Mechanical Properties of Recycled Polypropylene Mixed with Glass Fibers

Ayman M. M. Abdelhaleem*

Mechanical Design and Production Engineering Department, Faculty of Engineering, Zagazig University, Zagazig, Egypt

Abstract

The main objective of this research is to study the effect of adding glass fibers, GF, into recycled polypropylene, RPP, using the injection moulding process. The GF were mixed mechanically with the RPP in 10%, 20%, and 30% by weight. The mechanical properties of recycled polypropylene reinforced with glass fibers were investigated using tensile, impact, wear, and hardness tests. The melt flow indexes (MFI) of the recycled polypropylene with and without the glass fibers contents are examined. The results showed that, by adding GF to the RPP by 10%, 20%, and 30%wt to the RPP, the tensile strength are increased from 21 N/mm2 to 26 N/mm2 (i.e. 23.8%), 25 N/mm2 (i.e. 19%), 29 N/mm2 (i.e. 38%) and to 32 N/mm2 (i.e. 52.38%) respectively. Both of the modulus of elasticity and the hardness were increased as the fibers contents were increased in the RPP. Impact un-notched strength decreased with increasing of the GF in the RPP. The wear test results showed that, for load of 1500g the weight loss was decreased for RPP with 20% GF to be 0.0357g, when compared with 0.0548g for RPP, i.e. 34.8% improving against wear. As the GF was increased in the RPP matrix, the MFI was reduced. Scanning Electron Microscope (SEM) observations of the worn surfaces of the RPP material with GF detects interference and the adhesion between the RPP and GF which would lead to the improving of both of the tensile strength and the wear resistance.

Keywords

Polypropylene, Glass Fibres, Mechanical Properties, Wear Resistance, Melt Flow Index

Received: June 11, 2016

Accepted: June 21, 2016

Published online: July 16, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Polypropylene, (PP) is the most widely used polymers in automotive industry. It is replacing engineering plastics and metals from its applications because of the lower density, lower price materials and recycling benefits. However, PP can only meet mechanical specifications if the reinforcement with long glass fibers increases its elastic modulus and impact strength. The parts are made by either injection moulding or compression moulding glass fiber reinforced PP [1].

Since, pure plastic is expensive, and the recycled plastic is less expensive than that of pure plastic, the plastic manufacturers tend to use the recycled plastic material. Therefore, most of the plastic factories have a system to collect and reuse the damaged plastic products, the finished purpose plastic products, and the product plastic flashes, and runners. Although the plastic containers used for foodstuff and medicals are prevents to be used again for the same purpose, it may be used again and again for other industries such as auto parts, electrical appliances, child toys, and home parts such as chairs, tables, ˇetc.

Loredana Incarnato, et al [2], studied the rheological and mechanical properties of recycled polypropylene. They concluded that it is possible to add a high percentage 70% w/wt of RPP without a significant reduction of the mechanical performance of the polypropylene film. Sylvie Bertin and Jean Jacqub [3], studied the compatibilization of low density polyethylene, LDPE/ polypropylene, PP blends with graft copolymers. They found that, the recycled blends exhibit suitable properties leading to applications that require good mechanical properties. Nizar et al [4], studied the rheological behaviour PP runner waste blends towards using medical syringes production. They found that, the melt flow index value increases and the density decreases when the runner percentage, temperature and load are increased. Therefore, the recycling of plastic material is very important and useful, if it is not used for foodstuff or medical functions. One of the important plastic materials is the polypropylene which is commonly and frequently used in the areas of automotive, household, and electrical appliances.

Glass fiber reinforced polypropylene (GFRPP) is a widely used cost-effective composite material. The success of these composites relies on the unique performance/cost ratio of polypropylene among various engineering plastics as well as that of glass fibers among different fibrous reinforcements. The properties of the glass fiber reinforced polypropylene can be tailored by adjusting the volume fraction of glass and the length of the fiber. Increase in the fiber contents and fiber length results in improving the impact strength and tensile strength but lowers the process ability of the composite. Another important advantage is the possibility of recycling these composites [5, 6, 7].

