Effect of Firing Time and Temperature on Selected Physical Properties of Black Cotton Soil

Samwel Nyakach1, *, Seth F. O. Owido2, Japheth O. Onyando1

1Department of Agricultural Engineering, Egerton University, Njoro, Kenya

2Department of Crops, Horticulture and Soils, Egerton University, Njoro, Kenya

Abstract

Black cotton soils which are classified as Vertisols cover approximately 200 million hectares of land in the arid and semi arid tropics. In these environments they are considered the most suitable soils for agriculture because of their high water holding capacity. However, this water holding ability has been found to be deceptive since not all the water is readily available for crop use. In addition, the soils present a range of management challenges that limit their suitability for agricultural production. The soils are easily eroded, have poor infiltration rates coupled with very slow hydraulic conductivities which limit both irrigation and drainage, and a highly varied consistency. Various management technologies for the soils have been developed resulting into varying degrees of productivity and sustainability. This study evaluated the effect incorporating organic matter into the soil prior to firing at definite temperatures and for given durations of time. Based on factorial experimental design, analysis of variance (ANOVA) was done using the SAS studio. Results indicated that the mean bulk density decreased by 20% when 10% (by weight) of rice husk was added. The mean bulk density changed from 1.29 g/cm3 before firing to 1.12 g/cm3 on firing and further to 0.99 g/cm3 upon size reduction. The Pearson correlation coefficient was -0.019 for time of firing and increased marginally to 0.076 after size reduction. The time of firing had the least effect on bulk density. However, for saturated hydraulic conductivity, the temperature, time and percent black cotton soil all had a significant effect with Pearson’s correlation analysis giving coefficients of 0.77, 0.22 and -0.43 respectively. The mean saturated hydraulic conductivity for the aggregates was 0.0045 cm/s which compares closely to that of Loamy Sand as estimated as 0.0041 cm/s by the RETention Curve (RETC) model.

Keywords

Vertisols, Bulk Density, Hydraulic Conductivity, Temperature, Time

Received: November 24, 2016

Accepted: December 21, 2016

Published online: January 21, 2017

@ 2016 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY license. http://creativecommons.org/licenses/by/4.0/

1. Introduction

Clay soils around the world vary in their physical and chemical characteristics which are used to distinguish them. Modern soil classification which started with the publication of the 7th Approximation of the USDA Soil Taxonomy has made it possible to classify the soils based on precisely defined and quantified soil properties. Of interest are the black cotton soils which are classified as Vertisols both under the USDA Soil Taxonomy and the FAO soil classification systems. The soils have a high content of expansive clay that shrinks and swells depending on the moisture content. They have clay content of at least 30% to a depth of at least 50cm and wide, deep cracks that open and close periodically. In addition, they exhibit evidence of soil movement (e.g. slickensides, wedge-shaped aggregates), have varied soil temperature regimes and the soil moisture regime is erratic to allow for cracking in dry season and swelling in wet season.

The soils mainly occupy the hot environments in the semi arid tropics with marked alternating wet and dry seasons. Seasonal variations in precipitation and temperature result in the weathering of primary and secondary minerals during the wet season and the accumulation of basic cations in the dry season. These processes favour the formation of the black cotton soils from a wide variety of parent material [8]. The natural vegetation is predominantly grass, savannah, open forest or desert shrub. Trees that grow in these soils are limited to the deep rooted types such as acacia trees whose roots can withstand the frequent cracks on the soil. Although the black colour was originally being attributed to organic matter, the soils have been found to have low organic matter content of between 1 and 6% and even less than 1% in some areas [16]. The variations in soil colour are attributable to the drainage status of the soil. The black colour is therefore indicative of poor drainage conditions while, where there is improved drainage; the soils are more reddish and have stronger chroma [12]; [9].

The soils occupy an approximated 340 million hectares in the world. In the tropics, they cover about 200 million hectares of land mainly in the arid and semi arid tropics which receive average annual rainfall of between 500mm and 1000mm. They are common in lower landscape positions such as dry lake bottoms, river basins, lower river terraces and other lowland areas that are periodically wet in their natural state. They may also be found in lower foot slopes or as residual soils or even on gently sloping hillsides. In Africa, the black cotton soils are found in Sudan mainly in southern Sudan where they cover approximately 40 million hectares being 16% of the land area; Chad which has a coverage of 16.5 million hectares and Ethiopia with about 10 million hectares. In Kenya, the soils occur in patches in various locations including the Kano plains where it cover about 70% of the plain’s total area of about 430km2 [3]. The soils are also found in Australia, China and the USA [11].

