Studies on the Biodegradation of Cassava Peels (Manihot Esculenta) and Rice Straw (Oryza Sativa) by Some Selected Microorganisms

Aransiola Michael N.*, Fagade Obasola E.

![]() Environmental Microbiology and Biotechnology Laboratory, Department of Microbiology, Faculty of Science, University of Ibadan, Ibadan, Nigeria

Environmental Microbiology and Biotechnology Laboratory, Department of Microbiology, Faculty of Science, University of Ibadan, Ibadan, Nigeria

Abstract

Biodegradation of agricultural waste by microorganisms is an acceptable method which results in useful end product and reduces environmental pollution. Three agricultural wastes, cassava peels (Local and TMS 98/0505) and rice straw, were subjected to biodegradation. The wastes were collected from Teaching and Research farm, University of Ibadan, washed and oven dried at 60oC for 72hrs. The cassava peels were milled into powder while the rice straw was chopped into pieces. Bacteria and fungi were isolated from degraded cassava peels and then screened for cellulase production on carboxyl methylcellulose (CMC) agar. Selected isolates were characterized and identified. The biodegradation process was carried out by weighing 15g of each waste in basal medium (45ml for bacteria at pH 8 and 25ml for fungi at pH 5) at 28oC for 14 days in 250ml conical flasks. Each flask was set in duplicate. Reducing sugar content and available nitrogen were determined using Dinitrosalicylic Acid Assay method and Kjeldahl method respectively to evaluate biodegradation process. The selected isolates were identified as Pseudomonas sp., Bacillus sp., Trichoderma viride and Aspergillus terreus. The glucose level produced in mg/ml by Pseudomonas sp. was 0.37, 0.58 and 0.18 in cassava peels (Local and TMS 98/0505) and rice straw which were higher than in Bacillus sp. (0.35, 0.56 and 0.15mg/ml) while T. viride produced 0.99, 1.27, and 0.33mg/ml which were higher than in A. terreus (0.95, 1.24, and 0.29mg/ml). The bacteria combination produced 0.30, 0.55 and 0.14mg/ml while the fungi combination produced 0.81, 1.10 and 0.23mg/ml. The percentage increase in Nitrogen content was 14.3%, 38.9% and 12.5% in Pseudomonas sp. which were higher than in Bacillus sp. (11.8%, 35.3%, and 9.3%) while T. viride produced 20.0%, 50.3%, and 19.7% which were higher than in A. terreus (17.8%, 44.2%, and 16.9%). The bacterial combination produced 10%, 21.7% and 8.3% while the fungi combination produced 16.7%, 41.5% and 11.5%. Since the isolates showed appreciable degradation of the wastes, they can be used for biodegradation of agro-wastes in the environment to reduce pollution by these wastes.

Keywords

Biodegradation, Cassava Peels, Rice Straw, Pseudomonas sp.

Received: April 9, 2015

Accepted: April 25, 2015

Published online: May 22, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Growth of population, increasing urbanization, rising standards of living due to technological innovations have contributed to an increase (annually) both in the quantity and variety of solid wastes generated by industrial, mining, domestic and agricultural activities (Somesh, 2008). The amount of waste generated, since the turn of the 20th century has increased to the point where natural mechanisms for accomplishing their degradation are no longer efficient and therefore causing their accumulation (USEPA, 2005). The increasing annual production of solid waste and their accumulation are a major source of pollution. This ever-increasing rise in environmental pollution from agro-industrial sector, as well as other sectors of the economy, has brought about an increased research aimed at improving waste utilization (Moon et al., 2009). The biological decomposition of the organic fraction of Municipal Solid Waste (MSW) has been found to be in a number of life cycle analysis studies more cheap, environmentally effective and friendly than landfill, incineration or pyrolysis. Such MSW include: Wood, Plastics, Metals, Food scraps (e.g Cassava peels, and Rice straw), paper and paperboard etc (USEPA, 2005)

Cassava (Manihot esculenta) is the most important crop in many tropical countries, including Nigeria. It plays an important role in the African diet and they are processed using simple traditional methods into products such as fufu, garri, taploka etc (Odunfa, 1985). Okafor (1992) reported that rough estimates of about 10 million tones of cassava are processed annually in Nigeria alone. The cassava peels can constitute about 20-35% of the total weight of the tuber (Ekundayo, 1980).

