Hydroponic and Aquaponic Systems for Sustainable Agriculture and Environment

Tahseen Sayara*, Basel Amarneh, Tasneem Saleh, Khaled Aslan,

Rawaa Abuhanish, Asma Jawabreh

Environment and Sustainable Agriculture Department, Faculty of Agricultural Science and Technology, Palestine Technical University, Tulkarm, Palestine

Abstract

In this research, an integrated system for sustainable agriculture and environment was designed and built at the experimental farm of Palestine Technical University. The system included: a) Hydroponic unit, b) Aquaponic unit, c) Pilot plant for wastewater treatment, d) Home composter. Lettuce crop was used throughout the research to compare its yield under different agricultural systems. In this regard, lettuce was planted in hydroponic and aquaponic systems, whereas, conventional cultivation of the same crop was performed using direct irrigation with hydroponic solution, direct water effluent from fish rearing tank and effluent from wastewater treatment plant, in addition to control trial using fresh water and fertilizers. Lettuce production in each trial was evaluated using different parameters. The obtained results showed that hydroponic system is the most efficient one, where fast production with little resources could be achieved. Nevertheless, and even acceptable results were obtained in aquaponic system, it was clear that more attention should be applied as fish is affected by the surrounded ambient factors, mainly the temperature. Also, the wastes produced by fish may need more time to be degraded, or does not contain all nutrients needed by plants, thus hinder their growth. Both systems used around 80% less water than growing in soil, which is important especially with the scarcity of water resources for agricultural sector.

Keywords

Hydroponic, Aquaponic, Agriculture, Sustainability, Environment

Received: August 13, 2016

Accepted: August 24, 2016

Published online: October 9, 2016

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

It is expected that world population will grow up to nearly 9 billion by 2050. This number indicates the need for providing huge quantities of food in accordance with the expected huge demand [1]. Consequently, meeting the challenges of sustainably producing food in the face of a growing population, decrease in available land due to urbanization and global change without compromising the ability of future generations to meet their needs requires an integrated understanding of both the natural and human-driven systems involved in the production and consumption of food [2].

Farmers went towards intensive agriculture including growing high-yield crops, using fertilizers and pesticides and keeping animals indoors…etc. However, these activities are normally associated with various environmental problems, which all finally lead to depletion of natural resources on the long-term taking into account that these resources are limited. Moreover, intensive agriculture leads to use large quantity of agrochemicals that threaten human health. Accordingly, it seems vital and very important to create, investigate and finally employ a broad array of approaches/projects of sustainable agriculture. These projects should emphasize on the integration of different systems and different disciplines which could produce enough crops to meet the exponentially increasing demand, meanwhile these project have to be environmentally-friendly and able to conserve the available resources [3].

Aquaponic and Hydroponic agricultural systems have been introduced and used in agricultural sector worldwide [4,5]. Aquaponic systems are designed as enclosed recirculation systems, their agricultural waste and environmental footprints decrease, compared to conventional agriculture practices [6]. Furthermore, utilization of plants as a secondary crop reduces the pollution load through nutrient uptake and assimilation [7,8]. Since water within systems is re-circulated, the quantity of water needed to run the system is minimized compared to most fish and crop production systems. On average, 98% of the water in aquaponic systems is recycled for the duration of operation [4,9]. On the other hand, hydroponics is a subset of hydro culture and is a method for growing plants using mineral nutrient solution in water without soil. Terrestrial plants may be grown with their roots in the mineral nutrient solution only or in an inert medium, such as perlite or gravels [10].

The objective of the present work was to build a hydroponic and aquaponic systems, and then the two different agricultural techniques were used to highlight their efficiency in crop production and to conduct a comparison between them concerning growth rate and yield. The study was also employed to focus on problems and difficulties of using such techniques. Lettuce (Lactuca sativa) has been selected for this research. Also traditional agriculture of lettuce in land using treated wastewater (reuse), planting using hydroponic solution and direct discharge from fish rearing tank were performed in order to differentiate between the efficiency of each system with the above mentioned techniques.