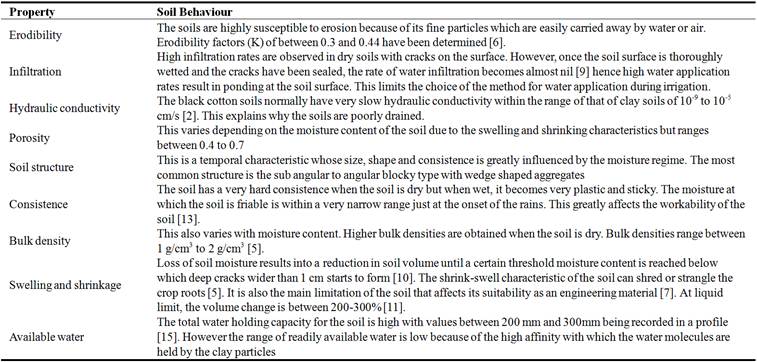

Black cotton soils are important for agriculture in the semi-arid tropics. This is because in these environments, they are considered the most productive soils due to their high water holding capacity. However, this water holding ability has been described as deceptive since not all the water held by the soil is readily available for crop use [5]. Other management related constraints for the soil can be summarized as in Table 1 below;

Table 1. Physical Characteristics of Vertisols that limit their suitability for Agriculture.

Based on the above constraints, various management practices have been suggested and adopted for Vertisols. These management practices combined with improved cultivars and cropping systems offer varied degrees of productivity and sustainability. The practices include;

1.1. Flood Fallowing

This is achieved by flooding the land for 6-9 months. The gases produced by fermentation and redistribution of oxides help improve rooting conditions.

1.2. Deep Ploughing

This is done to break the hardened sub soil and hence improve the hydraulic properties of the soils. However, heavy machinery is required to pull the implements through the soil. The cost of using such machinery is often out of reach of most farmers.

1.3. Surface Drainage

Since sub-surface drainage is not feasible in these soils, special attention is often given to surface drainage systems. This include shaping the land through the use of cambered beds, ridges, furrows, bunding and broad banks which have been applied in a number of countries including Ghana, India and the USA [5]. However, according to [14], these technologies have had limited success.

1.4. Use of Soil Amendments

This is reportedly being practiced in Kenya where tree planting holes are filled with red Alfisols brought from other areas [5]. This method is only feasible where such soils are available close to the farms otherwise the cost of transport may be prohibitive. Sand has also been used to improve the texture of the soils. Apart from the availability of the sand within the locality together with the accompanying costs, a soil must consist of nearly 50% sand by total volume before it takes on the characteristics of sandy soil [1].

1.5. Soil Heating and Burning

Burning causes the clay fraction to fuse to sand sized particles. This method has mainly been practiced in Ethiopia. This has often been done by spreading dry vegetation over the land and setting on fire. However, it is constrained by the high energy losses and the open fires used are also destructive to vegetation and soil organisms. There is no uniformity in soil heating either across the land surface or depthwise. Since there is no controlled heating, the temperatures attained may be too low to make any significant impact on the soil properties or too high to result in stone-like materials that may require re-weathering to make them suitable for crop production.

The objective of this study is to combine the effects of use of rice husk to amend the soil and then heating the mixture. Rice husk which is an organic waste is abundantly available in the rice growing areas of Kano plains. It is a light material which when mixed with the black cotton soil is expected to reduce its bulk density appreciably. Its size also makes it easy to mix with the clay. On firing, the organic matter is combusted leaving a more porous material and resulting in more macro pores than the original clay. In addition, at elevated temperatures of approximately 600°C, glowing combustion occurs and the resulting flaming can boost temperatures from 800°C to 1500°C [4].

2. Materials and Methods

The rice husks were obtained from the Lake Basin Development Company (LBDC) Kibos rice mills. The black cotton soil was obtained from the Kenya Agricultural and Livestock Research Organization (KALRO) Kibos Centre in Kisumu. The soil was mixed at predetermined ratios of 100:0, 97.5:2.5, 95:5 and 90:10 with the rice husks on a weight basis. The mixture was moulded after wetting with water into cylindrical blocks. This was accomplished by using a cylindrical galvanized iron mould and wooden extruder. The mould dimensions were 52mm diameter and 100mm height. The blocks were dried in an oven at 105°C for a period of 48 hours to ensure they attained uniform oven dry moisture content.

The dried blocks were fired under varied but controlled temperatures in an electric furnace. The firing temperatures were 700°C, 750°C and 800°C. The temperature range was chosen because all clay bodies contain some measure of carbon, organic materials, and sulfur which burn off at between 300°C and 800°C after which they fuse together.