Rice (Oryza sativa) is a major staple food for millions of people in West Africa and the fastest growing commodity in Nigeria’s food basket (Akande, 2003). The demand for rice has been increasing at much faster rate in Nigeria than in other West African countries since the mid 1970s. For example, Nigeria’s per-capita rice consumption level has grown significantly at 7.3% per annum, rising from 18kg in the 1980s to 22kg in 1990s (Imolehin and Wada, 2000). Rice production in Nigeria has boomed over the years, it is grown on 1.77 million hectares ranks fifth after sorghum (4.0m ha), millet (3.5m ha.) cassava (2.0m ha) and yam (2.0mha), but if placed on a social scale, it can well be ranked first because it is no longer just a mere festival meal as in the past, but the staple of most homes in urban, and rural area (Longtau, 2003).

In this present study, agricultural wastes, two cassava peels (Local and TMS 98/0505) and rice straw, were subjected to biodegradation by selected bacteria and fungi isolates (singly and in combination) with the cassava peels milled into powder while the rice straw was chopped into pieces. Reducing sugar content and available nitrogen were determined to evaluate biodegradation process.

2. Materials and Methods

2.1. Materials

Degraded cassava peels (Manihot esculenta) were obtained from a cassava processing factory, Agbowo, University of Ibadan, Ibadan. Nutrient Agar (NA) (Oxoid), Potato Dextrose Agar (PDA) (Oxoid) and CMC (Carboxyl Methyl Cellulose) Agar (Oxoid) were purchased from Sigma Aldrich and other chemicals used were of analytical grade.

2.2. Methods

2.2.1. Substrates

Fresh cassava peels (Manihot esculenta) (Local and TMS 98/0505) and rice straw (Oryza sativa) were collected from Teaching and Research farm, University of Ibadan. They were washed with tap water to free them of soil particles and oven dried at 600C for 72 hours. The cassava peels were grinded into powdery form while the rice straw was cut into pieces. The substrates were then separately stored in different dry polythene bags for further use.

2.2.2. Culture Media

All media used (Nutrient Agar (NA), Potato Dextrose Agar (PDA), and Carboxyl Methyl Cellulose (CMC) Agar) were prepared in accordance with the manufacturerʾs specification, homogenized and thereafter sterilized by autoclaving at 1210C for 15mins. The media were allowed to cool down to about 450C before use. Streptomycin (0.1%) was added to the Potato Dextrose Agar to prevent bacterial contamination of the media.

2.2.3. Bacteria and Fungi Isolates

Bacteria and fungi were isolated from degraded cassava peels (Manihot esculenta) by serial dilution and pour plate technique on NA for bacteria and PDA for fungi. The isolates were macroscopically examined for morphology and colony characteristics such as the shape, surface, elevation, pigment, edge, opacity, etc for bacteria and growth patterns, spore and mycelia colouration, distribution of spores, etc for fungi. The isolates were screened for cellulase production on carboxyl methylcellulose (CMC) agar (Shankar et al., 2011). The microscopic examination was done by Gram staining and then viewed under oil immersion objective (x100 magnification) to see the Color, Shape, etc for bacteria while the fungi were examined by lacto-phenol cotton blue staining and viewed under x10 magnification, then x40 magnifications to see the hyphae, spores, spore arrangement, etc. Biochemical tests such as Indole test, Catalase test, Citrate test, Motility test, Urease test, Starch hydrolyses test, etc and sugar fermentation test were carried out on the bacteria isolate (Fawole and Oso 1988). The isolates were identified using Bergey’s Manual of Systematic Bacteriology (Don et al., 2005) and Compendium of Soil Fungi (Domsch et al., 1980). The inoculum size for each isolate was standardized. The isolates were used singly and in combination.

