Comparative Analysis of Strength Tensile and Shear Between Cast-in-Place and Post-Instaled Anchors

Abdul Haris*, Wisnu Febriantoro

Civil Engineering Department, ITATS, Surabaya, Indonesia

Abstract

Classical anchors (Cast-In-Place Anchors) is an anchors installed according to design on the part of the concrete structure that will be in the cast, so its use is limited to new construction, while Dyna Bold (Post-instaled Anchors) is a bolt anchors mounted on concrete which has hardened or existing concrete. Installation of anchor bolts of this type can be used in new construction or rehabilitation of old construction. Due to the installation of different types, use/function, which together allow Dyna Bold if the role can be used to replace Classical anchors or allow to be otherwise. In this study conducted a comparative study of tensile strength and shear between Classical anchors (Cast- In-Place Anchors) and Dyna Bold (Post-instaled Anchors) using 2 methods of comparison is by manual calculation analysis refers ETag 001 and the test specimen in the laboratory. Tensile resilience and the maximum shear with the manual calculation method using "ETag 001 Metal Anchors For Use In Concrete". The results showed that tensile resistance of Classical anchors (Post instaled Anchors) is greater than the tensile resistance Dyna Bold (Cast In Place Anchors). The maximum shear resistance Classical Anchors (Post instaled Anchors) is greater than the shear resistance Dyna Bold (Cast In Place Anchors).

Keywords

Tensile Strength, Shear Strength, Anchors Classical, Dyna Bold

Received: August 22, 2016

Accepted: September 7, 2016

Published online: October 19, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

In an effort to improve the quality of the connection plate or the connection structure of concrete and steel beams, the civil engineering required a lot of references of practical connections without the plant anchor when casting. It was also found many unexpected needs additional structural beams in the column, after the column completed casting. In high-rise buildings, which have a complex structure many types of beams, columns, sloff different and even did not close the possibility of elevation is also different things that allow for errors structure which was realized in the future, for example:

a Classic anchor plans to post at the end of the column was forgotten in the tide only realized after the column was completed in the cast whereas the anchor should be prepared before the start. The casting process (Process iron) it is allowed to wear Dynabold as a substitute.

b Channeling / metal cuttings of the beam which is planned in the cast at a later stage after all in the cast, turns on the elevation, discovered channeling which has not been installed for example beam landing. It may be possible in pairs Dynabold as a substitute reinforcement distribution, etc.

c Concrete column with the composite beam did not rule required a classic anchor / Dyna bold on the connection. As we know the installation of anchors when the iron work lets not precisely within a hole, the size of the hole which is set on a plate runway it allows for alternatives to replace Classical anchors with Dyna Bold in order to be more practical and effective time during erection steel.

d Cuttings, for the installation of the beam from the floor does not need the reinforcement but can be an alternative Dynabold.

According to [1] said that the reinforcement stirrup has good adhesion to concrete that is able to withstand shear forces optimally match the shear forces that occur in the beam.

There have been many studies that have been done about the tensile strength of anchors among others by: [2-9]. However, research on comparative tensile resistance between classic anchor and DYNA bolt anchor has never been done by previous researchers. Therefore, research on comparative tensile resistance between classic anchor and DYNA bolt anchor to the concrete is created.

2. Literature Review

2.1. Application of Bolt Anchors

The use of anchor bolts as shear connectors are widely used generally for mechanical electrical appliances such as electric poles, AC, traffic signs, furing ceiling and so on. Lately many engineers use the anchorage in construction, such as the retaining wall anchors, anchor pole steel pedestal and the connections of steel construction. Bolt anchors being used is manufactured with the product specification of each service provider. Bolt anchors bolted to the structural anchor must be chemical as an additive so that adhesion between the anchor bolt and structurally stronger and reduces pull out of the joint. Product additives which are commonly used include Hilti branded trademarks, Ramset, He-Kress, Sormat, Simpson.

2.2. Strength of Anchor Bolts in Concrete

The distribution mechanism of the horizontal shear forces that occur from steel beams transferred entirely to the concrete slab by shear connectors, in this case iron and concrete anchors. That is where the power and wide contact area reinforcement concrete with concrete anchors greatly affect the capacity of a reinforced concrete anchors to be able to transfer horizontal shear. On the Floor Planning Guide Bridge Steel Frame Using CSP (Pd T-12-2005-B), stated that the strength of shear connectors system is affected by several things such as: The number of shear connectors, longitudinal tension average in the concrete slab around liaison, size, arrangement and strength reinforcement plate around joints, thickness of the concrete around the joints, degrees of freedom of each base plate to move laterally and the possibility of a pull up (up the lift force) on the connecting, sticking to the interface concrete-steel, concrete flexural strength and density of the concrete around the base of each shear connectors.