2. Materials and Methods

2.1. Aquaponic System

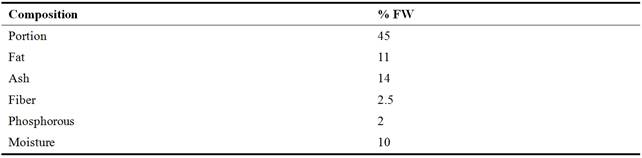

An aquaponic system was designed and built during the current research in the faculty farm. This system was designed based on aquaponic radial flow filter for solids removal model. It consists of one fish rearing unit of about 0.5 m3, a clarifier filter tank, and plant growth bed unit. The used water was discharged directly from artesian well so as to minimize any effect of chlorine on fish. The system operated continuously with a known density of fish biomass to maintain stable bacterial populations. Nile tilapia (Oreochromisniloticus) and Koi (Cyprinuscarpio) were stocked in the rearing tanks of 1 m3 (1m length *1m width *1m height), whereas water depth was 0.5m. Twenty two fish of different sizes were stocked and cultured for 4 months, the mean mass of stocked fish ranged from 30g to 450g. They were always fed one time daily with a pellet diet containing 45% protein at a mean rate of 3% of body weight per day. Table 1 shows the proximate composition (%) of the fish feed used in the experiment.

Water from fish tank pumped to the system via water pump at flow rate of 0.23 L/S works for 24 hour, delivering water to the rest of unit by a circular irrigation network between the plants, thus biological filtration of the culture water was constant and the microorganisms works better for degradation of wastes from fish and supplying nutrients for plants. The plants growth bed unit and fish rearing tank had 2 air diffusers (1 L min-1) which was working continuously (24 hours). Water from plant growth bed unit returns to the clarifier filter tank, after that to the rearing tank locating in the lowest point of the system.

Table 1. Proximate composition (%) of the fish feed used in the experiment.

2.2. Hydroponic System

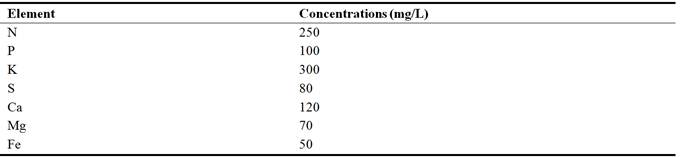

The hydroponic system was designed based on NFT (Nutrient Film Technique) system. It consisted of a water tank of 150 L, connected with a pump working at a flow rate of (0.19 L/S), the pump works sporadically (15 minutes per hour daily). Moreover, the system had air pump works on a flow rate of (4 L/minute) that pumps air 24 hour per day, and the tank cover also was perforated to prevent anaerobic conditions. The used water was supplied directly from the artesian well, which was located near field, and water was supplied directly when needed and when the water level was decreased. The addition of the nutrient solution to the water was in a ratio of 1:1000. The concentration of the nutrients within this solution is demonstrated in Table 2.

The growing bed is a perforated 4 inch plastic pipes (1% slope) supplied with pots for carrying the plants and submerged in water. The plants roots are in direct contact with water inside the pipe, so that there is no need for growing bed. Water flows from the first pipe and moves through other pipes in a spiral movement, and then it returns to the tank again. This movement of water adds oxygen to the water in addition to the oxygen directly supplied by the air pump. These conditions ensure that al lplants roots will respire perfectly and prevent lack of oxygen, and thus providing the best conditions for plants growth. To facilitate the circulation of water, a pipe line of 2 inch (0.1 L/S flow rate and 5% slope) was used to return excess water again to the tank. Water remains in the pipes for 45 minutes, whereas roots are dangling into the nutrient solution which allows them to absorb their nutrients directly. After that the pump works for 15 minutes to supply new water for the system.

Table 2. Nutrients concentration in hydroponic solution.

