Results of Researches on Receiving Biogas

E. Zhumartov1, *, K. T. Ospanov1, D. Andraka2

1Architecture and Building Faculty, Kazakh National Technical University Named After K. I. Satpayev, Almaty, Republic of Kazakhstan

2Department of Sanitary Engineering Systems, Bialystok Technical University, Bialystok, Poland

Abstract

This article presents the results of laboratory and pilot studies on biogas from a mixture of liquid manure and wastewater. The results showed that by adding cow manure in sewage sludge can intensify the process of anaerobic digestion. Thus, an increase of the yield of biogas reactor. According to the results of laboratory and semi-experimental studies found that the optimum fermentation parameters are pH - 6,75-7,45, alkalinity - 48-100 mEq/L and the content of CO2 in the biogas should be between 26-40%. And the best time boundary fermentation are 5-10 days at a humidity of 90-96% and 17-20% loading dose.

Keywords

Biogas, Anaerobic Digestion, Manure, Volatile Fatty Acids (VFAs), Digesters, Methane Production

Received: May 3, 2015

Accepted: May 31, 2015

Published online: July 7, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

Production of sustainable energy is one of the most challenging problems in contemporary world. Thus, replacement of traditional fuels like gas, petrol, coal and other fossil fuels with renewable energy sources is among the most important activities for many countries. One of such a clean energy sources is biogas produced in a process of anaerobic digestion of organic wastes.

Biogas production 1, 2, 3, as well as improving the process of biogas production 4, 5, extensively studied by many scientists around the world.

Farms, especially cattle, pig and poultry, produce most of organic wastes in agriculture. The problem of ecological disposal of those wastes is a subject of many scientific researches. They cover wide range of possible applications due to various methods of animals’ breeding which affect final physico-chemical characteristic of organic waste. That resulted in a need for different, safe and efficient technologies for ecological utilization and disposal of manure and other waste from agriculture.

In India, in 1975 there worked about 30000 biogas installations providing the fuel for 200 thousand people. According to the Indian researchers, from 100 kg of dry mass in manure it is possible to receive the amount of biogas equivalent to 75 kg of fuel (oil equivalent). In China, according to UNESCO, there is ca 7 million biogas installations covering up to 30% of energetic needs of the country 6.

Many European countries (Germany, Italy, France, United Kingdom, Netherlands, Denmark) encourage scientific and technical efforts for a development of biogas technologies. In Russia, there are also numerous organizations involved in studies on biogas production and utilization as well as design and constructing biogas installations. Among them: Mosvodokanal, Academy of Municipal Services, VIESH and newly created companies like JSC Center Ekoros, JSC October Poultry Farm, JSC Green-Velt, JSC Lessa, JSC Ekobio, JSC Stroyindustriya (Republic of Chuvashia), JSC Zavolzhye Car Repair Plant (Nizhny Novgorod Region), JSC Stroytekhnika Tulsky factory are worth of mentioning 7.

In many countries, biogas received from digestion of organic wastes like sludge from wastewater treatment, manure and other agriculture by-products, industrial waste from cotton production and food processing, is commonly used for heating, electricity generation and gas production and thus becomes significant source of green energy.

2. Research Problems

In this regard, there was a need for development of an installation applicable for individual farms for anaerobic digestion of biomass and receiving biogas. For the achievement of this goal, following research problems are studied:

a) theoretical and pilot studies of the processes of receiving biogas from manure and sewage sludge on a laboratory and semi-technical scale;

b) determination of technological parameters of digestion in the bioreactor.

Table (1) presents comparative data on a chemical composition of sewage sludge, cattle manure and food processing waste.

Table 1. Comparison of chemical properties of different organic waste.

| Parameter | Primary (raw) sludge | Waste activated sludge | Cattle manure | Food processing waste |

| % of total dry mass | ||||

| Organic matter | 70-80 | 72-75 | 83,8 | 59,6-80,2 |

| Lignin | 12-13 | 8-10 | 21,3 | 5-7 |

| Total nitrogen (N) | 1,6-3,6 | 5-7 | 48 | - |

| Total potassium (as K2O) | 0,3-2,1 | 1-4 | 21-26 | - |

| Total phosphorus (as P2O5) | 0,2 | - | 34-38 | - |

| pH | 6,7-7,2 | 6,5-8 | 6,5-8,5 | 6,3-8 |

| Carbohydrates (C), including: | 8-10 | 6-7 | 20-26 | 12-17 |

| - alpha-cellulose | 7-12 | 0,8-2 | 21-26 | - |

| - hemicellulose | 8-20 | 3-6 | 18-21 | - |

| Ash content | 10-27 | 23-26 | 16,2 | 19-23 |

| Moisture content | 94-96 | 98-99,2 | 78-80 | 52,7-62,7 |

Analysis of data presented in Table 1 showed that cattle manure contains more organic compounds in comparison with other types of organic waste, especially taking into account carbohydrates, including alpha-cellulose (21-26%).