The firing temperature was the time from which the desired temperature was attained in the furnace until when the furnace was switched off. The times were 30 minutes, 60 minutes and 90 minutes for each of the temperatures.

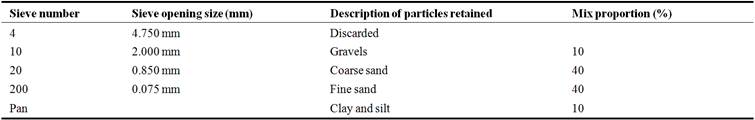

Size reduction of the expanded clay blocks was done mechanically to obtain smaller aggregates within the particle size range of soils. These were passed through a series of soil test sieves and the aggregates retained in each sieve mixed proportionately at predefined ratios. The sieves and mix proportions used are described in Table 2;

Table 2. Soil Test Sieves used.

The bulk density was computed as function of the dry mass divided by the total volume. Saturated hydraulic conductivity was measured using a constant head permeameter. The N-way ANOVA was done using the SAS studio to determine the significance of the effects. Pearson correlation analysis was carried out to measure the strength and direction of association that existed between two variables measured.

3. Results and Discussion

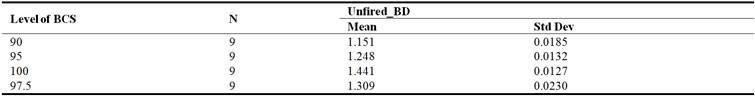

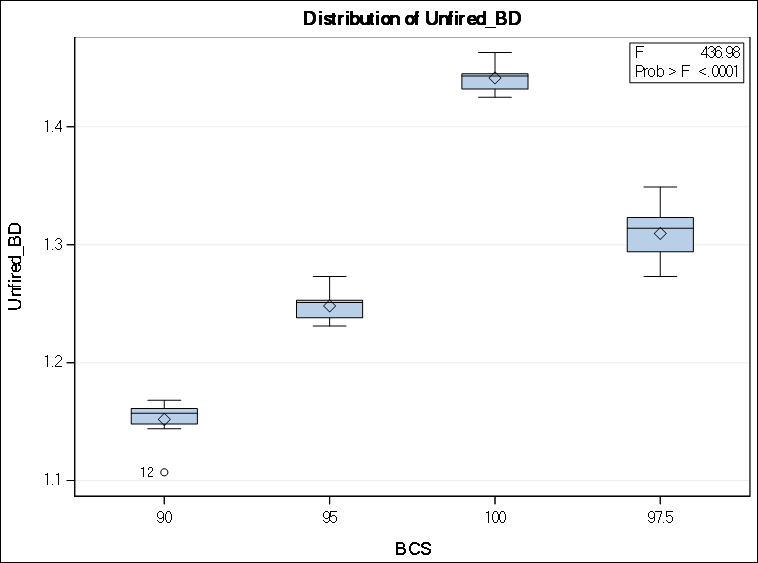

3.1. Bulk Density Before Firing

The bulk density of the dried blocks was determined based on the dry weight and the volume of the mould. It was found that the bulk density increased almost linearly with an increase in percent black cotton soil. Figure 1 gives the distribution of mean bulk density which varied from 1.15 g/cm3 to 1.44 g/cm3 depending on the percent black cotton soil as given in Table 3. The F value was 436.98 with R2 of 0.976 indicating that the addition of rice husk had a significant effect on the resulting bulk density. This is attributed to the low density of the husks which results in a decrease in weight per unit volume of the block.

Table 3. Mean Bulk Density before Firing.

Figure 1. Distribution of the Bulk Density before Firing.

3.2. Bulk Density After Firing (Before Size Reduction)

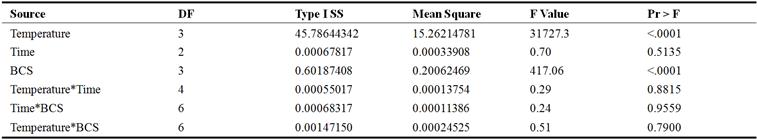

Upon firing of the blocks, the model gave an overall F-value of 4018.34 with R2 and RMSE of 0.991 and 0.0219 respectively. Table 4 gives the effect of each of the parameters. It is noted that temperature and percent black cotton soil had significant effects on the bulk density while the time for firing did not. The interactions also did not produce significant effects

Table 4. ANOVA for Fired Bulk Density of the blocks after Firing.

Application of heat energy combusted the rice husks and the higher the temperature, the greater was the combustion thereby increasing the porosity of the blocks. The corresponding Pearson correlation coefficients were 0.026, -0.0193 and 0.941 for temperature, time and percent black cotton soil respectively. This indicated the percent black cotton soil in the samples had the greatest effect on bulk density as was the case before firing. The firing temperatures and time had least correlation within the ranges selected.

