Estimation of Bio-kinetic Coefficients

M. Jawad A.1, Abdullah K.1, Arshad A.2, *, Ghayas K.1, Naveed A.1, H. Shahab2, H. Umaira S.3

1Department of Environmental Sciences, University of Haripur, District Haripur, Pakistan

2Civil Engineering Wing, MCE, National University of Sciences and Technology, Islamabad, Pakistan

3Department of Environmental Sciences, Northern University, Nowshera, Pakistan

Abstract

The UASB reactor was operated at optimum Organic Loading Rate (OLR) of 0.60kg-COD/m3-day, with Hydraulic Detention Time (HDT) of 2.67-1.58hrs during the study, using actual effluent of the textile mill. The mean values of K, Ks, Kd, Y and µmax obtained while operating the UASB reactor at optimum conditions were determine to be 0.31d-1, 77.5mg/L, 0.32d-1, 0.23 and 0.26d-1, respectively. The calculated concentration of effluent substrate, HDT, effluent biomass and biomass yield were found to be 10.95mg/L, 4.8hrs, 1632mg/L and 0.28, respectively. For a textile effluent of 1000GPD, the computed volume of the reactor was found to be 12.50m3. And the determined biomass per was estimated to be 2.12kg/day. Hence, the values of coefficients K, Ks, Kd, Y and µmax obtained will be used to validate the model and to predict treatment efficiency, and predict organic loading methane productivity of any UASB reactor treating textile effluent.

Keywords

UASB, Bio-kinetics, Optimum Usage, OLR

Received: April 5, 2015

Accepted: April 23, 2015

Published online: July 22, 2015

@ 2015 The Authors. Published by American Institute of Science. This Open Access article is under the CC BY-NC license. http://creativecommons.org/licenses/by-nc/4.0/

1. Introduction

In order to secure the environment from the adverse impacts of untreated industrial effluent, it is necessary that all the wastewater must be treated as an integral part of their production before discharging the wastes into the receiving streams or rivers. Since, Pakistan is facing an acute shortage of energy; therefore, encouraging the technologies like UASB technology, will not only prevents the water pollution but it can help to tackle the problem of energy crises to a certain extent. For the treatment of textile mill wastes the anaerobic technology seems to be more reliable, effective and economical [1, 2, 3]. Therefore, for the practical design of a UASB reactor, this study was design, to extract the required bio-kinetic coefficients of the UASB reactor, using actual textile mill effluent of the nearby source. The main purpose of this study was to estimate the bio-kinetic coefficients of UASB reactor at optimum operating conditions for actual textile effluent, and to compare the estimated and observed values of bio-kinetic coefficients. It was also studies to determine the volume of UASB reactor and biogas yield based on the data obtained.

2. Materials and Methodology

Due to the advantages and high application potential of UASB reactor for the developing countries, therefore, it was decided to employ UASB reactor for this study. An UASB reactor made up of acryl resin material each with a total effective volume of 6.0liters was employed in this study. The internal diameter of the reactor was 10.5cm and the thickness of the water jacket was 1.5cm. The reactor had a water jacket to maintain a constant temperature. The reactor was also equipped with a gas solid separator (GSS) and a mixer. Sixty five percent of UASB reactor was seeded with anaerobic digester and activated sludge the nearby wastewater treatment plant. The characteristics of the seeded sludge at the start up condition of the reactor are shown in the Table 1. The acclimatization process continued for about 28-29 days in the laboratory. The seed sludge provided 41 grams of volatile suspended solids (VSS). The loading rate was increased stepwise in order to avoid organic loading shocks [4]. Hydraulic retention time (HRT) was also studied. Mixing was done twice a day for about 15-20 minutes. The reactor was started-up in step-wise loading rates starting from 0.20kg-COD/m3-day to 2.20kg-COD/m3-day. The HRT was slowly decreased from 38hrs to 09hrs. The diluted actual effluent obtained from the local textile mill was used in this study.

Table 1. Characteristics of Seeded Sludge.

| Parameters | Value |

| Total Solids, TS (mg/L) | 86.50 |

| Total Suspended Solids, TSS (mg/L) | 59 |

| Volatile Suspended Solids, TVS (mg/L) | 41 |

| Color | Blackish |

3. Results and Discussion

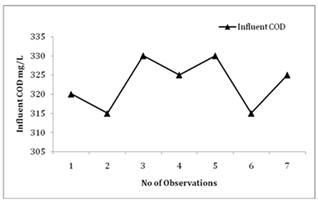

Fig. 1. Influent concentration of COD.