Abdulkadir G et. al. [6] reported that during tensile testing of the reinforced plastics, the load applied to the matrix is transferred to the glass fibers. In order to improve the strength of the composites, a strong interface bonding between the fibers and plastic is required. They also observed that humidity reduces the bonding force between the plastic and reinforcement element. Chuan et al [8] observed that, GFRPP shows good resistance against acid and salt solutions but bad resistance against alkali solutions. Ota et al [9] studied the combined effect of injection temperature and the fiber content on the properties of the polypropylene-glass fiber composites. They concluded that, the tensile strength and the elastic modulus are decreased with the increasing of the injection temperature, and that the melt flow index of the composites depend upon fibres content, fibres length and distributions. The tensile strength and elastic modulus was increased with increasing in fiber contents. Bajracharya et al [10] studied experimentally and theoretically the properties of injection moulded glass fiber reinforced mixed plastic composites. They found that, with the addition of 30 wt% of glass fiber, the strength properties and elastic modulus increased by as much as 141% and 357%, respectively. The best improvement is seen in the flexural properties due to the better orientation of the glass fibers in the longitudinal direction at the outer layers. Rafiq et al [11] studied the glass fiber reinforced polypropylene (GFRPP) recycled for four generations. And based on the experimental data, they concluded that the glass transition temperature of GFRPP is not affected during recycling. The tensile properties of GFRPP are significantly affected as a result of recycling. The decrease in tensile strength is more in case of third and fourth recycles as compared to first and second recycled generations. The decrease in the tensile strength for virgin to 4th recycle generation was about 29%. It is considered that the decrease in tensile strength due to recycling of GFRPP is possibly because of variation in the feed (mixed sizes) and less adhesion between matrix and fibers.

Even minor changes in the processing parameters can influence the properties of the plastics. These parameters make them very important materials for various applications. Therefore, it is shown by the researcher [1,8,9] that by controlling the process parameters the plastic can be tailored according to the requirements. Fiber and particulate reinforcements can improve the mechanical properties of plastics with less cost as compared to the materials of similar strength [12]. Mechanical properties of the composites of plastics and fibers depend on the fiber size, fiber density, fiber fraction, mode of distribution in the structure, working temperature and fiber plastic adhesion forces [13-14].

Badin Pinpathomrat et al [15] studied the interfacial adhesive property between the inserted part and an injected GF/PP. They found that interfacial adhesive property of GF/PP-PP insert injection moulded increased according with increasing of surface roughness, pre-heated the insert part and increasing the barrel temperature. They also found that the adhesive property of GFPP-PP insert injection moulded was unchanged by using the vent barrel system. The fracture mode of the insert injection moulded specimens was depended on the adhesive length of the inserted part.

The main aim of the present work is to investigate the effect of adding the GF into the RPP on the mechanical properties, wear, melt flow index, and microstructure using injection moulding process.

2. Experimental Works

2.1. Materials and Characterization

The pure PP used in this work was homopolymer (PP575P) which was supplied by SABIC from Egyptian market with density of 0.909 g/cm3 and melt flow index of 11 g/10 min [16]. RPP was supplied from Egyptian market as shown in Figure 1a. The well-known burn test was operated on the RPP to know it [17-18]. The burn test result of the RPP was (1) colour of the flame was yellow, (2) it was drips, (3) colour of the flame when continuous burning was blue and yellow tips, (4) smell was phenol, and (5) the speed of the burning was slow, (6) float in water. The density of the neat RPP was 0.92 g/cm3.

Glass Fibers used in present work was E6 and was supplied by Jushi co. Ltd [19] has diameter of 40 micron and was cut and dispersed for lengths of 100:200 mm, and its density 2.6g/cm3, Figure 1.

(a) RPP

(b) RPP+GF

Figure 1. Photo pictures of the raw materials, RPP and GF.

2.2. The Mould

Plastic injection mould for tensile, impact and wear test samples was designed and manufactured. The mould was checked many times to be suitable for producing the required test samples according to ASTM638 [20]. In this mould, direction of the flow of the plastic takes into account that it was in one direction for each sample to avoid any probability of producing weld lines which may cause weakness and hence cracking. Figure 2 shows the plastic injection moulding machine and the mould which were used to produce the required test samples.

(a) The injection moulding machine.

(b) The plastic injection mould in the machine.

Figure 2. The plastic injection moulding machine and the mould.

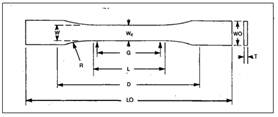

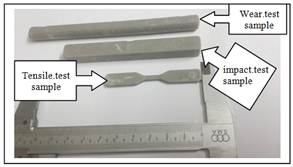

Figure 3. The sample dimensions, W=3.18 mm, L=9.53mm, and T=3mm.