3.3. Bulk Density After Size Reduction

The size reduction process resulted into aggregates corresponding in size to gravel (2.00 mm to 4.75 mm), coarse sand (0.85 mm to 2.00 mm), fine sand (0.075 mm to 0.85 mm) and the fines (0.0 mm to 0.075 mm). These were mixed in the ratio 1:4:4:1. The ANOVA for the bulk density of the mixture resulted in model mean bulk density of 0.99 g/cm3. The R2 and the RMSE were 0.97 and 0.02 g/cm3 respectively. The model indicated statistically significant difference in the means. Similar to the bulk density before size reduction, time did not have a significant effect as shown in Table 5 below.

Table 5. ANOVA for Bulk Density after Firing.

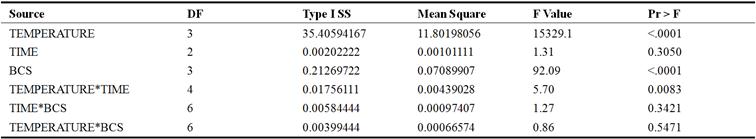

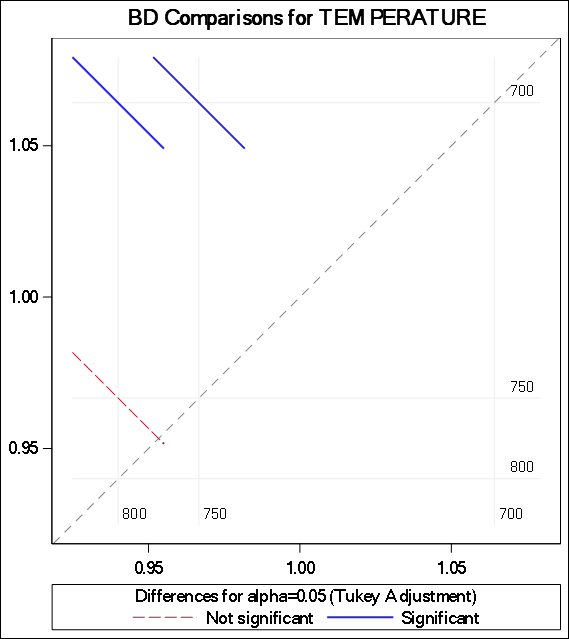

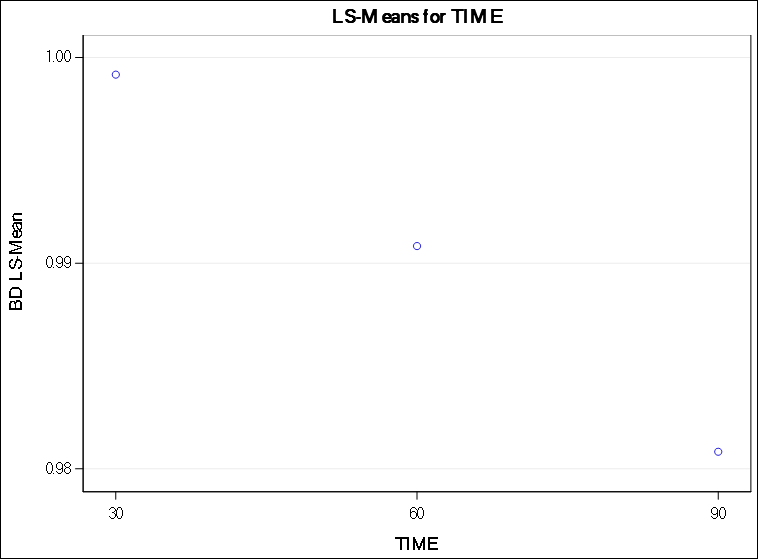

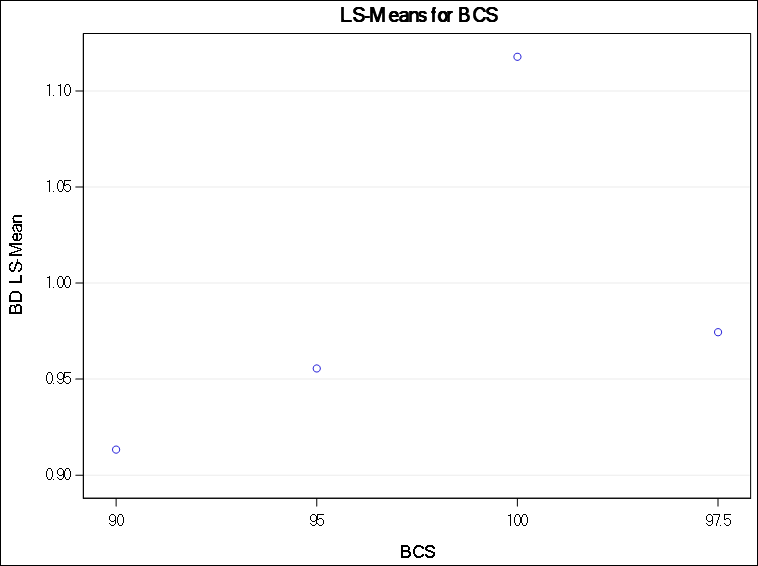

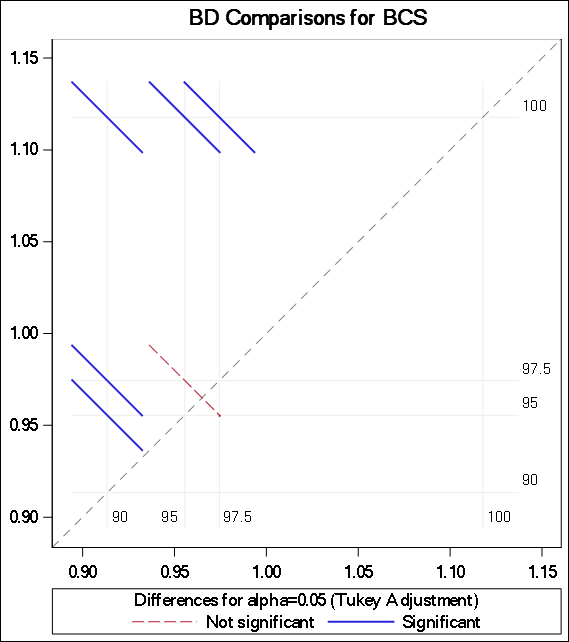

The least square means for bulk density was 1.06, 0.97 and 0.94 g/cm3 at temperatures of 700, 750 and 800°C respectively as shown in Figure 2 and supported by the Tukey adjustment as shown in Figure 3. Figures 4 to 7 show similar analysis for time and percent black cotton soil respectively.

Figure 2. Least Square Mean for Temperature.