2.3. Plants

Lettuce seedlings were used in all systems (aquaponic, hydroponic, control, direct aquaponic, direct hydroponic and reuse), such that 25 seedling for each system were planted.

The plants were grown in a greenhouse with 13 hours light phase, 11 hours dark phase. Greenhouse temperature wasn’t controlled. The average exterior ambient temperature during the experiment was (23.45°C) and the relative humidity was 89.25%. The experiment was conducted for 55 days. The plants were daily monitored, whereas old and damaged leaves were cut frequently. No chemicals or pesticides were added.

For aquaponic system, lettuce seedlings were typically planted in a growing bed consisted of toof stones (volcanic stones), where the roots are growing directly in the stones and get their nutrients from water supplied from the fish tank that contains fish excrete. No chemicals were added to the system, but the only nutrient supplementation was Fe, as symptoms of deficiency were noticed directly on leaves. Thereby this nutrient supplement was sprayed twice in the form (Fe-EDDHA) at a concentration of 4mg/L.

2.4. Control

The soil which is clayey soil was tilled and prepared for control planting. In this regard, basic fertilization including 25 kg compost and 1 kg Ammonium sulphate were applied before planting steps. Lettuce seedlings were typically planted in the soil like conventional (normal) land farming. The plants were planted and irrigated regularly with fresh water, such that about 250 ml for each seedling was performed once each three days. Additionally, the plants were fertilized twice with fertilizer (21.0.0.24); the first time was after 3 weeks and the second time was after 6 weeks. It is worth to mention that some diseases infected the plants such as Aphids and cutter worm moth. As a consequence, the plants were cured by spraying Proclaim and Marshal 25 insecticide (1 cm3/1L of water) to control pests.

2.5. Reuse

This trial included the same procedure as mentioned in the control trial. However, no fertilizers were applied, and treated water was used for irrigation instead of fresh water. The treated water was obtained from the effluent of the treatment plant included in the integrated system, and dedicated to treat the discharged wastewater from hydroponic and aquaponic systems.

2.6. Direct Aquaponic and Direct Hydroponic

Here, the same procedures were applied as in reuse trial. But, irrigation (250 ml) was performed directly using the discharged water from aquaponic and nutrient solution from hydroponic. Notably, no pests have infected the plants in this trial, and no chemicals or insecticides were applied.

2.7. Analysis and Measurements

Samples for water quality analysis were collected at the influent and effluent of the growth bed tanks and the rearing tank. The pH and electrical conductivity (EC) were measured along the experiment using pH and EC meters. Total ammonia-nitrogen (TAN), nitrite nitrogen and nitrate-nitrogen were measured once every month at different locations in the systems using advanced Spectrophotometer (data not included), where the levels of chlorophyll in leave were recorded using SPAD chlorophyll content meter.

3. Results &Discussion

3.1. pH, EC and Salinity in Hydroponic and Aquaponic Systems

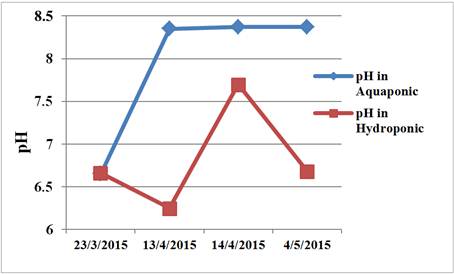

The majority of aquatic organisms prefer a pH range of 6.5-9.0, and if the pH of water is too high or too low, the aquatic organisms living within water will die. pH affects the solubility and toxicity of chemicals and heavy metals in water, so that an ideal range of pH must be adjusted and monitored [11,7]. Fig. 1 explains the pH behaviour during the experiment in hydroponic and aquaponic systems.

As shown in Fig. 1, the pH values in hydroponic system ranged between (6.26-7.77) which are considered as normal values for such systems. At the beginning of the experiment, normal pH was observed, however, a slight decrease (6.25) was observed due to the addition of new water with low pH. It raised again till it reached a pH of 7.77, this raising leads to precipitation of nutrients and other chemicals and was most probably due to the precipitation of calcium carbonate in pipes. Accordingly, phosphoric acid was added to water (0.01 ml /L water) to minimize this effect on the plants.