Figure 3 shows the tensile test sample dimensions according to ASTM D638, W=3.18 mm, L=9.53mm, Wo=9.53 mm, Lo=63.5 mm, G=7.62 mm, D=25.4mm, R=12.7 mm, and T=3mm. the photo of the real test samples (impact test sample, W*B=10mm*10mm), (wear test sample diameter D=10mm).

Figure 4. Real test samples (impact test sample, W*B=10mm*10 mm), (wear test sample diameter D=10mm).

2.3. Machines and Processing for Manufacturing

To produce the test samples the plastic injection mould is mounted into an injection moulding machine (HAITIAN PL1200), i.e. type maximum clamping force 1200KN. The barrel temperature profile along the injection-molding machine was adjusted to be 140, 160, 180, 190 and 200∑C. The barrel temperature was adjusted during the process when adding RPP with GF composite. Table.1 shows the conditions of operating machine to manufacture specimens.

The process may be described as follow:

Firstly: RPP was dried at 80oC for 2 h in an air dryer before processing to avoid possible moisture degradation reactions.

Secondly: It was mechanically mixed with (10, 20, 30)% wt of GF.

Thirdly: feeding the extruder of injection moulding machine (single screw extruder) by the mixed composites to produce the test samples.

Fourth: the produced test samples with its sprue and runners are crushed in a crusher forming small particles with identical sizes.

Fifth: the shredded particles were fed into the injection moulding machine to produce the final test samples. The main reason behind these stages is to obtain good distribution of the GF in the RPP.

The tensile, impact, and wear test samples of the real test samples were shown in Figure 4 which obtained from injection moulding were used to study mechanical properties, wear resistance and microstructure (impact test sample, W*B=10mm*10mm), (wear test sample diameter D=10mm).

Table 1. Conditions used for injection molding machine.

| Parameter pressure in (Bar) | Stage (1) | Stage (2) | Stage (3) | Stage (4) | Stage (5) |

| Charging | 40 | 40 | 40 | 40 | 40 |

| Closing | 40 | 40 | 50 | 50 | 70 |

| Injection | 100 | 100 | 90 | 80 | 80 |

| Holding | 100 | ||||

| Cooling | Holding | ||||

| Opening | 50 | 50 | 50 | 50 | 50 |

| Ejection | 30 | 30 | 30 | 30 | 30 |

2.4. Testing

The tensile test was carried out using LLOYD tensile testing machine (The model: LRX plus) at a cross-head speed of 5 mm/min at room temperature. Three tensile specimens were tested for each reported value and the average value was taken. The charpy impact tests were carried out on un-notched specimens, (10mm*10mm,*90mm), using digital charpy impact tester at 25∑C. A mass of energy was 5 J according to rectangular un-notched specimens. Also three samples were tested and reported the average value. The effects of impact strength were obtained to the composite.

Hardness test was carried out by Durometer shore D according to ASTM D2240 at room temperature. Six points on specimen were tested and the average value was reported. A pin on disc was used to carry out wear resistance. All samples are pressed against a rotating disc with surface roughness of (P1000) at room temperature, with disc speed of 57 rpm. The rotating disc serves as a counter face and the stationery block serves as the test specimen. At distance of (10, 25, and 50) m, weight loss were measured before and after the test for each sample at variety of loads (500, 1000, and 1500g) by using a digital balance with accuracy 10−3. The melt flow index for the RPP and the composite of RPP with GF were obtained using melt flow index machine. RPP reinforced specimens fracture surface were examined by scanning electron microscopy (SEM) (JEOL JSM.5500LV Scanning Electron Microscopy). The morphologies of the reinforced specimens, operating at an accelerating voltage of 20 kV were carried out to check surface fractured specimens crystallization.

3. Results

3.1. Results of the Tensile Test

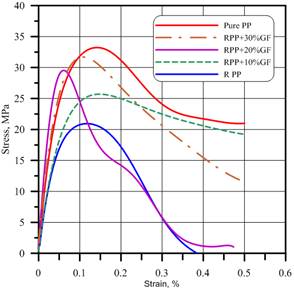

Three samples of each of the required compositions to be tested were generated, pure PP, RPP, RPP reinforced with different G.F. contents of ratios, 10%, 20%, and 30% wt. The average values of the results were calculated. Figure 5 shows the stress strain curves of the recycled polypropylene with different amount of glass fibers.

Figure 5. Stress strain curves of the RPP with different amount of GFs.