Figure 3. The Tukey Adjustment for Temperature.

Based on the Tukey adjustment plot, an increase in temperature from 750°C to 800°C does not result in a significant difference in the least square means of bulk density. The optimum temperature is therefore 750°C. Higher temperatures will not be appropriate in terms of the energy demand.

Figure 4. Least Square Means of Bulk Density for Time.

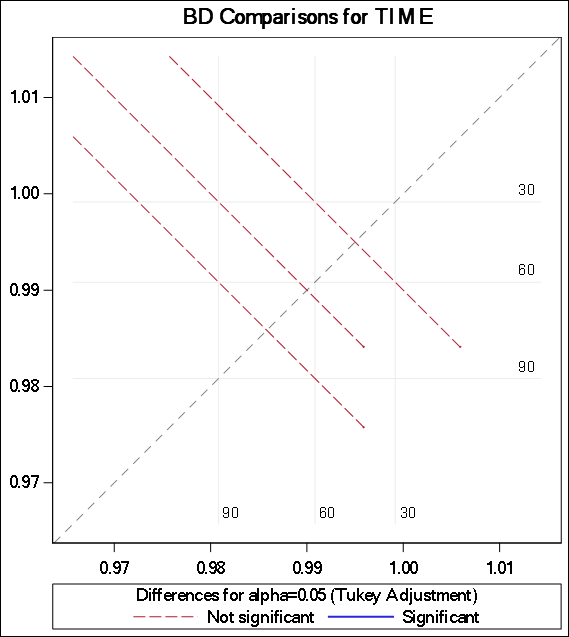

Figure 5. The Tukey Adjustment for Time.

There is no significant difference in the least square means of bulk density for time of firing through all the levels used in the experiment.

Figure 6. Least Square Means of Bulk Density for Percent Black Cotton Soil.

Figure 7. The Tukey Adjustment for Percent Black Cotton Soil.

A Pearson correlation analysis for the independent variables gave coefficients of -0.511, -0.076 and 0.67 for temperature, time and percent black cotton soil respectively. It shows that upon size reduction, the effect of temperature increased while that of percent black cotton soil reduced. This is because some of the pore spaces resulting from combustion of rice husk collapsed during size reduction or was occupied by the finer materials.