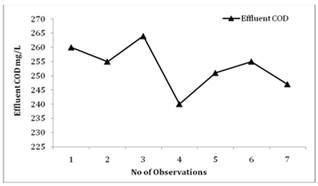

Fig. 2. Effluent concentration of COD.

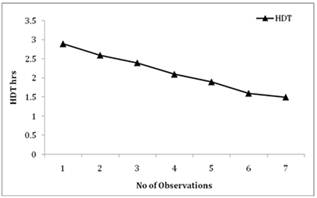

Fig. 3. Hydrualic Detention Time during the study period.

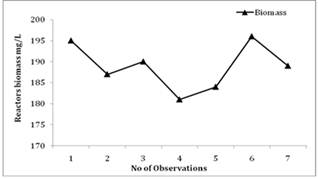

Fig. 4. Biomass concentration of the reactor during the study period.

The Figures 1-4 illustrates the concentration of both the influent and effluent BOD, the Hydraulic Detention Time (HDT) and biomass concentration of the reactor, respectively. The reactor was operated at an optimum Organic Loading Rate (OLR) of 0.6kg-BOD/m3-day. The BOD removal efficiency was gradually decreased from the initial value of 86% to 81% during the course of study period. Since, normally the biological treatment plants are practically designed to achieve a removal of 80-85% BOD/COD removal [5, 6], therefore. The 5th and 6th week values were considered for the further calculation of the bio-kinetics co-efficient. As shown in the Figure 3, the HDT was gradually decreased from 2.67hrs to 1.58hrs during the study, which might be the reason for the decrease in the BOD removal of the reactor. The study shows that the concentration of the biomass within the reactor remains constant, irrespective of any changes in HDT. Reference to the optimum operating conditions, i.e., the 5th and 6th week of the study, the HDT and biomass concentration of the reactors was used as 1.56-2.10hrs and 183-197mg/L, respectively.

The design and operation of an anaerobic digestion system are based on the fundamental kinetics and stoichiometry of biological reactions.

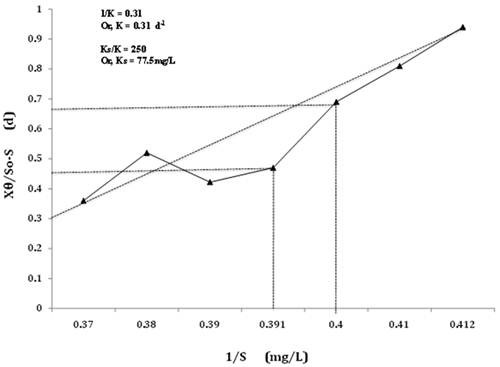

As shown in the Figure 5, the inverse of loading rate "Xθ / So-S" is plotted against the total loading rate of the reactor "1/S". A straight line result is obtained; the slope and intercept of the line are "K/Ks" and "Ks" [7, 8]. Using equations the value of utilization rate constant (K) and limiting substrate (Ks) were calculated to be 0.31d-1, 77.5mg/L, respectively.

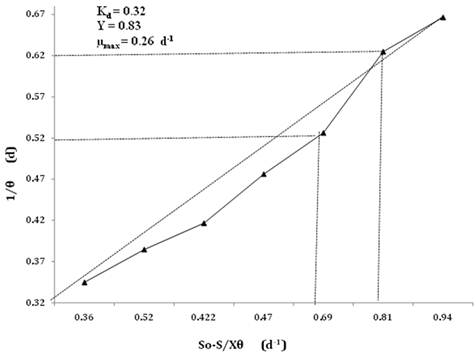

The values of "Kd" can be obtained by plotting a linear regression of "So-S/Xθ" and "1/θ". The intercept is equal to Kd and Y is the slope of the straight line that passes through the plotted points. The estimated endogenous decay coefficient "Kd"was observed to be 0.32d-1, as shown in the Figure 6. The estimated model coefficients obtained during this study are within the range of values reported in the literature for mesophilic anaerobic digestion of methanolic wastes, paper mill effluent, dairy mill effluent and sugary wastes [9,10].

Fig. 5. Estimation of bio-kinetic co-efficients – I.

Fig. 6. Estimation of bio-kinetic co-efficients – II.

