Impact of Microchannel Geometrical Parameters in W-EDM Using RSM

Jagdeep Sharma1, Sunny Puri1, Pawan Jaglan1, *, Akashdeep Singh1, Harry Garg2, Harvinder Singh3

1Chandigarh Group of Colleges Technical Campus, Jhanjeri, Mohali, Punjab, India

2Central Scientific Instruments Organisation, Chandigarh, India

3Mechanical Engineering Department, Punjabi University, Patiala, Punjab, India

Abstract

In present research Micro channels have been fabricated using Wire Cut Electric Discharge Machining (WCEDM). In non-traditional machining processing, Wire Cut Electrical Discharge Machining (EDM) has tremendous potential on account of the versatility of its applications and it is expected that it will be successfully and commercially utilized in modern industries. Copper Micro channels are fabricated on Wire Cut EDM. These are heat transfer devices used for dissipation of heat from integrated circuits and other electronic devices. The performance of the micro-channels depends upon the machining parameters. In the proposed work, three input parameters of WCEDM are varied to get optimum responses. The parameters of WCEDM varied are peak current (Ip), Pulse on time (Ton) and pulse off time (Toff).The parameters of WEDM are varied in the ranges of (Ip from 100 to 200 ampere, Ton from 105 to 115 µsec and Toff from 25 to 45 µsec). Two responses material removal rate (MRR) and surface roughness (SR) are evaluated for Micro channels. Response Surface Methodology (RSM) is used to correlate input and output parameters and mathematical equations have been generated for both responses. The variation of responses due to variations in input parameters has also been studied and shown in the form of surface plots and contour plots. The surface roughness (Ra) of each machined work piece was measured using the Mitutoyo Talysurf (SJ – 201). Each experiment was repeated three times for better results and the average was calculated. It has been found that Ton and Toff parameters are very significant in case of MRR and Ton(Maximum) is most significant in case of surface roughness.

Keywords

W-EDM (Wire Electrical Discharge Machining), Microchannel, RSM (Response Surface Methodology),

MRR (Material Removal Rate), SR (Surface Roughness)

Received: June 11, 2015

Accepted: June 20, 2015

Published online: August 11, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Fabrication of Micro channels is a challenging area. There are a lot of techniques but all these have certain advantages/disadvantages over each other. Wire Cut Electric Discharge Machining (WEDM) is an efficient machining method which uses spark discharges to melt and vaporize material from work piece. A spark is produced between wire and work piece having very small gap through dielectric fluid (generally deionised water) and material is eroded from work piece. It is a novel machining process used for fabrication of a micro-metal hole and can be used to machine hard electrically conductive materials. Microchannels are defined as flow passages that have hydraulic diameters in the range of 100 to 500 micrometers. These are used in the microelectronics cooling and other high heat-flux cooling applications. Due to their high area-to-volume ratio and also due to area enhancement Microchannel heat sinks are strong candidates for the effective dissipation of heat from devices, such as integrated circuits. Micro channel heat sinks are utilized generally with liquid coolants which provide higher heat transfer coefficients compared to gaseous coolants.

2. Literature Review

Literature has been reviewed to find some gaps in WEDM process and to find out the effect of different input parameters on surface finish and material removal rate in WEDM process. Some papers are discussed below: - Gaikwad. P discussed about development in the thermal and fabrication aspects of microchannels as applied in microelectronics and other high heat flux cooling application. [1]

Kandlikar G. S et. al discussed about Classification of microchannels and advantages of using microchannels in high heat flux cooling applications. [2]

Huang.T et.al.(2003) used SKD 11 alloy steel to conduct experiments. In this study Grey relational analyses are applied to determine the optimal selection of machining parameters for the Wire Electrical Discharge Machining (Wire-EDM) process. The relation between machining parameters and performances can be found by using the Grey relational Analysis. An L18 mixed orthogonal array table was chosen for the experiments using Taguchi quality design concept. [3]