3.4. Saturated Hydraulic Conductivity

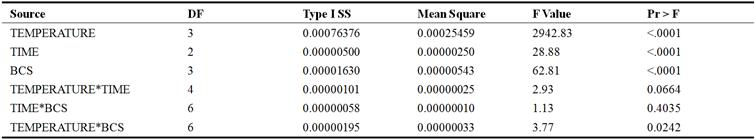

The analysis of saturated hydraulic conductivity data generally showed a statistically significant difference in the means. It gave an F-value of 379.82 with the corresponding R2 and RSME as 0.99 and 0.0003 cm/s respectively. The effect of each of the variables is represented in Table 6. It indicates that all the independent variables had a significant effect the saturated hydraulic conductivity of the aggregates as well as the interaction of temperature and percent black cotton soil.

Table 6. ANOVA for Saturated Hydraulic Conductivity.

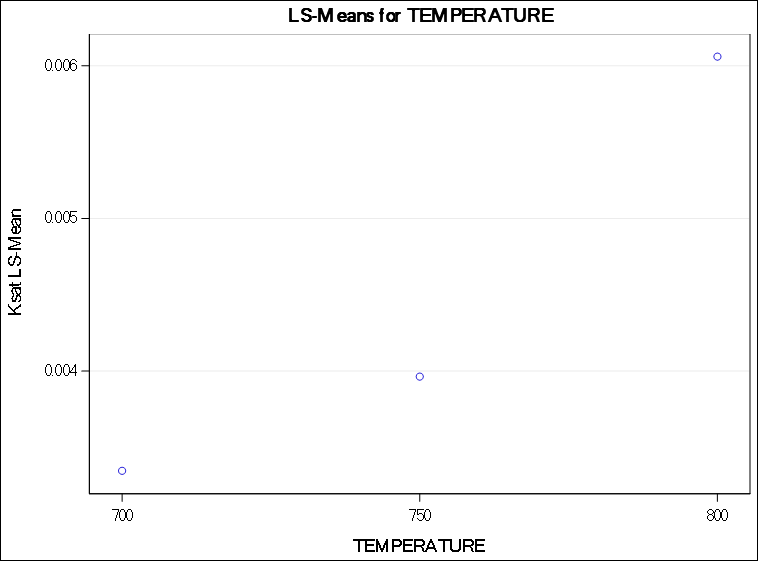

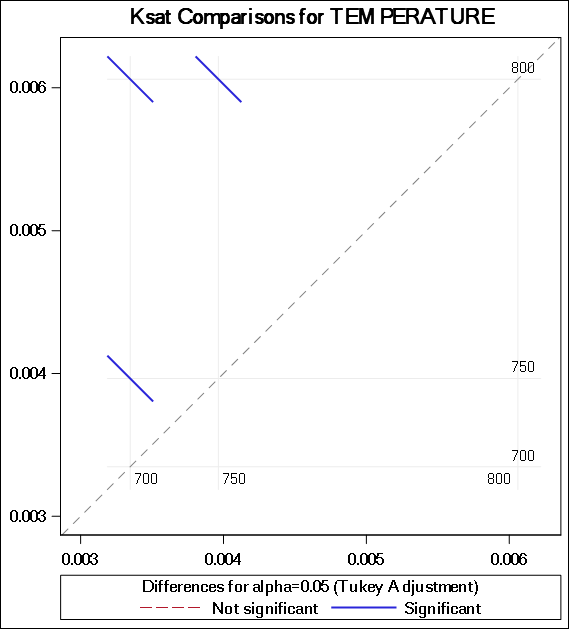

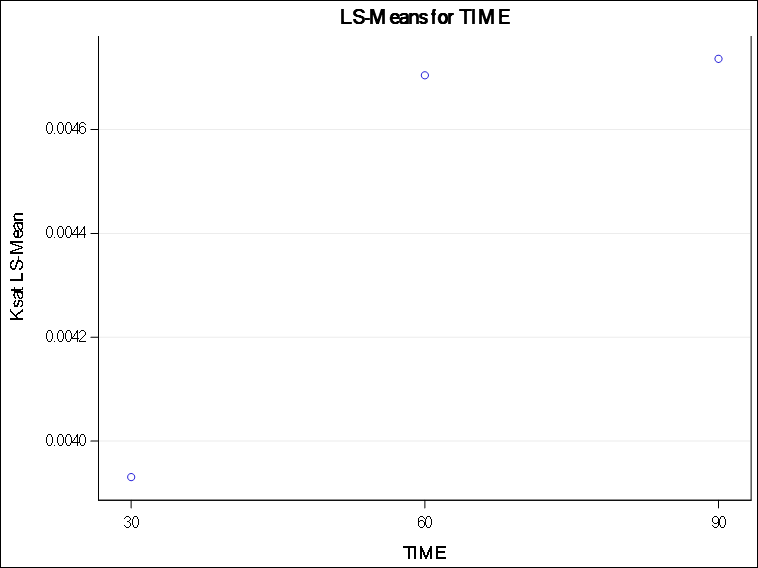

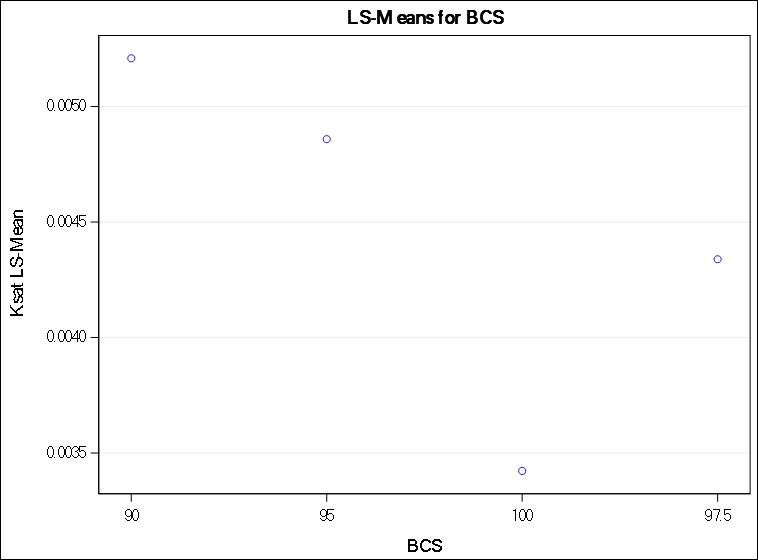