Using the given models, the Figure 5-6 were plotted as discussed to determine the value of substrate utilization rate constant (K), limiting substrate (Ks), biomass decay constant (Kd) and yielding co-efficient (Y). The mean values of K, Ks, Kd, Y and µmax obtained while operating the UASB reactor at optimum conditions were determine to be 0.31d-1, 77.5mg/L, 0.32d-1, 0.83 and 0.26d-1, respectively. Hence, the values of coefficients K, Ks, Kd, Y and µmax obtained will be used to validate the model and to predict treatment efficiency, and predict organic loading methane productivity of any UASB reactor treating textile effluent.

Using mathematical models, the concentration of effluent substrate, HDT, effluent biomass and biomass yield were calculated to be 2.56mg/L, 1.82hrs, 56.85mg/L and 0.26, respectively. Though there is a bit deviation of calculated values from the observed concentrations, but it might be due to some analytical errors, or some procedural problems which could not be identified during the study period.

Based on the present study, a unit volume of UASB reactor was determined for a textile effluent of 1000GPD. The computed volume of the reactor was found to be 12.5m3. The determined biomass per was estimated to be 2.12kg/day. And the methane production was found to be 0.28m3/kg-CODrem at mesophilic temperature range. Thus, the total biogas production was calculated to be 24.50m3/day, which is sufficient for above 50 persons for their domestic usage [11].

4. Conclusion and Recommendation

1 The mean values of K, Ks, Kd, Y and µmax obtained while operating the UASB reactor at optimum conditions were determine to be 0.31d-1, 77.5mg/L, 0.32d-1, 0.23 and 0.26d-1, respectively.

2 The calculated concentration of effluent substrate, HDT, effluent biomass and biomass yield were found to be 10.95mg/L, 4.8hrs, 1632mg/L and 0.28, respectively.

3 For a textile effluent of 1000GPD, the computed volume of the reactor was found to be 12.50m3. And the determined biomass per was estimated to be 2.12kg/day.

4 The methane production was found to be 0.28m3/kg-CODrem at mesophilic temperature. Thus, the total biogas production was calculated to be 24.50m3/day, which is sufficient for above 50 persons for their domestic usage.

But a long-term study is required to explore various treatment options for the effluent of textile mill to find more cost-effective wastes pollution control strategies for this type of wastes. Since, most of the bio-kinetic co-efficient determined in this study, has deviation from the theoretical values obtained, therefore, more comprehensive study is required to find the exact values.

References

- Vieira, S.M.M., (1988). Anaerobic treatment of domestic sewage in Brazil. Research results and full-scale experience. In: Hall, E.R., Hobson, P.N. (Eds.). Proceedings of Fifth International Symposium on Anaerobic Digestion, Bologna, Italy, pp. 185–196.

- Scholz-Muramatsu, H., Neumann, A., MeBmer, M., Moore, E., Diekert, G., (1995). Isolation and characterization of Dehalospirillummutivorans gen. non.sp.nov, a tetrachloroethene utilizing, strictly anaerobic bacterium. Arch. Microbiol. 163: 48-56.

- Ali, M. Sreekrishnan, and T.R. (2001). Anaerobic toxicity from pulp and paper mill effluents: A review, Adv. Environ. Res., 5:175-196.

- Bryant, M.P. (1979). Microbial methane production – theoretical aspects. J. Animal Sci., 48: 193-201.

- Arshad, A., Shahid, I., Anwar, U.H.C., Baig, M.N., Khan, S. and Shakir, K. (2014). The wastes utility in concrete. International Journal of Environmental Research, 8(4), 1323-1328

- Bambang, S. (2014). Toward green concretefor better sustainable environment. Procedia Engineering, 95, 305-320.

- Driessen, W.J.B.M., Tielbaard, M.H., Vereijken, T.L.F.M. (1994). Experiences on anaerobic treatment of distillery effluent with the UASB process. Water Science Technology 30:12.

- Fitzsimons, R. Ek, M., Eriksson, K.E.L., (1990). Anaerobic dechlorination/degradation of chlorinated organic compounds of different molecular masses in bleach plant effluent. Environ. Sci. technol. 29: 1744-1748.

- Bhatti, Z.I. (1995). Studies on the biological treatment of methanolic waste in UASB reactor, PhD Thesis, Osaka University, Japan.

- APHA, AWWA, and WEF, 1995, Standard Methods for the examination of water and wastewater, 19th edition, Washington DC

- Eckenfelder, W.W.Jr (2nd Ed) 1989: Industrial water pollution control, McGraw Hill Book Company.