon steel in acidic medium",Journal of Applied Chemistry, Volume 7, Issue 6 Ver. II. (Jun. 2014), PP 13-25.

- Mohammed A. Amin, M.A. Ahmed, H.A. Arida, Fatma Kandemirli, Murat Saracoglu, Taner Arslan,Murat A. Basaran,"Monitoring corrosion and corrosion control of iron in HCl by non-ionic surfactants of the TRITON-X series – Part III. Immersion time effects and theoretical studies", Corrosion Science 53 (2011) pp1895–1909.

- N.A. Negm, A.M. Al Sabagh, M.A. Migahed, H.M. Abdel Bary, H.M. El Din,"Effectiveness of some diquaternary ammonium surfactants as corrosion inhibitors for carbon steel in 0.5 M HCl solution" Corrosion Science 52 (2010) pp 2122–2132.

- Mohammed A. Amin, K.F. Khaled, Q. Mohsen, H.A. Arida,"A study of the inhibition of iron corrosion in HCl solutions by some amino acids", Corrosion Science 52 (2010) pp1684–1695.

- N.A. Negm, Y.M. Elkholy, M.K. Zahran, S.M. Tawfik,"Corrosion inhibition efficiency and surface activity of benzothiazol-3-ium cationic Schiff base derivatives in hydrochloric acid", Corrosion Science 52 (2010) pp3523–3536.

- Yaroslav G. Avdeev, Yurii I. Kuznetsov, Aleksey K. Buryak," Inhibition of steel corrosion by unsaturated aldehydes in solutions of mineral acids", Corrosion Science 69 (2013) pp50–60.

- A. Chetouani, B. Hammouti, A. Aouniti, N. Benchat, T. Benhadda," New synthesised pyridazine derivatives as effective inhibitors for the corrosion of pure iron in HCl medium", Progress in Organic Coatings 45 (2002) pp373–378.

- A. Chetouani, B. Hammouti, A. Aouniti, N. Benchat, T. Benhadda," New synthesised pyridazine derivatives as effective inhibitors for the corrosion of pure iron in HCl medium", Progress in Organic Coatings 45 (2002) pp373–378.

- H. Ashassi-Sorkhabi, D. Seifzadeh," The inhibition of steel corrosion in hydrochloric acid solution by juice of Prunus cerasus", Int. J. Electrochem. Sci., 1(2006)pp92-98.

- M.Yadav, Sumit Kumar and P.N. Yadav,"Corrosion Inhibition of Tubing Steel during Acidization of Oil and Gas Wells", Journal of Petroleum Engineering, Volume 2013, 9 pages.

- J Buchweishaija," Phytochicals as green corrosion inhibitors in various corrosive media", Tanz. J. Sci. Vol 35 2009 pp79-92.

- Ambrish Singh, Eno E. Ebenso, and M. A. Quraishi," Corrosion Inhibition of Carbon Steel in HCl Solution by Some Plant Extracts", International Journal of Corrosion Volume 2012, 20 pages.

- Ayssar Nahl´e, Ideisan Abu-Abdoun, Ibrahim Abdel-Rahman, andMaysoon Al-Khayat," UAE Neem Extract as a Corrosion Inhibitor for Carbon Steel in HCl Solution", International Journal of Corrosion Volume 2010, 9 pages.

- Marian Bobina, Andrea Kellenberger, Jean-Pièrre Millet, Cornelia Muntean, Nicolae Vaszilcsin,"Corrosion resistance of carbon steel in weak acid solutions in the presence of L-histidine as corrosion inhibitor", Corrosion Science 69 (2013) pp389–395.

- Pandian Bothi Raja, Ahmad Kaleem Qureshi, Afidah Abdul Rahim, Hasnah Osman, Khalijah Awang," Neolamarckia cadambaalkaloids as eco-friendly corrosion inhibitors for mild steel in 1 M HCl media",Corrosion Science 69 (2013) pp292–301.

- Simone Santana de Assuncao Araujo Pereira, Michelle Macedo Pegas, Tatiana Lopez Fernandez,Mariana Magalhaes, Thais Gadiole Schontag, Dalva Cristina Lago,Lilian Ferreira de Senna Eliane D’Elia,"Inhibitory action of aqueous garlic peel extract on the corrosion of carbon steel in HCl solution", Corrosion Science 65 (2012) pp360–366

- Y. Abboud1, B. Hammouti3, A. Abourriche1, B. Ihssane1, A. Bennamara1, M. Charrouf1,S.S Al-Deyab," 2-(o-Hydroxyphenyl)Benzimidazole as a New Corrosion Inhibitor for mild Steel in Hydrochloric Acid Solution", Int. J. Electrochem. Sci., 7 (2012) pp2543 – 2551.

- Ahmed A. Al-Amiery, Abdul Amir H. Kadhum, Abdul Hameed M. Alobaidy, Abu Bakar Mohamad and Pua Soh Hoon," Novel Corrosion Inhibitor for Mild Steel in HCl", Materials 2014, 7, pp662-672.

- Ambrish Singh, Eno E. Ebenso, and M. A. Quraishi," Corrosion Inhibition of Carbon Steel in HCl Solution by Some Plant Extracts", International Journal of Corrosion Volume 2012, 20 pages.

- Xianghong Li, Shuduan Deng,"Inhibition effect of Dendrocalamus brandisii leaves extract on aluminum in HCl, H3PO4 solutions", Corrosion Science 65 (2012) pp299–308.

- J. Arockia Selvi, Susai Rajendran, V. Ganga Sri, A. John Amalraj,2 B. Narayanasamy " Corrosion Inhibition by Beet Root Extract", Portugaliae Electrochimica Acta 2009, 27(1), pp1-11.

- Nabel A. Negma, Nadia G. Kandile , Emad A. Badr , Mohammed A. Mohammed,"Gravimetric and electrochemical evaluation of environmentally friendly nonionic corrosion inhibitors for carbon steel in 1 M HCl", Corrosion Science 65 (2012) pp94–103.

- Mohammad Taher-Maddah, Naser Maheri-Sis, Ramin Salamatdoustnobar, Alireza Ahmadzadeh," Comparing nutritive value of ensiled and dried pomegranate peels for ruminants using in vitro gas production technique", Scholars Research Library, Annals of Biological Research, 2012, 3 (4):pp1942-1946.

- Chaturvedula, Venkata Sai Prakash, and Indra Prakash," Bioactive Chemical Constituents from Pomegranate (Punica granatum) Juice, Seed and Peel-A Review", Int. J. Res. Chem. Environ. Vol. 1 Issue 1 July 2011(1-18).

- Amani S. Al-Rawahi, Giles Edwards, Mohammed Al-Sibani, Ghanim Al-Thani, Ahmed S. Al-Harrasi and Mohammed Shafiur Rahman," Phenolic Constituents of Pomegranate Peels(Punica granatum L.) Cultivated in Oman", European Journal of Medicinal Plants 4(3): pp315-331, 2014.