Figures 8 to 13 give the graphical representation for the least square means and Tukey adjustments for each of the variables. The LSMeans almost doubles from 0.003 cm/s to 0.006 cm/s for a temperature increase from 700°C to 800°C.

Figure 8. Least Square Mean for Temperature.

Figure 9. The Tukey Adjustment for Temperature.

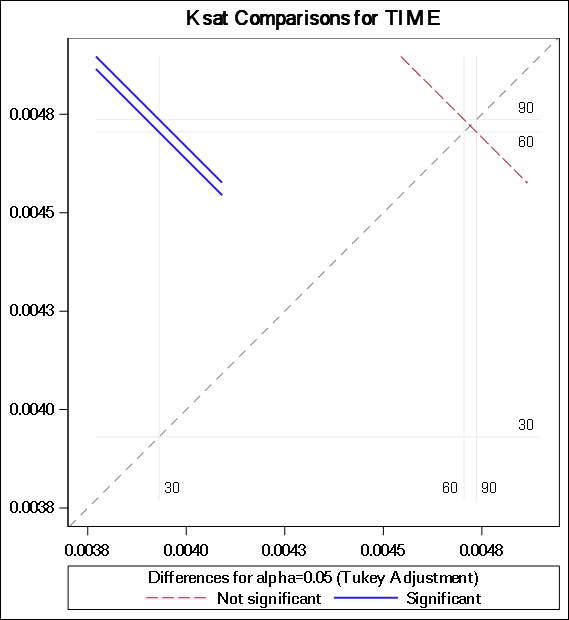

Figure 10. Least Square Means for Time.

Figure 11. The Tukey Adjustment for Time.

Increasing the time for firing from 60 minutes to 90 minutes has no significant effect in the saturated hydraulic conductivity of the aggregates. This means that the optimum time for firing is 60 minutes since even upon switching off the furnace, the temperatures would still be sustained for a longer period.

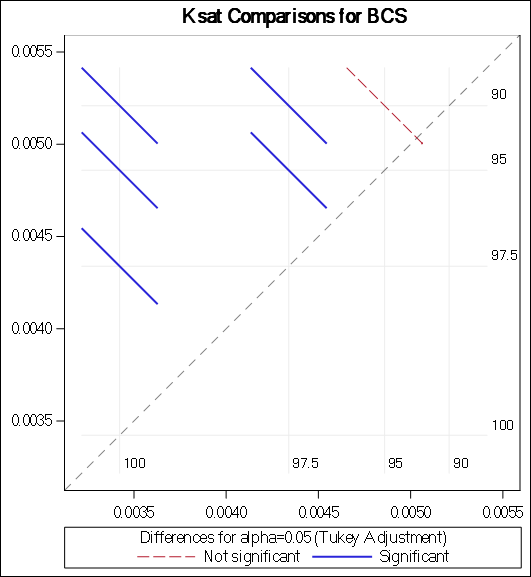

Figure 12. Least Square Means for Percent Black Cotton Soil.