2.2.4. Biodegradation of Substrates

The biodegradation process was carried out by weighing 15g of each waste in basal medium (45ml for bacteria and 25ml for fungi) at 280C for 14 days in 250ml conical flasks. The basal medium for bacteria contained (g/l): Yeast extract, 1; peptone, 5; ![]() , 2; and

, 2; and ![]() , 5 at pH 8.0 (Souichiro et al., 2004) while the basal medium for fungi contained (g/l):

, 5 at pH 8.0 (Souichiro et al., 2004) while the basal medium for fungi contained (g/l): ![]() , 10.0;

, 10.0; ![]() , 10.5;

, 10.5; ![]() , 0.33;

, 0.33; ![]() , 0.5;

, 0.5; ![]() , 0.004;

, 0.004; ![]() , 0.0013;

, 0.0013; ![]() , 0.004;

, 0.004; ![]() , 0.0067; and peptone, 0.5 at pH 5.0 (Ajao et al., 2009). The basal medium with the substrate were sterilized at 1210C for 15mins and then inoculated with 1 McFarland standard (x108) and a spore suspension 1.0 x 105 for each flask after cooling respectively. Each flask was set in duplicate. Controls were made similarly without inoculation with bacteria or fungi. After 14 days, the content of each flask was filtered and the residue (substrate) was dried in oven at 600C. Reducing sugar (glucose) content and available nitrogen were determined.

, 0.0067; and peptone, 0.5 at pH 5.0 (Ajao et al., 2009). The basal medium with the substrate were sterilized at 1210C for 15mins and then inoculated with 1 McFarland standard (x108) and a spore suspension 1.0 x 105 for each flask after cooling respectively. Each flask was set in duplicate. Controls were made similarly without inoculation with bacteria or fungi. After 14 days, the content of each flask was filtered and the residue (substrate) was dried in oven at 600C. Reducing sugar (glucose) content and available nitrogen were determined.

Analytical method

Reducing sugar content was determined by Dinitrosalicylic Acid (DNS) colorimeter method of Miller (1959). A reaction mixture composed of 0.2ml of crude enzyme solution was added to 1.8ml of 0.5% CMC in 50mM sodium phosphate buffer (pH 7). The mixture was incubated at 370C in a shaking water bath for 30min. The reaction was terminated by adding 3ml of DNS reagent. The mixture was boiled for 5min. and the optical density of samples was measured at 575nm against a blank containing all the reagents minus the crude enzyme.

Available nitrogen content was determined by Kjeldahl method of Association of Official Analytical Chemists (1990). In brief, samples were grinded and 1gram of each was digested in boiling concentrated sulfuric acid with a catalyst and then boiled. The ammonia was collected by distillation into a trapping solution and then measured by titration with a standard solution.

The percentage (%) increase in Nitrogen content in the substrates was calculated as:

![]()