Tosun. N et al. (2003): - In this study SAE 4140 STEEL was used as a work piece. The variation of workpiece surface roughness with varying pulse duration, open circuit voltage, wire speed and dielectric fluid pressure was experimentally investigated in WEDM. Brass wire with 0.25 mm was used. It is found experimentally that the increasing pulse duration, OCV and wire speed, increase the surface roughness whereas increasing dielectric pressure decreases the surface roughness. Non-linear regression analysis method is used to obtain relation between input-output parameters. [4]

Lin. Y.C et al (2006): -SKH 57 HIGH SPEEDSTEEL was used in the study as work material. Experiments were conducted with the L18 orthogonal array based on the Taguchi method. In this investigation six machining parameters (polarity, peak current, pulse duration, auxiliary current with high voltage, no-load voltage, servo reference voltage) were varied to find effects of these on MRR, EWR and SR.[5]

Yeakub Ali. M et al. (2008): - Copper was used as a work material. The effect of discharge current, pulse-on time, and gap voltage on surface finish were studied. The cost of micro-fabrication with WEDM is smaller than lithography, FIB etc. Peak current and pulse on time has a significant influence on surface finish. Roughness increases with increase in peak current and decreases with pulse on time. [6]

Caydas U. et al. (2009) conducted the experiments on AISI D5 TOOL STEEL. In this paper an adaptive neuro-fuzzy inference system (ANFIS) model has been developed for the prediction of the white layer thickness (WLT) and the average surface roughness achieved as a function of the process parameters. Pulse duration, OCV, flushing pressure and wire feed rate were input parameters. Both artificial neural network (ANN) and fuzzy logic (FL) are used in ANFIS architecture taken as model’s input features. This approach greatly improved the process responses such as surface roughness and WLT in WEDM. [7]

Kumar. A et al (2010).: - Material used was EN-24 TOOL STEEL. A technique for optimization of abrasive mixed electrical discharge machining (AEDM) process with multiple performance characteristics based on the orthogonal array with grey relational analysis has been studied. AEDM is a hybrid process in which dielectric is mixed with powder form abrasive. As a result, the process becomes more stable, thereby improving machining rate and surface finish. It was found that abrasive powder addition has stronger effect on multi performance characteristics than peak current, pulse on time, and duty factor. [8]

Phipon. R et. al. (2012): - The material was Titanium Super alloy (Ti-6Al-4V).This present research study deals with the single and multi-objective optimization of micro EDM process using Genetic Algorithm. Mathematical models using Response Surface Methodology (RSM) is used to correlate the response and the parameters. The desired responses are minimum tool wear rate and minimum overcut while the independent control parameters considered are pulse on time, peak current and flushing pressure. [9]

Majumder. A (2013): -AISI 316LN STAINLESS STEEL was used as a work material. A Taguchi L9 orthogonal array was produced to plan the experimentation and the regression method was applied to model the relationship between the input factors and responses. A fuzzy model was employed to provide a fitness function to PSO by unifying the multiple responses. Finally, PSO (particle swarm optimization) was used to predict the optimal process parametric settings forth multi-performance optimization of the EDM operation. [10]

Habib. S (2009): - Four input parameters had been taken in this study. Four responses were evaluated. RSM was used to design experiments and for mathematical modeling. ANOVA was used to find most significant input factor. [11]

3. Design of Experiments

Parameters of WEDM are varied in a particular range to get optimal values of these parameters to achieve desired results. The parameters of wire-EDM which are varied in this work are peak current (Ip), pulse on time (Ton) and pulse off time (Toff).The variation of these parameters is also represented below in table 1. The desired responses are material removal rate and surface roughness. It is desired to get maximum material removal rate and minimum surface roughness.

Table 1. Parameter Variations.

| Parameters | Alpha | -1 | 0 | 1 | Alpha | Units |

| Peak Current | 65.91 | 100 | 150 | 200 | 230 | Amp |

| Pulse On Time | 101.5 | 105 | 110 | 115 | 118.4 | µsec |

| Pulse Off Time | 18.4 | 25 | 35 | 45 | 51.81 | µsec |

The design of experiments technique used is response surface methodology (RSM). Mathematical modeling has been done by using response surface methodology and equations has been generated which show the relationship between input parameters and responses. Two different equations have been generated for both responses.