While the factors that influence the occurrence of deformation in concrete steel anchors, namely: the shape and size, its location on the beam, the location of maximum moment and how to install the steel beams. In planning the installation of anchor steel and concrete according to the ACI on the Anchorage to Concrete in general can be a reference, other rules can be adopted from the European Organisation for Technical Approvals (EOTA) which also has set guidelines for the technical "Guideline for European Technical Appropal of Metal Anchors for Use in Concrete (ETAG-001)".

A wide variety of failures that may occur due to a variety of load (tensile and shear) as follows: steel failure, pull -out failure, concrete cone failure, splitting failure. Model collapse can be seen in Figure 1.

Figure 1. Type of the collapse of the anchors in concrete.

In the present study will be discussed classical anchors and anchor bolt. Classic anchors is anchors first plugged into the material along with casting structure. The difference is not necessarily required drilling here because the anchor was added to the structure when the casting structure is done. While the anchor bolt, the bolt is planted or bolt that is used to glue the two pieces of objects that have a cylindrical sleeve which will expand when tighten bolts. Dynabolt used in the installation of fastening objects to a concrete stone and other materials.

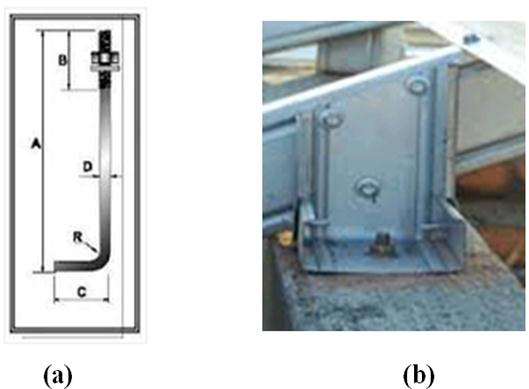

Figure 2. Type of the anchor (a) Angkur classic, (b) Angkur dyna bold.

3. Method

3.1. The Step of Testing the Tensile Strength

The steps in testing the tensile strength and torsional to use classical anchor (Cast In Place) and Dyna Bold (Post instaled) are as follows:

In this test there are two methods of testing are:

1. Using manual calculations appropriate manner (ETag 001 Annex C: Design Methods For Anchorages).

2. Using tensile test and shear test by Test Laboratory.

These methods have advantages and disadvantages of their own in accordance with the implementation and needs.

3.2. Steps from Tensile Test

Following the steps of testing the tensile test approach based on a manual count: Image Structure, Conduct literature from multiple sources, Design samples of the type Anchor, Setting data anchors and concrete to be calculated strength, Calculating Strength Anchor embedded under regulation (ETAG 001 Annex C: Design Methods For anchorages), Trial n ' Error of calculation, Done.

4. Result & Discussions

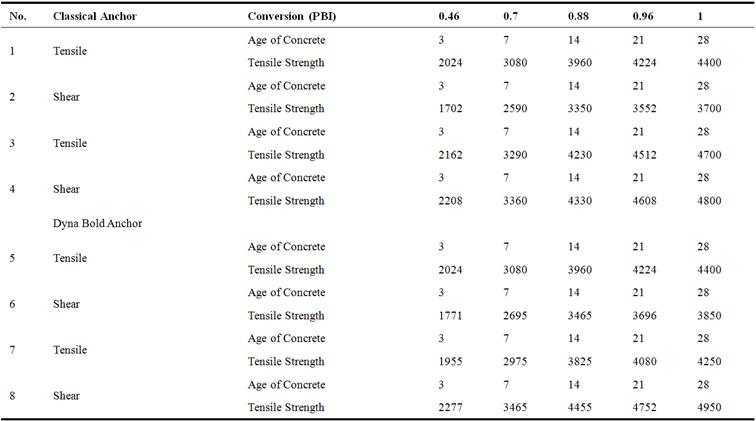

Laboratory test results will be described according to the number of objects in a test in the laboratory. The test results also lay in a graph of comparison, in this case will also compare the results of tensile and shear resistance between classical and Dynabold anchor. The purpose displays in graphic form is to determine the increase in tensile resistance and shear resistance anchor within a period of 3 to 28 days of age concrete.