Figure 13. The Tukey Adjustment for Percent Black Cotton Soil.

Pearson’s correlation gave coefficients of 0.77, 0.22 and -0.43 for temperature, time and percent black cotton soil respectively. The greater effect of temperature can be attributed to its direct effect on bulk density of the material which enhances its porosity.

4. Conclusions

The percent black cotton soil has the greatest effect on the bulk density of the material before and after firing. The relation is linear with an increase in percent rice husk resulting in a reduction in bulk density. This is attributed to the low density of the husks and being an organic material, combust upon firing leaving voids in the material. The porosity of a material affects its permeability and therefore the hydraulic conductivity of the material takes a similar trend.

Firing temperatures also resulted in reduced bulk density. An increase in temperature increased the efficiency of combustion of the organic matter and at higher temperatures, there was also burn off of carbon and sulphur as well as the expulsion of chemically bonded water which explains the further decrease in bulk density. Firing reduces the adhesiveness of the aggregates, minimising re-aggregation therefore the pore sizes and shapes are maintained even when water is added.

Time taken during firing had the least effect. This is because once the desired temperature was attained, the combustion process would continue even if additional heat energy was withdrawn and therefore the time of firing was actually longer in all cases. It must be noted that even after a period of 20 hours after switching off the furnace, temperature would always still be higher than 60°C.

In general, the resultant material had lower porosity and improved hydraulic conductivity compared to the original clay. Clay properties relating to its permeability are greatly enhanced by a combination of adding organic matter and then burning. The material also becomes easy to work because of loss of cohesiveness making it to retain its structure for a long time.

References

- Chalker-Scott, L. (2009). The Myth of Soil Amendments Part II. http://www.theinformedgardener.com. Accessed on 24/6/2013.

- Chow, V. T., Maidment, D. R. and Mays, L. W. (2012). Applied Hydrology. Tata Mc Graw Hill. New Delhi, India. 572pp.

- Da Costa, V. P. F. X. (1973). Characterization and Interpretation of the Soils of the Kano Plains for Irrigation Agriculture. MSc. Thesis. University of East Africa.

- DeBano, L. F. (1990). The Effect of Fire on Soil Properties. Paper presented at the Symposium on Management and Productivity of Western-Montane Forest Soils, Boise, ID, April 10-12, 1990.

- Eswaran, H. and Cook, T. (1988). Classification and Management-related Properties of Vertisols IN Management of Vertisols in Sub Saharan Africa. Proceeding of a Conference held at ILCA, Addis Ababa, Ethiopia.

- Freebairn, D. M., Lock, R. J. and Silburn, D. M. (1996) Soil Erosion and Soil Conservation in Vertisols IN Vertisols and Technologies for their Management. Elsevier, Canada pp 306-363.

- Gheorge, R., Adia, G., Dorin, T., and Radu, B. (2013) Engineering Properties of Vertisols. Soil Forming factors and Processes from the Temperate zone, 12 (1): 59-67.

- Grunwald, S. (2003). Vertisols. University of Florida. http://soils.ifas.ufl.edu. Accessed on 29/7/2013.

- ISRIC – World Soil Information. (2007). Vertisols. www.isric.org. Accessed on 7/8/2013.

- Kutilek, M. and Nielsen, D. R. (1994). Soil Hydrology. Catena Verlag, Germany. 370pp.

- Mehta, K. S., Sonecha, R. J., Daxini, P. D., Ratanpara, P. B. and Gaikward, K. S. (2014) Analysis of stabilization of Black cotton Soils and Stabilization using Lime. International Journal of Engineering Research and Applications 4 (5): 25-32.

- Millan, R. (1973). Problem of the Natural Environment on the Kano Plains of Western Kenya IN Cahiers d’etudes Africaines, 13 (50): 181-192.

- Ozsoy, G. and Aksoy, E. (2007). Characterization, Classification and Agricultural Usage of Vertisols Developed on Neogen Age Calcarous Marl Parent Materials. Journal of Biological and Environmental Science, 1: 5-10.

- Swindale, L. D. (1988). Developing, Testing and Transferring Improved Vertisol Technology. The Indian Experience IN Management of Vertisols in Sub Saharan Africa. Proceeding of a Conference held at ILCA, Addis Ababa, Ethiopia.

- Virmani, S. M. (1988). Agroclimatology of the Vertisol and Vertic Soil Areas of Africa IN Management of Vertisols in Sub Saharan Africa. Proceeding of a Conference held at ILCA, Addis Ababa, Ethiopia.

- Virmani, S. M., Sahrawat, K. L. and Burford, K. L. (1982). Physical and Chemical Properties of Vertisols and Their Management.