4. Experimental Setup and Metrology

The experimental runs (WEDM) are performed on Electronica ELPULS40ADLX.The wire used in experimental runs is of also brass. The diameter of wire is 0.25mm. Taylor Hobson’s Profilometer is used to get surface roughness (Ra) of microchannel after wire edm experiment.

Material removal rate is calculated by the formula given below:-

![]()

5. Results and Discussion

The values of material removal rate and surface finish are tabulated in table 2.

Table 2. MRR and Surface Roughness.

| S. No | Peak Current(Ip) (Ampere) | Pulse On time (Ton) ( µsec) | Pulse Off Time (Toff) ( µsec) | M.R.R (mm3/min) | Ra(µm) |

| 1 | 150 | 101.5 | 35 | 1.540966 | 1.7742 |

| 2 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 3 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 4 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 5 | 100 | 115 | 45 | 4.128363 | 3.3082 |

| 6 | 100 | 105 | 45 | 2.191467 | 2.7337 |

| 7 | 150 | 118.4 | 35 | 2.950441 | 3.3977 |

| 8 | 230 | 110 | 35 | 4.28866 | 2.8493 |

| 9 | 200 | 115 | 25 | 4.124907 | 4.0286 |

| 10 | 200 | 115 | 45 | 3.500422 | 3.0794 |

| 11 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 12 | 100 | 105 | 25 | 1.961063 | 3.3152 |

| 13 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 14 | 150 | 110 | 35 | 3.226529 | 3.344133 |

| 15 | 200 | 105 | 45 | 1.890781 | 2.22 |

| 16 | 100 | 115 | 45 | 4.128363 | 3.3082 |

| 17 | 150 | 110 | 18.18 | 2.911937 | 3.082525 |

| 18 | 65.91 | 110 | 35 | 2.412243 | 2.7115 |

| 19 | 200 | 105 | 45 | 1.890781 | 2.22 |

| 20 | 150 | 110 | 51.81 | 2.57765 | 6.1397 |

Fig. 1. This figure shows the Microchannel substrate before WEDM.

Fig. 2. This figure shows Microchannel substrate after WEDM.

After getting the values of surface roughness and material removal rate, using MINITAB software equations for both responses have been generated as written below.

![]()

![]()

These are equations which show relationship between input parameters and responses.

After generating these equations surface plots and contour plots are generated in MINITAB. These plots show variations in responses when input parameters are varied.

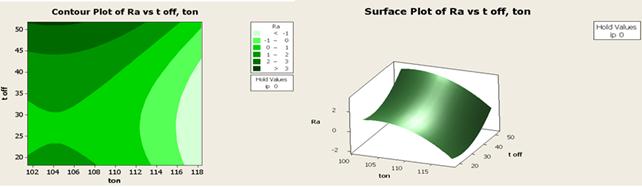

Fig. 3. Contour Plot and surface plot between Ton, Toff (Ra).

In first contour, it can be seen that value of surface roughness is minimum at lightest area and is maximum at darkest area. So, it shows that when Ton is maximum and Toff varies from 20 ampere to 40 ampere, surface roughness is minimum.

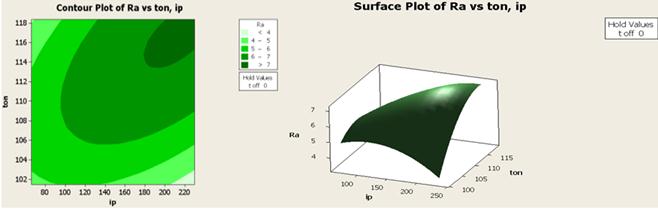

Fig. 4. Contour plot and Surface plot between Ip and Ton (Ra).

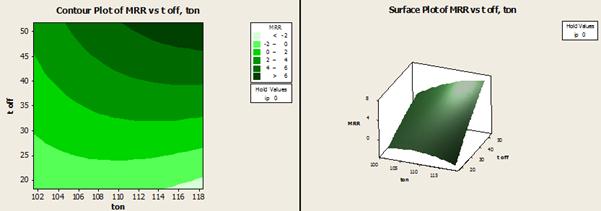

Fig. 5. Contour and surface plot between Ton and Ip(MRR).