Carbohydrates in manure are presented generally by cellulose, hemicellulose and a lignin, which is the main compound of a wall of plant cells.

One of the most significant sources of organic waste in agriculture is cattle farming. Table (2) presents production and composition of manure for different types of cattle farms.

Table 2. Daily excrement production from one animal at cattle farms.

| Parameter | Bulls | Cows | Calves up to 6 months, 4 months on feedlot | Young cattle (weaners) | |||

| 6-12 months, 4-6 m. on feedlot | 6-12 months on feedlot | 12+ months on feedlot | 12-18 months and heifers | ||||

| Feces, kg | 30 | 35 | 5 | 10 | 14 | 23 | 20 |

| Urine, kg | 10 | 20 | 2,5 | 4 | 12 | 12 | 7 |

| Excrements, total, kg | 40 | 55 | 7,5 | 14 | 26 | 35 | 27 |

Notes: 1. Average moisture content of excrements: 88% - for dairy cattle; 86% - for calves and beef cattle. 2. Moisture content of cattle manure depends on the type of bedding and can be estimated for dairy cattle / weaners / calves respe ctively: a) fastened bedding (mattresses) – 78/72/68%; b) bedded packs – 79/78/72%; c) loose housing and deep bedding – 69/71/70%

The main research problem presented in this paper was studying of key parameters of the digestion process, including: pH, temperature, conditions of mixing bioreactor’s content, biogas production and overall process performance.

3. Materials and Methods

The investigations were carried out using cattle manure mixed with communal sewage as the load to the digester. The main chemical parameters of the loading material were as follows: pH - 7,5; volatile fatty acids (VFAs) - 13,3 mg/l; alkalinity - 100 mEq/l; ammonium nitrogen - 190 mg/l; organic matter - 83% of total dry mass; ash content - 16,2%.

The manure was carefully crashed before loading and then mixed with a raw sewage in proportion of 1:1 or 1:0,5 in order to get moisture content of the mixture in the range of 90-92%. To achieve more intensive digestion and biogas production, the mixture was heated up to the temperature 550C and then loaded to the laboratory digester (bioreactor).

Three series of experiment were carried out using following technological parameters, reflecting literature data and analysis of existing digestion systems in different countries:

- 1st series: dose of loading of the digester, DL = 10%; temperature of the process, T = 21-530C; mixing pattern – 10-20 minutes per hour; moisture content in manure, WL = 85-90%;

- 2nd series: DL = 20%; T = 43-530C; mixing – 20-30 minutes per hour; WL = 91-95%;

- 3rd series: DL = 25%; T = 48-530C; mixing – 5-10 minutes per hour; WL = 92-97%;

Analysis of available research results 8-11 shows wide spectrum of quantitative technological parameters that enable full mineralization of the digested sludge and achievement of stabilized final product that is not decaying during storage and thus, free of offensive odours. In our opinion, the most important and useful quantitative factors describing digestion process of the sludge are: C:N ratio in digested sludge, alkalinity and concentration of volatile fatty acids (VFAs) in the filtrate. Therefore, the key parameters of the methane digestion that reflect gas production are three chemical indicators of the process: VFAs concentration, alkalinity and pH

4. Results and Discussions

In the 1st series of experiment, the initial stage of digestion was characterized by decrease in pH and increase in the concentration of VFAs, that confirmed progress in acid fermentation (acidogenesis) of the sludge.

At the beginning of fermentation process, significant amount of gas was produced, in which CO2 was a dominating compound. Together with acidogenesis, in the bioreactor there was also methane fermentation (methanogenesis) occuring, because some part of methane creating bacteria (methanogens) was introduced into the bioreactor together with a digested sludge (seed sludge). The seed sludge was entered on the 4th day. Because process of methanogenesis is carried out in the alkaline environment (at pH from 7,5 to 8,5), the crucial parameters for the controlling digestion were: pH, VFAs, alkalinity and volume of biogas. After introduction of the seed sludge containing methanogens, value of pH increased to 8,4-8,5; the concentration of VFAs decreased and biogas production increased.