Table 1. The results from laboratorium.

With lab test results in the conversion will obtain the graph changes in tensile and shear resistance of anchors gradually up to maximum shear and tensile resistance.

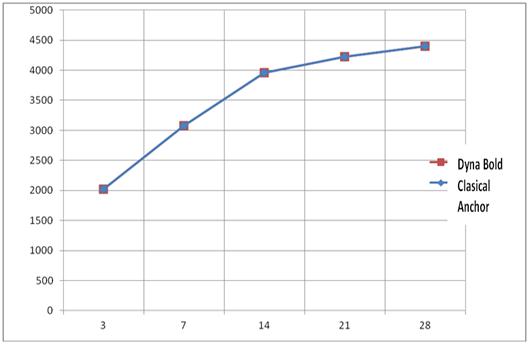

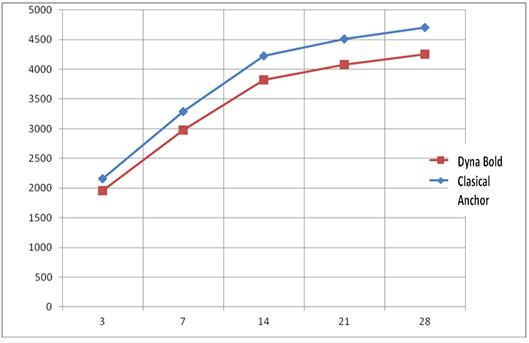

4.1. Comparison of Tensile Resistance of the Test Object 1 and 5

Figure 3. Comparison of tensile resistance of anchors classic and bold dyna.

Test results of tensile resistance in the laboratory with test specimen 1 and 5, the age of concrete 28 days of relatively flat at 4400 kg. From the graph, the resistance from anchors to concrete specimen 1 and 5 are as follows: Age 3 days is 2024 kg, Age 7 days is 3080 kg, Age 14 days is 3960 kg, Age 21 days is 4224 kg, Age 28 day is 4400 kg.

4.2. Comparison of Tensile Resistance of the Test Object 3 and 7

Figure 4. Comparison of tensile resistance of anchors classic and bold dyna.

The results of the test, the tensile resistance in laboratory of Classic anchor specimen 3 and Dynabold specimen 7 obtained chart resistance attractiveness of anchors are as follows: Age 3 days is 2162 kg, Age 7 days is 3290 kg, Age 14 days is 4230 kg, Age 21 days is 4512 kg, Age 28 days is 4700 kg. As for Dyna bold specimen 7: Age 3 days is 1955 kg, Age 7 days is 2975 kg, Age 14 days is 3825 kg, Age 21 days is 4080 kg, Age 28 days is 4250 kg.

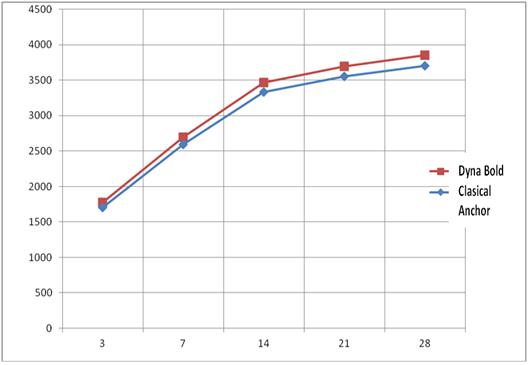

4.3. Comparison of Shear Resistance of the Test Object 2 and 6

Figure 5. Comparison of shear resistance between classic anchor and dyna bolt.

The results of the test tensile resistance in the lab to Classical anchor and Dyna bold specimen 2 and 6 obtained the graph of tensile resistance to anchor the test object 2 are as follows: Age 3 days is 1702 kg, Age 7 days is 2590 kg, Age 14 days is 3330 kg, Age 21 days is 3552 kg, Age 28 days is 3700 kg. As for Dynabold specimen 6: Age 3 days is 1771 kg, Age 7 days is 2695 kg, Age 14 days is 3465 kg, Age 21 days adalah3696 kg, Age 28 days is 3850 kg.

