Study of Tribological Characteristics of Al-SiC Metal Matrix Composite

Shouvik Ghosh1, Prasanta Sahoo2, *, Goutam Sutradhar2

1Department of Mechanical Engineering, National Institute of Technology, Sikkim, India

2Department of Mechanical Engineering, Jadavpur University, Kolkata, India

Abstract

In the present paper, the tribological characteristics (wear and friction) of Al-SiC metal matrix composite fabricated by stir casting technique are studied. The metal matrix composite is fabricated using LM6Aluminium alloy as base metal and mixed with SiC as reinforcement. The volume fraction of SiC reinforcement is varied in the range of 5-10% by volume. The tribological tests were performed in a multi tribotester using block-on-roller setup at room temperature of 280C. Block samples of 20mm x 20mm x 8mm was prepared from the casted material and tested against EN8 steel roller. A load range of 50-100 N and sliding speed range of 180-220 rpm was chosen for the purpose. Wear depth and co-efficient of friction are chosen as system responses for wear and friction study. Wear resistance increases with increase in vol% of SiC whereas co efficient of friction is higher for Al-7.5%SiC and minimum for Al-10%SiC. The micro-hardness test conducted by Vickers micro-hardness tester concluded increase in hardness with increase in volume fraction of the reinforcement. To study the wear phenomenon wear tracks were analyzed using scanning electron microscopy.

Keywords

Al-SiC, Composite, Friction, Wear, Hardness

Received: April 9, 2015 / Accepted: April 20, 2015 / Published online: May 19, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Nowadays metals or alloys having light weight and good mechanical and tribological properties have high demand. The metal matrix composites reinforced with hard ceramics such as silicon carbide (SiC), alumina (Al2O3) and graphite show high specific strength and thermal conductivity. The reinforcements are widely found in the form of particulate also others forms such as fibers and whiskers are also available [1]. Thus, Al-MMCs have become an increasingly interesting material to study the tribological characteristics. Mostly researchers study the effect of volume fraction [1-10]. Some researchers have studied the effect of applied load [11-15] and sliding speed [16-21] on the friction and wear behavior of Al-SiC MMC. Mostly stir casting process is used as fabrication process for such composites also other processes such as die casting, rheo casting, spray foaming, etc. have lured many investigators to prepare such composites [4]. The aluminium MMCs are widely chosen for their rare combination of light weight and improved property than of aluminium alloy. This kind of material has good use in automobile, aerospace and mining industries. Some of the component such as brake drum, cylinder liners and drive shaft are fabricated using Al composites in the automobile industry [6]. Besides MMC, researchers have studied other strong and hard materials with similar tribological properties, such as some nano-structured carbon based materials [22,23].

The effect of volume fraction on the friction and wear behavior of Al-SiC metal matrix composite was studied by different researchers at different range of volume fraction. Al-Rubaie et al [1,2] performed their study varying the volume fraction in the range of 5-20%. Their study showed decrease in wear rate with increase in volume fraction of the reinforcement. Chen et al [3] studied the effect of volume fraction and concluded that coefficient of friction increased with increase in volume fraction of reinforcement whereas wear rates decreased with increase in volume fraction. Another study by Ghosh and Saha [4] also indicated that wear rates decrease with increase in volume fraction of SiC. Gurcan and Baker [5] carried out their study at volume fractions of 20% and 60%. The study concluded that wear resistance increased by nearly five times with increase of volume fraction of reinforcement from 20% to 60%. Mostly researchers have taken volume fraction range of 5-20% for their study [7,10]. Thus, in the present study considering the literature review volume fraction range of 5-10% is chosen.

Wear rates mostly vary with the change of volume fraction. Since, increasing volume fraction increases hardness of the material [3,5,9]. But there are other factors affecting the wear rates such as applied load and sliding speed. Since load range is determined dependent on the apparatus. The studies conducted on pin-on-disk setup choose a load range of 5-40 N. Some researchers have used a wide load range of 30 to 120N [9,12]. For other experimental setups like ball-on-disk [4,10] a very low load range is chosen. A similar setup used for the present experimental purpose such as block-on-ring uses a load ranging from 22 to 111N [17]. Thus a load range of 50-100N is chosen for the present study. The wear studies show increase in wear rates with increase in load. The wear rates increased from mild wear to severe wear for some studied with increase in load [9,17]. The effect of sliding speed was also studied by some researcher. The studied indicated that wear rates increased with increase in sliding speed and coefficient of friction decreased with increase in sliding speed.