Fig. 1. pH value of Aquaponic and Hydroponic systems.

For aquaponic system, the pH values ranged between (6.65-8.37) as demonstrated in Fig. 1. pH started with 6.65 which is a normal and ideal pH for this system. Actually, in the beginning the conditions were ideal as water was clean, and no big amounts of wastes were produced yet, and no big densities of microorganisms existed. After a period of time the pH raised dramatically (8.35), which is correlated to the increasing of wastes quantities and microorganisms. The pH kept rising till it reached 8.37 which is a slightly high pH. This is mainly due to the accumulation of wastes and chemicals produced from fish and other microorganisms in water. Nevertheless, a slightly high pH is usually not a problem in this system, because the "Cycling" process is designed to encourage beneficial nitrifying bacteria to take up residence in the system.

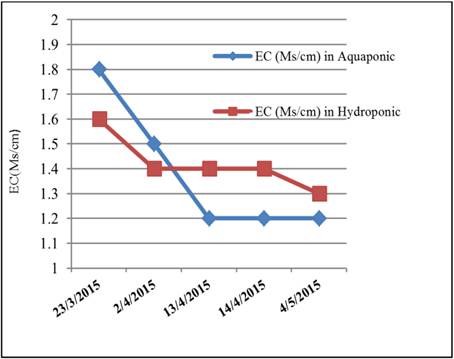

Fig. 2, illustrates the EC values and their variation throughout the experiment in both hydroponic and aquaponic systems. In fact, this parameter is important in determining the availability of nutrients for plants [12].

As shown in Fig. 2, the EC of hydroponic system ranged between (1.1-1.6Ms/cm). These values are within ideal range for this agricultural technique especially for lettuce growth. In fact, the EC was slightly high at the beginning (1.6) and to avoid any further increase, the solution was replaced and diluted. After about 10 days, and with the increase in plant growth, the EC values decreased and later remained almost stable. This could be attributed to the absorption of chemicals and nutrients from water as plants growth increased rabidly in this stage, which requires high amounts of nutrients and finally leads to low EC.

Fig. 2. EC (Ms/cm) in Hydroponic and Aquaponic.

In the aquaponic system, EC values ranged between (1.2-1.8 Ms/cm) as shown in Fig. 2. The observed high EC values in the beginning (1.8Ms/cm) were caused by high temperature of water (ambient temperature was high at that period) which resulted in dissolving of salts and other solids in water. Actually, these conditions had a negative impact on lettuce growth and caused fish death also (high temperature caused thermal shock for fish). To overcome this problem, the water in the rearing tank was replaced and an isolation system was provided to this tank to minimize the effect of ambient temperature.

For both hydroponic and aquaponic systems, the salinity values was low (Fig. 3). These values indicate that there was no negative impact caused by salinity in both systems.

Fig. 3. Salinity in Hydroponic and Aquaponic systems.

3.2. Vegetative Growth (Chlorophyll Content)

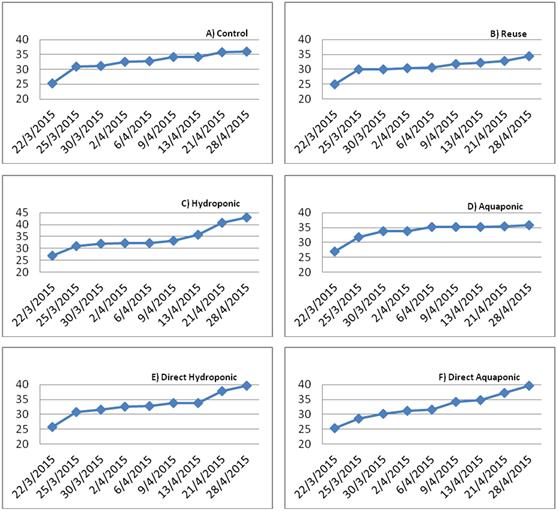

The chlorophyll content was measured using the SPAD chlorophyll meter. Average values are presented in Fig. 4. As shown, there was significant difference among all systems, where the highest chlorophyll content was found in hydroponic system followed by trial irrigated directly by water discharged from hydroponic and aquaponic tanks. Whereas, the lowest values were obtained in the trial using treated wastewater (Reuse).