3. Results

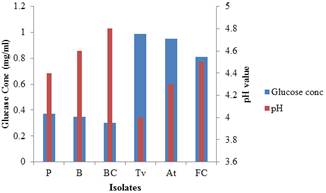

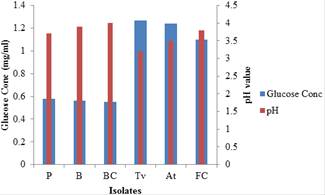

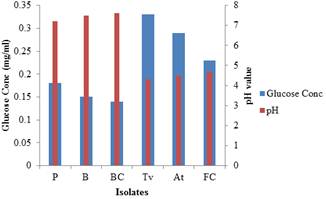

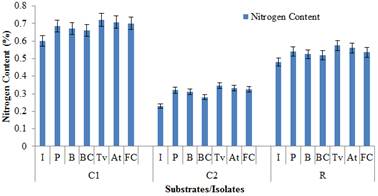

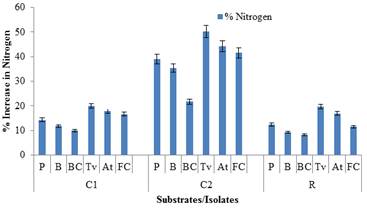

The ability of Pseudomonas sp., Bacillus sp., Trichoderma viride and Aspergillus terreus to degrade two cassava peels (Local and TMS 98/0505) and rice straw was studied. The results indicated that all the three substrates (two cassava peels (Local and TMS 98/0505) and rice straw) are degradable by these isolates. Based on the amount of reducing sugar (glucose) produced, cassava peels (TMS 98/0505) was most degraded (Fig 2), follow by cassava peels (Local) (Fig 1) while the rice straw was least degraded (Fig 3). As shown in Fig 1, 2 and 3, the pH decreases with increase in glucose content and Pseudomonas sp. had higher degradation value among the bacteria isolates with glucose concentration 0.37.005, 0.58.010 and 0.18.005mg/ml in cassava peels (Local and TMS 98/0505) and rice straw than in Bacillus sp. (0.35.000, 0.56.005 and 0.15.010mg/ml) while T. viride produced 0.99.005, 1.27.010, and 0.33.000mg/ml which were higher than in A. terreus (0.95.000, 1.24.005, and 0.29.010mg/ml). The bacteria combination produced 0.30.010, 0.55.000 and 0.14.000mg/ml while the fungi combination produced 0.81.010, 1.10.000 and 0.23.000mg/ml. Fig 4 shows the percentage Nitrogen content in the three substrates before and after degradation. The percentage Nitrogen content increased in all the isolates with T. viride having the highest yield of 0.72.02, 0.35.00 and 0.57.00% while the bacteria combination had the least yield of 0.66.00, 0.28.01 and 0.52.00% in cassava peels (Local), cassava peels (TMS 98/0505) and rice straw with initial percentage Nitrogen content of 0.6, 0.23 and 0.48% respectively. As shown in Fig 5, the percentage increase in Nitrogen content was 14.3%, 38.9% and 12.5% in Pseudomonas sp. which were higher than in Bacillus sp. (11.8%, 35.3%, and 9.3%) while T. viride produced 20.0%, 50.3%, and 19.7% which were higher than in A. terreus (17.8%, 44.2%, and 16.9%). The bacterial combination produced 10%, 21.7% and 8.3% while the fungi combination produced 16.7%, 41.5% and 11.5%.

Table 1. Selected Isolates and the Diameter of Zones of Cellulose Activity

| Isolates | Diameter (mm) |

| Pseudomonas sp. | 22 |

| Bacillus sp. | 20 |

| Trichoderma viride | 32 |

| Aspergillus terreus | 27 |

Figure 1. Glucose concentration and pH value of the fermented cassava peels (Local) with the isolates and combinations.

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination.

Figure 2. Glucose concentration and pH value of the fermented cassava peels (TMS 98/0505) with the isolates and combinations.

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination.

Figure 3. Glucose concentration and pH value of the fermented rice straw with the isolates and combinations.

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination.

Table 2. Glucose concentration and pH value of the fermented cassava peels (Local)

| Isolates | Glucose Concentration (mg/ml) | pH | ||||||

| Set-up1 | Sep-up2 | Mean | SD | Set-up1 | Sep-up2 | Mean | SD | |

| P | 0.36 | 0.37 | 0.37 | .005 | 4.5 | 4.3 | 4.4 | .10 |

| B | 0.35 | 0.35 | 0.35 | .000 | 4.6 | 4.6 | 4.6 | .00 |

| BC | 0.31 | 0.29 | 0.30 | .010 | 4.7 | 4.8 | 4.8 | .05 |

| Tv | 0.99 | 0.98 | 0.99 | .005 | 3.9 | 4.1 | 4.0 | .10 |

| At | 0.95 | 0.95 | 0.95 | .000 | 4.3 | 4.3 | 4.3 | .00 |

| FC | 0.80 | 0.82 | 0.81 | .010 | 4.6 | 4.4 | 4.5 | .10 |

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination, C= Control, SD= Standard deviation.

Table 3. Glucose concentration and pH value of the fermented cassava peels (TMS 98/0505)

| Isolates | Glucose Concentration (mg/ml) | pH | ||||||

| Set-up1 | Sep-up2 | Mean | SD | Set-up1 | Sep-up2 | Mean | SD | |

| P | 0.58 | 0.58 | 0.58 | .010 | 3.7 | 3.7 | 3.7 | .00 |

| B | 0.56 | 0.55 | 0.56 | .005 | 4.0 | 3.8 | 3.9 | .10 |

| BC | 0.55 | 0.55 | 0.55 | .000 | 4.0 | 4.0 | 4.0 | .00 |

| Tv | 1.28 | 1.26 | 1.27 | .010 | 3.2 | 3.2 | 3.2 | .00 |

| At | 1.23 | 1.24 | 1.24 | .005 | 3.4 | 3.6 | 3.5 | .10 |

| FC | 1.10 | 1.10 | 1.10 | .000 | 3.8 | 3.8 | 3.8 | .00 |

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination, C= Control, SD= Standard deviation.