For the present investigation Al-SiC metal matrix composite is prepared by varying volume fraction of reinforcement in the range of 5-10% with a variation of 2.5%. The tribological studies were conducted in a Multi tribotester test. Using 50, 75 and 100N loads and sliding speeds of 180, 200, 220 rpm was selected and various tests were performed at room temperature and dry condition. The hardness of the three types of composite was evaluated in a Vickers micro-hardness tester at 1kgf load for a dwell time of 15s. To determine the wear phenomenon the wear tracks were analyzed by scanning electron microscopy.

2. Fabrication Process

Al-SiC metal matrix composites having three different volume fraction of SiC were fabricated using stir casting process. For the fabrication process aluminium alloy i.e. LM6, is used as matrix metal that has been reinforced with 5, 7.5, 10 wt. % of SiC particles of 400 mesh size. The chemical composition of the matrix material (LM6) was given in Table 1. The process is both simple and less expensive, so the process is chosen for the fabrication of the composite. The small ingots of LM6 is melted in clay graphite crucible using an electric resistance furnace and 0.5 wt.% Mg is added with the liquid metal, in order to achieve a strong bonding by decreasing the surface energy (wetting angle) between the matrix alloy and the reinforcement particles. The addition of pure magnesium has also enhanced the fluidity of the molten metal. Before mixing of the silicon carbide particles with the liquid LM6, the particles are preheated at 9000C for 2-3 hours to make their surface oxidized. The melt is mechanically stirred by using a mild steel impeller and then the pre-heated silicon carbide particles (at 9000C) added with the stirred liquid metal. The processing of the composite is carried out at a temperature of 7200C with a stirring speed of 400-500 rpm. The melt is then poured at a temperature of 6900C into a green silica sand mould. The material is then cooled and samples for tribological testing are prepared by different machining processes.

Table 1. Chemical composition of LM6

| Elements | Si | Cu | Mg | Fe | Mn | Ni | Zn | Pb | Sb | Ti | Al |

| Percentage (%) | 10-13.0 | 0.1 | 0.1 | 0.6 | 0.5 | 0.1 | 0.1 | 0.1 | 0.05 | 0.2 | Remaining |

3. Tribological Test

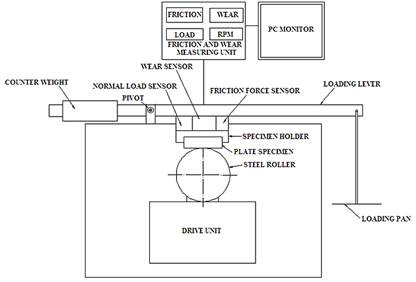

The tribological tests are carried out in a block on roller Multi tribotester TR25 (Ducom, India) (Fig. 1). It is used to measure the tribological characteristics of Al-%SiC under dry non lubricated condition and at ambient temperature (280C) and relative humidity of about 85%. The Al-SiC samples (size 20mm x 20mm x 8mm) are pressed against a rotating steel roller (diameter 50 mm, thickness 50 mm and material EN8 steel) of hardness 55 HRc. The setup is placed in such a way that the rotating roller serves as the counter face material and stationary plate serves as the test specimen. A 1:5 ratio loading lever is used to apply normal load on top specimen. The loading lever is pivoted near the normal load sensor and carries a counter weight at one end while at the other end a loading pan is suspended for placing the dead weights. The frictional force is measured by a frictional force sensor and wear depth is measured by a LVDT. Three sets of experiments were performed firstly to study the effect of volume fraction 50 N applied load, 200 rpm sliding speed and 40 min time is chosen for the purpose. For the second set of experiment where effect of load is studied 200 rpm sliding speed and 30 s time was selected and for different volume fraction tribological tests were performed at loads of 50, 75 and 100 N. And for the final set to study the effect of sliding speed 50 N load and 30 min time was selected and for different volume fraction of SiC at sliding speeds of 180, 200 and 220 rpm the tribological tests were performed.

The hardness of different Al-SiC composition is tested in Vickers micro-hardness tester at load of 1kgf. Microstructure study of the wear tracks are carried out by scanning electron microscopy to analyze the wear phenomenon.

Fig. 1. Layout of Multi tribotester

4. Result and Discussions

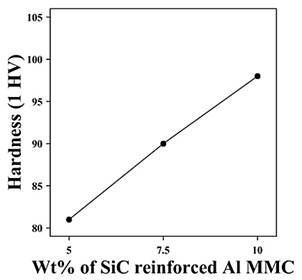

Fig. 2. Variation of hardness with different volume fraction of reinforcement

From the Vickers micro-hardness test results tabulated in Fig. 2, hardness values increase with increase in volume fraction of SiC reinforcement. The hardness of a material determines the depth of penetration on a material depending on load. In case of composites, the depth of penetration is governed by the protruded reinforcement particles. The reinforcement particle actually helps to support the contact stress preventing high plastic deformation and abrasion between contact surfaces. Thus increase in volume fraction of SiC reinforcement increases the hardness of the composite material.