On the 40th day of the process, temperature in the bioreactor fell down to 240C and stayed at this level for two days. Due to the high sensitivity of methane creating bacteria to change of external conditions, the gas production dropped significantly, and fermentation process practically wasn't restored for the next month. Thus, rapid and continuous temperature drop (below optimum value for the fermentation process), has a strongly destructive effect on methane creation process.

By the end of the second month the biogas production was practically stopped, while the concentration of VFAs was 2 mg/l, alkalinity - 30-34 mEq/l and pH 7,5-8. That indicated practically termination of digestion process.

In the 2nd series of the experiment it was observed that in the digester No. 1, after loading with biomass, pH decreased from 7,5 to 6,95 due to rapid growth of acid-forming microorganisms. The concentration of VFA was ranging from 30 to 45 mg/l, and produced biogas consisted mainly of carbon dioxide with a small amount of ethane. On the 9th day pH raised to 7-7,5. With addition of seed, pH was established within range from 7,5 to 8,5 through all the experiment (2 months). The concentration of VFA was 2-45 mg/l, alkalinity - 35-150 mEq/l, and biogas production - 1,5-2,5 l/day.

During the 3rd stage of experiment, in digester No. 2 (which was loaded with biomass and digested sludge from wastewater treatment plant), observations proved that such a mode of operation was more stable than others. Biogas output was ranging from 1,2 to 2,5 l/d and was very stable through all the time of digestion process – except the days of temperature drops, when biogas production also decreased to 0,3 – 0,8 l/d.

In our experiment, there were observed several causes of the process breakdown. One of them was sudden temperature drop from 55 to 230C, that occurred within two days. In this case also biogas production decreased significantly, from 200 ml/d to20 ml/d. After this event the temperature of the process increased back, up to normal operational range as well as production of biogas, although the recovery of the process was very slow.

Disturbances of the digestion process due to temperature drops also caused high increase in concentration of VFAs in the digester No. 1, up to 10-15 mg/l. Such an accumulation of VFAs in the biomass is related with high sensitivity of methanogens to changes in external conditions. As the result, the quantity of acidogenesis products in the bioreactor is growing. For the process recovery it was necessary to heat up the bioreactor and to stop loading with biomass. Initial level of biogas production of 2,1 l/d was achieved back only after 15 days after temperature drop.

In some cases there were problems related with a lack of hermetic conditions during loading the biomass. As the result, the air was introduced to the reactor and the oxygen present in the air destroyed part of methanogens population. Insufficient bacterial growth caused decrease in biogas production down to 0,7 l/d. Analysis of biogas composition showed high concentration of nitrogen. According to our experience, after some time the air present in the bioreactor was blown away by inert gas – argon. The biogas production was recovered to normal level after 5-10 days.

The process of digestion is also influenced by the pattern and intensity of mixing. During our experiments, mixing in the laboratory digesters was performed manually – for 10 minutes, 1 to 3 times a day. The lack of mixing in the bioreactor results in stratification of the reactor content into the sludge, supernatant and scum. Also, there can be more dead zones, where not biodegraded solids and liquids may accumulate. Therefore, careful periodic mixing maintains proper distribution of the biomass load within the whole volume of bioreactor, enabling optimum access to food for microorganisms and low concentrations of end products of biodegradation, as they are evenly distributed inside reactor. Proper mixing also maintains even allocation of temperature and nutrients in the reactor, creating suitable environment for bacteria involved in a digestion process. In the absence of mixing for two days, decrease in biogas production down to 0,8 l/d was observed.

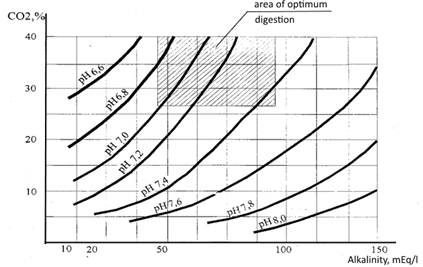

Analysis of the results of carried out experiments enabled determination of relationship between alkalinity, pH and concentration of CO2 in the biogas, which is presented in the figure (1). From this relationship it is possible to conclude that during digestion process a continuous decrease in concentration of carbon in the sludge is achieved, due to its transformation to CH4 and CO2. Considerable part of total nitrogen is converted from organic form to ammonium nitrogen (NH4) which reacts with dissolved CO2 causing alkalinity of the system. It is also possible to state, that after decomposition of sludge particles according to equation 4, alkalinity of the process environment reaches 4-5 mEq/l. Another conclusion that can be drawn is, that the higher alkalinity of sludge, the more VFAs can be neutralized without decrease in pH

Figure 1. Dependence between alkalinity, pH and the concentration of CO2 in biogas.