The melt flow index and ultimate tensile strength are listed in Table 2. The tensile properties of RPP are determined as a function of GF content (10%, 20%, and 30% wt). It can be noticed from these results that by increasing the percentage of glass fiber in the RPP, the ultimate tensile strength is improved. However, for all the samples with the addition of glass fiber (10%, 20% and 30%), its ultimate tensile strength was greater than the recycled PP without glass fiber. From Figure 5, it can be noticed that, by increasing the glass fibers percentage the ultimate tensile strength was improved according to the following discussions. For RPP reinforced with 10% GF, the ultimate tensile strength was increased to 25 MPa (19%), for 20% GF the ultimate tensile strength was increased to 29 MPa (38%), and for 30% GF the ultimate tensile strength was increased to 32 MPa (52.38%).

Table 2. Shows the tensile strength, and melt flow index for each composition.

| Description and Composition | Ultimate Tensile strength, MPa | Melt flow index (g/10min) |

| Pure PP | 33 | 11 |

| RPP | 21 | 17 |

| RPP+10% GF | 25 | 15 |

| RPP + 20% GF | 29 | 14 |

| RPP + 30% GF | 32 | 12 |

From Figure 5 the trend behaviour of the modulus of elasticity, MOE, of the composite was increased as the GF contents were increased. The MFI was measured using the MFI machine for both the RPP which used and for the composition of the RPP with the GF content for each ratio. Some of the produced samples of the RPP with the GF were crushed and collected in separated bags. Hence, the MFI machine was used to measure the MFI for each composition of the RPP and the RPP with the GF. The results are shown in Table 2, from which it may be concluded that, as the GF is increased in the RPP, the MFI was reduced. For example, the MFI of the RPP with 10% wt GF was reduced from 17 g/10min to 15 g/10min (11.7%). The reason of reducing the MFI were the existing of the GF in the RPP impedes and resists the composites fluidity.

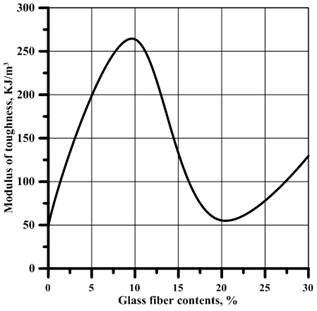

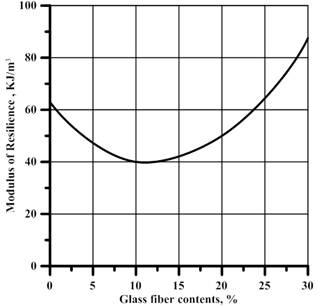

Modulus of resilience, modulus of toughness of the composites were generated from Figure 5 and shown in Figures 6 and 7. It can be shown from Figure 6 that, the toughness of the composites was increased when increasing the G.F. contents to 10% but when the GF increased higher than 10%, the toughness was reduced to the value near to that of the RPP. This may be explained as follows, both of RPP and GF carry the loads. But when adding 20% GF and the load was increased, so the composite more brittle than at 10% GF and the fibres were separated from the matrix. On the other hand, Form Figure 7 the modulus of resilience was decreased until 10%, then it increased for GF higher than10% due to the increasing of GF contents in the RPP which making the composite to be more brittle and has low toughness.

It is observed from the stress strain curves Figure 5 that, the presence of GF reinforcement in the RPP matrix raises the composite strength. Therefore, the effect of glass fiber content on the tensile properties of the reinforced composites was of particular interest and important for many researchers [6, 8, 11, 15].

Figure 6. The effect of GFs reinforced RPP on the modulus of toughness.

Figure 7. The effect of GF reinforced RPP on the modulus of resilience.

3.2. Impact Test

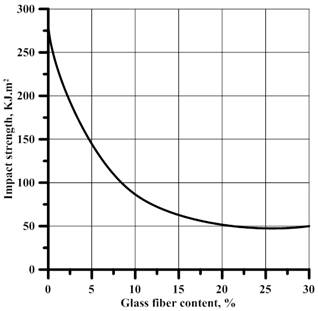

Figure 8 illustrates the variations of un-notched charpy impact strength of the RPP/GF composite. The maximum impact strength occurred to the neat RPP sample was 288 kJ.m2. The existing of GF in the RPP results in a sharp reduction in the impact strength which was dropped significantly. It decreased from 288 kJ.m-2 for the neat RPP to 100 kJ.m-2 for the RPP with 10% GF. So, it may be explained that the existing of the GF in the composite resist the plastic deformation so the toughness gradually decreased. At the same time the MOE increased as the GF in the contents were increased as a result of the existing of the GFs made the produced material brittle.