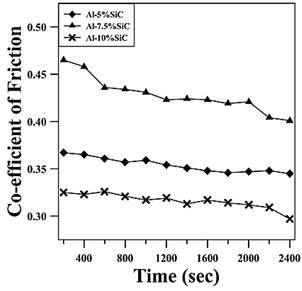

Fig. 3. Variation of coefficient of friction with sliding time

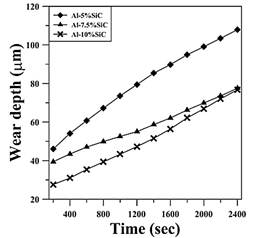

From the tribological test results wear depth and coefficient of friction are obtained as system responses for wear and friction study respectively. From Fig. 3 & 4 the effect of increase of volume fraction of reinforcement can be analyzed. Coefficient of friction initially increases with increase in volume fraction (from 5% to 7.5%) but then decreases (from 7.5% to 10%). Al-7.5%SiC shows the maximum value of coefficient of friction. Thus from friction perspective either low or very high amount of reinforcement is desirable as it provides lower coefficient of friction. In case of wear study, it is observed that wear depth decreases with increase in volume fraction of SiC reinforcement. This is due to increase in hardness with increase in volume fraction of SiC reinforcement. Thus from wear resistance point of view, higher volume fraction of SiC reinforcement is desirable.

Fig. 4. Variation of wear depth with sliding time

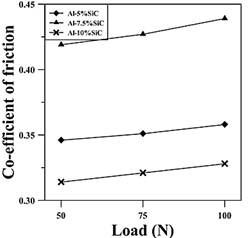

The effect of variation of applied load on friction and wear behavior of Al-SiC is shown in Fig. 5 and 6. It is observed that with increase in applied load coefficient of friction increases. This is due to the fact that at higher applied load the amount of deformation or ploughing is more leading to higher coefficient of friction. In case of wear behavior, wear depth decreases with increase in load from 50-75N and again increases at 100N load. It means there is no monotonic trend of variation of wear resistance with applied load probably due to non-homogeneous nature of the material.

Fig. 5. Variation of coefficient of friction with applied load

Fig. 6. Variation of wear depth with applied load

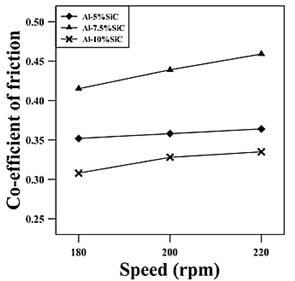

Fig. 7. Variation of coefficient of friction with sliding speed

Fig. 8. Variation of wear depth with sliding speed

The effect of variation of sliding speed on friction and wear characteristic is shown in Fig. 7 and 8 respectively. With increase in sliding speed, coefficient of friction increases marginally while wear depth increases at a steeper rate for all the compositions of the composites. Higher sliding speed induces greater amount of ploughing leading to higher wear depth.

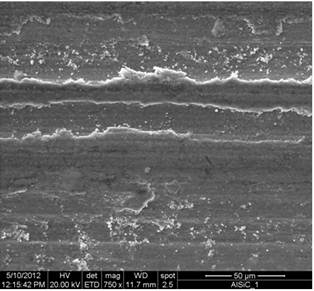

The wear tracks on the worn out surfaces of the composite are seen with the help of scanning electron microscope and is illustrated in Fig. 9. We can see longitudinal grooves and partial irregular pits which indicates adhesive wear behavior. The presence of grooves indicates the micro-cutting and micro-ploughing effect of the counter face while pits or prows are indicative of adhesive failure of Al-SiC composite. The adhesion occurs under the experimental conditions that induce a substantial attractive force between the mating surfaces leading to a high mutual solubility of aluminium and iron. Hence the wear phenomenon encountered in case of Al-SiC is a combination of abrasive and adhesive wear.

Fig. 9. SEM image of wear tracks on worn out composite

5. Conclusion

From the present tribological study for different compositions of Al-SiC composites, varying load and sliding speed, we can conclude the following:

(1) Hardness of the composite increases with increase in SiC reinforcement.

(2) The variation of coefficient of friction of Al-SiC composite with increase in volume fraction of reinforcement is not monotonic. However, wear rates decrease with increase in volume fraction of SiC reinforcement.

(3) With increase in applied load, coefficient of friction increases for all the compositions. On the other hand, variation of wear rates with increase in applied load is not monotonic.

(4) With increase in sliding speed both coefficient of friction and wear depth increases.