Table 4. Glucose concentration and pH value of the fermented rice straw

| Isolates | Glucose Concentration (mg/ml) | pH | ||||||

| Set-up1 | Sep-up2 | Mean | SD | Set-up1 | Sep-up2 | Mean | SD | |

| P | 0.18 | 0.17 | 0.18 | .005 | 7.2 | 7.4 | 7.3 | .10 |

| B | 0.14 | 0.16 | 0.15 | .010 | 7.7 | 7.5 | 7.6 | .10 |

| BC | 0.14 | 0.14 | 0.14 | .000 | 7.7 | 7.7 | 7.7 | .00 |

| Tv | 0.33 | 0.33 | 0.33 | .000 | 4.7 | 4.7 | 4.7 | .00 |

| At | 0.30 | 0.28 | 0.29 | .010 | 4.6 | 4.4 | 4.5 | .10 |

| FC | 0.23 | 0.23 | 0.23 | .000 | 4.3 | 4.3 | 4.3 | .00 |

Key: P= Pseudomonas sp., B= Bacillus sp., BC= Bacteria Combination, Tv= Trichoderma viride, At= Aspergillus terreus, FC= Fungi Combination, C= Control, SD= Standard deviation.

Table 5. Nitrogen content and percentage increase on Nitrogen content of fermented cassava peels (Local and TMS 98/0505) and rice straw.

| Isolates | Nitrogen content (%) | |||||||

| C2 | R | |||||||

| Set-up1 | Sep-up2 | Mean | SD | % increase | Set-up1 | Sep-up2 | Mean | |

| I | 0.60 | 0.60 | 0.60 | .00 | 0.23 | 0.23 | 0.23 | |

| P | 0.70 | 0.68 | 0.69 | .01 | 14.3 | 0.33 | 0.33 | 0.33 |

| B | 0.66 | 0.68 | 0.67 | .01 | 11.8 | 0.29 | 0.32 | 0.31 |

| BC | 0.66 | 0.66 | 0.66 | .00 | 10.0 | 0.29 | 0.27 | 0.28 |

| Tv | 0.74 | 0.70 | 0.72 | .02 | 20.0 | 0.35 | 0.35 | 0.35 |

| At | 0.69 | 0.71 | 0.70 | .01 | 17.8 | 0.36 | 0.32 | 0.34 |

| FC | 0.68 | 0.68 | 0.68 | .00 | 16.7 | 0.32 | 0.34 | 0.33 |

Table 5. Continued

| Isolates | Nitrogen content (%) | ||||||

| C2 | R | ||||||

| SD | % increase | Set-up1 | Sep-up2 | Mean | SD | % increase | |

| I | .00 | 0.48 | 0.48 | 0.48 | .00 | ||

| P | .00 | 38.9 | 0.54 | 0.56 | 0.55 | .01 | 12.5 |

| B | .02 | 35.3 | 0.53 | 0.53 | 0.53 | .00 | 9.3 |

| BC | .01 | 21.7 | 0.52 | 0.52 | 0.52 | .00 | 8.3 |

| Tv | .00 | 50.3 | 0.57 | 0.57 | 0.57 | .00 | 19.7 |

| At | .02 | 44.2 | 0.58 | 0.54 | 0.56 | .02 | 16.9 |

| FC | .01 | 41.5 | 0.53 | 0.55 | 0.54 | .01 | 11.5 |

Key: I = Initial, P = Pseudomonas sp., B = Bacillus sp., BC = Bacteria Combination, Tv = Trichoderma viride, At = Aspergillus terreus, FC = Fungi Combination, C= Control, C1 = cassava peels (Local), C2 = cassava peels (TMS 98/0505), R = rice straw, SD= Standard deviation.

Figure 4. Changes in Nitrogen content of the fermented cassava peels (Local, TMS 98/0505) and rice straw

Key: I = Initial, P = Pseudomonas sp., B = Bacillus sp., BC = Bacteria Combination, Tv = Trichoderma viride, At = Aspergillus terreus, FC = Fungi Combination, C1 = cassava peels (Local), C2 = cassava peels (TMS 98/0505), R = rice straw.

Figure 5. Percentage increase in Nitrogen content of the fermented cassava peels (Local, TMS 98/0505) and rice straw

Key: P = Pseudomonas sp., B = Bacillus sp., BC = Bacteria Combination, Tv = Trichoderma viride, At = Aspergillus terreus, FC = Fungi Combination, C1 = cassava peels (Local), C2 = cassava peels (TMS 98/0505), R = rice straw.