In second contour, it can be clearly understood that when Ton is minimum, surface roughness will be minimum and vice versa. Surface roughness is maximum when peak current and Ton are maximum. As indicated in these plots, MRR is greatly influenced by Ton and peak current. Material removal rate increases when both peak current (Ip) and Ton increase and MRR decreases when both input factors decrease.

In this plot, it is clear that material removal rate is minimum when Toff is at lowest level and when the value of Toff is increased material removal rate increases.

Fig. 6. Contour and surface plots between Ton and Toff (MRR).

Table 3. Analysis of Variance for Ra.

| Source | DF | Seq SS | Adj SS | Adj MS | F | P |

| Regression | 9 | 9.4283 | 9.42829 | 1.04759 | 2.25 | 0.111 |

| Linear | 3 | 2.9299 | 2.59076 | 0.86359 | 1.85 | 0.201 |

| IP | 1 | 0.0547 | 0.63436 | 0.63436 | 1.36 | 0.270 |

| Ton | 1 | 2.6181 | 1.61004 | 1.61004 | 3.46 | 0.093 |

| Toff | 1 | 0.2570 | 0.03280 | 0.03280 | 0.07 | 0.796 |

| Square | 3 | 5.3038 | 5.39440 | 1.79813 | 3.86 | 0.045 |

| IP x IP | 1 | 1.2239 | 1.29899 | 1.29899 | 2.79 | 0.126 |

| Ton x Ton | 1 | 2.1453 | 1.83124 | 1.83124 | 3.93 | 0.076 |

| Toff x Toff | 1 | 1.9345 | 1.78703 | 1.78703 | 3.84 | 0.079 |

| Interaction | 3 | 1.1947 | 1.19467 | 0.39822 | 0.85 | 0.495 |

| IP x Ton | 1 | 1.1504 | 1.14998 | 1.14998 | 2.47 | 0.147 |

| IP x Toff | 1 | 0.0442 | 0.03439 | 0.03439 | 0.07 | 0.791 |

| Ton x Toff | 1 | 0.0002 | 0.00016 | 0.00016 | 0.00 | 0.986 |

| Residual Error | 10 | 4.6589 | 4.65894 | 0.46589 | ||

| Lack of Fit | 3 | 4.6589 | 4.65894 | 1.55298 | ||

| Pure Error | 7 | 0.0000 | 0.0000 | 0.0000 | ||

| Total | 19 | 14.0872 |

It is clear from tables 3 and 4 that Ton and Toff are parameters are very significant in case of MRR and Ton is most significant in case of surface roughness. Main effect plot are also generated for both responses which are discussed figure7 and 8. The graph depicted above shows that with increase in Ip the MRR increases first then remains constant and then increases again. MRR increases sharply with Ton and then decreases after 115µm. MRR remain almost constant in beginning due to increase in Toff and then decreases slightly. As shown in this graph, surface roughness (Ra) varies to some extent when Ip increaseas with increase in Ton roughness value increases and then become constant. Roughness value increase with increase in Toff in the beginning, then decreases and then again increases.

Table 4. Analysis of Variance for MRR.