(5) SEM micrographs show presence of both adhesive and abrasive wear phenomenon.

References

- Al-Rubaie K.S., Goldenstein H., Biasoli de Mello J.D., Three-body abrasion of Al–SiC composites, Wear 225–229 (1999a) 163–173.

- Al-Rubaie K.S., Yoshimura H.N., Biasoli de Mello J.D., Two-body abrasive wear of Al–SiC composites, Wear 233–235 (1999b) 444–454.

- Chen R., Iwabuchi A., Shimizu T., Seop Shin H., Mifune H., The sliding wear resistance behavior of NiAI and SiC particles reinforced aluminum alloy matrix composites, Wear 213 (1997) 175-184.

- Ghosh S.K., Saha P., Crack and wear behavior of SiC particulate reinforced aluminium based metal matrix composite fabricated by direct metal laser sintering process, Materials and Design 32 (2011) 139–145.

- Gurcan A.B., Baker T.N., Wear behaviour of AA6061 aluminium alloy and its composites, Wear 188 (1995) 185-191.

- Hassan A.M., Alrashdan A., Hayajneh M.T., Mayyas A.T., Wear behavior of Al–Mg–Cu–based composites containing SiC particles, Tribology International 42 (2009) 1230–1238.

- RaoR.N., Das S., Effect of matrix alloy and influence of SiC particle on the sliding wear characteristics of aluminium alloy composites, Materials and Design 31 (2010) 1200–1207.

- Sahin Y., Abrasive wear behaviour of SiC/2014 aluminium composite, Faculty of Technology, Gazi University, 06500, Besevler-Ankara, Turkey, Tribology International 43 (2010) 939–943.

- Venkataraman B., Sundararajan G., The sliding wear behaviour of Al-SiC particulate composite-I Macro behaviour, Acta mater Vol 44, No 2, pp 451-460, (1996).

- Yalcin Y., Akbulut H., Dry wear properties of A356-SiC particle reinforced MMCs produced by two melting routes, Materials and Design 27 (2006) 872–881.

- Dan H., Wei-ping C., Shao-yang H., Zeng-xian H., Dry friction and wear performance of SiC3D continuous ceramic frame reinforced 7075Al alloy, Trans. Nonferrous Met Soc. China 20(2010) 54-58.

- Daoud A., Abou El-khairM.T., Wear and friction behavior of sand cast brake rotor made of A359-20 vol% SiC particle composites sliding against automobile friction material, Tribology International 43 (2010) 544–553.

- Izciler M., Muratoglu M., Wear behaviour of SiC reinforced 2124 Al alloy composite in RWAT system, Journal of Materials Processing Technology 132 (2003) 67–72.

- Kaur K., Anant R., Pandey O.P., Tribological Behaviour of SiC Particle Reinforced Al–Si Alloy, Tribology Letters 44(1) (2011) 41-58.

- Mindivan H., SabriKayali E., Cimenoglu H., Tribological behavior of squeeze cast aluminum matrix composites, Wear 265 (2008) 645–654.

- Kwok J.K.M., Lim S.C., High-speed tribological properties of some Al/SiCp composites: I. Frictional and wear-rate characteristics, Composites Science and Technology 59 (1999) 55-63.

- Ma T., Yamaura H., Koss D.A., Voigt R.C., Dry sliding wear behavior of cast SiC-reinforced Al MMCs, Materials Science and Engineering A360 (2003) 116-125.

- Natarajan N., Vijayarangan S., Rajendran I., Wear behaviour of A356/25SiCp aluminium matrix composites sliding against automobile friction material, Wear 261 (2006) 812–822.

- Onat A., Mechanical and dry sliding wear properties of silicon carbide particulate reinforced aluminium–copper alloy matrix composites produced by direct squeeze casting method, Journal of Alloys and Compounds 489 (2010) 119–124.

- Shorowordi K.M., Haseeb A.S.M.A., Celis J.P., Velocity effects on the wear, friction and tribo chemistry of aluminum MMC sliding against phenolic brake pad, Wear 256 (2004) 1176–1181.

- Shorowordi K.M., Haseeb A.S.M.A., Celis J.P., Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures, Wear 261 (2006) 634–641.

- Furlan A., Gueorguiev G.K., Czigány Zs., Darakchieva V., Braun S., Correia M.R., Högberg H., Hultman L., Structure and properties of phosphorus-carbide thin solid films, Thin Solid Films 548 (2013) 247-254.

- Gueorguiev G.K., Broitman E., Furlan A., Stafström S., Hultman L., Dangling bond energetics in carbon nitride and phosphorus carbide thin films with fullerene-like and amorphous structure, Chemical Physics Letters 482 (2009) 110-113.