4. Discussion

The result of this investigation showed that Pseudomonas sp., Bacillus sp., Trichoderma viride and Aspergillus terreus are able to degrade and cause considerable changes in the nutrient composition of the wastes [two cassava peels (Local and TMS 98/0505) and rice straw]. This was possibly due to their ability to utilize various organic substances present in these wastes as sources of carbon and energy. Bacillus sp. has been reported to produce cellulases with activity on soluble and crystalline cellulose in the earlier work of Miranda et al. (2009). The specific cellulolytic activity shown by the bacteria species was also said to depend to the source of occurrence. From the result presented, it could also be seen that Pseudomonas sp. performed better than Bacillus sp. This is in accordance with the work of Sonia et al. (2013).

The enzymatic degradation of waste cellulose by fungal enzyme for the conversion of lignocellulosics into simple sugars has been revealed by the work of Durand et al. (1984).The ability of species of Trichoderma and Aspergillus to produce hydrolytic enzymes such as cellulases has been earlier reported by Oksanen et al. (2000), Coral et al. (2002) and Onsori et al. (2005). The result of this work showed that Trichoderma viride has higher performance than Aspergillus terreus which is in agreement with the work of Omojasola et al. (2008).

The bacterial species used in this study were able to degrade the cassava peels (Local and TMS 98/0505) and rice straw. Although they were not effective as the two fungi species this is because fungal mycelia are known to penetrate the substrate for nutrients uptake while bacteria are found growing on the surface of the waste material. This complied with the work of Nigam and Singh (1994).

The glucose concentration and nitrogen content reduction by the bacteria and fungi combinations observed might be due to antagonistic effects or their ability to scavenge the glucose derived from cellulose, which otherwise deteriorate cellulolytic activity (Souichiro et al., 2004).

It could also be observed from the figures presented that the glucose concentration and the percentage increase in Nitrogen content respectively for each isolate from the rice straw was the least followed by the cassava peels (Local) and the cassava peels (TMS 98/0505) has the highest glucose concentration and the percentage increase in Nitrogen content respectively. Therefore, cassava peels were more degraded than the rice straw which could be probably due to the low lignin content in cassava peels. This is in agreement with the work of Tuah (1990) and Okolo et al. (1995).

5. Conclusion

The results of this present study have shown that cassava peels are more susceptible to biodegradation than the rice straw and the susceptibility of cassava peels to biodegradation depends on the cassava varieties.

Conversion of rice straw and cassava peels by the fungal and bacterial isolates means that these wastes could be used as raw materials by industries for value added product. This will reduce wastage and improve economic gain. However, whenever it is economically and technologically possible, emphasis should be laid on the utilization of waste materials for recycling and upgrading purposes.

Finally, the problem of food waste disposal will continue to increase in a country like Nigeria with increase in production of food products. The only available solution to this problem is to treat some of these accumulated food waste with specific microorganisms so as to recycle and if possible convert them to useful materials of high economic value. They could also serve as growth media for fungi, bacteria and reduce pollution.

References

- Ajao A.T., Abdullahi H. J., Atere T. G. and Kolawole O. M., 2009. Studies on the biodegradation and utilization of selected tuber wastes by Penicillium expansum. Journal of Bioscience Research Communication. 21(5): 221-227.

- Akande T., 2003. The rice sector in Nigeria. United Nation Crop Project (UNCP) Country Agricultural Project on trade liberalization in Agricultural sector and the environment, Geneva. Pp 10.

- Association of Official Analytical Chemists, 1990. Protein (Crude) Determination in Animal Feed: Copper Catalyst Kjeldahl Method. (984.13) Official Methods of Analysis. 15th Edition.

- Coral G., Arikan B., Unaldi M. N. and Guvenmes H., 2002. Some properties of crude carboxymethyl cellulase of Aspergillus niger Z10 wild-type strain. Turkish Journal of Biology, 26 (4):209-213.

- Domsch K.H., Gams W. and Traute-Heidi A., 1980. Compendium of Soil Fungi.1:1-1240

- Don J. B., Noel R. K., James T. S., 2005. [1984(Williams & Wilkins)]. George M. G., ed.Introductory Essays. Bergey's Manual of Systematic Bacteriology 2A (2nd ed.). New York: Springer. p. 304.