All plants had low chlorophyll content at the beginning due to the slow growth of the seedlings associated with low photosynthesis process. Clearly, the leaves were small at that time, but with more time the process started to increase due to the growth of seedlings and larger size of leaves. More biological processes and reactions within the plant could be occurred. These results indicate that the best growth of plants was in the "Hydroponic System" and that’s normal because an ideal nutrient of plants and the best growth conditions were in the hydroponic.

Fig. 4. Chlorophyll content.

3.3. Plants Length

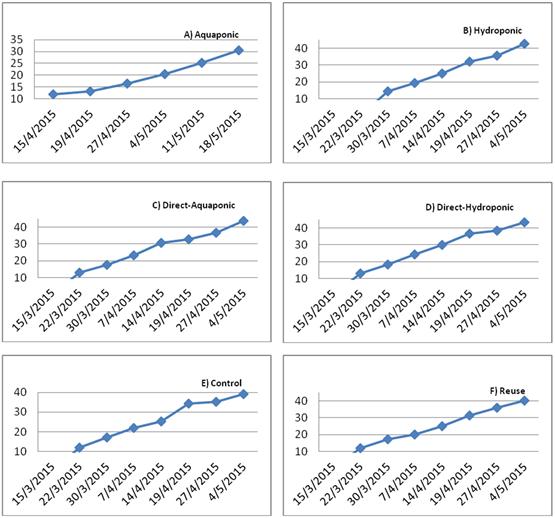

Plant length is an as indicator for plant growth and represented by the increasing of height during a period of time. Plants length in all treatments is presented in Fig. 5. n aquaponic system, initially and during planting, many problems occurred including lack of nutrients and death of fish due to thermal shocks caused by high ambient temperature. These conditions resulted in delaying growth rates or finally ended with death of plants. Fortunately, all problems were solved in the system and later new seedlings were planted and their results are shown in Fig. 5. As it can be noticed, plants growth was initially slow as they need to create roots, but after that period, a notable increase was noticed (20.54, 25.32, 30.46 cm). Normally the growth rate in aquaponic systems is slow as plants rely on fish waste, thus it is important to add some nutrients to support their growth [13,14].

In hydroponic system, the increase in plants length was quick comparing with other trials. This could be explained by readily available nutrients for plants growth and the easily of roots movement in water unlike in soil. Consequently the obtained results clearly indicated that freely movement of roots in a solution rich of nutrients will enhance growth rate as nutrients would be easy absorbed in such system like hydroponic. For trial of direct Irrigation with aquaponic or hydroponic water, the results showed again that the readily available of nutrients from the water solution accelerated the plants growth compared with others.

Fig. 5. Plants length (cm).

3.4. Plants Weight

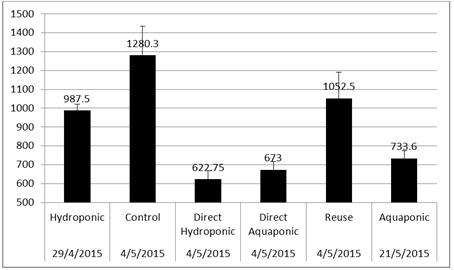

Under natural rate of growth (availability andabsorption of nutrients) during a period of time ranging between (60-80) days, the range of normal weight for lettuce is (700-1100) g.