At the subsequent stage of research our investigations were focused at determining optimum parameters for the biogas production, including moisture content of the sludge in the bioreactor, time of digestion and loading rate. It was observed that deviations from standard values of alkalinity and ammonium nitrogen in the supernatant were leading to violations resulting in decrease in biogas production. This events were directly connected with moisture content of the slurry in the bioreactor, and thus – with moisture of the loading. According to literature data, moisture content of the slurry should be within the limits 90-97%.

The other factor necessary for effective decomposition of organic matter to CH4 and CO2 is sufficient retention time for the microorganisms in the digester reflected by digestion time. This is basic parameter used for determination of digester’s volume.

Digestion time, dose of loading and ash content are related one with the others by direct proportional dependence. Those parameters are crucial for decomposition of organic matter and biogas production. In the literature 12 it is stated, that increasing ash content up to 76,7% practically stops fermentation process.

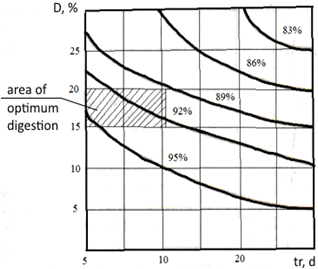

Thus, the analysis of the 3rd series of experiments, and especially analysis of process violations, enabled determination of relation between aforementioned parameters in regard of digestion efficiency, which is presented in figure (2).

Figure 2. Dependence between the dose of loading (D) and retention time (tr) for a different moisture content.

From the graph presented in figure (2) it can be easily noticed that the lower moisture content of the slurry in the bioreactor, the higher dose of loading is required for the same digestion time and vice-versa, for the same dose of loading – the lower moisture the higher retention time is required. The optimum conditions for the digestion process determined by experimental results are as follows: retention time – 5-10 days, moisture content – 90-96%, dose of loading – 17-20%.

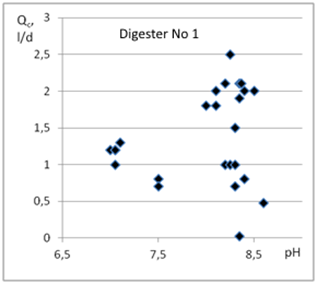

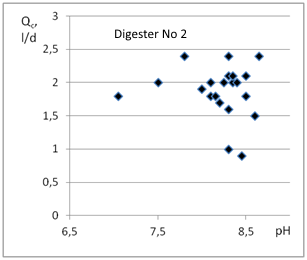

According to experimental data collected throughout research on digestion process in bioreactors No. 1 and No. 2 and presented in figure (3), the hypothesis about linear relation between pH and biogas production Qc was established, according to formula 1:

![]() (1)

(1)

where: Y – biogas production Qc, l/day; X – pH

Figure 3. Experimental data on biogas production in digesters No 1 and No 2 in relation to pH.

Figure (3) indicates that for a single value of pH there were reported different values of biogas production Qc. Therefore, it was necessary to perform statistical analysis of data in order to determine coefficient of correlation between analyzed parameters. Due to possible errors in collected data caused by process disturbances, inaccuracy of measurements etc., filtered data set was prepared, including mean values of biogas production for a given pH (table 3).

Table 3. Averaged values of biogas production (Y) for considered values pH (X) for digester No 2.

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| X | 7,5 | 7,9 | 8,1 | 8,3 | 8,4 | 8,5 | 8,6 |

| Y | 1,9 | 1,88 | 1,85 | 1,85 | 1,85 | 1,82 | 1,81 |

For data presented in table (3) there was estimated r-Pearson’s coefficient of correlation. The results of calculations are presented in table (4).