Figure 8. The effect of GFs reinforced RPP on the impact strength.

3.3. The Results of Wear Test

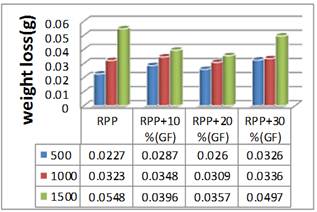

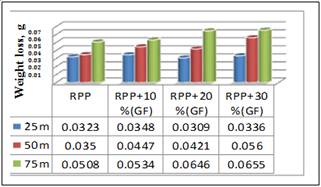

The weight loss were calculated using pin on disc method, for each sample at travelling distances 10m,25m, and 50m with speed=34mm/s, when using 500g, 1000g, and 1500g as applied loads and shown in Figures 9 &10.

Figure 9. The effect of GF reinforced RPP on the weight loss for 500g, 1000g, and 1500g at 25m displacement, V= 34 mm/s.

From Figure 9, at 500g: we observe that weight loss increased at 10% GF, then it decreased at 20%, finally it rises again at 30% compared with neat RPP. At 1000g: the weight loss rise at 10% GF, then it reduced at 20%, finally it rise again at 30% compared with neat RPP. While at 1500g, the weight loss decreased at 10% GF, and continues decreasing at 20%, finally it increases at 30% GF.

Figure 10. The effect of GF reinforced RPP on the weight loss at displacement of 25m, 50m, and 75m with 1000g weight, V=34 mm/s.

From Figure 10 at 25m: it is observed that weight loss increased at 10% GF, then it decreased at 20%, finally it rise again at 30% compared with neat RPP. And at 50m, the weight loss rise at 10% GF, then it reduced at 20% GF, finally it rise again at 30% GF, compared with neat RPP. While at 75m, it gradually increasing by increasing the percentage of GF, because of GF particles, which come out of the composite and exist in the wear surface, lead to increase and speed up the wear rate.

3.4. The Result of Hardness Test

The hardness was measured using shore D, Durometer and shown in Table 3. From these results it can be noted that the pure PP has 72 and the RPP has 71. When adding 10% GF with the RPP, the hardness becomes 74 (4.2%). When adding 20% GF with the RPP, the hardness became 77 (8.4%). On the other hand, when adding 30% GF with the RPP, the hardness was increased again to 82.5, (16.9%). It can be investigated that the existing of GF in the RPP resists the plastic deformation and so made the composite more brittle.

Table 3. Hardness of the materials, Shore D.

| Materials | Hardness |

| Pure PP | 72 |

| RPP | 71 |

| RPP+10% GF | 74 |

| RPP+20% GF | 77 |

| RPP+30% GF | 82.5 |

3.5. Microstructure of Recycled polypropylene/Glass Fiber Composite

Microstructures of fracture surfaces of recycled polypropylene (RPP) composites with different GF contents were performed. Some of these photos from SEM are shown in Figure 11.

Figure 11. Scan Electronic Microscopy (SEM) of RPP reinforced with 30% GF.

Most of the glass fibers appeared to be well dispersed and adhesive in the RPP plastic matrix, as shown in Figure 11a which means that, the GF were mixed well with RPP matrix. Most of the orientations of the fibers were in one direction because of the injections was made from one side and the flow in one direction. The glass fibers were seen outside the fractured matrix surface Figure 11b, c indicate that during applying the load, the initial crack, the glass fibres break up and pulled out of the RPP matrix. The existing of the RPP matrix on the fiber surface indicated that, good adhesion between the fibers and the RPP as shown in Figure 11c.