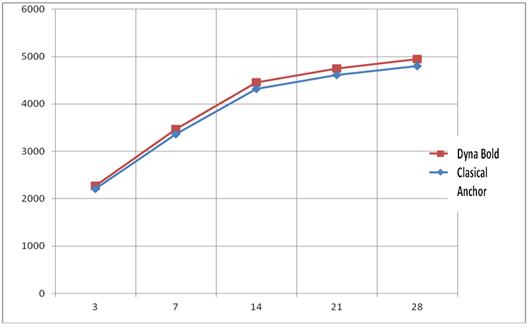

4.4. Comparison of Shear Resistance of the Test Object 4 and 8

Figure 6. Comparison of shear resistance between classic anchor and dyna bolt.

The results of tensile resistance test in the laboratory for Classical anchor and Dyna bolt specimen 4 and 8 obtained the graph of tensile resistance is as follows. For a classic anchor specimen 4; Age 3 days is 2208 kg, the age of 7 days is 3360 kg, age 14 days is 4320 kg, age 21 days is 4608 kg, age 28 days is 4800 kg. While for Dynabold specimen 8; Age 3 days is 2277 kg, Age 7 days is 3465 kg, Age 14 days is 4455 kg, Age 21 days is 4752 kg, Age 28 days = 4950 kg.

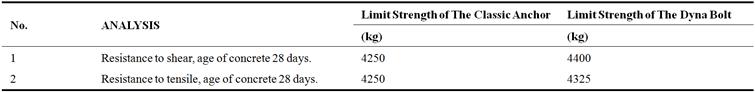

From the results of laboratory tests obtained an average limit of the maximum strength of a tensile and shear resistance Classical Anchor and Dyna bold are as follows:

Table 2. The maximum resilience of tensile and shear for anchors classic and Dyna Bolt (On the laboratory test results).

This Table is the average yield resistance of tensile and shear for classic and Dyna bolt anchor that embedded in the concrete aged 28 days (based on laboratory test results).

5. Conclusions

From the discussions that have been outlined in the final report is obtained as follows:

1) Method of calculation manually, using ETag 001 Metal Anchors For Use In Concrete obtained tensile resistance of the classic anchor greater than the tensile resistance Dyna Bold. Medium shear resistance of classic anchor is greater than the shear resistance Dyna Bold.

2) The results of laboratory tests, in the classic anchor the tensile resistance greater than the tensile resistance Dyna Bold. While the maximum shear resistance for classical anchor greater than Dyna Bold.

3) Its can conclude that the classic anchor more effective than Dyna Bold.

References

- Arwanto . 2006. Experimental Study of Effects of stirrups Against bond between concrete and reinforcement, Master Degree Thesis, Master Program from Civil Enginering, Universitas Diponegoro Semarang.

- Stephen hawkshaw. 2003. Strength and reliability of chemically bonded rock climbing anchors in sandstone, Undergraduate Thesis, Department of Civil Engineering, The University of Sydney.

- Heath, David J., Gad, Emad F. 2013. Design Guidelines For Cast-In And Post-Installed Anchors In Australia. Australian Engineered Fasteners and Anchors Council. AEFAC Technical Note TN01-2-12-13. Australia.

- Hiroshi Sato, Kazunori Fujikake and Sidney mindess. 2004. Study on dynamic pullout strength of anchors based on failure modes, 13th World Conference on Earthquake Engineering Vancouver, B. C., Canada.

- Widianto, Chandu patel, and Jerry owen. 2005. Design of anchor reinforcement in concrete pedestals, CSA today, Vol. III, No. 12, pp. 1-20.

- Appa rao, G. and Arora, J. 2006. Strength and modes of failure of adhesive anchors in confined concrete under direct tensile loading, VIII International Conference on Fracture Mechanics of Concrete and Concrete Structures, FRAMCOS-8, pp. 1-11.

- František Wald, Zdenek Sokol, and Jean-Pierre Jaspart. 2008. Base plate in bending and anchor bolts in tension, HERON Vol. 53, No. 1, pp. 21-50.

- Contrafatto, L. and Cosenza, R. 2014. Prediction of the pull-out strength of chemical anchors in natural stone, l. contrafatto et al., frattura ed integrità strutturale, (29) pp. 196-208; doi: 10.3221/igf-esis.29.17

- Zhechao fan and Jun sun. 2016. Numerical optimization design of anchoring end of pre stressed cable at some hydropower station, The Open Civil Engineering Journal, 10, pp. 246-250.

- Radu lucian trifan. 2016. Behavior of metal expansion anchors and bonded anchors in reinforced non-cracked and compressed concrete, Buletinul Institutului Politehnic Din Iasi, Volumul 62 (66), numarul 1, Technical University of Cluj-Napoca.