| Source | DF | Seq SS | Adj SS | Adj MS | F | P |

| Regression | 9 | 12.6678 | 12.66878 | 1.40754 | 64.38 | 0.000 |

| Linear | 3 | 8.1798 | 2.2004 | 0.73347 | 33.55 | 0.000 |

| IP | 1 | 0.3131 | 0.1986 | 0.19857 | 9.08 | 0.013 |

| Ton | 1 | 7.8045 | 0.9801 | 0.98006 | 44.83 | 0.000 |

| Toff | 1 | 0.0623 | 0.7868 | 0.78684 | 35.99 | 0.000 |

| Square | 3 | 1.568282 | 1.6477 | 0.54923 | 25.12 | 0.000 |

| IP x IP | 1 | 0.2211 | 0.1534 | 0.15338 | 7.02 | 0.024 |

| Ton x Ton | 1 | 1.1334 | 1.2428 | 1.24277 | 56.85 | 0.000 |

| Toff x Toff | 1 | 0.2137 | 0.2058 | 0.20579 | 9.41 | 0.012 |

| Interaction | 3 | 2.9198 | 2.9198 | 0.97328 | 44.52 | 0.000 |

| IP x Ton | 1 | 0.0254 | 0.0263 | 0.02630 | 1.20 | 0.298 |

| IP x Toff | 1 | 1.5555 | 2.6167 | 2.61671 | 119.70 | 0.000 |

| Ton x Toff | 1 | 0.0002 | 0.00016 | 0.00016 | 0.00 | 0.986 |

| Residual Error | 10 | 4.6589 | 4.65894 | 0.46589 | ||

| Lack of Fit | 3 | 4.6589 | 4.65894 | 1.55298 | ||

| Pure Error | 7 | 0.0000 | 0.0000 | 0.0000 | ||

| Total | 19 | 14.0872 |

Fig. 7. Main Effects Plots for MRR.

Fig. 8. Main Effects Plots for Roghness.

6. Conclusion

In this work, experimental investigations were done to find out significant factor of WEDM machining process while machining microchannels. Mathematical models for MRR and SR were developed for peak current, pulse on time, pulse off time using RSM. Major findings in this work are:

1 With the help of central composite factorial design in RSM, the number of experiments was reduced.

2 From ANOVA table it is concluded that Ton and Toff parameters are very significant in case of MRR.(p-value is minimum in ANOVA table)

3 Ton is most significant in case of surface roughness.(p-value is minimum in ANOVA table)

4 Better prediction of WEDM process is possible because of higher values of multiple regression coefficients.

References

- Gaikwad V.P, "Microchannelheatsink fabrication techniques,"IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) PP: 51-57.

- Kandlikar S.G,Grande.W.J" evolution of microchannel flow passages thermohydraulic performance and fabrication technology," Proceedings of IMECE2002 ASME International Mechanical Engineering Congress &Exposition, New Orleans, Louisiana,2002.

- Huang J.T,Liao.Y.S," Optimization of machining parameters of Wire-EDM based on Grey relational and statistical analyses" int. j. prod. res.,vol. 41, no. 8, 1707–1720.2003

- Tosun N,Cogun.C,Inan.A,"The Effect of Cutting Parameters on Workpiece SurfaceRoughness in Wire EDM", MACHINING SCIENCE AND TECHNOLOGY, Vol. 7, No. 2,.pp. 209–219,2003.

- Lin Y.C,Cheng.C.H,Su.B,Hwang.L," Machining Characteristics and Optimization of Machining Parameters of SKH 57 High-Speed Steel Using Electrical-Discharge Machining Based on Taguchi Method" Materials and Manufacturing Processes, 21:pp: 922–929, 2006.

- YeakubAli M,SamiMohammad,A,et al." Experimental Study of Conventional Wire Electrical Discharge Machining for Micro-fabrication" Materials and Manufacturing Processes,23,pp:641–645.2008.

- Çayda U,Hascalik A,Ekici S," An adaptive neuro-fuzzy inference system (ANFIS) model for wire EDM" Expert Systems with Applications 36 pp:6135–6139,2009.

- Kumar A, Maheshwari S,Sharma C,Beri N" A Study of Multiobjective Parametric Optimization of SiliconAbrasive Mixed Electrical Discharge Machining of Tool Steel" Materials& Manufacturing Processes, 25: pp.1041–1047,2010.

- Phipon R,Pardhan B" Process Parameters Optimization of Micro Electric Discharge Machining Process Using Genetic Algorithm" International Journal of Engineering Research and Applications. Vol. 2, Issue 5, pp.1986-1993.September- October 2012.

- Majumder A "Process parameter optimization during EDM of AISI 316 LN stainless steel by using fuzzy based multi-objective PSO", Journal of Mechanical Science and Technology 27 (7),pp 2143~2151.2013.

- Habib S"Study of the parameters in electrical discharge machining throughresponse surface methodology approach" Applied Mathematical modeling 33pp-4397-4407,2009.