4. Conclusions

The RPP was mixed mechanically with the GF and then injecting into the plastic injection mold and extract the following conclusions:

a. The recycled polypropylene has the ability to be used with the glass fibers

b. The ultimate tensile strength of the RPP reinforced with GF was increased as the GF were increased. The impact fracture toughness was affected by existing of the GF in the RPP by decreasing.

c. The modulus of elasticity of the reinforced RPP by GF was increased as the fibers contents were increased, because of the GF in the RPP resist the plastic deformation and hence making the RPP more brittle.

d. The weight loss of the RPP/GF was decreased for RPP with 20% GF when compared with neat RPP.

e. As the GF was increased in the RPP matrix, the MFI was reduced, because of the GF resists the RPP/GF composite to flow.

f. When adding 10% GF to the RPP, the hardness becomes 74 which is higher than that of the neat RPP by 4.2%. When adding 20% GF with the RPP, the hardness becomes 77 (8.4.2%). On the other hand, when adding 30% GF with the RPP, the hardness is increased again to 82.5, (16.9%). Generally, as the GF content was increased the hardness of the composite was increased as a result of existing of the GF which made the composite to be more brittle.

g. Using of Scanning Electron Microscope explained that the worn surfaces of the RPP with the GF detects interference and the adhesion between the RPP and GF which would lead to the improving of both of the tensile strength and the wear resistance.

References

- Erwin Burkle et al, "Injection Moulding of long glass fiber reinforced pp", Translated from Kunststoffe plastic Europe, pp, 47-50, 3/2003.

- Loredana Incaranato, Paola Scarfato, and Domenico Acierno, "Rheological and Mechanical Properties of Recycled Polypropylene, Polymer Polypropylene Engineering and Science", Vol. 39, No. 4, April 1999.

- Sylvie Bertin, Jean-Jacques Robin, "Study and characterization of virgin and recycled LDPE/PP blends", European Polymer Journal 38, 2255–2264, 2002.

- Cavalieri F and Padella F, "Development of composite materials by mechano chemical treatment of post-consumer plastic waste", Waste Manage, Vol.22, p.913, 2002.

- Cabrera N, "Recyclable All-Polypropylene Composites: Concept, Properties and Manufacturing", Ph D Thesis, School of Engineering and Materials Science, Queen Mary University of London, UK, p 177, 2004.

- AbdulKadir G, Ahmet Ö,and Emin Ö, "Experimental investigation of the effect of glass fibres on the mechanical properties of polypropylene (PP) and polyamide 6 (PA6) plastics", Materials & Design, Vol. 27, Issue 4, pp 316-323, 2006.

- Nizar Jawad Hadi, Najim A. Saad, Zainab A.A Saadi, "Study the Rheological Behaviour of PP-Runner Waste Blends towards using for Medical Syringes Production", IJET Vol. 3 No.10, Oct., 2013.

- Chuan W, Li L. S. and Jin P. O., "Experimental Study on the Corrosion Resistance of GFRPP Rebar in Alkali, Acid and Salt Solution" Advanced Materials Research, Vol. 146–147, pp 1356-1360, 2011.

- Ota W. N., Amico, S. C. & Satyanarayana, K. G., "Studies on the combined effect of injection temperature and fiber content on the properties of polypropylene-glass fiber composites", Composites science and technology, Vol. 65(6), pp.873-881, 2005.

- Rohan Muni Bajracharya, Allan C. Manalo, Warna Karunasena, Kin-tak Lau, "Experimental and theoretical studies on the properties of injection moulded glass fiber reinforced mixed plastics composites", Composites: Part A 84 393–405, 2016.

- M. A. Rafiq, B. Saleem, M. Ajmal and M. Y. Anwar, "Effect of Glass Fibers Reinforced Polypropylene" JFET 19, Journal of Faculty of Engineering & Technology, 125-134, 2012.

- Titow W. V., and Lanham B. J, "Reinforced thermoplastics", Elsevier Applied Science Publishers, London, 1974.

- Yu Z, Brisson J., and A. Ait-Kadi A., "Prediction of Mechanical Properties of Short Kevlar Fiber-Naylon–6,6 Composites", Polymer Composites, Vol. 15, pp 64–73, 1994.

- Lee S. C, Yang D. Y, Ko J and Youn J. R, "Effect of Compressibility on Flow Field and Fiber Orientation During the Filling Stage of Injection Molding", J Mater Process Technol, Vol. 70, pp83–92, 1997.

- Badin Pinpathomrat, Suchalinee Mathurosemontri, Putinun Uawongsuwan, Supaphorn Thumsorn, Hiroyuki Hamada, "Study on adhesive property of insert injection molded glass fiber reinforced polypropylene composites", Energy Procedia 89 (2016) 291–298.

- https://www.sabic.com/

- Paragon Plastics Santa Ana,"Material identification Guide"PARAGON PLASTICS.

- www.boedeker.com/burntest.htm,"how to identify plastic material".

- Http://www.jushi.com,Email:info@jushi.com

- ASTM Standard reference, "D638".