Table 4. Calculations of r-Pearson coefficient of correlation.

| Y | X | Y2 | X2 | XY | X+Y | (X+Y)2 |

| 1,9 | 7,5 | 3,61 | 56,25 | 14,25 | 9,4 | 88,36 |

| 1,88 | 7,9 | 3,53 | 62,41 | 14,825 | 9,78 | 95,648 |

| 1,85 | 8,1 | 3,42 | 65,61 | 14,985 | 9,95 | 99,002 |

| 1,85 | 8,3 | 3,42 | 68,89 | 15,355 | 10,15 | 103,022 |

| 1,85 | 8,4 | 3,42 | 70,56 | 15,54 | 10,25 | 105,062 |

| 1,82 | 8,5 | 3,31 | 72,25 | 15,47 | 10,32 | 106,502 |

| 1,81 | 8,6 | 3,27 | 73,96 | 15,566 | 10,41 | 108,368 |

| In total: | ||||||

| 12,96 | 57,3 | 23,98 | 478,93 | 105,991 | 70,26 | 705,964 |

| Mean | ||||||

| 1,85 | 8,18 | |||||

| Standard deviation | ||||||

| 0,056 | 0,46 | |||||

| Coefficient of correlation, r = ( 105,991/7 – 1,85 8,18) / (0,46 0,056) = 0,333 | ||||||

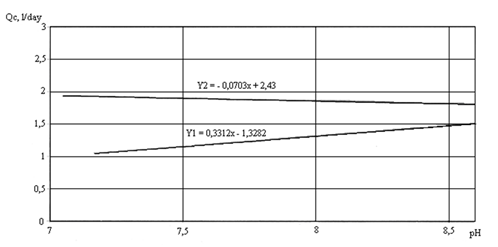

Estimated coefficient of correlation r = 0,333 is valid from statistical point of view, then it is approved to conclude about dependence between pH in digester and biogas production Thus, regression lines for digesters No 1 and No 2 were calculated and presented in figure (4) as well as in formulas 2 and 3:

![]() for digester No 1 (2)

for digester No 1 (2)

![]() for digester No 2 (3)

for digester No 2 (3)

Figure 4. Relation between biogas production and pH in bioreactor, based on linear regression.

5. Conclusions

According to results of carried out experiments, following conclusions may be drawn:

- most important parameters for the efficient performance of digestion process are 3 inter dependent chemical factors: concentration of VFAs, alkalinity and pH;

- there were estimated optimal conditions for the digestion, including: pH = 6,75-7,45 and alkalinity – 48-100 mEq/l; within this limits concentration of CO2 in the biogas should be 26-40%;

- optimal parameters of the digestion process predicted on the base of research results are: digestion time – 5-10 days, moisture content – 90-96%, dose of loading – 17-20%.

References

- Banks C, Chesshire M, Heaven S, Arnold R. Anaerobic digestion of sourcesegregated domestic food waste: performance assessment by mass and energy balance. Bioresour Technol 2011;102:612e20.

- E. Neyens, J. Baeyens, A review of thermal sludge pre-treatment processes to improve dewaterability, J. Hazard. Mater. 98 (1–3) (2003) 51–67.

- Prade T, Scensson S-E, Mattsson J. Energy balances for biogas and solid biofuel production from industrial hemp. Biomass Bioenergy 2012;40:36e52.

- Ward A, Hobbs P, Holliman P, Jones D. Optimisation of the anaerobic digestion of agricultural resources. Bioresour Technol 2008;99:7928e40.

- R.T. Haug, D.C. Stuckey, J.M. Gossett, P.L. Mac Carty, Effect of thermal pretreatment on digestibility and dewaterability of organic sludges, J.Water Pollut. Control Fed. (1978) 73–85.

- Zhang XH, Deng SH, Wu J, Jiang WJ (2010) A sustainability analysis of a municipal sewage treatment ecosystem based on energy. Ecol Eng 36:685–696

- Zhumartov E.B. Improvement of equipment and technology of sewage treatment in small sewerage systems – Doctor’s thesis abstract, 2010. KazNTU, Almaty, 40 pages.

- Chen I.K., Voral V.H , Hashimoto A.G. Methane production from agricultural residuals. A short Review. // Symposium on chemical from Cellulosic Materials. National meeting of the American Chemical Society.-Houston.- Texas, -1980 . March.

- Giinter L.I. The role of carbohydrates, fats and proteins in gas generation at fermentation of a sewer sludge in digesters. - In book:-Urban sewerage. -M, 1961.-ed. 6.-Page 158-163.

- Abramov A.V. Drachikova E.S. Nasedkina E.V. Research on composition of the supernatant generated at thermal treatment of a sewage sludge. - Tp. Ying-ta/VODGEO, 1976. - ed. 59 .

- Matvienko N. I. Dobrovolsky Zh.K. Karpenko S. N. Processing of a sewage sludge by thermal methods. - In book: Progressive decisions in the field of sewage treatment. Kharkov, 1972.

- Turovsky I.S. Bukreeva T.E. Processing of a sewage sludge and solid waste from household //Water supply and sanitary equipment, 1986. - No. 7. Page 18-21.