Fig. 6 shows the average weights oflettuce plants in the different systems during different time periods. The highest weights rate was obtained in the control which was cultivated under traditional agriculture. This result was due to longer period of planting with more consumption of water and fertilizers. However, it was clear that best weight rate was obtained in the Hydroponicsystem that gave highest weight in shortest possible time with lower amount of water and fertilizers (80% less water). Aquaponic came after the hydroponic system and needs less water, but as it depends on decomposition of fish wastes, this will normally decelerate plants growth. The Reuse system gave better results than aquaponic, but longer period of time and more quantity of water were needed, even though no fertilizers were applied.

Fig. 6. Plants weight.

4. Conclusions

The obtained results showed that lettuce production under different trials included in this research were almost convergent except for hydroponic system. Indeed lettuce production using hydroponic system gave the highest yields, faster, and with decreased production costs compared to other systems. These observations are related to free available nutrients in water and easy root growth in water. On the other side, lettuce growth in aquaponic system needs somewhat longer period than the other systems. This is because it mainly depends on the residues of fish wastes which are organic materials and usually take time to be decomposed by microorganisms. Both hydroponic and aquaponic demonstrated high efficiency in water consumption (about 80% less water) comparing with traditional cultivation in soil.

References

- Harris, J. M. 2001. Agriculture in a global perspective. Global Development and Environmental Institute Working Paper No. 01-04.

- Tilman, D., Cassman, C. G., Matson, P. A., Naylor R., Polasky S.2002. Agricultural sustainability and intensive production practices. Nature 418:671-677.

- Merriam-Webster Online Dictionary. 2013. Aquaculture. [online]. Available from: http://www.merriam-webster.com/dictionary/aquaculture. Accessed July 2013

- Al-Hafedh, Y. S., Alam, A.,Beltagi, M. S. 2008. Food production and water conservation in a recirculating aquaponic system in Saudi Arabia at different ratios of fish feed to plants. Journal of the world Aquaculture Society 39:510-520.

- Rakocy, J. E., Masser, M. P., Losordo, T. M. 2006. Recirculating aquaculture tank production systems: Aquaponics- integrating fish and plant culture. Southern Regional Aquaculture Center; SRAC Publication No. 454.

- Nelson, R.L., 2008. Aquaponic Food Production. Nelson and Pade Inc. Press, Montello, WI, USA, 218 pp.

- Timmons, M.B., and Ebeling, J.M. 2007. Recirculating Aquaculture. 2nd ed. Northeastern Regional Aquaculture Center. Ithaca, NY: Cayuga Aqua Ventures.

- Lennard, W.A. 2006. Aquaponic integration of murray cod (Maccullochellapeeliipeelii) aquaculture and lettuce (Lactuca sativa) hydroponics. Thesis submitted for fulfillment of the Degree of Doctor of Philosophy. RMIT University, Victoria, Australia.

- Treadwell, D., S. Taber, Tyson, R.,Simonne, E. 2010. Foliar-applied micronutrients in aquaponics: A guide to use and sourcing. Horticultural Sciences Department, Florida Cooperative Extension Service, Institute of Food and Agricultural Sciences, University of Florida; Publication No. HS1163:1-8.

- Rakocy, J.E.,Hargreaves, J.A. 1993. Integration of vegetable hydroponics with fish culture: a review. In: J.-K. Wang, Ed. Techniques for Modern Aquaculture. American Society of Agricultural Engineers: St. Joseph, MI; 112-136.

- Nash, C.E. The history of aquaculture. 1st ed. Ames, Iowa: Blackwell Publishing Ltd. 2011.

- Landowne, D., 2006.Cell Physiology, McGraw-Hill Education / Medical; 1 edition (1600)

- Seawright, D.E., Stickney, R.R., Walker, R.B., 1998.Nutrient dynamics in integrated aquaculture-hydroponics systems. Aquaculture 160, 215–237.

- Graber, A., Junge, R., 2009. Aquaponic systems: nutrient recycling from fish wastewater by vegetable production. Desalination 246, 147–156.