- Durand H, Soucaille P, Tiraby G., 1984. Comparative study of cellulases and effect on pH, EC and maturity of the composting mixtures. Bioresource and Technology, 78, 301-308.

- Ekundayo J. A., 1980. In: Fungal Biotechnology. Ed: Smith J E., Benny P.R and Kristiasen B. London Academic press. pp 244-270.

- Fawole M. O. and Oso B. A. 1988. LaboratoryManual for Microbiology (1st Edn). Spectrum book Ltd. Ibadan, pp 1-168.

- Imolehin E. D. and Wada A. C., 2000. Meeting the rice production and consumption demands of Nigeria with improved technologies. National Cereals Research Institute Badeggi Niger State, Nigeria. 12p.

- Longtau S., 2003. Rice Production in Nigeria. Literature Review. Multi-agency partnerships in West African Agriculture. A review and description of rice production system in Nigeria pp. 98.

- Miller G. L., 1959. “Use of dinitrosalicylic acid reagent for determination of reducing sugar,Analytical Chemistry, 31(3): 42628.

- Miranda M., Kam T. L., and Wensheng Q., 2009. The prospects of cellulase- producing bacteria for the bioconversion of lignocellulosic biomass. Int J Biol Sci. 5:50016.

- Moon H. C., Song I. S., Kim J. C., Shirai Y., Lee D. H., Kim J. K., Chung S. O., Kim D. H., Oh K. K. and Cho Y. S., 2009. Enzymatic hydrolysis of food waste and ethanol fermentation.Int J Energ Res 33:164-172.

- Nigam P. and Singh D., 1994. Solid state fermentation systems and their application in biotechnology. Journal of Basic Microbiology, 34(6) 465-423.

- Odunfa S.A., 1985. African foods: In Microbiology of fermented foods Ed. Wood; B.J.B. Elsevier Sci., London and New York. 2:155-159.

- Okafor N., 1992. Commercialization of fermented foods in sub-Saharan Africa In Application of Bacteriology to Traditional Fermented foods, National Academy press, U.S.A. 165-169.

- Okolo B. N. E., Lewis M. I., and Charles N., 1995. Production of raw starch digesting amylase by Aspergillus niger grown on native starch sources. J. Sci. Food Agric. 69(1): 109-115.

- Oksanen T., Pere J., Paavilaninen L., Buchert J. and Viikari L., 2000. Treatment of recycled pulps with Trichoderma reesei hemicellulases and cellulases. J.Biotechnol. 8: 39-48.

- Omajasola P.F. and Jilani O. P., 2008. Cellulase production by Trichoderma longi, Aspergillus niger and Saccharomyces cerevisae cultured on waste materials from orange. Pak. J. Biol. Sci., 11(20): 2382-2388.

- Onsori H., Zamani M. R., Motallebi M. and Zarghami N., 2005. Identification of over producer strain of endo-B-1-4- glucanase in Aspergillus species: Characterization of crude carboxy methyl cellulase. African Journal of Biotechnology.4(1):26-30.

- Shanker T., Mariappan V. and Isaiarasu L., 2011. Screening Cellulolytic Bacteria from the Mid-Gut of the popular composting Earthworm, Eudrilus eugeniae (Kinberg). World Journal of Zoology.6(2): 142-148.

- Somesh A., 2008. Bioconversion of cellulosic agricultural wastes. An M.Tech Dissertation. Thapar University, Patiala. Pp 1-72

- Sonia S., Aparna D. B., Lal G. and Saksham G., 2013. Optimization of cellulase production from bacteria isolated from soil. Hindawi Publishing Corporation, ISRN Biotechnology. Article ID 985685.

- Souichiro K., Shin H., Zong J. C, Masaharu I., Akira Y. and Yasuo I., 2004. Clostridium straminisolvens sp. nov., a moderately thermophilic, aerotolerant and cellulolytic bacterium isolated from a cellulose-degrading bacterial community. Int. J. Sys. Evol. Microbiol., 54: 2043-2047

- Tuah A.K., 1990. Utilization of agricultural by-products for village and commercial production of sheep rations in Ghana. FAO CORPORATE DOCUMENT REPOSITORY; Trypanotolerant livestock in West and Central Africa Journal. Vol 2, country studies.

- USEPA, 2005. Municipal solid waste. United States Environmental Protection Agency